Understanding the Husqvarna 120 Chainsaw Parts Diagram

When delving into the intricacies of a popular cutting instrument, it becomes essential to grasp its internal composition and how each element functions harmoniously. This knowledge not only enhances the efficiency of the tool but also aids in troubleshooting and maintenance, ensuring longevity and optimal performance.

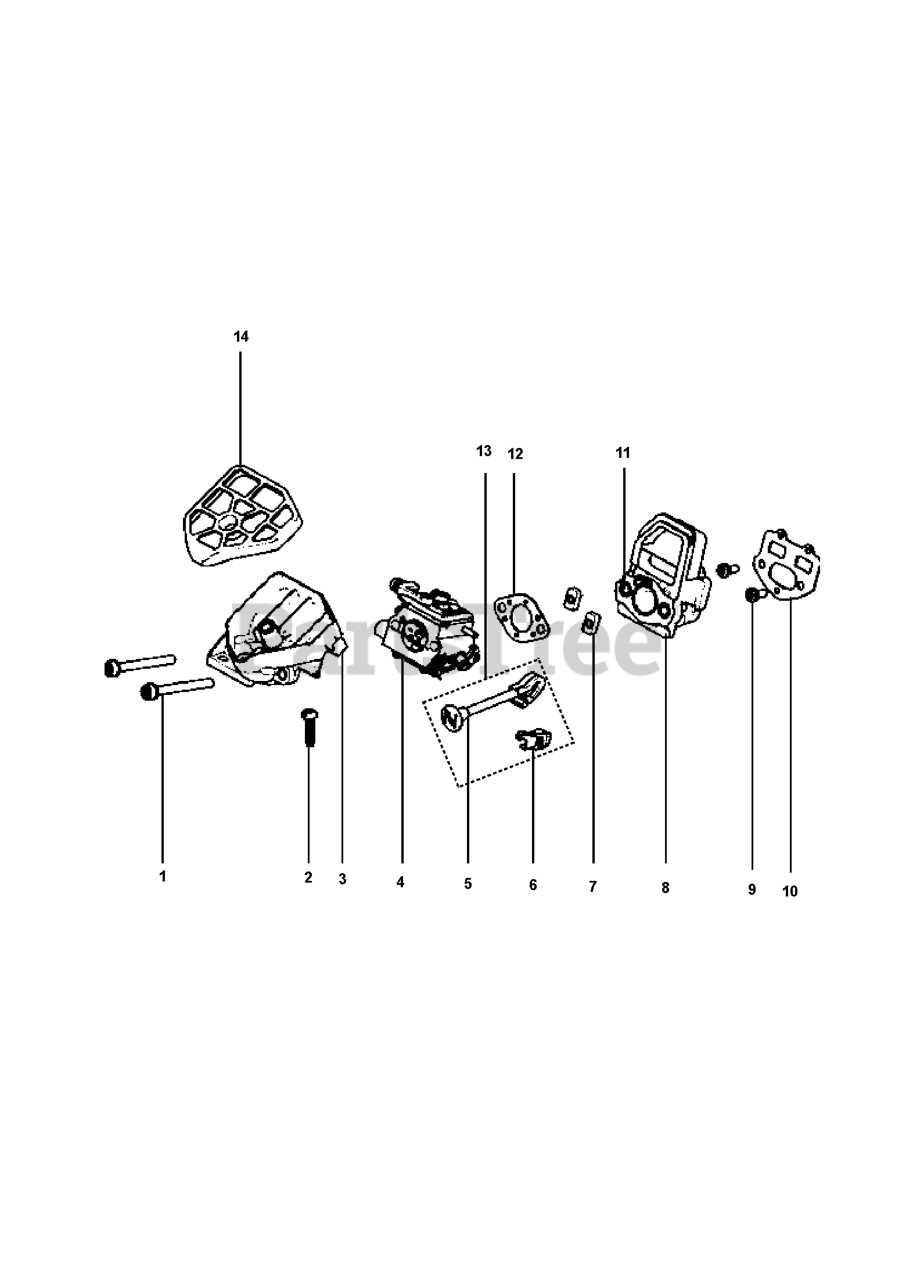

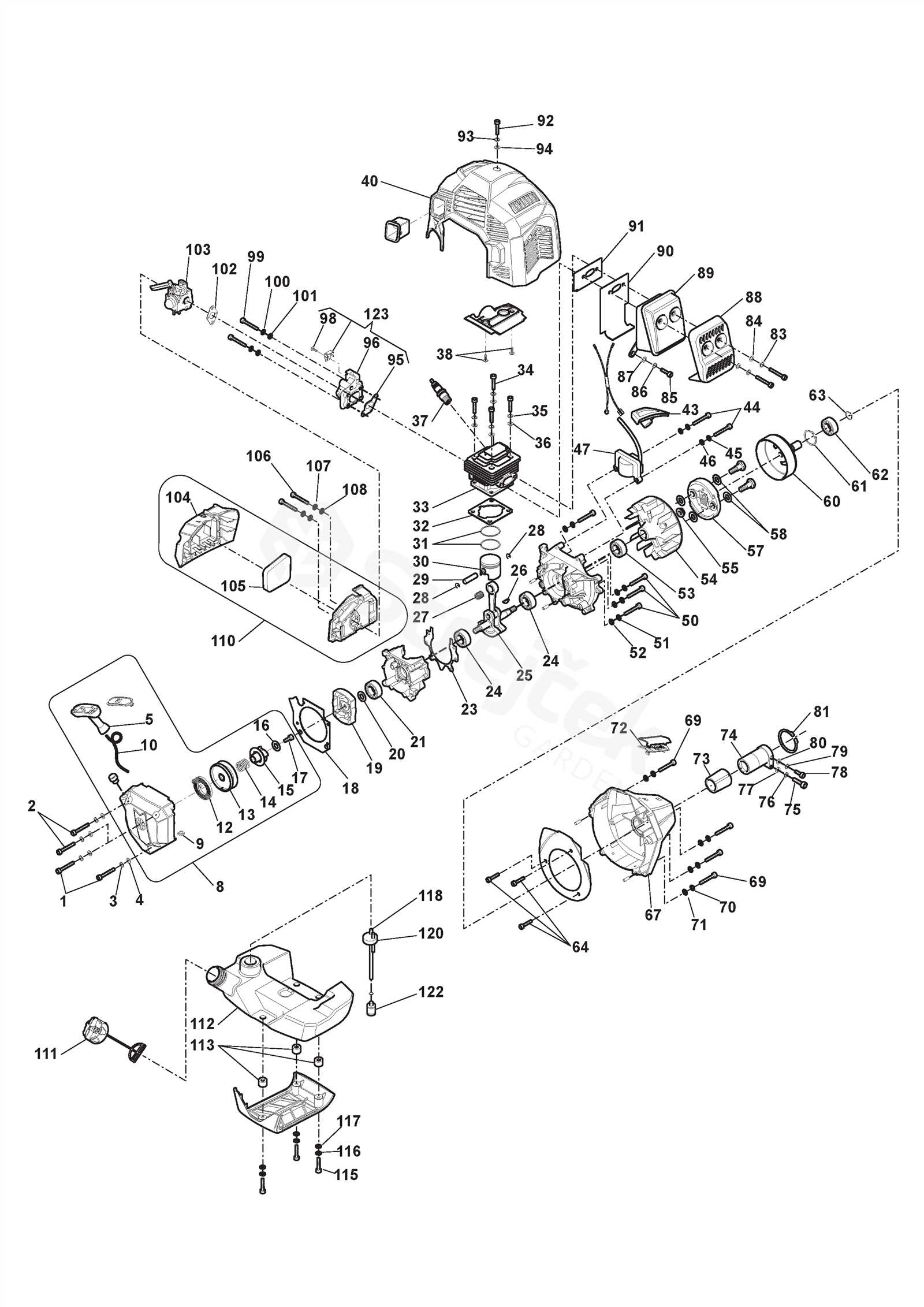

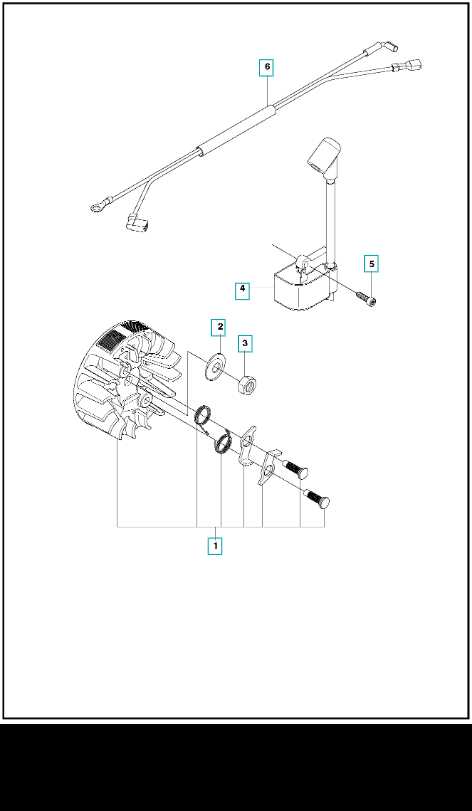

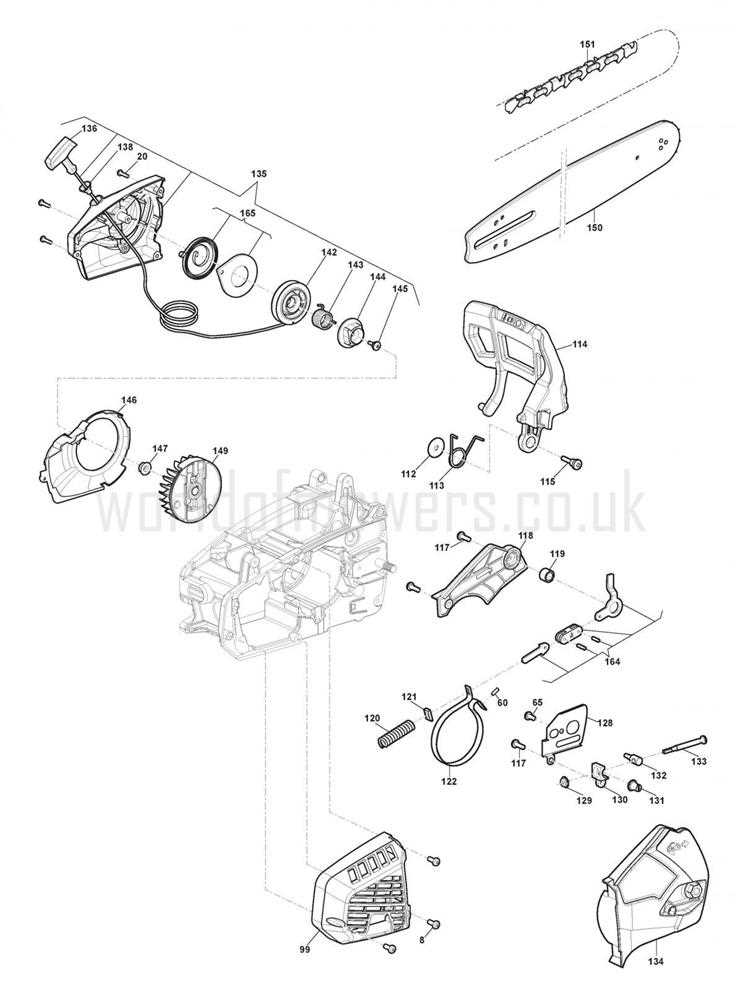

