Toro SGR 13 Parts Diagram Overview

In the realm of outdoor maintenance, efficient machinery plays a pivotal role in ensuring a pristine landscape. For those who seek to delve deeper into the intricate workings of such equipment, a thorough exploration of its essential elements becomes paramount. By gaining insight into the various sections and mechanisms, users can enhance their operational knowledge and ensure optimal performance.

Grasping the layout of each individual component is crucial for both maintenance and troubleshooting. A comprehensive overview allows operators to identify specific areas requiring attention, thereby minimizing downtime and extending the life of the machinery. This understanding also empowers users to perform routine checks and adjustments with confidence.

Furthermore, familiarity with the structure of these machines can lead to better decision-making when it comes to repairs or upgrades. As enthusiasts and professionals alike navigate the complexities of their tools, a detailed reference guide can serve as an invaluable asset, simplifying the process of identifying parts and enhancing overall functionality.

Understanding Toro SGR 13 Components

Grasping the various elements of this equipment is crucial for effective operation and maintenance. Each component plays a significant role in the overall functionality, contributing to performance, reliability, and efficiency. By familiarizing oneself with these features, users can ensure optimal performance and address any issues that may arise.

The key components can be categorized into several essential groups:

- Power System:

- Engine: Provides the necessary power for operation.

- Fuel System: Ensures a consistent supply of energy.

- Control Mechanisms:

- Throttle: Regulates engine speed and performance.

- Steering: Allows for precise maneuverability.

- Operational Attachments:

- Cutting Mechanism: Responsible for trimming and shaping.

- Accessories: Additional tools that enhance versatility.

- Safety Features:

- Braking System: Ensures secure stopping capabilities.

- Protective Guards: Shield critical parts from debris.

Understanding these components allows users to effectively troubleshoot and maintain their machinery, ensuring longevity and reliable performance in various applications.

