Understanding the Earthquake Auger Parts Diagram

The efficiency of any drilling equipment is largely determined by its individual elements, each playing a crucial role in overall performance. A comprehensive understanding of these components not only enhances operational effectiveness but also ensures longevity and reliability in the field.

When delving into the intricacies of these mechanisms, it becomes evident that each part contributes to the ultimate functionality of the tool. From the motor to the cutting edge, the synergy between these elements allows for precision and power in various applications.

In this section, we will explore the various segments of a drilling apparatus, highlighting their unique characteristics and how they interact to achieve optimal results. Gaining insight into these features will empower users to make informed decisions regarding maintenance and upgrades.

Understanding Earthquake Augers

This section explores the essential tools designed for soil penetration and excavation tasks. These devices are critical for a variety of outdoor projects, enabling users to effectively manage ground conditions while ensuring efficiency and precision in their work.

Key Components

Every excavation tool consists of several crucial elements that work together seamlessly. Understanding these components can significantly enhance operational efficiency and extend the tool’s lifespan. Each piece contributes to the overall performance and adaptability of the machine.

Applications and Benefits

The versatility of these tools allows them to be used in various settings, from gardening to construction. They provide the ultimate solution for drilling holes, ensuring quick results with minimal physical effort. Additionally, their design often includes features that enhance safety and usability for operators of all skill levels.

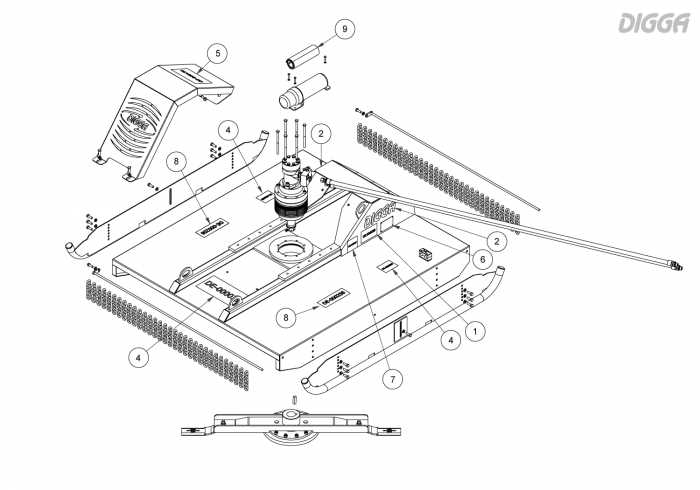

Components of an Earthquake Auger

This section delves into the essential elements that contribute to the functionality and efficiency of a drilling tool designed for challenging soil conditions. Understanding these components is crucial for both maintenance and effective operation in various applications.

Drilling Mechanism

The core mechanism is responsible for penetrating the ground. It often features a rotating bit designed to efficiently break through different types of soil. This component is engineered for durability and precision, allowing for smooth operation even in tough terrains.