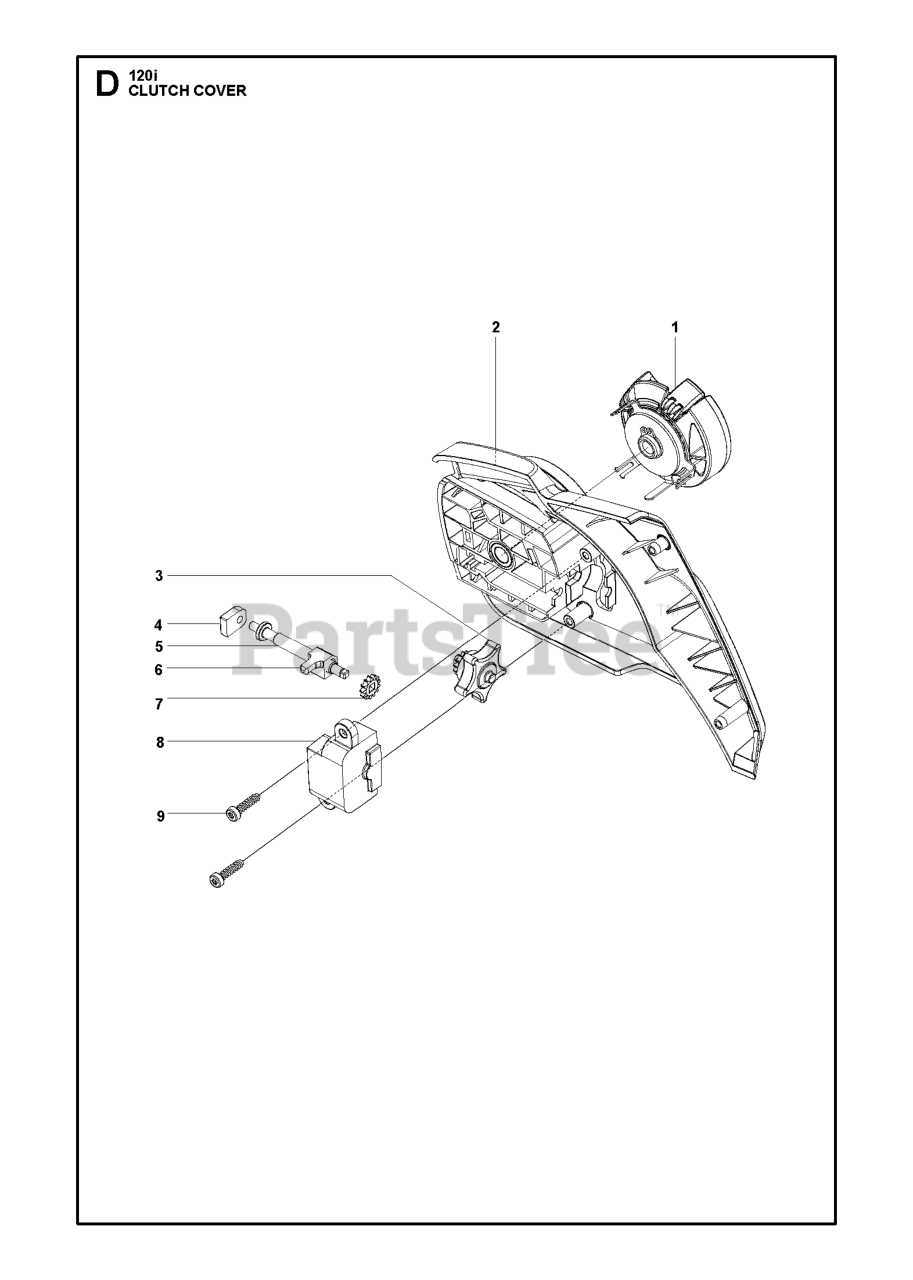

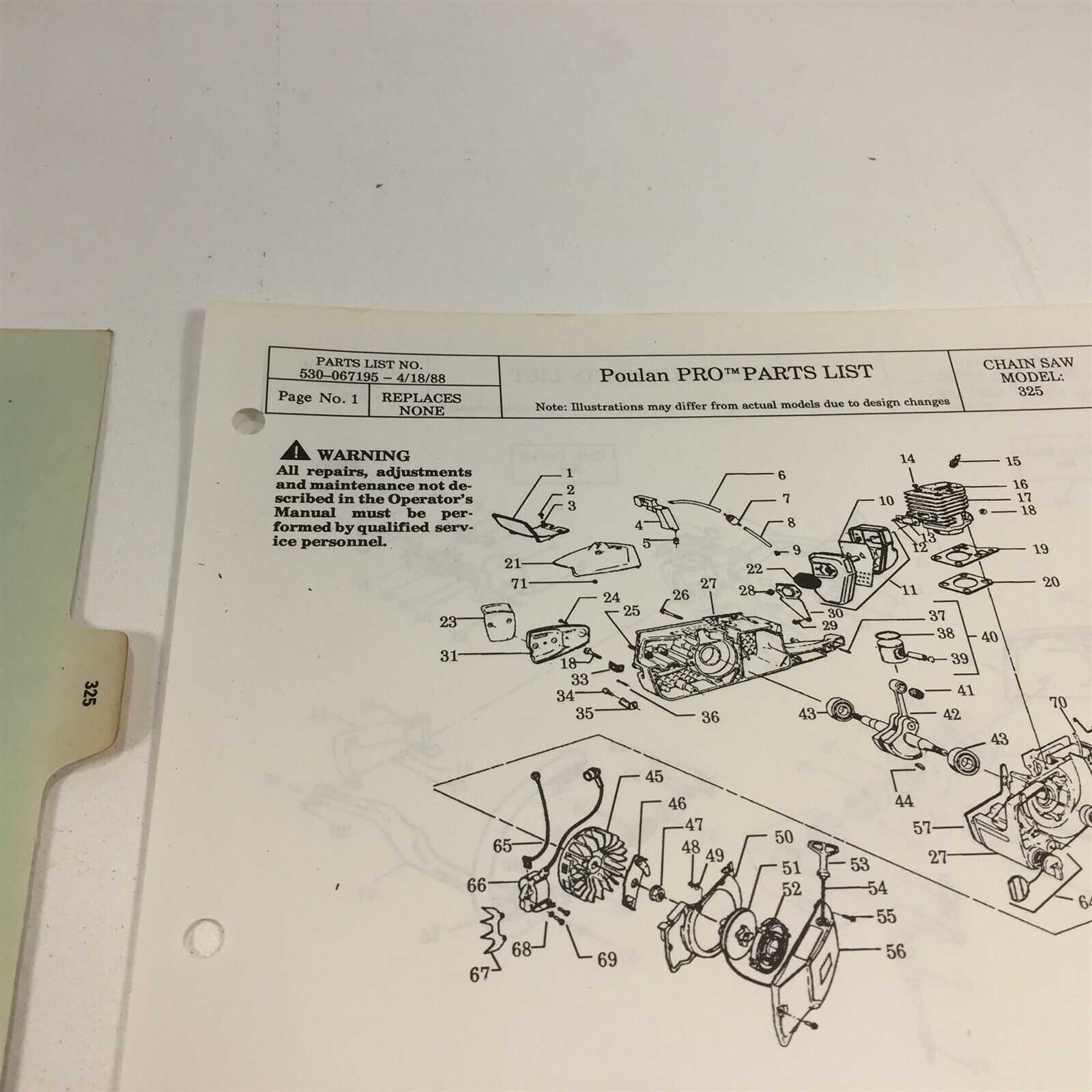

Visual representation of the various components can provide a clearer understanding of how these pieces interconnect and operate together. Familiarizing oneself with these elements empowers users to make informed decisions regarding repairs and upgrades, ultimately leading to a more effective usage experience.

