New Process 542 Transmission Parts Overview

The structure and organization of mechanical systems are crucial for maintaining efficiency and reliability. By analyzing how various elements interact within a machinery setup, one can ensure smoother operations and quicker troubleshooting when challenges arise. This overview delves into the arrangement of specific internal elements, providing clarity on their functions and interactions.

In complex machinery, each component plays a distinct role, contributing to the overall performance. Recognizing how these pieces fit together can be invaluable for those working on repairs or maintenance. This section aims to offer insight into the assembly of various mechanisms, helping to simplify the understanding of their intricate design.

With a focus on improving comprehension, the following information offers a closer look at how the different elements are

New Process 542 Transmission Overview

This section provides a comprehensive insight into the inner workings and structure of a robust gearbox known for its durability and versatility in various vehicles. It highlights the key features and components that ensure smooth operation and efficient power transfer, making it a reliable choice for different driving conditions.

| Feature | Description |

|---|---|

| Gear Ratios | Offers a balanced range of ratios to adapt to different speed and torque requirements, ensuring optimal performance across various terrains. |

| Durability | Constructed with high-strength materials, the design is made to withstand continuous use, providing a long-lasting solution for heavy-duty applications. |

| Smooth Shifting | Designed to deliver seamless shifts between gears, minimizing wear and enhancing overall driving experience. |

| Cooling Mechanism | Incorporates a cooling system to maintain optimal temperatures, preventing overheating during extended use and ensuring reliable performance. |

This overview aims to give an understanding of how this specific gearbox functions, highlighting its strengths and benefits in a practical context.

Main Components of NP542 Gearbox

The gearbox is built with several critical elements that ensure smooth power transfer and efficient functionality. Each piece plays a distinct role in the overall operation, contributing to its durability and reliable performance. Below, we explore the essential elements that make up this mechanical system.

- Input Shaft: This component is responsible for receiving rotational energy from the engine and transmitting it into the gearbox for further distribution.

- Output Shaft: This shaft takes the modified energy from the internal gears and transfers it to the driveline, ensuring the vehicle moves efficiently.

- Gear Cluster: A set of gears that determine the different speed ratios. Each gear varies in size, allowing for adjustments in speed and torque.

- Synchronizers: These devices help align the speed of gears during shifting, making transitions smoother and reducing wear on the components.

- Bearings: These support the rotating parts, minimizing friction and maintaining the alignment of the internal elements for smooth operation.

- Shift Forks: These mechanisms are used to move gears into place during a change in speed, facilitating precise control over gear selection.

- Casing: The outer structure that houses all internal parts, providing protection and structural support to ma