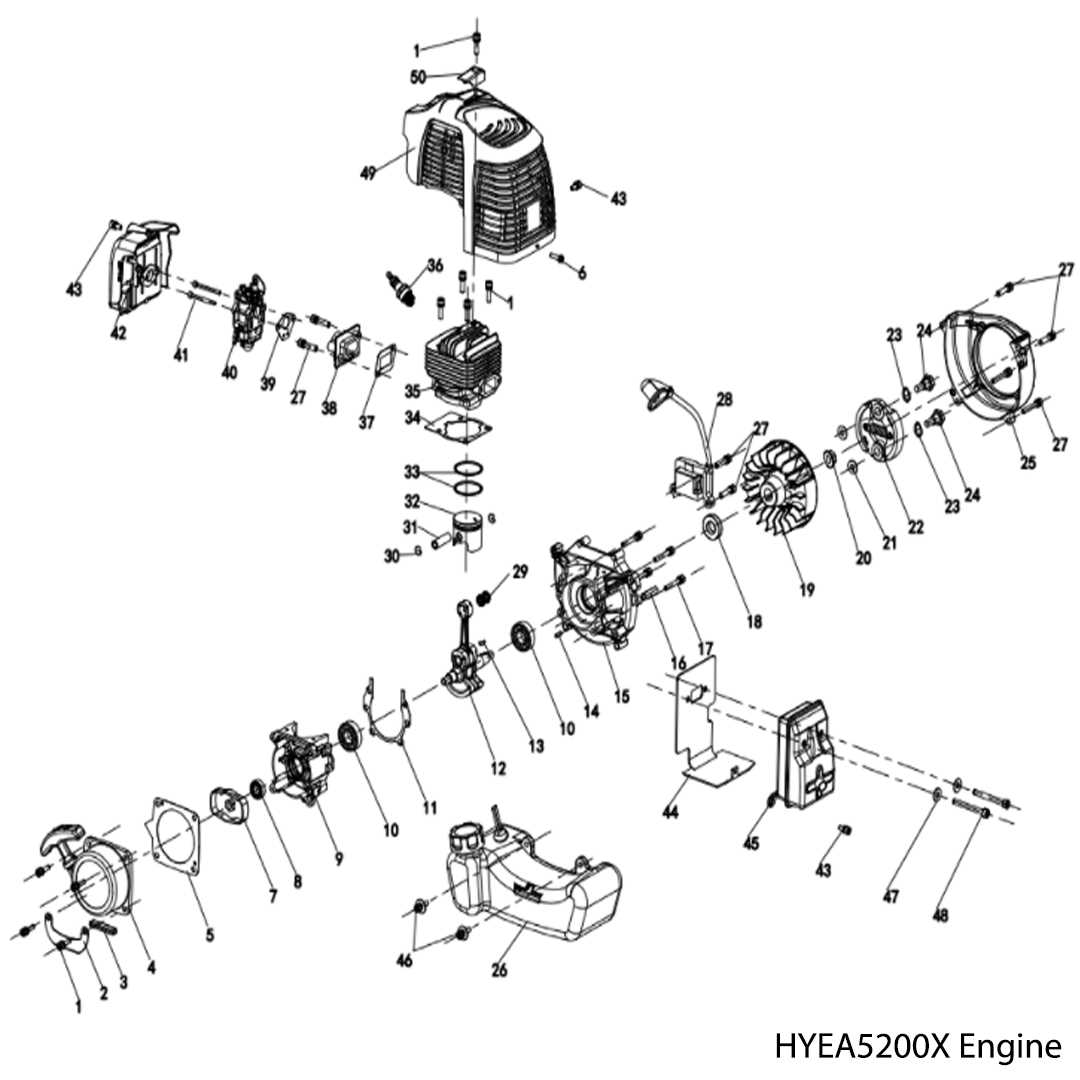

Power Source

A reliable energy source drives the entire system. Whether it’s a combustion engine or an electric motor, this element plays a vital role in ensuring that the tool operates consistently. The choice of power source can greatly influence the tool’s performance and suitability for specific tasks.

How Augers Work in Drilling

Understanding the mechanics behind drilling tools reveals the intricate processes involved in breaking ground and creating holes efficiently. These devices utilize a helical structure to penetrate various surfaces, facilitating the removal of material while minimizing resistance.

Principles of Operation

The fundamental operation of these tools is based on several key principles:

- Spiral Design: The helical shape allows for easy movement through the earth.

- Rotational Force: As the tool rotates, it pulls material upward, preventing clogging.

- Pressure Application: By applying force downwards, the device enhances its drilling capability.

Applications in Various Fields

These drilling instruments are widely used in numerous industries:

- Construction: For creating foundations and installing posts.

- Agriculture: Used to prepare soil for planting.

- Utilities: Ideal for installing underground cables and pipes.

Importance of Quality Parts

The significance of utilizing high-grade components cannot be overstated. When constructing or maintaining machinery, the durability and reliability of each element play a crucial role in ensuring optimal performance. Subpar materials can lead to frequent breakdowns, increased maintenance costs, and compromised safety, ultimately affecting overall productivity.

Quality components enhance efficiency and longevity, providing peace of mind for operators and users alike. Investing in superior materials not only boosts functionality but also minimizes the risk of unexpected failures.

