Understanding the Craftsman YT4000 Steering Parts Diagram

Maintaining the functionality of your outdoor equipment is essential for optimal performance and longevity. A clear grasp of its operating components can greatly enhance your ability to troubleshoot and repair any issues that may arise. This section will explore the intricacies of the steering assembly, providing a comprehensive overview of its essential elements.

For enthusiasts and professionals alike, knowing how each segment interacts can streamline maintenance and ensure a smooth user experience. Delving into the layout of these components allows you to appreciate their roles and identify potential areas for improvement or replacement.

Ultimately, a well-informed approach to managing your machinery not only enhances efficiency but also ensures safety during operation. Understanding the assembly will empower you to take charge of repairs, fostering a deeper connection with your equipment.

Understanding the Craftsman YT4000 Steering System

This section explores the essential components that enable precise navigation and control in your lawn equipment. A well-functioning mechanism is crucial for achieving optimal performance and maneuverability, ensuring that users can maintain their landscapes efficiently.

Key Components of the Control Mechanism

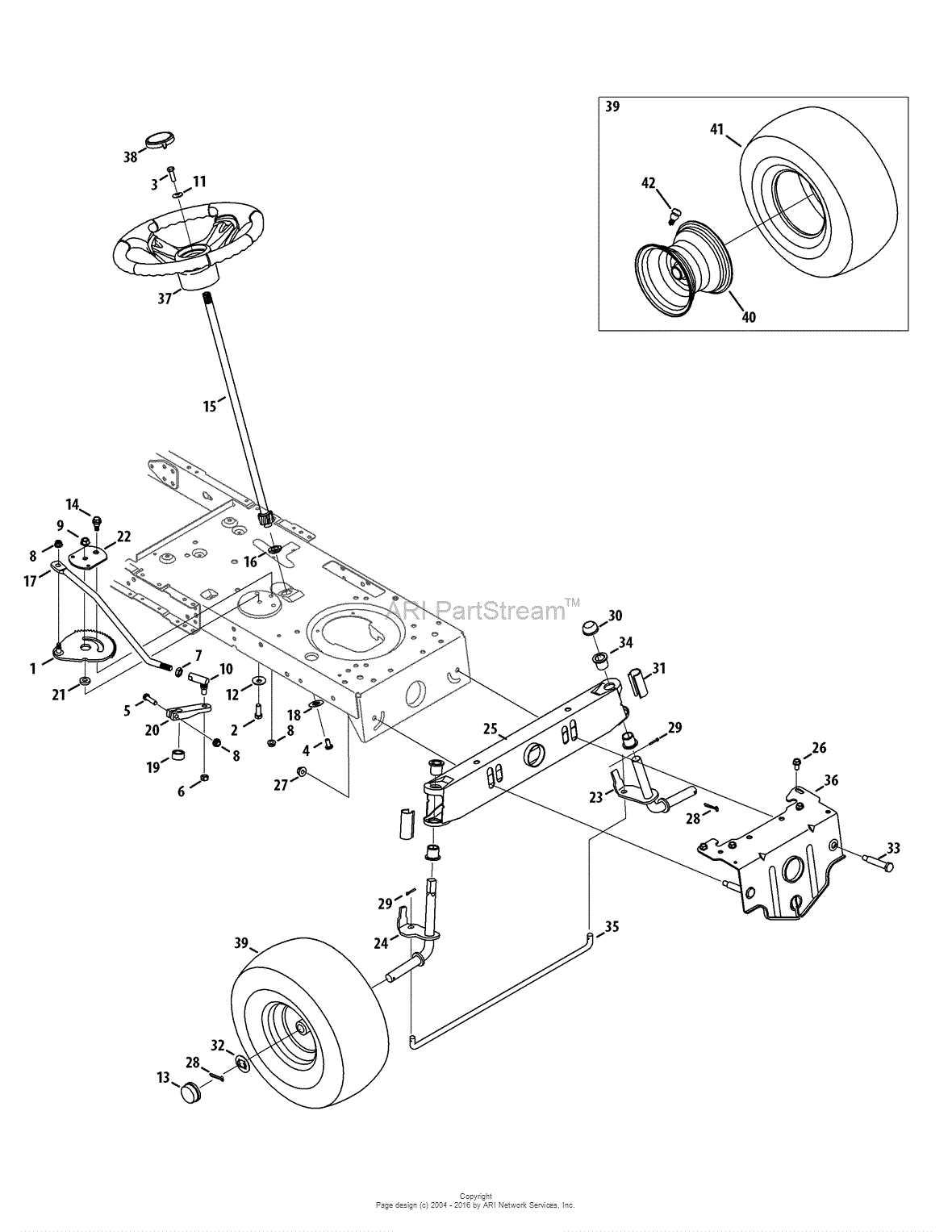

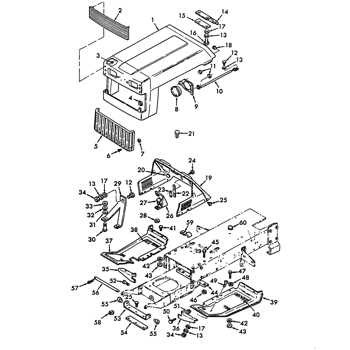

Several vital elements contribute to the functionality of the directional system. These include the wheel assembly, linkages, and the operator interface. Each component plays a significant role in translating user input into motion, making it essential to comprehend their individual and collective impacts.

Maintenance for Longevity

Regular upkeep is crucial for sustaining the efficiency of the directional system. Inspecting for wear and tear, lubricating moving parts, and ensuring proper alignment can greatly extend the lifespan of these crucial elements. Understanding these maintenance practices will ultimately enhance the reliability of your equipment.

Essential Components of Steering Mechanism

The effectiveness of directional control in machinery relies on a well-designed framework that encompasses various critical elements. Each of these components plays a vital role in ensuring smooth navigation and precise maneuverability.

Control Wheel: The primary interface for the operator, this circular apparatus allows for intuitive adjustment of the vehicle’s direction. Its design is crucial for comfort and efficiency during operation.

Linkage System: This network of rods and joints transmits the movements initiated by the control wheel to the wheels themselves. It ensures that every action translates accurately into directional changes.