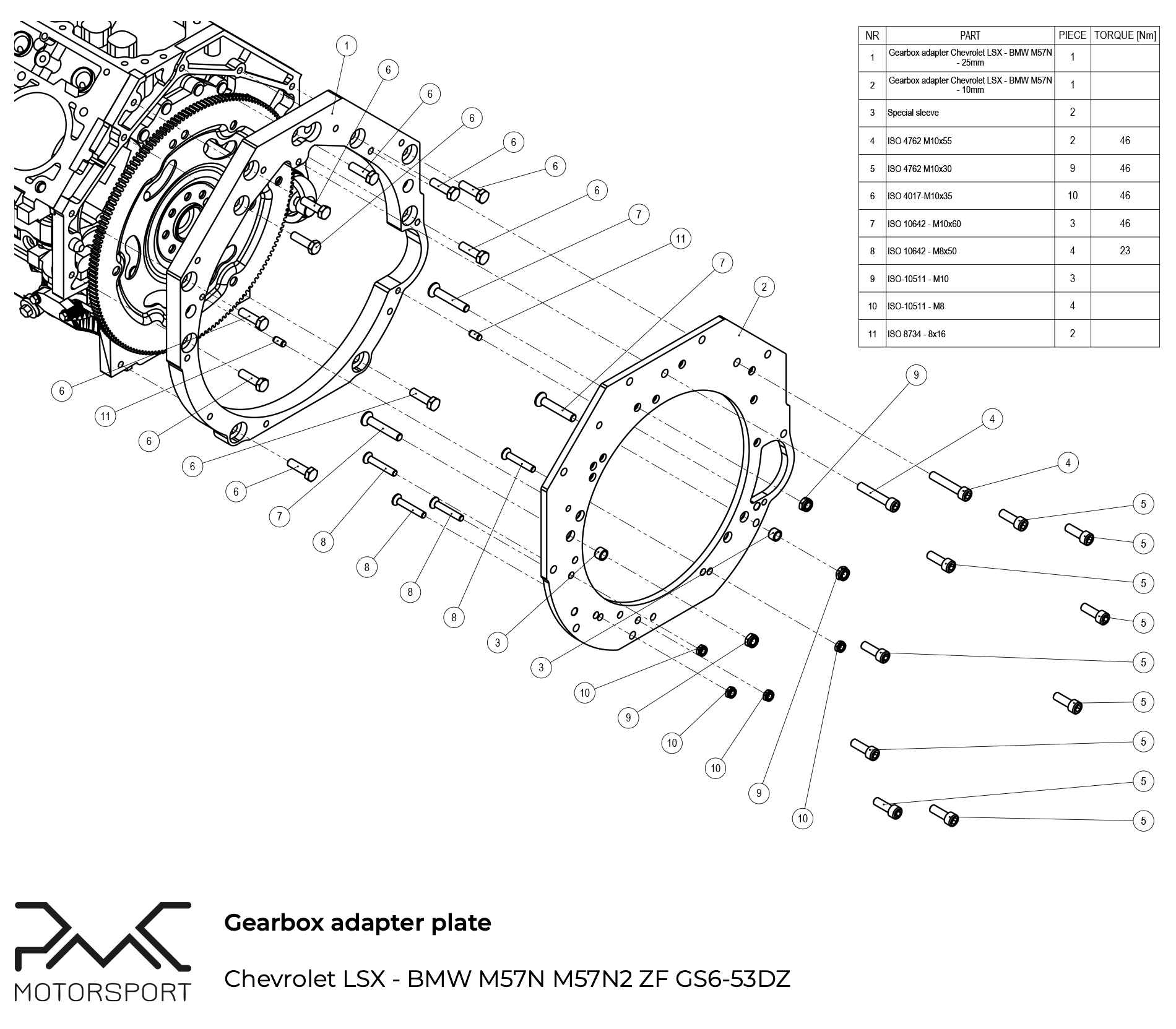

Identifying Key Parts in NP542

Understanding the structure and key elements of this mechanical system is crucial for effective maintenance and troubleshooting. Each component plays a specific role in ensuring smooth performance and reliability. Recognizing these elements helps in diagnosing issues and optimizing functionality.

Core Mechanisms include various gears and shafts that interact to provide the desired performance. These gears adjust to different speeds and torque levels, while shafts ensure the smooth transfer of power throughout the system. Proper alignment and condition of these elements are essential for efficiency.

Adjustment Components such as levers and synchronizers allow for smooth shifts between different operational modes. They manage the coordination between gears, ensuring that transitions are precise and reduce potential wear and tear.

Support Structures include housings and seals that protect the internal mechanisms from external elements. They provide a secure environment for the internal parts, preventing contamination and ensuring that the assembly operates within optimal conditions.

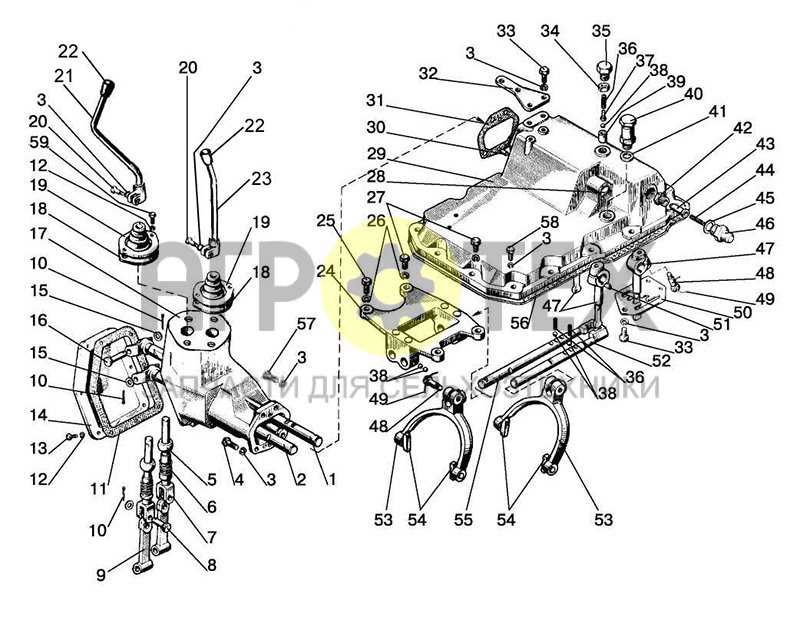

Disassembly Guide for NP542 Transmission

Careful dismantling of this gear system requires a methodical approach, ensuring each component is handled with precision. This guide outlines key steps for separating the various elements, allowing for thorough inspection and maintenance.

