Comprehensive Guide to New Holland H7230 Parts Diagram

In the realm of agricultural technology, the intricate design and functionality of machinery play a crucial role in enhancing productivity. A comprehensive overview of the various components of these machines provides invaluable insights for operators and technicians alike. This understanding not only facilitates efficient maintenance but also optimizes performance in the field.

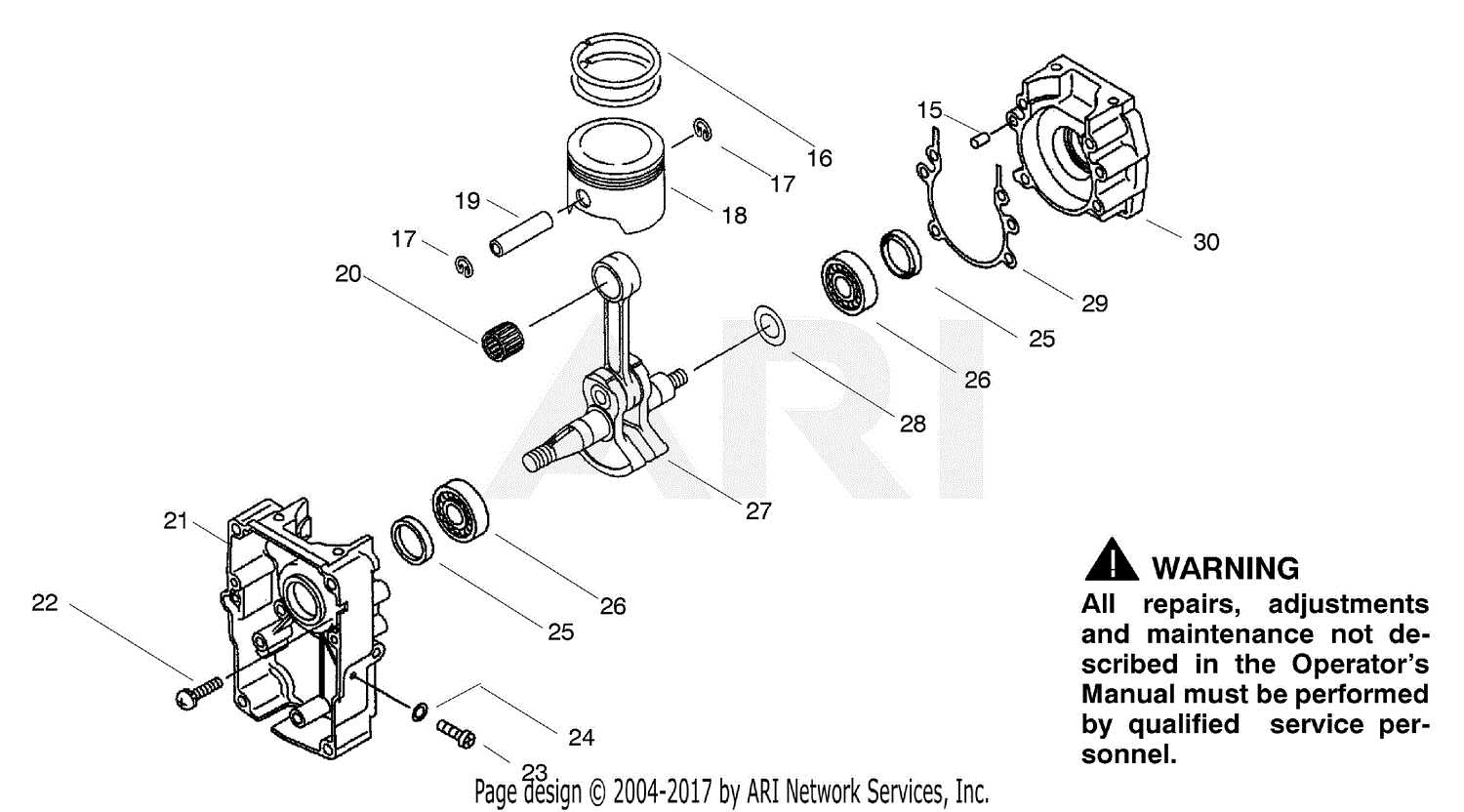

Visual representations of machinery elements can significantly aid in grasping the complex interrelationships between different parts. By examining these schematics, one can easily identify each component’s role and function, leading to more informed decision-making during repairs and upgrades. Furthermore, such illustrations serve as essential tools for both novices and seasoned professionals in the industry.

