Understanding Indmar Marine Engine Parts Diagram for Optimal Performance

The intricacies of power units are essential for anyone involved in aquatic activities. A comprehensive knowledge of the various elements that contribute to the performance of these mechanisms can enhance both maintenance and operation. Proper understanding ensures longevity and efficiency, ultimately leading to an enjoyable experience on the water.

When exploring the assembly of these systems, it’s crucial to familiarize oneself with how each component interacts within the overall structure. From the core elements to the ancillary units, every part plays a significant role in functionality. By analyzing the connections and layouts, enthusiasts can better appreciate the engineering marvel behind these power sources.

In this section, we will delve into the specific configurations and functions of vital components. Identifying the ultimate arrangement aids in troubleshooting and repair, allowing users to confidently address any issues that may arise. This foundational knowledge empowers operators to make informed decisions and enhance their proficiency in managing their aquatic machines.

Understanding Indmar Marine Engines

When it comes to performance on the water, having a reliable propulsion system is essential for any aquatic adventure. This section explores the intricacies of high-quality systems designed for optimal functionality and efficiency. By grasping their components and operation, enthusiasts can ensure longevity and peak performance in their vessels.

Key Components

The core of these systems includes a variety of crucial elements that work harmoniously. Each component plays a vital role in generating power and enhancing overall reliability. Familiarity with these parts allows users to maintain and troubleshoot their systems effectively.

Importance of Maintenance

Regular upkeep is paramount for preserving the functionality of these systems. Routine checks and timely replacements can prevent significant issues and extend the lifespan of your machinery. Prioritizing maintenance not only improves performance but also enhances safety during use.