As you explore this guide, you will encounter a detailed overview of the essential sections of the equipment, emphasizing their roles and significance. By examining the layout and interactions of these components, users can gain deeper insights into the mechanics at play and improve their overall expertise in handling this indispensable tool.

Understanding the Husqvarna 120 Chainsaw

This section aims to provide insights into a popular model of cutting tools renowned for its reliability and efficiency. Whether you’re a seasoned professional or a casual user, grasping the essential features and components of this equipment can enhance your overall experience and ensure proper maintenance.

Key Features

Designed with user-friendliness in mind, this model boasts lightweight construction, making it suitable for extended use without causing fatigue. Its powerful motor ensures high performance, allowing users to tackle a variety of tasks with ease. Additionally, the ergonomic handle offers improved control and comfort during operation.

Maintenance and Care

Regular upkeep is crucial to prolong the lifespan of this equipment. It is essential to familiarize yourself with the various components to ensure they are in optimal condition. Routine checks on the oil levels, chain tension, and air filters can prevent potential issues and enhance performance. Understanding the individual elements will aid in identifying any needed repairs or replacements.

By mastering the fundamentals of this cutting tool, users can confidently approach their projects, ensuring both safety and efficiency.

Key Features of Husqvarna 120

This model is designed to offer efficiency and ease of use, making it a popular choice for both amateur and professional users. Its innovative characteristics ensure that tasks are completed with precision and minimal effort.

Engine Performance

- Equipped with a powerful engine that provides excellent cutting capability.

- Low fuel consumption, promoting eco-friendliness without sacrificing performance.

- Quick start technology that minimizes the effort required to initiate operation.

User-Friendly Design

- Lightweight construction for enhanced maneuverability during use.

- Ergonomic handle designed for comfortable grip, reducing fatigue during prolonged operation.

- Tool-less chain tensioning system for easy adjustments and maintenance.

Overall, this model combines functionality and practicality, making it an essential tool for various cutting tasks.

Essential Components of the Chainsaw

Understanding the fundamental elements of a cutting tool is crucial for both maintenance and optimal performance. Each component plays a vital role in ensuring the device operates smoothly and effectively. Familiarity with these parts allows users to troubleshoot issues and enhance their experience.

- Engine: The powerhouse of the tool, converting fuel into mechanical energy to drive the cutting mechanism.

- Guide Bar: The long metal piece that supports and guides the cutting chain, determining the depth and width of the cut.

- Cutting Chain: The loop of linked metal segments equipped with sharp teeth, essential for slicing through wood.

- Chain Brake: A safety feature designed to stop the chain quickly in the event of kickback, protecting the operator.

- Fuel Tank: Holds the mixture of fuel and oil, providing the energy needed for operation.

- Oil Pump: Ensures the cutting chain remains lubricated, reducing wear and enhancing performance.

- Throttle Control: Allows the user to regulate the speed of the engine, providing better control during operation.

Each of these elements must work in harmony to achieve the desired results. Regular inspection and maintenance of these components will extend the lifespan of the tool and improve its efficiency.

How to Read a Parts Diagram

Understanding an assembly representation is essential for effective maintenance and repairs. This visual guide breaks down components, illustrating their relationships and functions within a machine. By familiarizing yourself with this layout, you can simplify troubleshooting and ordering replacement elements.

To effectively interpret the representation, follow these key steps:

- Identify the Legend: Look for a legend or key that explains the symbols used in the illustration. This will clarify what each icon or number signifies.

- Understand the Layout: Observe how the components are arranged. Typically, parts are shown in their operational positions, helping you visualize assembly.

- Focus on Connections: Pay attention to how different pieces connect. Arrows or lines often indicate movement or interaction between components.

- Note Part Numbers: Each component usually has a designated number. Make a note of these for ordering replacements or further reference.

- Refer to the Manual: Use the user manual in conjunction with the visual representation. It often provides additional context and detailed descriptions of each component.