Delving into the specifics of machine architecture fosters a deeper appreciation for the engineering involved in modern agricultural equipment. This knowledge empowers users to troubleshoot issues more effectively, ensuring that operations remain smooth and efficient. As we explore the essential elements of this machinery, it becomes clear that a solid understanding of their composition is vital for anyone involved in agricultural practices.

Understanding New Holland H7230 Parts

When it comes to maintaining agricultural machinery, comprehending the components involved is crucial for optimal performance and longevity. Each element plays a significant role in the overall functionality, making knowledge about these elements essential for operators and technicians alike.

Key components can be categorized into various groups:

- Drive System: Ensures efficient power transfer and mobility.

- Cutting Mechanism: Responsible for effective harvesting, featuring blades and assemblies.

- Hydraulic System: Facilitates smooth operation of various functions through fluid power.

- Frame and Structure: Provides the necessary support and durability for all activities.

- Electrical Components: Powers systems, including lights and sensors for enhanced operation.

Understanding the interplay between these categories helps in troubleshooting and performing maintenance effectively. Familiarity with the arrangement and function of each section not only aids in repairs but also in ensuring that the machinery operates at peak efficiency.

For anyone involved in the upkeep of such equipment, a solid grasp of these elements can lead to better decision-making and reduced downtime.

Overview of H7230 Components

This section provides a comprehensive look at the various elements that make up the agricultural machinery in question. Understanding these components is essential for optimal functionality and maintenance. Each part plays a crucial role in the overall performance, contributing to efficiency and reliability in the field.

Main Elements

- Cutting Mechanism: This includes blades and reels designed for efficient crop management.

- Transport System: Comprises wheels and axles that facilitate movement across different terrains.

- Hydraulic System: Responsible for powering various operations, enhancing performance and control.

- Engine Assembly: The heart of the machine, providing the necessary power for all functions.

- Control Panel: User interface for monitoring and adjusting settings for optimal operation.

Support Structures

- Frame: The backbone that supports all components, ensuring durability and stability.

- Fenders: Protect vital parts from debris and damage during operation.

- Safety Guards: Implemented to prevent accidents and ensure operator safety.

Each of these components interacts with others to create a cohesive and efficient unit, crucial for achieving desired agricultural outcomes.

Importance of Accurate Parts Diagrams

Precision in illustrations that depict components is crucial for effective maintenance and repair. These visuals serve as essential references, guiding technicians through the intricacies of assembly and disassembly. Without clear and detailed representations, the risk of errors increases, potentially leading to costly mistakes and extended downtime.

Understanding Complexity

Complex machinery consists of numerous interconnected elements. Accurate illustrations simplify this complexity, allowing users to grasp the relationship between different pieces quickly. This understanding is vital for ensuring that repairs are executed correctly and efficiently.

Enhancing Efficiency

When individuals can easily identify components and their functions, it streamlines the maintenance process. Time saved in locating and understanding elements directly translates to improved operational efficiency. In environments where machinery uptime is critical, this efficiency can significantly impact overall productivity.

Facilitating Communication

Clear visual references improve communication among team members. When everyone has access to accurate representations, discussions about repairs or modifications become more straightforward. This shared understanding fosters collaboration and reduces the likelihood of misunderstandings.

Supporting Training

Accurate illustrations are invaluable for training new personnel. They provide learners with visual cues that enhance comprehension and retention. Effective training ultimately leads to a more skilled workforce capable of maintaining and troubleshooting complex equipment.

In summary, reliable representations of components are fundamental to effective machinery management. Their role in simplifying complexity, enhancing efficiency, facilitating communication, and supporting training cannot be overstated.

Common Issues with H7230 Parts

In the realm of agricultural machinery, several common challenges can arise with components that are essential for optimal performance. Understanding these issues can significantly enhance the longevity and functionality of the equipment. Addressing problems promptly can prevent larger malfunctions and ensure efficient operation.

Wear and Tear

One of the most frequent issues encountered is the natural deterioration of components over time. Various factors, such as environmental conditions and usage intensity, can accelerate this process. Regular inspections are crucial to identify signs of wear, allowing for timely replacements that can maintain efficiency.

Compatibility and Fit

Another prevalent concern involves the compatibility of components with the machinery. Using parts that do not fit correctly can lead to operational inefficiencies and even damage. It is vital to ensure that replacements are designed for specific models to avoid potential complications.

Where to Find Replacement Parts

Finding components for your equipment can be a straightforward process if you know where to look. Numerous resources exist that can help you locate the necessary items to keep your machinery running smoothly.