- Preparation: Begin by securing the unit on a stable work surface. Make sure all necessary tools are on hand, such as wrenches, screwdrivers, and a rubber mallet.

- Removing the Casing: Loosen and carefully take off the outer cover, ensuring that no bolts or screws are misplaced during this process.

- Accessing Internal Mechanisms: Once the outer layer is removed, the internal gear sets become accessible. Pay attention to the arrangement of gears and retainers as you remove them one by one.

- Extracting Shafts: Detach the primary and secondary shafts, taking care to note their positioning. These components are crucial for the overall function and should be handled with care.

Handling Delicate Components

During disassembly, it’s vital to treat smaller, delicate parts like bearings and seals with caution. Place each piece on a clean surface, grouping similar items together to ease reassembly.

- Bearings Removal: Use a puller tool to gently remove the bearings from their housings, applying even pressure to avoid damage.

- Seals Extraction: Pry the seals out with a flat tool, making sure not to scratch the surrounding surfaces.

- Inspect and Clean: Once all elements are disassembled, inspect each for wear and clean thoroughly before proceeding with repairs or replacements.

Following this guide will help ensure that each component is separated safely, preserving their integrity for reassembly. Proper care during this process can prevent future issues and extend the overall li

Common Wear Areas in NP542

Over time, some components in this system tend to experience more stress, leading to natural deterioration. Understanding these areas can help identify the need for maintenance before more serious issues arise.

- Bearings: These elements support rotating parts and can wear down due to friction and heat, eventually leading to increased noise or vibration.

- Seals and Gaskets: These parts prevent fluid leaks, but with constant exposure to temperature changes, they may crack or lose their sealing ability.

- Gear Teeth: The meshing of gears can cause gradual wear on their surfaces, which might result in rough shifts or reduced efficiency.

- Synchronizers: Designed to smooth out gear changes, synchronizers can wear with frequent use, leading to grinding noises or difficulty in shifting.

- Shifter Forks: These components guide the gears during operation, but they may bend or wear over time, causing misalignment or hard shifting.

Regular inspection of these areas can extend the system’s lifespan and ensure smooth operation. Addressing early signs of wear can prevent costly repairs in the future.

Rebuilding Tips for NP542 Transmission

Reconstructing an automotive gearbox can be a rewarding endeavor, offering both improved performance and a sense of accomplishment. Understanding essential guidelines and best practices is crucial for achieving optimal results and ensuring longevity in operation. Here are some valuable suggestions to consider during the rebuilding journey.

- Preparation is Key: Before diving into the project, gather all necessary tools and components. A well-organized workspace will streamline the process and minimize disruptions.

- Consult Manuals: Refer to detailed guides and documentation specific to your model. These resources provide crucial insights into assembly procedures and specifications.

- Inspect Components: Carefully examine each part for wear and damage. Replace any worn-out elements to avoid future issues and enhance overall efficiency.

During assembly, ensure that all components fit together smoothly. Align gears and shafts correctly to prevent misalignment, which can lead to premature wear. Utilize appropriate lubricants as recommended to facilitate smooth operation and protect against friction.

- Testing: After assembly, perform thorough testing. Check for leaks, unusual noises, and proper functionality before reinstalling.

- Documentation: Keep detailed records of all steps taken during the rebuild. This documentation can be invaluable for future reference or repairs.

- Seek Expert Advice: If you encounter challenges, don’t hesitate to consult with professionals or experienced hobbyists. Their expertise can provide valuable insights and solutions.

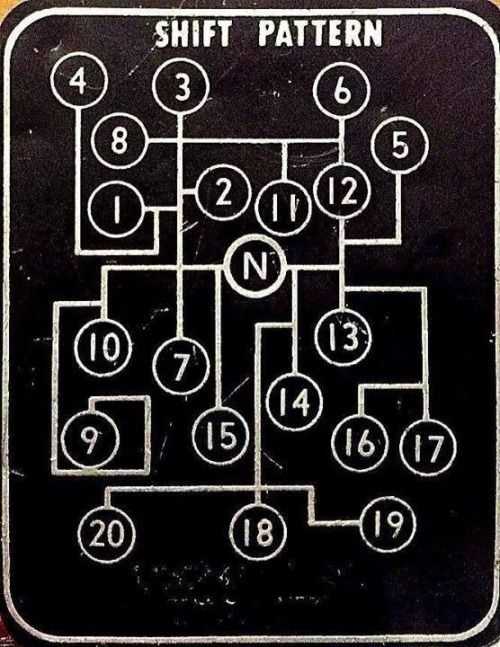

NP542 Gear Ratios and Configurations

This section explores the various ratios and setups associated with a specific gear mechanism, providing insights into their operational efficiency and adaptability. Understanding these elements is crucial for optimizing performance and enhancing the overall driving experience.