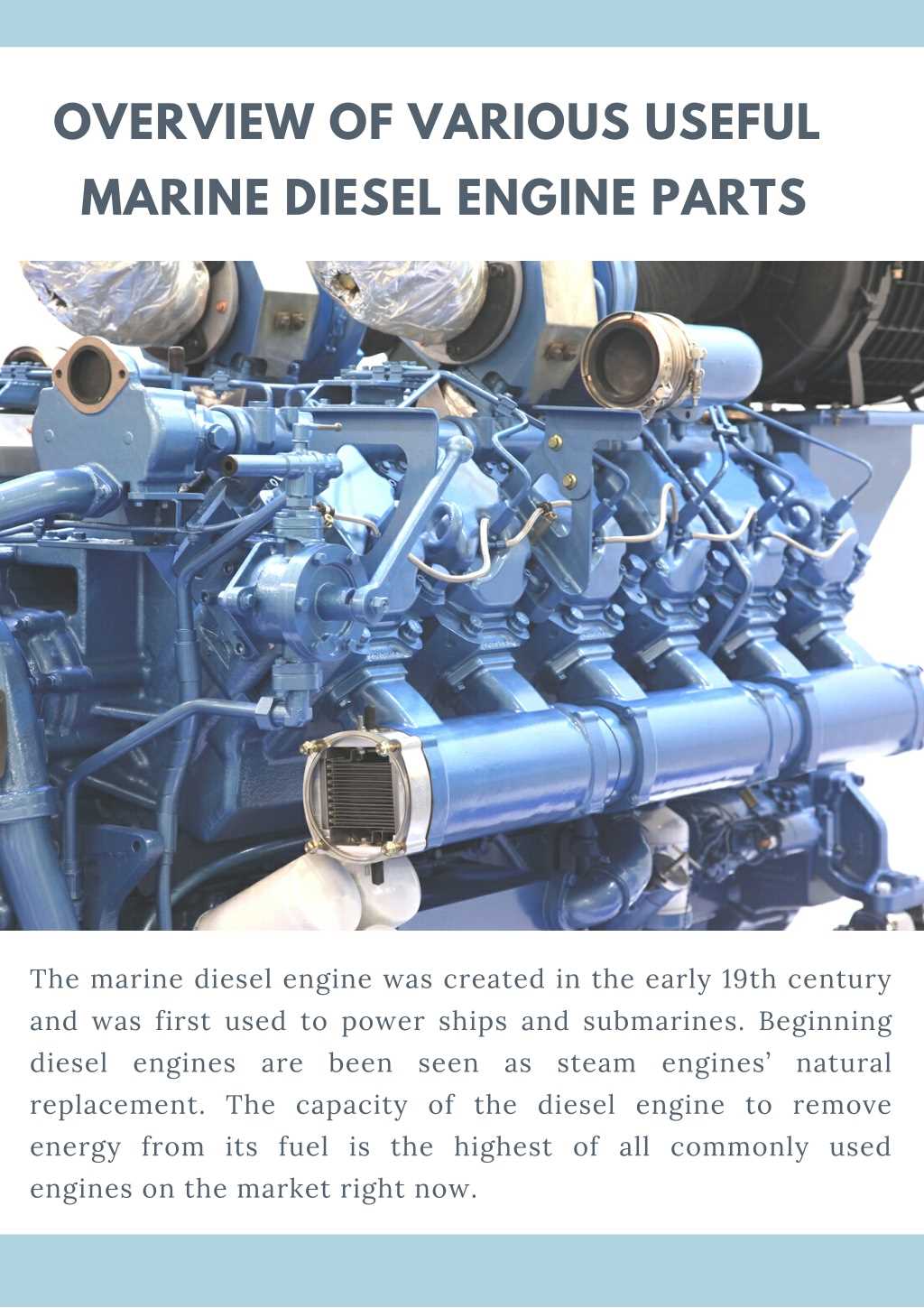

Importance of Marine Engine Components

Understanding the significance of various elements within a vessel’s propulsion system is crucial for maintaining optimal performance and reliability. Each component plays a specific role, contributing to the overall functionality and efficiency of the machinery. A well-functioning assembly ensures smooth operation, safety, and longevity of the craft.

Reliability is one of the foremost reasons why these elements are vital. When each part operates correctly, the likelihood of unexpected breakdowns diminishes significantly. This reliability is essential for safe navigation and for avoiding costly repairs or delays at sea.

Moreover, efficiency in energy consumption is another critical aspect. Each segment is designed to work harmoniously with others, optimizing fuel use and enhancing overall performance. An efficient system reduces operational costs, allowing for better resource management.

Additionally, understanding the interconnectivity of these components aids in troubleshooting and maintenance. Familiarity with how each element interacts empowers operators to make informed decisions regarding repairs and replacements, ultimately extending the lifespan of the entire system.

In conclusion, the effective functioning of all these integral components is essential for ensuring safety, efficiency, and longevity in nautical operations. A comprehensive grasp of their roles fosters better maintenance practices and enhances the overall boating experience.