- Authorized Dealers: One of the most reliable sources is through official distributors. They often carry a full range of components tailored for your model.

- Online Retailers: E-commerce platforms specialize in various machinery components. Websites like Amazon or specialized machinery sites can offer a wide selection.

- Local Repair Shops: Many local mechanics or repair shops have access to suppliers and can order parts for you, sometimes at competitive prices.

- Manufacturers’ Websites: Visiting the manufacturer’s official site can provide access to their catalog, allowing you to identify and order specific components directly.

- Salvage Yards: For those looking for budget-friendly options, salvage yards may have used parts in good condition. This can be an excellent way to save money.

By exploring these avenues, you can efficiently locate the components you need to ensure your equipment remains in optimal working condition.

Maintenance Tips for H7230 Equipment

Proper upkeep of agricultural machinery is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also minimizes unexpected breakdowns. By following a systematic approach, operators can keep their equipment running smoothly and reduce repair costs over time.

Regular Inspections

Conduct routine checks to identify any signs of wear or damage. Focus on critical components such as belts, bearings, and hydraulic systems. Early detection of issues can prevent costly repairs and downtime. Ensure that all moving parts are lubricated according to the manufacturer’s guidelines to maintain functionality.

Scheduled Maintenance

Establish a maintenance schedule based on usage and manufacturer recommendations. Regularly changing fluids, filters, and other consumables is crucial. Keep a log of maintenance activities to track performance and identify patterns that may indicate underlying issues. This proactive approach will help in maintaining the overall health of your machinery.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visual guides provide a comprehensive overview of components and their interconnections, allowing users to identify and locate specific elements within a machine. Mastering this skill enhances efficiency and accuracy in any service task.

Here are key steps to effectively interpret these illustrations:

- Familiarize Yourself with Symbols:

- Recognize common symbols used to represent various components.

- Understand color codes that may indicate function or status.

- Identify the Main Sections:

- Look for labels that categorize parts into groups.

- Note how sections are organized based on functionality or location.

- Trace Connections:

- Follow lines or arrows that depict how components interact.

- Understand the flow of operation illustrated in the guide.

- Refer to the Legend:

- Use the accompanying legend or key for clarification on symbols and notations.

- Ensure that you understand any annotations that provide additional information.

- Cross-Reference with Manuals:

- Consult the maintenance manual for detailed explanations of the components.

- Compare illustrations with actual machinery to enhance understanding.

By following these steps, anyone can become proficient at interpreting technical illustrations, leading to more effective troubleshooting and repair strategies.

Identifying Genuine New Holland Parts

When maintaining and repairing agricultural machinery, recognizing authentic components is crucial for optimal performance and longevity. Utilizing original elements ensures compatibility, reliability, and enhanced efficiency, ultimately safeguarding your investment.

To distinguish between authentic and counterfeit components, several key factors should be considered:

| Feature | Authentic Components | Counterfeit Components |

|---|---|---|

| Packaging | Well-branded and sealed, often includes warranty information | Poor quality, lack of branding, or damaged packaging |

| Markings | Clear manufacturer logos and serial numbers | Inconsistent or missing markings |

| Weight | Typically heavier due to quality materials | Lightweight, indicating inferior materials |

| Price | Generally reflects quality; higher cost for reliability | Significantly lower, raising suspicion about quality |

Investing time in identifying authentic components not only protects machinery but also enhances operational efficiency, making it a worthwhile endeavor for all equipment owners.

DIY Repairs Using Parts Diagram

Engaging in self-repairs can save time and resources while enhancing your understanding of machinery. Utilizing a visual representation of components allows you to identify and address issues with precision. This method not only fosters confidence but also empowers you to tackle repairs independently.

When embarking on a repair journey, the first step is to familiarize yourself with the layout of the equipment. By studying the illustration, you can pinpoint the necessary components and their functions. This knowledge streamlines the troubleshooting process, enabling you to focus on the specific areas that require attention.

Furthermore, having a clear guide can facilitate the ordering of replacement items. Instead of guessing or making assumptions about what you need, you can refer directly to the visual aid. This approach minimizes errors and ensures that you acquire the correct items for your project.

Safety is paramount during any repair endeavor. Always ensure that you follow safety protocols and wear appropriate protective gear. Understanding the structure of the machinery will also help you avoid potential hazards, making the repair process smoother and safer.

In conclusion, utilizing a comprehensive visual reference enhances the DIY repair experience. It equips you with the tools needed to effectively resolve issues, reinforces your knowledge, and promotes a sense of achievement. Whether you’re a seasoned mechanic or a novice, this method is invaluable for successful repairs.