By following these guidelines, you’ll enhance your understanding of the assembly and streamline your repair process.

Common Replacement Parts for Husqvarna 120

Maintaining optimal performance of your cutting tool often requires the replacement of certain components over time. Understanding which elements may need to be refreshed can enhance efficiency and prolong the lifespan of your equipment.

Among the frequently replaced items are the chain, which ensures smooth operation and cutting efficiency. A dull or damaged chain can lead to poor performance and increased wear on the unit.

The bar is another essential component that may require attention. Over time, it can wear down, affecting the tool’s cutting ability and necessitating replacement to maintain precision.

Additionally, the fuel filter plays a crucial role in keeping the engine clean. A clogged filter can lead to performance issues, making regular checks and replacements vital for reliable operation.

Another key item is the spark plug. This small but significant part can influence starting and overall engine efficiency. Replacing a worn or fouled spark plug can restore power and responsiveness.

Lastly, the air filter is essential for maintaining optimal airflow to the engine. A clean air filter improves combustion efficiency, ensuring that your equipment runs smoothly.

By regularly inspecting and replacing these critical components, you can ensure that your tool remains in peak condition and ready for any task at hand.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor power equipment requires consistent care and attention. Regular maintenance not only enhances performance but also extends the life of your tools. Here are some essential tips to keep in mind for optimal upkeep.

Regular Cleaning

Keeping your equipment clean is crucial for preventing debris buildup, which can lead to operational issues. Follow these steps:

- Wipe down the exterior after each use.

- Remove any residues from the cutting components.

- Inspect and clear any blockages in air filters.

Routine Inspections

Frequent checks can identify potential problems before they escalate. Pay attention to the following:

- Examine the sharpness of blades and replace them when dull.

- Inspect the fuel system for leaks or cracks.

- Check the tension and condition of the drive belt.

By integrating these maintenance practices into your routine, you can ensure that your tools operate efficiently and remain reliable for years to come.

Identifying Wear and Tear Signs

Recognizing the indicators of deterioration in your equipment is crucial for maintaining optimal performance and longevity. Regular inspections can help detect issues early, preventing costly repairs and ensuring safe operation. Below are some common signs that may indicate wear and tear.

Common Indicators

- Unusual Noises: Listen for grinding, rattling, or any unexpected sounds during operation, which may suggest internal damage.

- Difficulty Starting: If the machine struggles to start or requires multiple attempts, it may be a sign of component wear.

- Excessive Vibration: Increased vibration during use can indicate loose or worn parts that need attention.

- Reduced Efficiency: A noticeable drop in cutting power or performance may signal that components are wearing out.

Visual Inspections

- Check for cracks or chips on external components, which can affect stability and safety.

- Inspect the blades or cutting edges for dullness or damage, as these are critical for effective operation.

- Look for signs of leakage, which could indicate failing seals or gaskets.

- Examine the handles and grips for wear, ensuring a secure and comfortable hold.

Regular monitoring and timely maintenance can extend the life of your equipment, ensuring it remains in peak condition for years to come.

Tools Needed for Repairs

When it comes to maintaining and fixing your outdoor power equipment, having the right tools is essential for effective and efficient repairs. Each task may require specific instruments to ensure precision and safety, allowing you to carry out your work smoothly.

Here’s a comprehensive list of tools that are commonly needed for repairs:

- Wrenches: Various sizes of wrenches are crucial for loosening and tightening bolts and nuts. A set that includes both metric and standard sizes will be beneficial.

- Screwdrivers: A variety of screwdrivers–flathead and Phillips–are necessary for different types of screws found in your equipment. Consider having a magnetic tip for easier handling of screws.

- Pliers: Needle-nose and standard pliers assist in gripping and manipulating small components. They are also useful for bending wires and securing loose parts.

- Fuel and Oil Containers: Proper storage for fuel and oil is vital. Using clean, labeled containers helps avoid contamination and ensures you have the correct types of fluids when performing maintenance.