Pivot Points: These are the fulcrums around which the linkage operates. Their placement and integrity are fundamental for the stability and responsiveness of the entire mechanism.

Ball Joints: These flexible connections allow for a range of motion while maintaining alignment. They are essential for adapting to varying terrain and ensuring smooth transitions during operation.

Gear Assembly: This collection of gears transforms the rotational movement from the control wheel into the lateral movements needed for effective navigation. Proper gearing is critical for enhancing responsiveness.

Understanding these fundamental elements is crucial for anyone involved in maintenance or improvement of machinery designed for movement, as they collectively ensure operational efficiency and safety.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These visual aids provide a clear overview of the various elements and their relationships, making it easier to identify and source replacements when necessary.

Key Elements to Observe

- Labels: Each component is often labeled with a specific identifier, helping you locate it quickly.

- Numbers: Numerical codes typically correlate with a list of items, indicating their details.

- Connections: Arrows or lines illustrate how parts interact, showing assembly and disassembly paths.

Steps to Effectively Analyze

- Start with the overall layout to grasp the arrangement.

- Focus on each labeled item, referencing the accompanying list for details.

- Note the connections to understand how each part fits into the whole.

Common Issues with Steering Components

Understanding the frequent challenges associated with directional control mechanisms is essential for maintaining optimal performance. Various factors can contribute to difficulties in maneuverability, often leading to user frustration and increased wear on the system.

Wear and Tear

Over time, components can experience significant degradation due to regular use. Friction and exposure to elements can lead to loosening or breaking, making precise navigation difficult.

Alignment Problems

Misalignment can result from impacts or uneven terrain, causing instability and erratic handling. Regular checks and adjustments are crucial to ensure proper orientation for safe operation.

Step-by-Step Repair Guide for Steering

This guide offers a comprehensive approach to resolving common issues associated with directional control systems in lawn care equipment. By following these detailed instructions, you can restore functionality and enhance the overall performance of your machinery.