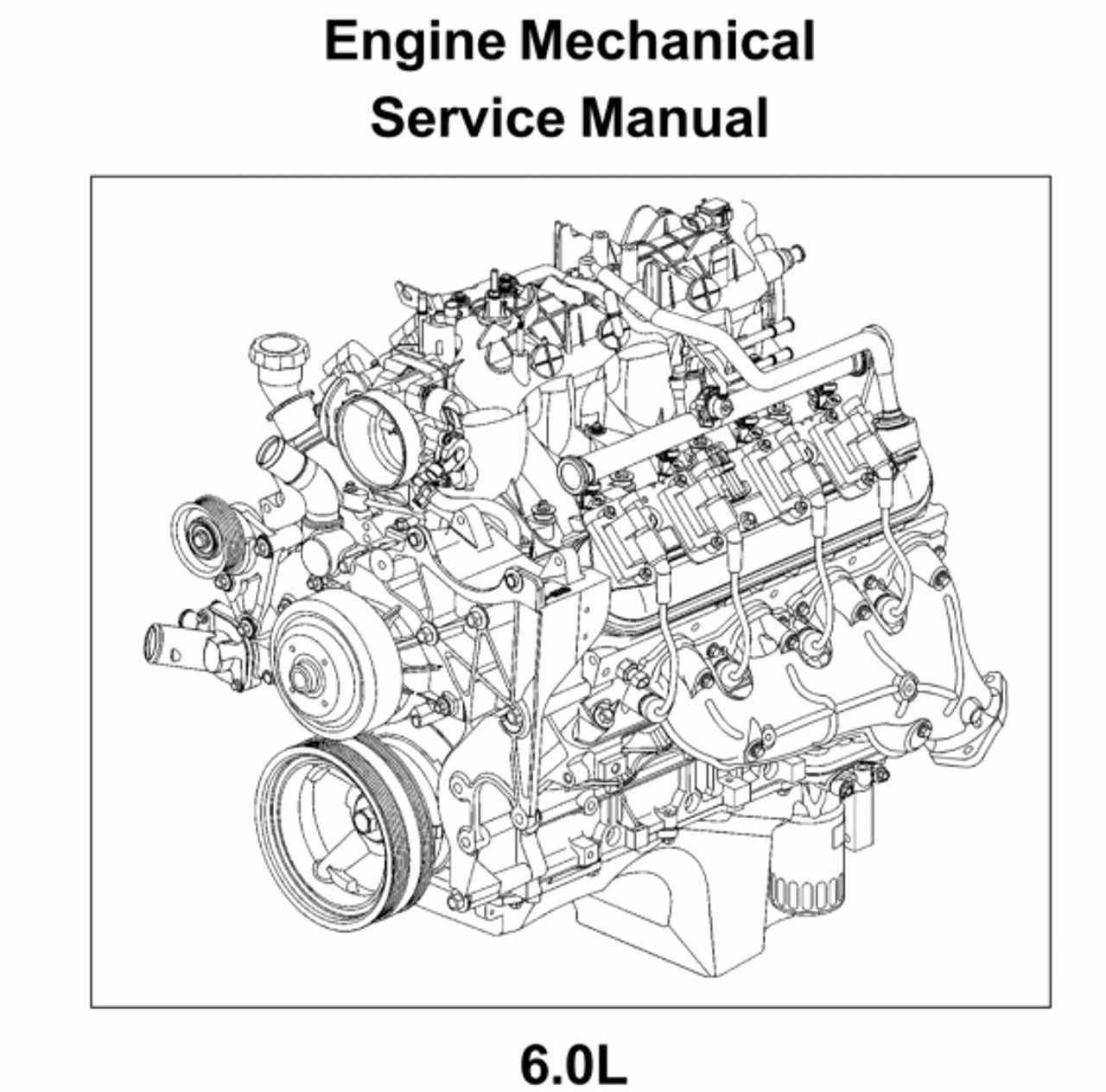

Overview of Indmar Engine Models

This section explores various power unit configurations tailored for aquatic applications, highlighting their unique features and specifications. Understanding these models is essential for anyone involved in maintenance or performance enhancement.

Performance Variants

Different configurations offer varying horsepower and torque outputs, catering to diverse needs, from recreational use to competitive environments. Each model is engineered to deliver optimal performance under specific conditions.

Technological Innovations

Recent advancements in design and materials have enhanced efficiency and durability. These innovations not only improve fuel consumption but also contribute to a smoother operational experience, making them suitable for a wide range of activities on the water.

Common Parts in Indmar Engines

Understanding the essential components of a power unit is crucial for effective maintenance and optimal performance. Each element plays a specific role in ensuring smooth operation, contributing to the overall functionality of the system. Familiarity with these components can help users identify potential issues and facilitate timely interventions.

Key Components

Among the most vital elements are the cylinders, which are responsible for combustion. They are complemented by pistons, which convert the energy produced into mechanical movement. Additionally, the crankshaft plays a pivotal role in transforming linear motion into rotational force, while the valves regulate airflow in and out of the cylinders, ensuring efficient operation.

Supporting Systems

Equally important are the cooling and lubrication systems. The cooling system prevents overheating, utilizing a mixture of water and antifreeze to maintain optimal temperatures. Meanwhile, the lubrication system minimizes friction between moving parts, prolonging the lifespan of the unit and enhancing performance. Understanding these supporting systems is vital for ensuring longevity and reliability.