Overview of Gear Ratios

Gear ratios play a pivotal role in determining how power is transmitted within the system. Different ratios affect acceleration, speed, and fuel efficiency. The selection of an appropriate ratio can significantly influence vehicle performance.

- Lower ratios provide increased torque and better acceleration.

- Higher ratios enhance top speed but may compromise low-end power.

- Balanced ratios aim to optimize both acceleration and fuel economy.

Configurations and Their Impact

Different configurations can be employed to meet specific performance requirements. These setups can be customized based on driving conditions and personal preferences.

- Standard Configuration: Ideal for everyday driving with a good balance of speed and efficiency.

- Sport Configuration: Designed for enhanced performance, offering quicker acceleration and responsive handling.

- Off-Road Configuration: Tailored for rugged terrains, prioritizing torque and stability over top speed.

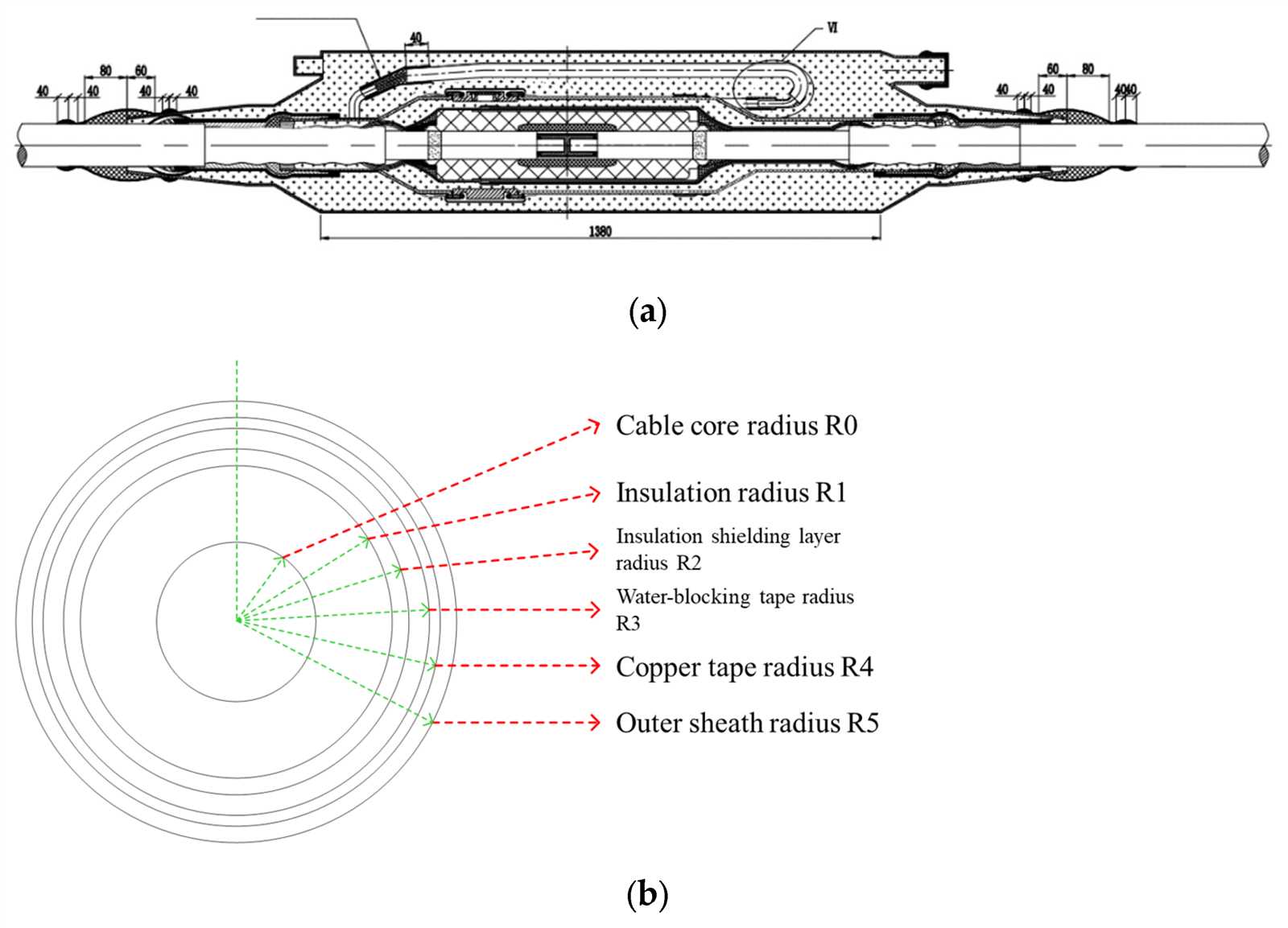

Lubrication Points in NP542 Gearbox

Proper maintenance of a gearbox is essential for ensuring its smooth operation and longevity. Identifying the key areas for lubrication is crucial, as it helps prevent wear and tear while promoting optimal functionality. Understanding where to apply lubricant can significantly enhance performance and reduce the likelihood of mechanical failures.

Key Lubrication Areas:

- Input Shaft: This area requires regular lubrication to minimize friction during operation.

- Output Shaft: Ensuring adequate lubrication here is vital for smooth power transfer.

- Bearings: Lubricating the bearings helps maintain their integrity and reduces noise.

- Seals: Proper lubrication around seals prevents leaks and enhances sealing efficiency.

It is important to follow the manufacturer’s guidelines regarding the type and frequency of lubrication for each point. Regular checks and maintenance can lead to a more reliable and efficient system.

Troubleshooting Issues in NP542 Parts

When dealing with challenges related to specific components, it’s essential to identify potential sources of problems effectively. This section focuses on common issues that may arise, providing insights into diagnosis and resolution techniques.

Understanding the nature of faults is crucial for efficient troubleshooting. Below are frequent concerns and recommended solutions:

-

Fluid Leaks:

- Check for signs of leakage around seals and gaskets.

- Inspect hoses for wear or damage that could lead to fluid loss.

-

Unusual Noises:

- Listen for grinding or whining sounds, which may indicate wear.

- Evaluate if the noise correlates with specific actions, such as shifting.

-

Overheating:

- Ensure proper fluid levels are maintained to prevent excess heat.

- Investigate the cooling system for blockages or failures.