| Benefits | Consequences of Poor Quality |

|---|---|

| Enhanced durability | Frequent replacements |

| Improved efficiency | Increased downtime |

| Greater safety | Potential hazards |

| Long-term cost savings | Higher repair expenses |

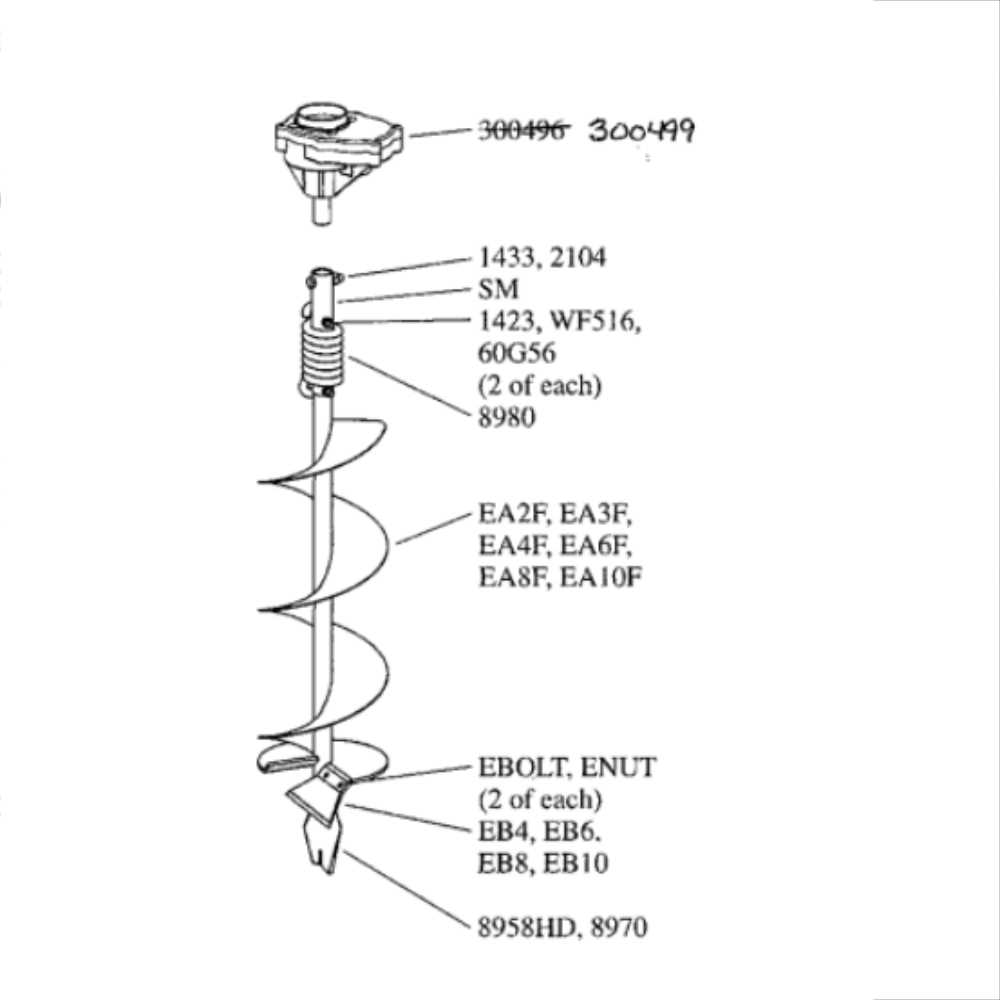

Common Auger Part Types

Understanding the essential components of drilling equipment is crucial for effective operation and maintenance. Each element plays a vital role in ensuring optimal performance, contributing to the overall functionality and longevity of the machinery.

Here are some of the most common types of components found in drilling equipment:

- Bit: The cutting tool that penetrates the ground, available in various shapes and sizes for different soil conditions.

- Shank: The connection point between the bit and the drive mechanism, designed to transfer power effectively.

- Flighting: The spiral blades that help transport material up and out of the hole, ensuring efficient removal of debris.

- Drive System: The mechanism that powers the drilling action, which can be manual or machine-operated.

- Handle: Provides grip and control for manual operation, allowing for precise adjustments during use.

Each of these components is integral to the overall system, and familiarity with them enhances both usage and repair. Proper care and maintenance can significantly extend the life of the equipment, making it essential for operators to understand their functions and importance.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your equipment requires regular care and attention. Implementing a routine maintenance schedule can prevent costly repairs and extend the lifespan of your machinery. Here are essential tips to keep your tools operating smoothly for years to come.

Regular Cleaning: After each use, remove dirt, debris, and other residues that can accumulate. This helps prevent corrosion and ensures optimal performance. Use a soft brush or cloth to gently clean all surfaces, paying special attention to areas prone to buildup.

Lubrication: Regularly lubricate moving components to reduce friction and wear. Use the manufacturer’s recommended lubricant and follow the suggested intervals for application. This simple step can significantly enhance the efficiency and longevity of the equipment.