- File: A metal file is essential for sharpening blades or smoothing rough edges on parts. Keeping cutting components sharp ensures optimal performance.

- Safety Gear: Always prioritize safety. Protective eyewear, gloves, and ear protection shield you from potential hazards during repairs.

- Cleaning Tools: Brushes and rags are necessary for keeping components clean and free from debris. Regular cleaning can prolong the life of your equipment.

- Torque Wrench: This tool helps in applying a specific torque to fasteners, preventing over-tightening and potential damage to parts.

- Service Manual: Having the manufacturer’s service manual on hand is invaluable. It provides diagrams, specifications, and guidelines for repairs, ensuring you follow correct procedures.

Equipping yourself with these tools not only streamlines the repair process but also enhances your understanding of how your equipment operates. Proper maintenance can significantly extend the lifespan of your machinery, making it a worthwhile investment in your tools and knowledge.

Step-by-Step Disassembly Guide

This guide provides a detailed approach to dismantling your equipment effectively. Following these steps will help you understand each component and ensure proper handling during the process.

Required Tools

| Tool | Purpose |

|---|---|

| Screwdriver | To remove screws and fasteners |

| Wrench | To loosen bolts |

| Plier | For gripping and pulling parts |

| Safety Gloves | To protect your hands |

Disassembly Steps

Begin by ensuring the device is powered down and disconnected from any power source. Remove outer casing screws to expose internal components. Carefully detach the housing, taking note of wire connections and their placements. Continue by extracting each element systematically, documenting your process to aid in reassembly. This methodical approach will ultimately enhance your understanding and maintenance of the unit.

Reassembly Best Practices

Reassembling machinery requires attention to detail and adherence to specific techniques to ensure optimal performance and longevity. Following structured methods not only enhances functionality but also minimizes the risk of future malfunctions.

Preparation Steps

- Gather all components and tools in a clean, organized workspace.

- Refer to the assembly manual for guidance on specific parts and their placement.

- Inspect each component for wear or damage before reassembly.

Reassembly Tips

- Start with the foundation and build up, ensuring each part fits securely.

- Use appropriate lubricants on moving parts to facilitate smooth operation.

- Double-check all fasteners to ensure they are tightened to the manufacturer’s specifications.

Where to Find Original Parts

Locating authentic components for your equipment can significantly enhance its performance and longevity. It’s essential to ensure that you are using genuine items, as this guarantees compatibility and reliability.

Here are some reliable sources to consider:

- Authorized Dealers: Visit local authorized retailers or service centers that specialize in outdoor machinery. They often carry a full range of original components and can assist with installation.

- Official Websites: Check the manufacturer’s official website for an online shop or parts catalog. This is a direct way to access genuine products.

- Online Marketplaces: Explore reputable e-commerce platforms that offer verified sellers. Ensure that the listings clearly state that the items are authentic.

- Repair Shops: Many specialized repair shops maintain stocks of original items. They can also provide expert advice on what you might need.

When searching for components, always verify the product descriptions and part numbers to ensure compatibility with your equipment. This diligence can prevent potential issues and ensure that your machine operates at its best.

Understanding Warranty and Support Options

When investing in outdoor power equipment, knowing the available protection and assistance can greatly enhance your experience. Understanding the terms and services offered can help ensure longevity and satisfaction with your purchase.

- Warranty Coverage: Most products come with a warranty that protects against manufacturing defects.

- Duration: Warranties typically last for a specified period, often one to three years.

- Claim Process: Familiarize yourself with how to file a claim if issues arise.

Support options play a crucial role in maintenance and troubleshooting:

- Customer Service: Access to knowledgeable representatives can assist with inquiries.

- Manuals and Guides: Comprehensive resources are often available for reference.

- Authorized Service Centers: Locate nearby facilities for repairs and maintenance.

Understanding these aspects ensures you can make the most of your equipment while feeling secure in your investment.