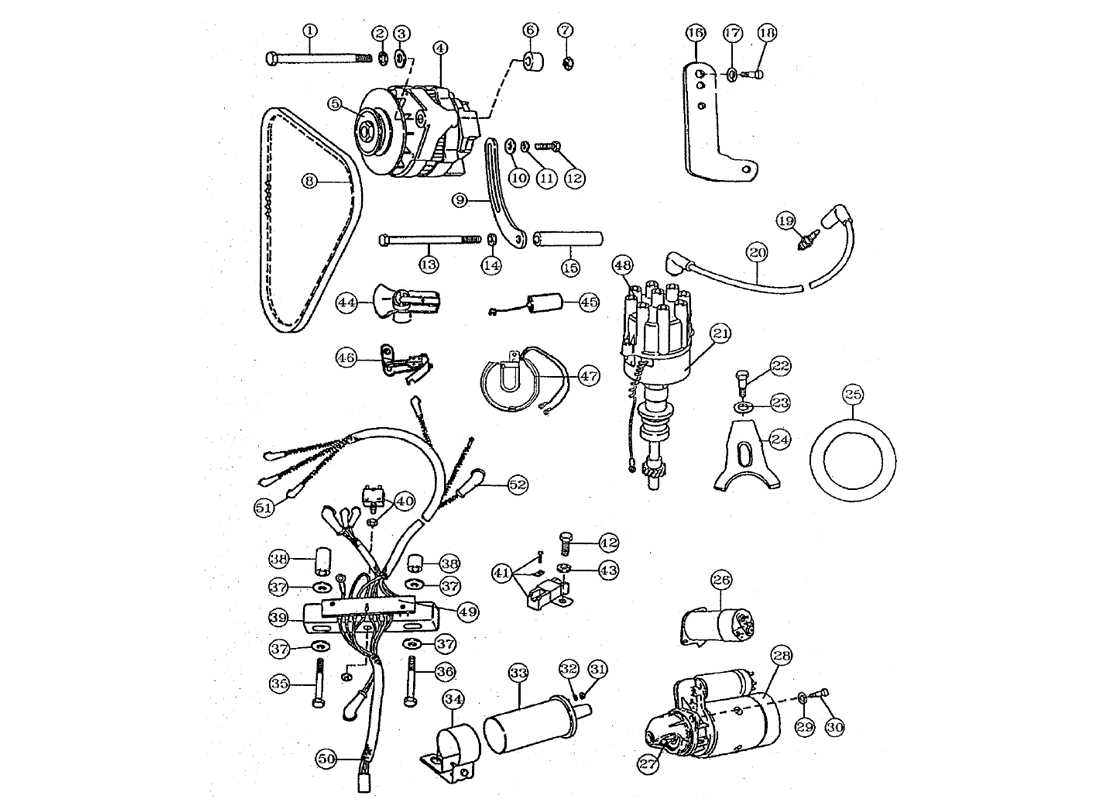

How to Read an Engine Diagram

Understanding a technical illustration can seem daunting at first, but grasping its components is essential for effective maintenance and troubleshooting. Each section conveys specific information about the machinery’s functionality and layout, making it easier to identify where issues may arise.

To decode these illustrations, start by familiarizing yourself with the various symbols and labels used. Different representations indicate specific functions and connections, often using color coding for clarity.

| Symbol | Description |

|---|---|

| Circle | Indicates a critical component or junction point. |

| Arrow | Shows the direction of flow or movement. |

| Line | Represents connections or pathways between parts. |

| Box | Denotes a grouped assembly or subsystem. |

By taking the time to explore these symbols, you will ultimately enhance your understanding and ability to work with complex machinery efficiently.