Inspect Components: Conduct routine inspections to identify any signs of wear or damage. Look for cracks, bends, or other irregularities in critical parts. Addressing issues early can prevent more significant problems down the line.

Proper Storage: Store your machinery in a dry, sheltered location to protect it from the elements. Using covers can also provide additional protection against dust and moisture. Ensure that tools are stored in an organized manner to avoid accidental damage.

Follow Manufacturer Guidelines: Always refer to the manufacturer’s instructions for maintenance practices specific to your model. Adhering to these guidelines can help you understand the best care techniques and maintenance intervals, ensuring your equipment remains in top condition.

Choosing the Right Auger Size

Selecting the appropriate size for your drilling tool is crucial for achieving optimal results. The diameter and length play a significant role in determining the efficiency and effectiveness of the operation, impacting factors such as soil type and project scale.

When assessing dimensions, consider the nature of your task. For smaller projects or softer soil, a narrower option may suffice, while larger endeavors or tougher ground conditions might necessitate a wider and longer instrument. Understanding these requirements will ultimately enhance your productivity.

Additionally, it’s important to evaluate the equipment’s compatibility with your existing machinery. Ensuring that your chosen model fits seamlessly with your tools will prevent complications during use, leading to a smoother workflow and successful outcomes.

Safety Precautions During Operation

Ensuring a safe working environment is paramount when operating machinery designed for digging and drilling tasks. Adhering to specific safety measures minimizes risks and enhances the efficiency of the equipment. Operators should familiarize themselves with these precautions to promote a secure atmosphere for themselves and those nearby.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. Operators should equip themselves with gear that provides adequate protection against potential hazards encountered during operation.

| Type of PPE | Purpose |

|---|---|

| Hard Hat | Protects the head from falling objects |

| Safety Goggles | Prevents eye injuries from debris |

| Gloves | Provides grip and protects hands from sharp edges |

| Steel-Toed Boots | Protects feet from heavy items |

| High-Visibility Vest | Makes the operator easily seen |

Operational Guidelines

Following proper operational guidelines enhances safety and prolongs equipment life. Operators should maintain a safe distance from others, remain aware of their surroundings, and ensure that all safety features are functional before commencing work.

Applications of Earthquake Augers

These powerful drilling tools find numerous applications across various fields, showcasing their versatility and efficiency. Their design allows for the creation of deep holes quickly, making them invaluable for a range of tasks from construction to landscaping.

Construction and Infrastructure

In the realm of construction, these tools are essential for installing foundations and setting poles. They enable contractors to achieve precise depths and diameters, ensuring stability and durability in structures. Their ability to work in diverse soil conditions further enhances their utility.

Agricultural Uses

In agriculture, these implements are employed for planting trees and large crops, facilitating soil aeration and improving growth conditions. Their efficiency reduces labor time, allowing farmers to focus on other essential tasks while promoting healthier yields.

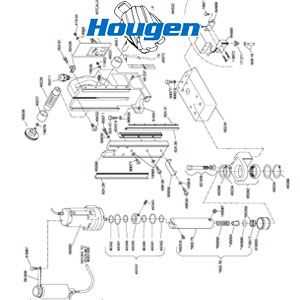

Upgrading Your Auger Equipment

Enhancing your drilling machinery can significantly improve performance and efficiency. By focusing on key components, you can ensure that your equipment meets the demands of modern tasks while also prolonging its lifespan. Whether for professional use or personal projects, an upgrade can provide the necessary boost to tackle any challenge.

Identifying Essential Components

Start by assessing the crucial elements of your machinery. Components such as the motor, cutting tools, and control systems play vital roles in overall functionality. Upgrading these parts can lead to increased power and precision, enabling you to handle tougher materials and achieve cleaner results.

Choosing Quality Materials

When selecting replacements, prioritize high-quality materials. Durable and efficient options will not only enhance performance but also reduce maintenance costs over time. Investing in superior components can make a significant difference in how effectively your equipment operates.

Comparing Auger Models and Brands

When selecting a drilling device for your projects, understanding the various models and manufacturers is crucial. Each brand offers unique features and specifications that cater to different needs and preferences. This comparison aims to highlight the strengths and weaknesses of various options available in the market.

Key Factors to Consider

- Performance: Assess the power and efficiency of different machines. Consider their drilling speed and the type of soil they can handle.