-

Shifting Difficulties:

- Examine linkages for misalignment or obstructions.

- Assess if the control mechanism is functioning as intended.

By systematically addressing these issues, individuals can enhance the performance and longevity of the components in question. Regular maintenance and prompt attention to signs of trouble can prevent more significant complications in the future.

Maintenance Practices for NP542 Gearbox

Ensuring the longevity and efficiency of a gearbox requires a systematic approach to upkeep. Regular maintenance routines play a crucial role in preventing issues and optimizing performance. By adhering to best practices, one can enhance the reliability and functionality of the mechanism.

Regular Inspections: Conduct frequent evaluations to identify any signs of wear or damage. Checking fluid levels, seals, and external components can prevent minor issues from escalating into major failures.

Fluid Changes: Changing lubricants at recommended intervals is vital for maintaining smooth operation. Fresh fluids reduce friction and help in cooling, thereby prolonging the life of internal components.

Component Cleaning: Keep the exterior and accessible internal parts clean. Dirt and debris can hinder functionality and lead to premature wear. Utilizing proper cleaning methods ensures optimal performance.

Seal and Gasket Replacement: Regularly inspect and replace worn seals and gaskets. This practice prevents leaks and maintains pressure within the system, which is essential for effective operation.

Alignment Checks: Ensure that the gearbox is properly aligned with connected systems. Misalignment can lead to uneven wear and operational inefficiencies.

By implementing these maintenance strategies, one can ensure the gearbox operates at peak performance, reducing the likelihood of costly repairs and downtime.

Replacement Parts Guide for NP542

This section offers essential information for those seeking components compatible with the NP542 model. Understanding the available options and their specifications is crucial for ensuring optimal functionality and longevity of the equipment.

Essential Components Overview

Identifying the core components necessary for maintenance and repair can enhance the overall performance of the system. Each element plays a vital role in the effective operation, thus prioritizing their quality is imperative. Regular checks and timely replacements can prevent significant issues down the line.

Recommended Quality Standards

When selecting replacement items, it’s advisable to consider those that meet or exceed industry benchmarks. High-quality alternatives not only provide reliability but also contribute to the durability of the machinery. Investing in premium options can result in better performance and reduced need for frequent changes.