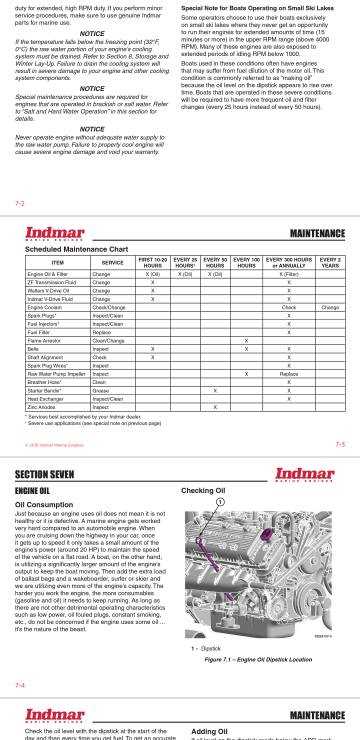

Maintenance Tips for Marine Engines

Proper care and regular upkeep are essential for ensuring optimal performance and longevity of your vessel’s power unit. By adhering to a systematic maintenance routine, you can prevent potential issues and enhance the reliability of your watercraft. Below are some key practices to keep in mind.

Regular Inspections

Conduct frequent assessments of crucial components to identify any signs of wear or damage. Pay particular attention to hoses, belts, and cooling systems. Early detection of problems can save you time and money in the long run. Make it a habit to check the fluid levels and ensure they are within the recommended range.

Routine Cleaning

Keep your machinery free from dirt, salt, and debris. Regularly wash the exterior and perform a thorough cleaning of internal parts as needed. Utilize appropriate cleaning agents that won’t harm sensitive surfaces. A clean environment prevents corrosion and enhances overall efficiency.

Identifying Key Engine Parts

Understanding the essential components of a power unit is crucial for effective maintenance and performance optimization. Each segment plays a specific role in ensuring the smooth operation and longevity of the system. Familiarity with these elements allows for better troubleshooting and repairs.

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and supports other parts. |

| Piston | Converts pressure from combustion into mechanical energy. |

| Crankshaft | Transforms linear motion into rotational motion. |

| Camshaft | Controls the timing of valve openings and closings. |

| Valves | Regulate the intake and exhaust of gases. |

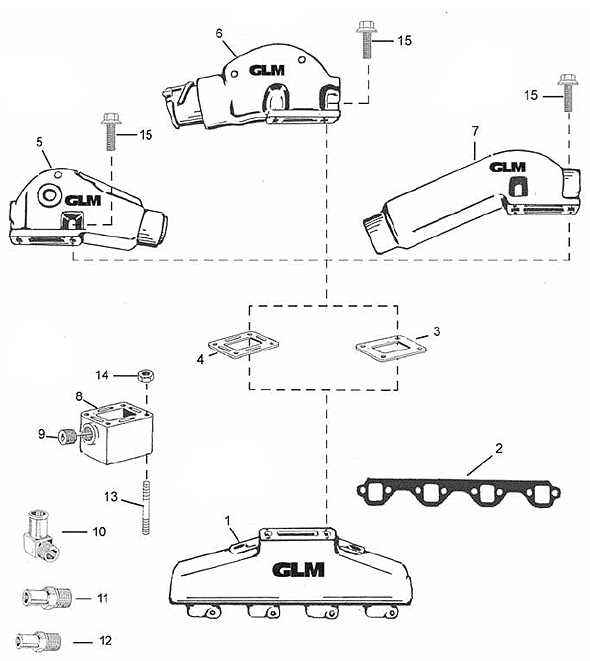

Replacement Parts for Indmar Engines

Maintaining optimal performance of your aquatic propulsion system is essential for ensuring longevity and reliability. High-quality components are crucial when repairs or upgrades are necessary. Selecting the right substitutes not only enhances functionality but also safeguards the overall integrity of the machinery.

Types of Components Available

When seeking replacements, various types of items are typically available, ranging from gaskets and seals to fuel injectors and cooling elements. Each plays a vital role in the smooth operation of your vessel. It’s important to source items that meet or exceed original specifications to maintain efficiency and prevent premature wear.

Benefits of Quality Substitutes

Investing in reputable alternatives ensures enhanced performance and minimizes the risk of malfunction. Utilizing quality replacements can lead to better fuel efficiency, increased power output, and improved responsiveness. Always consider consulting with experts or trusted suppliers to find the best solutions tailored to your specific needs.