- Durability: Look for materials and construction quality. Some brands emphasize sturdier designs, making them suitable for heavy-duty tasks.

- Weight: The overall weight can impact portability. Lighter models may be easier to transport but might sacrifice some power.

- Ease of Use: User-friendly controls and features can significantly affect your experience, especially for beginners.

Popular Brands Overview

- Brand A: Known for its robust construction and reliability. Ideal for heavy tasks but may be on the heavier side.

- Brand B: Offers lightweight options that are great for portability. However, they may not perform as well in tougher conditions.

- Brand C: Focuses on innovative designs and user-friendly features. A great choice for those new to drilling.

- Brand D: Balances power and weight, making it versatile for various applications. Considered a solid all-around performer.

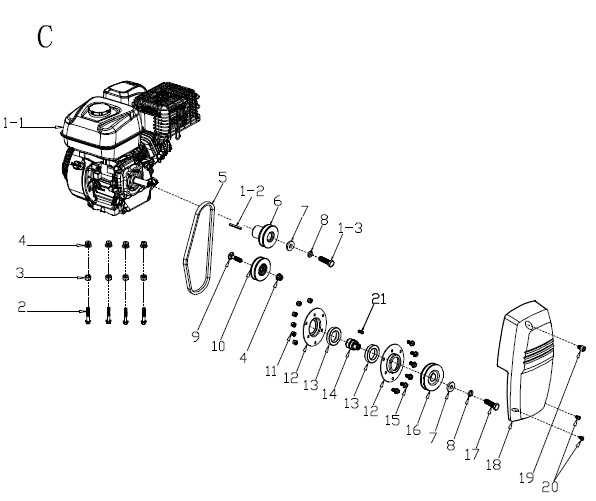

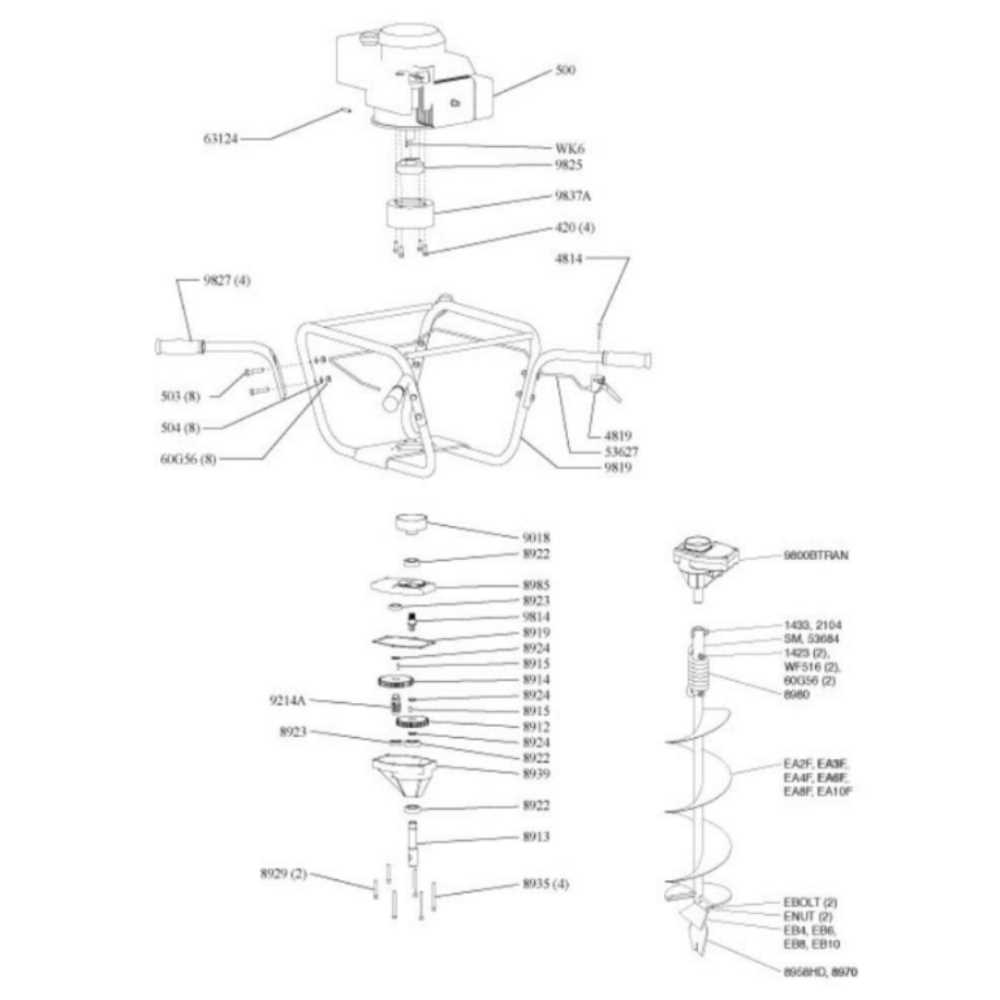

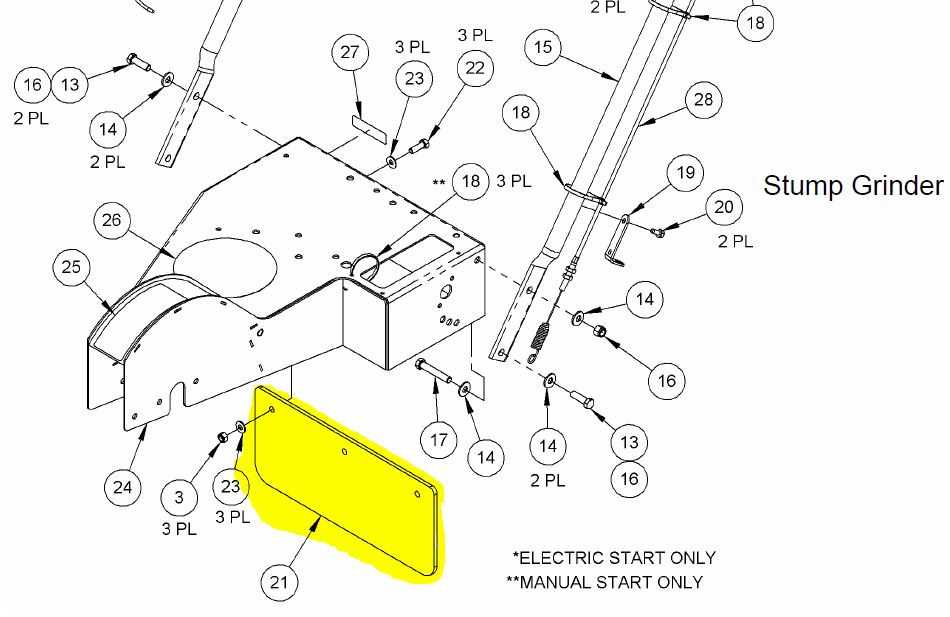

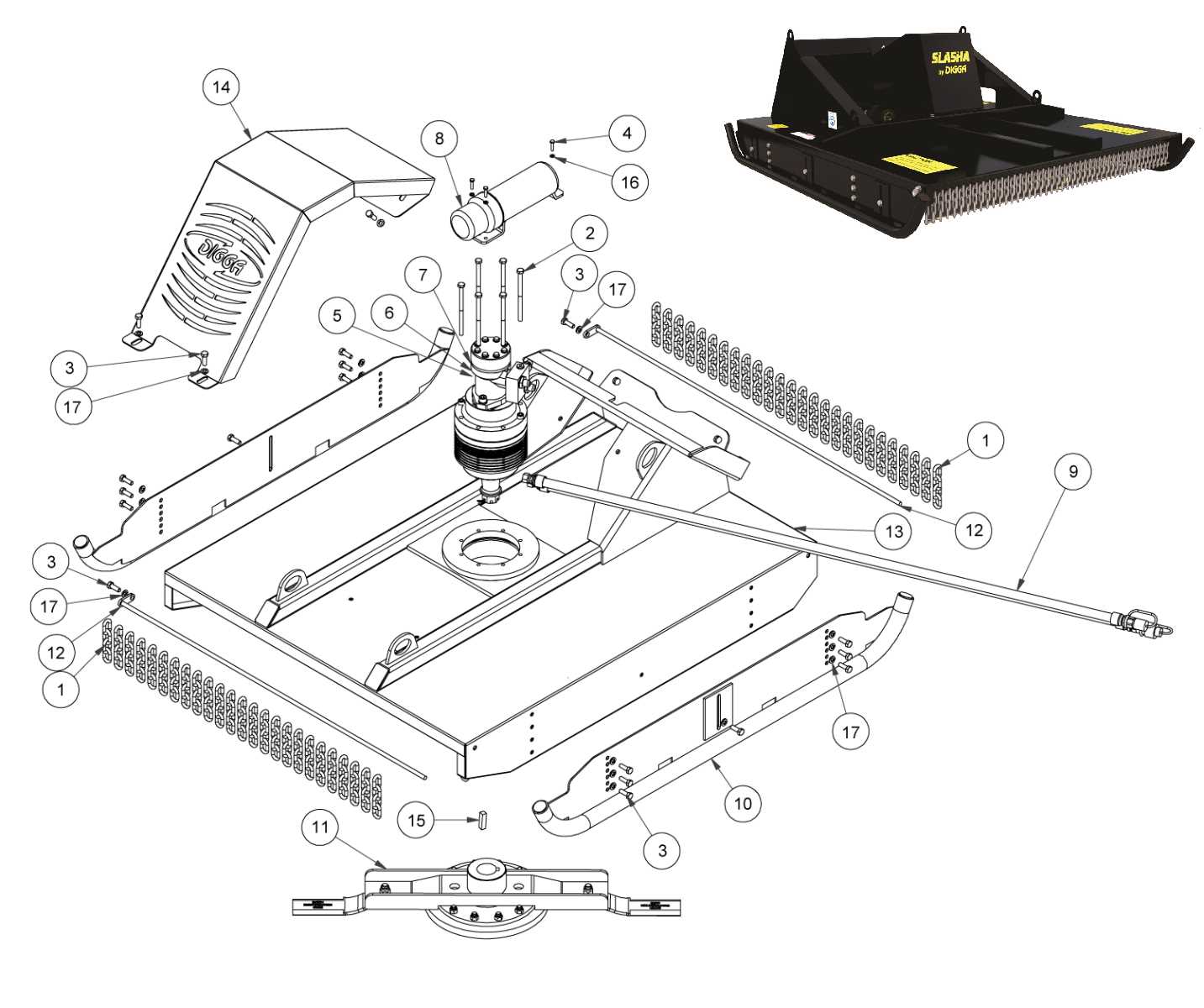

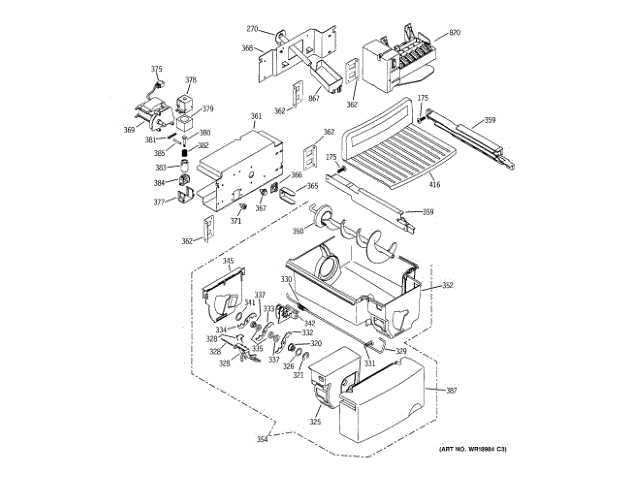

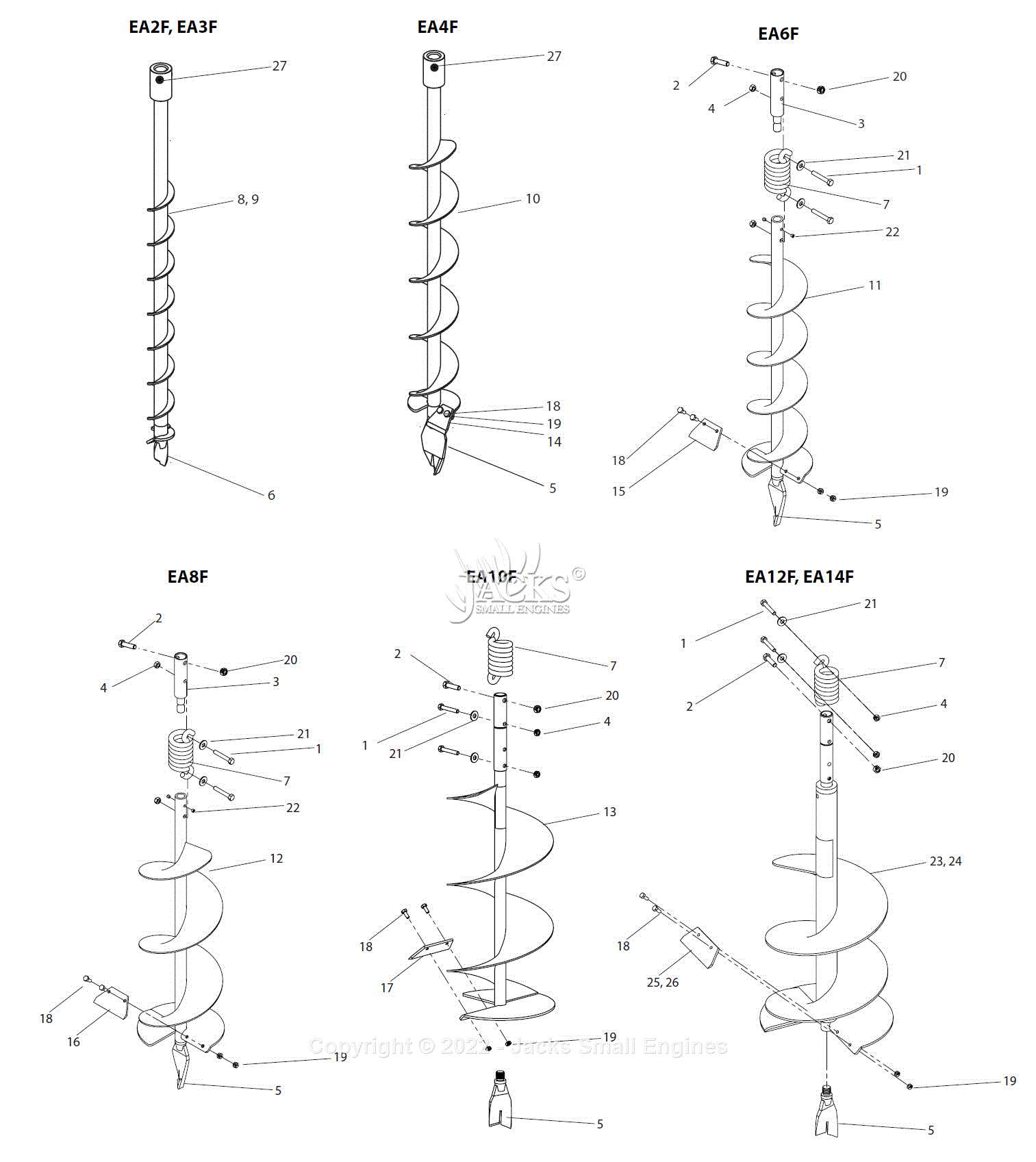

Understanding Auger Diagrams

Grasping the intricacies of drilling mechanism schematics is essential for effective operation and maintenance. These visual representations not only illustrate the various components involved but also highlight their interconnections and functionalities. By exploring these layouts, users can gain insights into the equipment’s design and performance.

Components and Their Functions