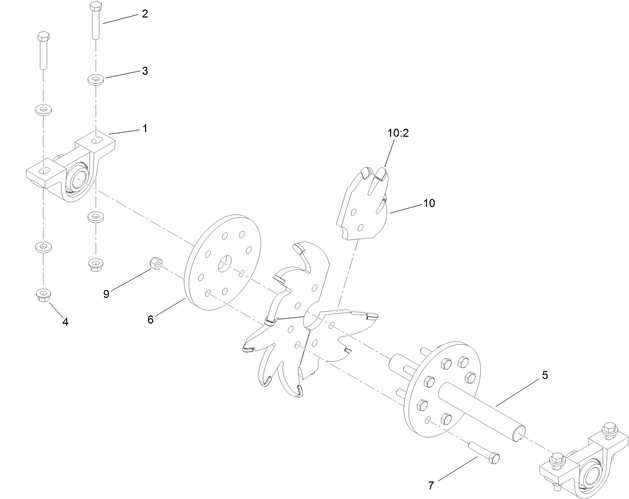

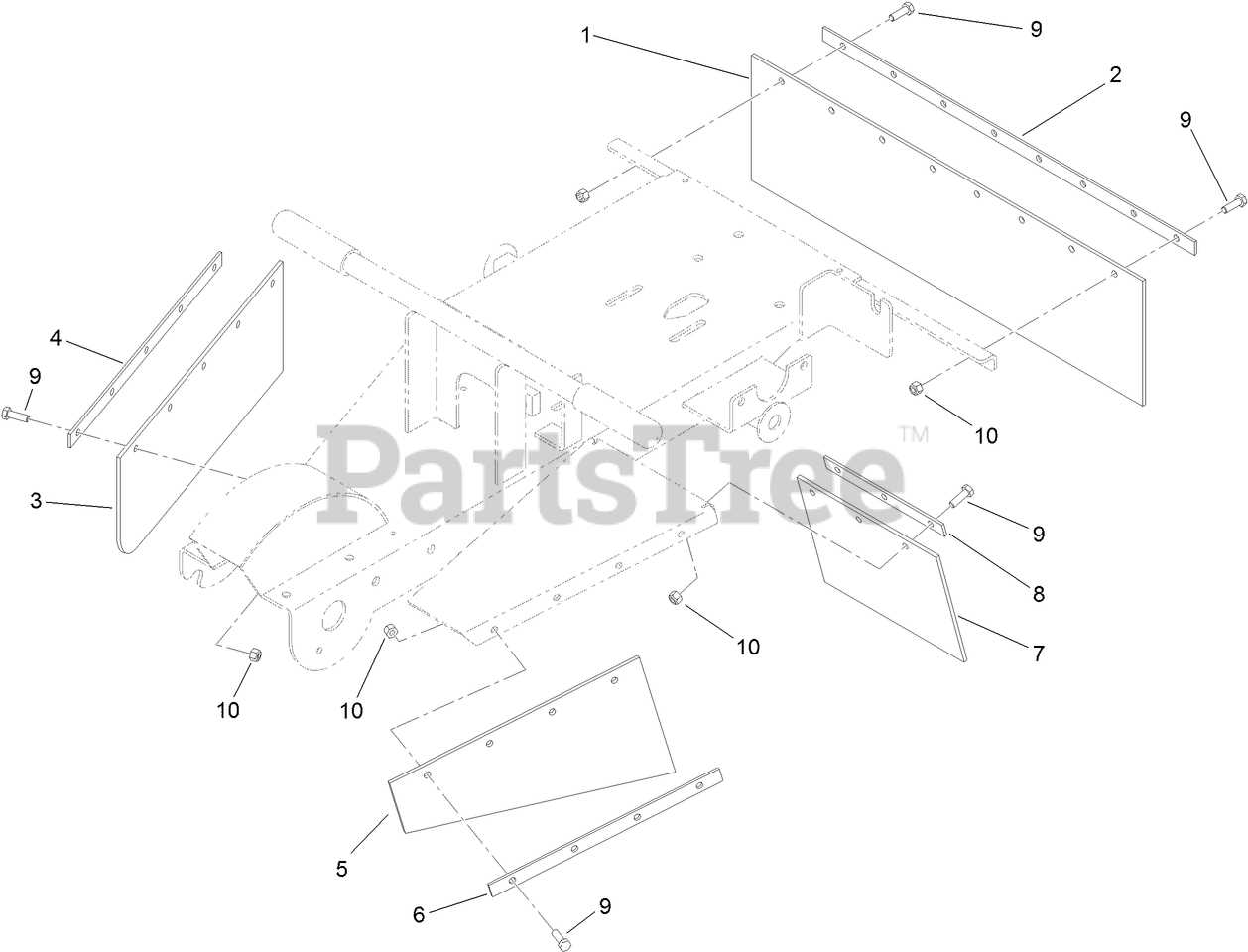

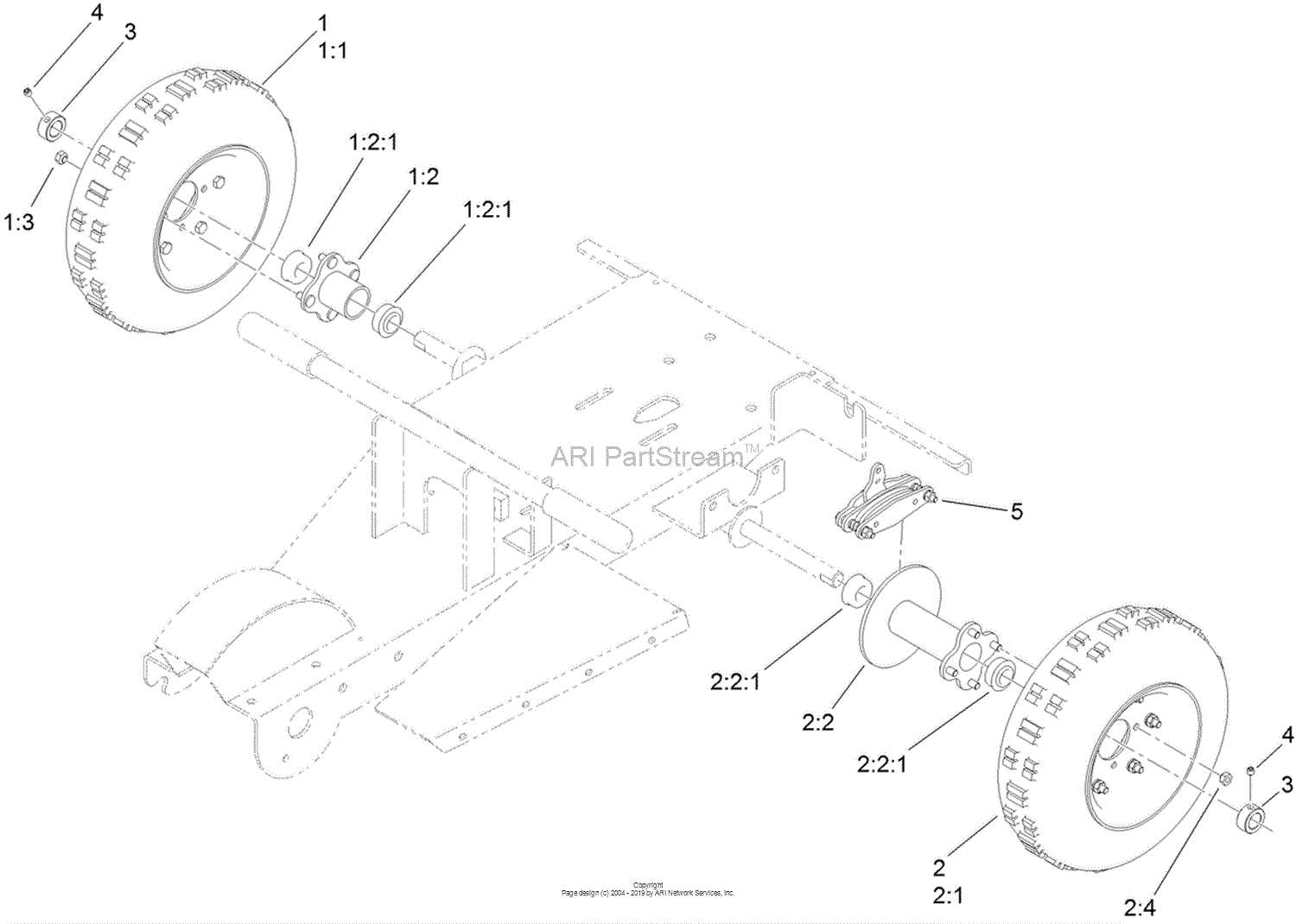

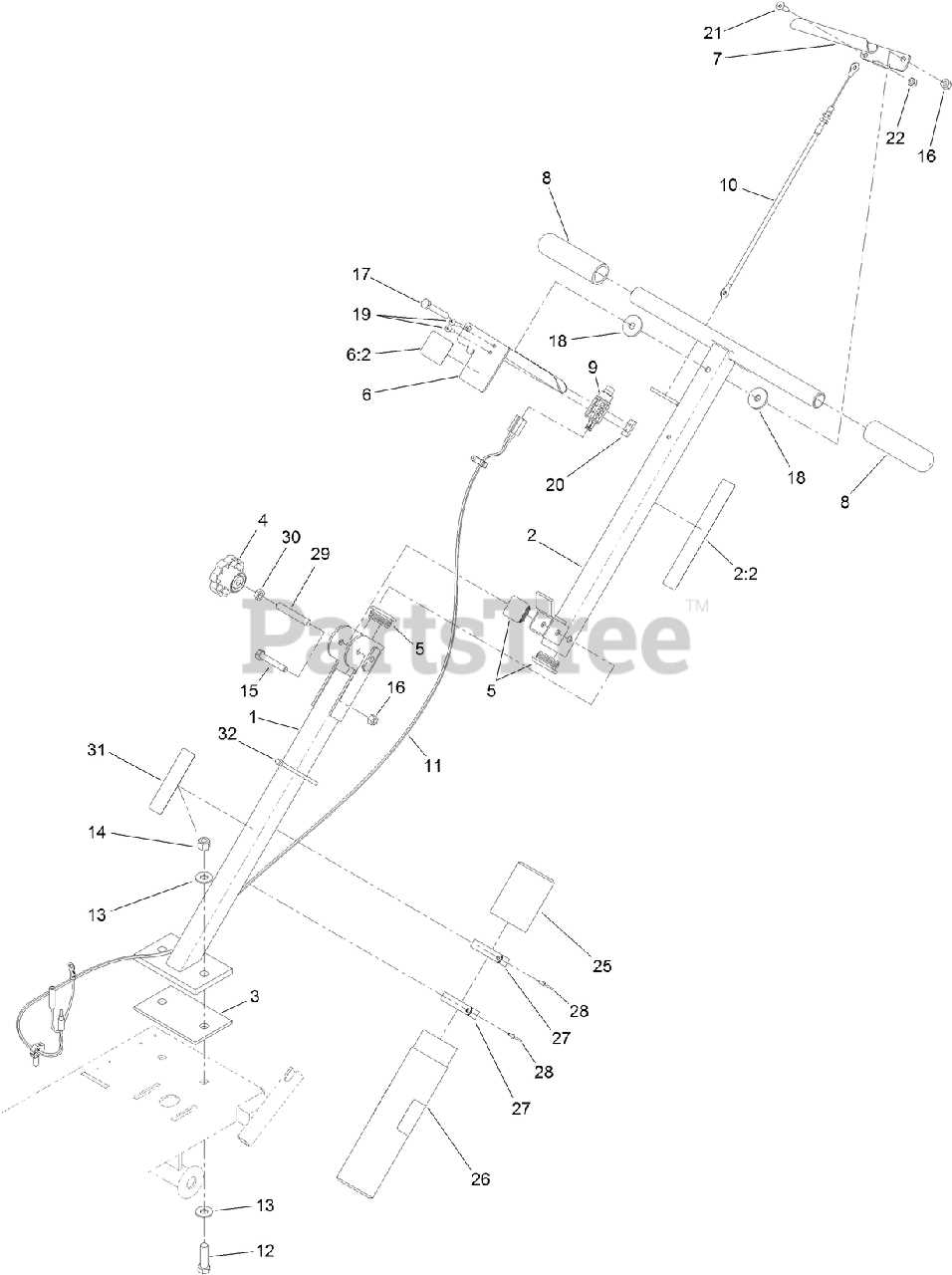

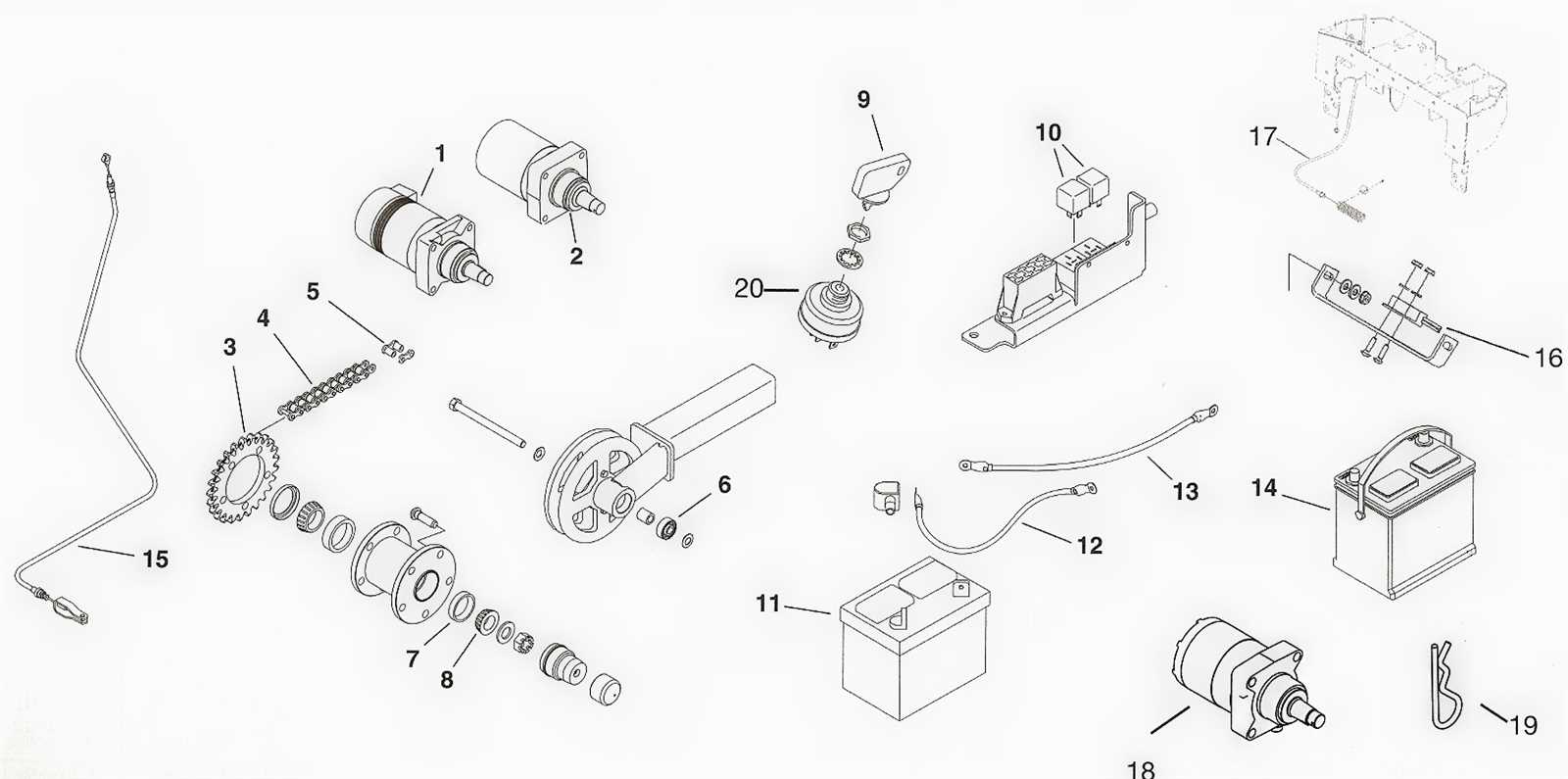

Overview of Toro SGR 13 Diagram

This section provides a comprehensive look at the visual representation of components related to a specific model of lawn maintenance equipment. Understanding this illustration is crucial for maintenance, repair, and effective usage.

The diagram serves as a vital tool, offering insights into various elements and their interconnections. It simplifies the identification of individual pieces, ensuring users can easily navigate through the assembly.

- Component Identification: Each part is labeled clearly, allowing for straightforward recognition.

- Functional Relationships: Lines and arrows illustrate how different components interact, enhancing understanding of the machinery’s operation.

- Maintenance Guidance: The visual guide aids in routine checks and repairs, helping users to maintain optimal performance.

By studying this representation, operators can familiarize themselves with the equipment, ensuring proper care and troubleshooting techniques are applied effectively.