Common Issues with Marine Engines

Understanding the typical problems that can arise with aquatic propulsion systems is crucial for any enthusiast or operator. These challenges can stem from various factors, including environmental conditions, mechanical wear, and improper maintenance. Awareness of these issues can help in timely intervention and prolonging the lifespan of the unit.

Frequent Problems

- Overheating: Excessive temperatures can lead to significant damage. Common causes include insufficient coolant, blockages in the cooling system, or a malfunctioning thermostat.

- Fuel Issues: Contaminated or old fuel can cause performance problems. Regular checks on fuel quality and filtration systems are essential.

- Electrical Failures: Electrical components may fail due to corrosion or poor connections, leading to starting issues or performance loss.

- Oil Leaks: Leaks can result from worn seals or gaskets, necessitating regular inspection and timely replacement.

Preventive Measures

- Conduct regular maintenance checks.

- Keep the cooling system clean and free of obstructions.

- Ensure fuel quality by using additives and changing filters regularly.

- Inspect electrical connections and components periodically.

By recognizing these common challenges and implementing preventive strategies, operators can ensure smoother operations and reduce the likelihood of costly repairs.

Upgrading Your Engine Components

Enhancing the efficiency and performance of your propulsion system can significantly improve your overall experience. By selecting superior elements, you can achieve greater reliability and responsiveness, ultimately leading to a more enjoyable outing on the water.

Benefits of Upgrading

- Improved fuel efficiency

- Enhanced power output

- Increased durability

- Better handling and responsiveness

Key Areas to Focus On

- Fuel Delivery: Consider advanced injectors for optimized combustion.

- Cooling System: Upgrade to high-performance radiators for better temperature management.

- Exhaust System: Invest in a more efficient setup to reduce back pressure and improve airflow.

- Ignition Components: High-quality ignition systems can enhance spark efficiency.

Benefits of Genuine Indmar Parts

Using authentic components ensures optimal performance and longevity for your vessel. Quality assurance is paramount when it comes to maintaining reliability and efficiency, leading to a more enjoyable experience on the water.

Quality Assurance

Authentic components are manufactured to meet specific standards, ensuring durability and reliability. This commitment to excellence minimizes the risk of malfunction and promotes safety.

Cost-Effectiveness

Though genuine components may have a higher upfront cost, they often result in long-term savings. Reduced maintenance needs and fewer replacements can offset initial expenses.

| Feature | Genuine Components | Aftermarket Alternatives |

|---|---|---|

| Durability | High | Variable |

| Performance | Optimal | Inconsistent |

| Warranty | Comprehensive | Limited |

DIY Repairs and Troubleshooting

Taking on repairs and diagnosing issues on your own can be both rewarding and cost-effective. With the right approach, you can identify common problems and apply straightforward solutions without professional assistance.

Begin by gathering essential tools, such as wrenches, screwdrivers, and multimeters, which will aid in your assessment. Familiarize yourself with the system’s basic components to enhance your understanding during the troubleshooting process.

Start with a visual inspection to spot any obvious signs of wear or damage. Look for leaks, cracks, or loose connections that might be causing inefficiencies. Document any findings to help track recurring issues.

Consult available resources, such as manuals or online forums, to deepen your knowledge. These platforms often provide invaluable insights from experienced enthusiasts who have faced similar challenges.

Remember to prioritize safety. Always disconnect power sources before performing any repairs and wear appropriate protective gear. This not only safeguards you but also ensures a smoother repair process.

Where to Find Engine Diagrams

Locating comprehensive visual representations of mechanical systems can greatly enhance understanding and maintenance. Numerous resources are available that provide detailed illustrations and specifications.

Online Resources

- Manufacturer Websites: Check the official sites for manuals and technical documents.

- Online Forums: Join communities focused on machinery where members share valuable information.

- Educational Platforms: Explore sites offering technical courses that often include resources.

Printed Materials

- Service Manuals: Purchase or download manuals specific to your equipment.

- Technical Books: Look for comprehensive guides available at bookstores or libraries.

- Trade Magazines: Subscribe to publications that frequently feature maintenance tips and diagrams.