Each element within these representations serves a unique purpose, contributing to the overall efficiency of the system. Identifying these components allows operators to delve into their specific roles, ensuring optimal performance during usage.

Importance of Understanding Layouts

Familiarity with these schematics enhances troubleshooting skills and aids in the identification of potential issues. A clear understanding ultimately leads to improved maintenance practices and increased lifespan of the equipment.

Frequently Asked Questions on Augers

This section aims to address common inquiries related to the drilling equipment used for creating holes in various surfaces. Understanding these tools is crucial for both beginners and experienced users, as it helps in making informed decisions regarding their usage and maintenance.

| Question | Answer |

|---|---|

| What types of drilling tools are available? | There are several types, including manual, electric, and gas-powered variants, each suited for different applications. |

| How do I choose the right size for my project? | The size depends on the diameter of the hole required and the type of material being drilled. Always refer to the specifications for guidance. |

| What maintenance is needed for these tools? | Regular cleaning, lubrication of moving parts, and checking for wear and tear are essential for optimal performance. |

| Can I use these tools for various soil types? | Yes, but the efficiency may vary. Softer soils require different techniques compared to hard or rocky surfaces. |

| Is it safe to operate these machines? | When used correctly and with appropriate safety gear, they can be safe. Always follow the manufacturer’s instructions. |