Key Parts of Toro SGR 13

Understanding the essential components of this equipment is crucial for optimal performance and maintenance. Each element plays a significant role in ensuring efficiency, reliability, and durability during operation.

Drive Mechanism

The drive mechanism is fundamental for the mobility of the unit. It comprises various gears and belts that work together to facilitate movement. Regular inspection and maintenance of this system can prevent unexpected breakdowns and prolong the lifespan of the machine.

Cutting Assembly

The cutting assembly is responsible for achieving the desired finish on the terrain. This assembly includes blades and supports, designed to provide precision and effectiveness. Ensuring that these components are sharp and well-aligned is vital for achieving optimal results.

Regular maintenance of these crucial elements not only enhances performance but also contributes to the longevity of the equipment, ensuring that it remains in top condition for years to come.

Benefits of Using Toro Equipment

Utilizing high-quality machinery designed for outdoor maintenance and landscaping offers numerous advantages for both professionals and homeowners. These tools not only enhance efficiency but also improve the overall quality of work performed in gardens, lawns, and public spaces.

- Durability: Well-constructed machines are built to withstand rigorous use, ensuring longevity and reliable performance.

- Efficiency: Advanced technology and ergonomic designs streamline tasks, allowing users to complete work faster and with less effort.

- Versatility: A wide range of equipment is available, making it easy to find tools suited for various applications, from mowing to aeration.

- Innovative Features: Modern devices often incorporate cutting-edge technology that enhances usability and effectiveness.

- Cost-Effectiveness: Investing in quality equipment can lead to savings over time due to reduced maintenance costs and increased productivity.

Overall, choosing reliable machinery significantly contributes to achieving better results in outdoor tasks while ensuring a more enjoyable experience for users.

Maintenance Tips for Toro SGR 13

Proper upkeep is essential for ensuring optimal performance and longevity of your equipment. Regular attention to maintenance tasks not only enhances efficiency but also helps prevent potential issues that could arise from neglect. Here are some valuable tips to keep your machine running smoothly.

Begin with routine inspections to identify any signs of wear or damage. Pay close attention to the engine, belts, and blades, as these components are critical for functionality. Keeping everything clean and free from debris will also promote better performance.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Check oil level | Before each use | Use the recommended type for optimal performance. |

| Inspect air filter | Monthly | Replace if dirty to ensure proper airflow. |

| Sharpen blades | Every 25 hours of use | Sharp blades promote cleaner cuts and reduce strain. |

| Clean spark plug | Every 50 hours of use | Replace if worn or damaged. |

| Inspect tires | Monthly | Check for proper inflation and wear. |

Following these maintenance tips will not only improve the performance of your equipment but also extend its lifespan, ensuring you get the most out of your investment.

Common Issues and Solutions

In the realm of machinery, various complications can arise, impacting performance and efficiency. Understanding these frequent challenges and their corresponding remedies is crucial for maintaining optimal operation. This section highlights typical problems encountered and practical solutions to address them effectively.