Impact of Quality Parts on Performance

The performance of machinery significantly relies on the components utilized in its construction. High-quality elements contribute to efficiency, reliability, and overall functionality. When the right materials and precision engineering are employed, the outcomes can greatly enhance productivity and reduce downtime.

Key benefits of utilizing superior components include:

- Improved Durability: High-grade materials withstand wear and tear, extending the lifespan of the machinery.

- Enhanced Efficiency: Well-designed components work seamlessly together, minimizing energy loss and optimizing performance.

- Reduced Maintenance: Quality elements often require less frequent replacement, lowering maintenance costs and efforts.

- Better Safety: Reliable components contribute to safer operation, reducing the risk of failures that could lead to accidents.

Furthermore, investing in top-notch components can lead to:

- Increased Productivity: Efficient machinery operates at higher capacity, allowing for greater output in less time.

- Cost Savings: While the initial investment may be higher, the long-term savings from decreased repairs and increased efficiency are substantial.

- Enhanced Resale Value: Well-maintained equipment with quality components retains value better than those with inferior parts.

In summary, the choice of components plays a pivotal role in determining the overall performance of machinery. Prioritizing quality ensures that operators achieve optimal results and maintain smooth operations over time.

Comparing OEM vs Aftermarket Parts

When it comes to maintaining machinery, the choice between original components and those from third-party manufacturers is crucial. Each option presents unique benefits and potential drawbacks, influencing not only performance but also long-term costs. Understanding these differences helps users make informed decisions tailored to their specific needs.

| Aspect | OEM Components | Aftermarket Components |

|---|---|---|

| Quality | Typically high and meets strict manufacturer standards. | Varies widely; some are comparable to OEM, while others may be subpar. |

| Price | Generally more expensive due to brand reputation. | Often more affordable, providing potential savings. |

| Warranty | Usually backed by the original manufacturer’s warranty. | Warranties can vary; some offer good coverage, while others do not. |

| Availability | May require ordering from specific dealers, which can lead to delays. | Often readily available through various retailers and online platforms. |

| Compatibility | Guaranteed to fit and function with the specific machine. | Compatibility may vary; it’s essential to verify before purchasing. |

Ultimately, the choice between original and third-party components depends on individual circumstances, including budget, reliability expectations, and specific application needs. Weighing these factors carefully will lead to a more satisfactory maintenance experience.

Frequently Asked Questions About H7230

This section addresses common inquiries regarding the specific model, providing clarity on various aspects that users frequently encounter. Whether you’re seeking maintenance tips, compatibility information, or troubleshooting advice, the following questions and answers aim to assist you in understanding this equipment better.

What are the most common maintenance practices for this model?

Regular upkeep is essential to ensure optimal performance. Key practices include routine lubrication, checking fluid levels, and inspecting belts and hoses for wear. Adhering to the manufacturer’s recommended schedule can significantly extend the lifespan of the machine.

Where can I find replacement components?

Replacement components can be sourced from authorized dealers, online retailers, or specialized agricultural supply stores. It’s important to verify compatibility with your specific model to ensure proper functionality.

How can I troubleshoot common issues?

If you encounter operational problems, begin by reviewing the user manual for diagnostic guidelines. Common issues may include electrical malfunctions or hydraulic failures. Identifying symptoms can help pinpoint the cause more effectively.

Are there any upgrades or enhancements available?

Many users consider upgrades to improve efficiency or functionality. Options may include advanced monitoring systems or performance-enhancing attachments. Researching available enhancements can provide valuable insights into maximizing your equipment’s potential.

What warranty options are available?

Warranty coverage varies by dealer and model specifics. Typically, it includes protection against manufacturing defects for a set period. It’s advisable to review warranty terms at the time of purchase for complete understanding.

Resources for H7230 Owners

For owners of this specific agricultural equipment, accessing reliable information and support is crucial for effective operation and maintenance. Various resources are available to enhance your understanding and ensure optimal performance.

Online Forums and Communities

Engaging with fellow owners can provide valuable insights and troubleshooting tips. Here are some popular platforms:

- Dedicated agricultural machinery forums

- Social media groups focused on farm equipment

- Reddit communities discussing agricultural topics

Official Manuals and Guides

Referencing official documentation can be immensely helpful. Consider the following resources:

- Owner’s manuals for operation and maintenance

- Service manuals for in-depth technical information

- Manufacturer’s website for updates and downloadable resources

Utilizing these tools will empower you to maximize the efficiency and longevity of your machinery.