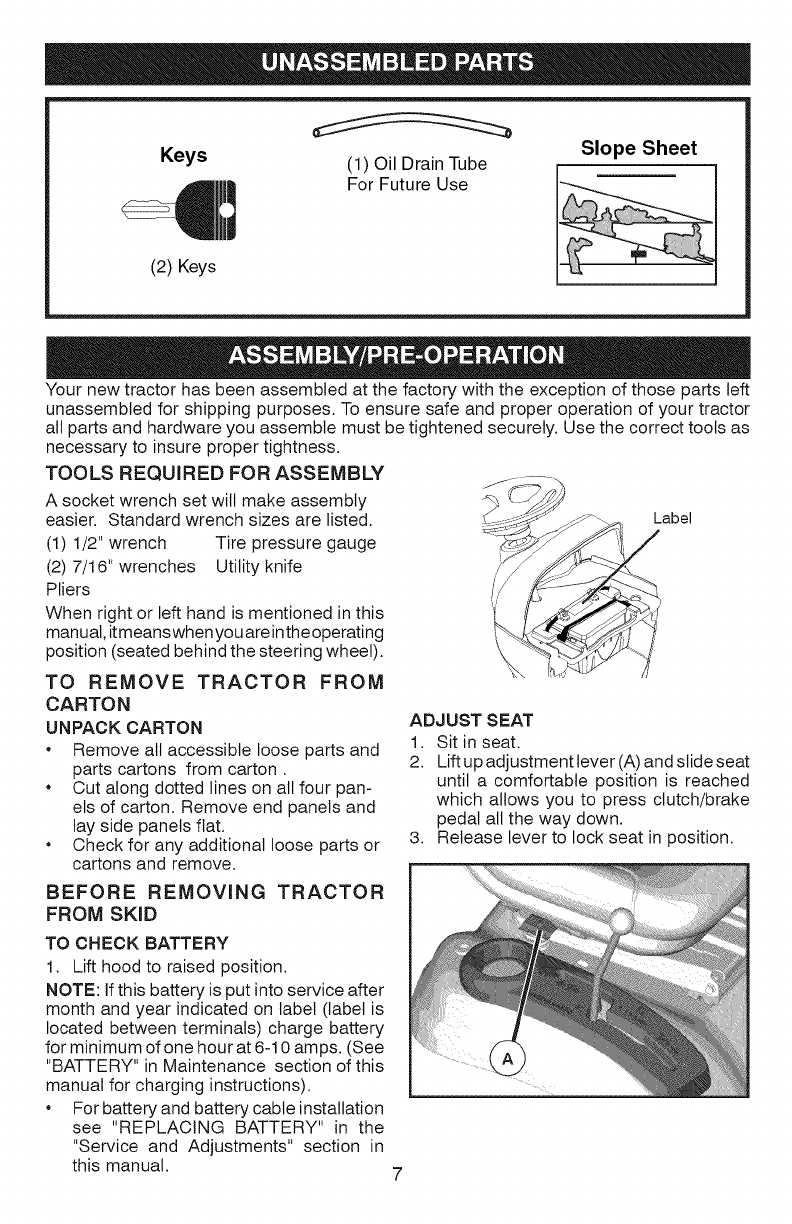

Step 1: Gather Your Tools

Before starting the repair, ensure you have all necessary tools on hand. Common tools may include wrenches, screwdrivers, pliers, and replacement components. Having everything prepared will streamline the process.

Step 2: Safety First

Always prioritize safety. Disconnect the power source to prevent accidental activation. Wear protective gear such as gloves and goggles to safeguard against potential injuries.

Step 3: Inspect the Assembly

Carefully examine the entire mechanism for any visible damage or wear. Look for loose connections, broken pieces, or signs of rust that may require attention. Identifying issues early can save time and effort.

Step 4: Disassemble the Mechanism

Using the appropriate tools, gently take apart the assembly. Keep track of each component and its placement to ensure a smooth reassembly later. Organizing parts can help avoid confusion.

Step 5: Replace Worn Components

As you disassemble, replace any damaged or worn-out elements. Consult a reference guide or manufacturer specifications to ensure you select the correct replacements.

Step 6: Reassemble with Care

Once all necessary replacements are made, carefully reassemble the entire structure. Pay attention to the order of components and ensure everything is securely fastened.

Step 7: Test the Functionality

After reassembly, reconnect the power source and conduct a thorough test. Check for smooth operation and make any adjustments as needed. Observing the functionality helps confirm a successful repair.

Step 8: Final Safety Check

Before using the equipment, conduct a final inspection to ensure all tools and materials are cleared away. Verify that all components are secure and that the machinery operates correctly.