Frequent Complications

| Issue | Description | Solution |

|---|---|---|

| Engine Stalling | Unexpected shutdowns during operation. | Check fuel levels and inspect the air filter for clogs. |

| Uneven Cutting | Inconsistent performance leading to patchy results. | Adjust the blade height and ensure proper sharpening. |

| Excessive Vibration | Unusual shaking during use. | Tighten loose bolts and inspect for wear on components. |

Preventive Measures

Regular maintenance is key to preventing these issues. Routine inspections and timely replacements of worn parts can significantly reduce the likelihood of complications. Always refer to the manufacturer’s guidelines for specific maintenance schedules and recommendations.

How to Interpret the Parts Diagram

Understanding the visual representation of components can greatly enhance your ability to maintain and repair machinery. These illustrations serve as a guide, enabling you to identify individual elements and their relationships within the overall system. Familiarizing yourself with this layout is essential for effective troubleshooting and efficient assembly.

Key Elements to Note

Start by examining the various sections of the illustration. Each part is usually labeled with a unique identifier that corresponds to a list or index. Pay attention to the numbers and letters used; these are crucial for cross-referencing in manuals or catalogs. The arrangement often reflects how components interact, helping you to visualize their function within the larger assembly.

Reading the Legend

Most visual guides include a legend that explains symbols or color coding. This can be invaluable when trying to discern specific functions or compatibility of the components. Take time to study this section carefully, as it can clarify the various aspects and ensure that you are accurately interpreting the information presented.

Essential Tools for Repairs

Having the right instruments at your disposal is crucial for any maintenance task. Whether you’re tackling routine upkeep or more complex fixes, the proper equipment can make all the difference. This section will highlight some key tools that are indispensable for ensuring smooth and efficient repairs.

Basic Hand Tools

Basic hand tools form the backbone of any repair kit. Items such as screwdrivers, wrenches, and pliers are essential for performing a wide variety of tasks. A sturdy set of these tools allows you to easily access and manipulate different components, ensuring that you can handle minor adjustments and larger fixes alike.

Specialized Equipment

In addition to standard tools, specialized equipment can greatly enhance your repair capabilities. Items like torque wrenches, diagnostic meters, and specific cleaning tools are invaluable for addressing particular issues. Investing in high-quality specialized gear can save time and prevent potential errors during maintenance.

Upgrading Toro SGR 13 Parts

Enhancing the efficiency and performance of your machine can significantly improve its longevity and functionality. By carefully selecting superior components and accessories, you can elevate the operational capabilities of your equipment, making it more effective for various tasks.

Benefits of Upgrading

- Improved Performance: Newer components often provide better efficiency and power.

- Increased Durability: High-quality materials can withstand wear and tear, extending the lifespan of your machine.

- Enhanced Features: Upgraded parts can introduce modern technology, offering advanced functionalities.

Considerations for Upgrades

- Compatibility: Ensure that new components are compatible with existing systems to avoid installation issues.

- Quality: Opt for reputable brands known for their reliability and performance.

- Cost vs. Benefit: Assess whether the investment in upgrades justifies the expected improvements.

Comparing Toro Models and Diagrams

When evaluating different models of equipment, it’s essential to understand the variations in their components and layouts. Each version showcases distinct features and engineering choices, reflecting the manufacturer’s design philosophy and user requirements. Analyzing these differences can enhance the maintenance and operational efficiency of the machines.

Key aspects to consider include the arrangement of elements, compatibility of interchangeable parts, and the overall accessibility for repairs. By comparing visual representations of various models, users can identify which configurations best suit their needs, ultimately leading to informed decisions regarding upgrades or replacements.

Additionally, examining similarities and disparities across models can provide insights into common issues and troubleshooting techniques. This comparative approach not only aids in practical applications but also fosters a deeper appreciation for the innovation behind each design.

Where to Find Replacement Parts

When seeking components for your equipment, it is essential to know where to look for reliable options. Various sources provide a wide selection of spare elements that can restore functionality and enhance performance. Understanding these avenues will help ensure you find what you need efficiently.

Authorized Dealers

Visiting certified retailers is often the most straightforward approach. These establishments offer genuine components that match the original specifications, ensuring compatibility and quality. Additionally, trained staff can assist in identifying the right items and may provide warranties on the products sold.

Online Marketplaces

Another effective method is to explore digital platforms that specialize in machinery supplies. These websites typically feature a comprehensive inventory, often including user reviews to aid in your decision-making process. Be sure to verify the seller’s credibility to avoid counterfeit goods.

In conclusion, whether through authorized outlets or online resources, locating the necessary components for your machinery can be accomplished with a bit of research and diligence.