Tools Needed for Steering Repairs

Proper maintenance of your vehicle’s directional system requires specific equipment to ensure effective restoration and functionality. Utilizing the right instruments not only enhances the repair process but also guarantees safety and reliability in operation.

1. Wrenches and Sockets: These are essential for loosening and tightening various components. A set of both metric and standard sizes will provide versatility for different fasteners.

2. Pliers: Useful for gripping and manipulating parts, pliers come in various types, including needle-nose and slip-joint, aiding in precision tasks.

3. Screwdrivers: A range of screwdrivers, including flathead and Phillips, is crucial for removing and installing screws that hold various assemblies together.

4. Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

5. Lubricants and Cleaners: These substances help maintain the integrity of components and facilitate smoother operations during repairs.

6. Safety Gear: Always prioritize safety with gloves and goggles to protect yourself from potential hazards during repairs.

Maintenance Tips for Longevity

Ensuring the extended life of your machinery requires consistent care and attention. Regular upkeep not only enhances performance but also prevents costly repairs in the long run.

1. Regular Inspections: Frequently check all components for signs of wear or damage. Addressing issues early can save time and money.

2. Lubrication: Keep moving parts well-lubricated to reduce friction and prevent premature wear. Use the appropriate lubricants as recommended in the manual.

3. Cleanliness: Maintain a clean environment around your equipment. Debris can lead to malfunction and inefficiency.

4. Proper Storage: Store your equipment in a dry, sheltered area to protect it from harsh weather conditions and potential rust.

5. Follow Manufacturer Guidelines: Adhere to the maintenance schedule outlined in the user manual. This ensures that you don’t overlook critical service points.

By implementing these strategies, you can significantly enhance the longevity and reliability of your machinery.

Identifying Compatible Replacement Parts

When maintaining machinery, ensuring that components match perfectly is crucial for optimal performance. Understanding compatibility helps avoid complications during installation and enhances longevity.

Key Considerations

- Model Number: Always refer to the specific model to find suitable components.

- Manufacturer Guidelines: Consult the manufacturer’s specifications for recommended replacements.

- Dimensions: Measure existing components to ensure new ones fit correctly.

- Material Quality: Select high-quality materials to maintain durability and functionality.

Where to Find Parts

- Authorized Dealers: They offer genuine components that meet original specifications.

- Online Retailers: Websites often have extensive catalogs for various models.

- Local Repair Shops: These may carry a selection of compatible alternatives.

Where to Buy Steering Components

Finding the right components for your equipment can be essential for maintaining performance and safety. There are several avenues to explore when looking for these items, each offering unique advantages in terms of availability and pricing.

Online Retailers

Numerous websites specialize in providing a wide range of components. These platforms often have user-friendly interfaces, detailed descriptions, and customer reviews to assist in your selection process.

Local Stores

Visiting nearby shops can be beneficial for immediate needs. Staff members may offer valuable advice and ensure you receive the correct components without the delay of shipping.

| Source | Advantages |

|---|---|

| Online Retailers | Wide selection, convenient ordering |

| Local Stores | Immediate availability, personal assistance |

| Manufacturer Websites | Direct sourcing, quality assurance |

Upgrades for Improved Steering Performance

Enhancing maneuverability and precision in vehicle handling can significantly elevate the overall experience. Various modifications can be implemented to optimize the response and stability, providing a smoother operation and increased control during navigation.

| Upgrade | Description |

|---|---|

| Advanced Suspension System | Incorporating a more sophisticated suspension setup can absorb shocks more effectively, leading to a steadier ride. |

| High-Quality Tires | Choosing tires designed for better grip and traction can drastically improve handling on different terrains. |

| Performance Bushings | Upgrading to stiffer bushings enhances responsiveness, reducing play and improving feedback from the ground. |

| Precision Linkage | Installing high-precision linkages ensures better alignment and a more direct connection between the control mechanism and wheels. |

Frequently Asked Questions About Steering Parts

This section aims to address common inquiries regarding the components that facilitate directional control in various machines. Understanding these elements can enhance maintenance and troubleshooting efforts.

Common Inquiries

- What are the main components involved in directional control?

- How can I identify if a component needs replacement?

- What maintenance practices can extend the life of these elements?

Replacement and Repair

- Is it necessary to replace all components at once?

- Where can I find reliable replacement options?

- How can I perform a basic repair myself?