Understanding Husqvarna 235 Parts Diagram

In the world of machinery, comprehending the intricate layout of individual elements is essential for effective maintenance and repair. This knowledge allows users to efficiently identify components and their respective functions, ensuring optimal performance and longevity of the equipment.

Through careful examination of these elements, one can gain valuable insights into the operational mechanisms at play. Whether it’s understanding how different parts interact or recognizing the importance of each component in the overall functionality, this exploration leads to a deeper appreciation of the machinery.

By delving into the schematic representations of these items, users can streamline their approach to repairs and maintenance. This familiarity not only enhances the user’s capability but also promotes a proactive stance toward equipment care.

Understanding the Husqvarna 235

This section provides insights into a specific model of a popular outdoor equipment brand, focusing on its components and functionality. Understanding how each element works together enhances the overall user experience and maintenance efficiency.

Key Features

Various aspects of this model contribute to its effectiveness and user-friendliness. Each feature serves a purpose, making tasks more manageable for users, whether they are professionals or hobbyists.

Component Overview

| Component | Function |

|---|---|

| Engine | Powers the device for optimal performance |

| Blade | Facilitates precise cutting |

| Handle | Provides stability and control |

| Fuel System | Ensures efficient operation |

Key Components Overview

This section provides a comprehensive look at the essential elements that make up a specific outdoor power tool. Understanding these components is crucial for efficient operation and maintenance, ensuring the device performs optimally over time.

- Engine: The heart of the machine, responsible for providing the necessary power for operation.

- Bar and Chain: Integral parts for cutting, determining the effectiveness and speed of the tool.

- Fuel System: Includes the tank, lines, and filter, ensuring proper fuel delivery to the engine.

- Air Filter: Vital for maintaining engine performance by preventing dust and debris from entering.

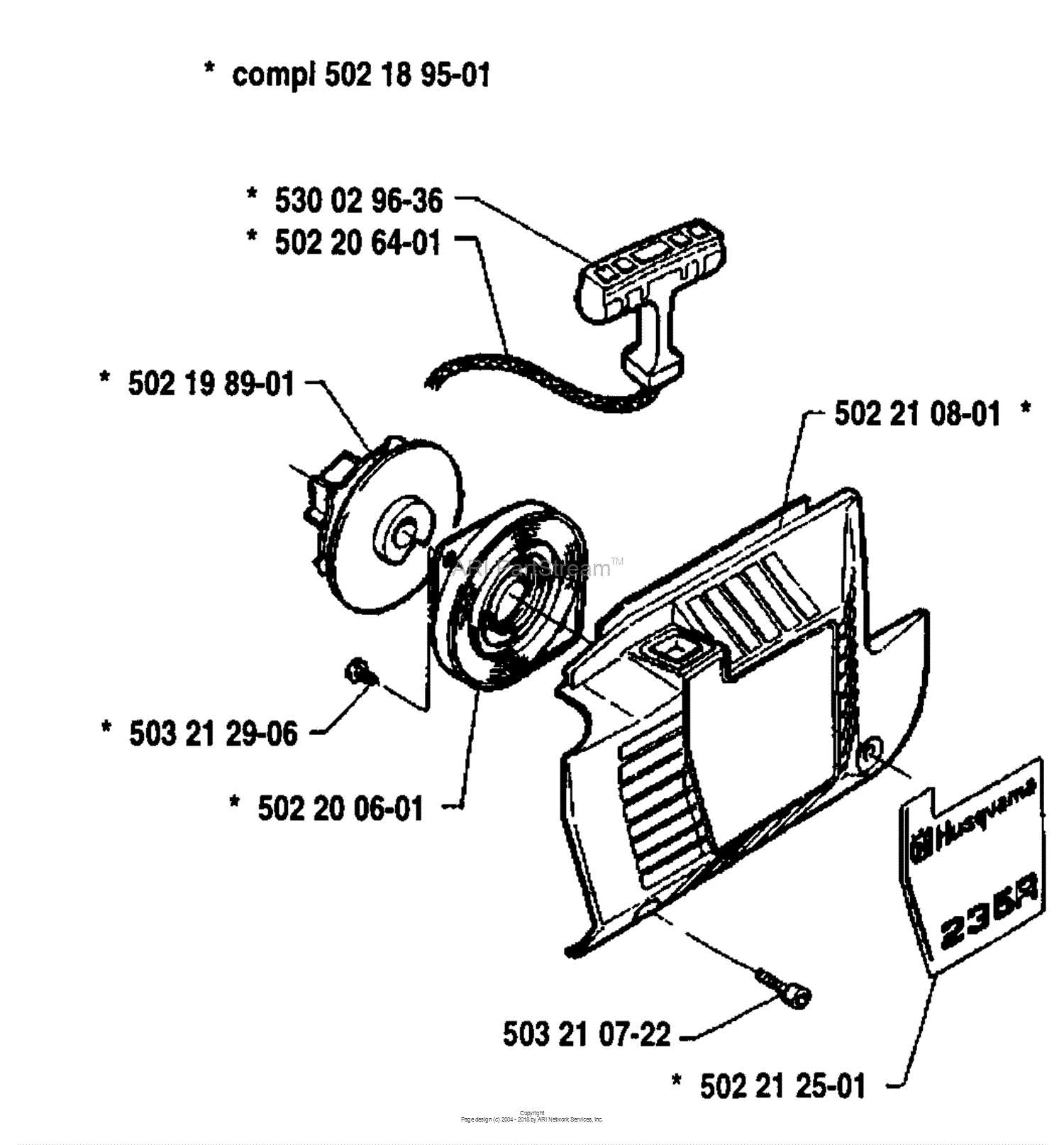

- Starter Mechanism: Enables quick ignition of the engine, often featuring a recoil system.

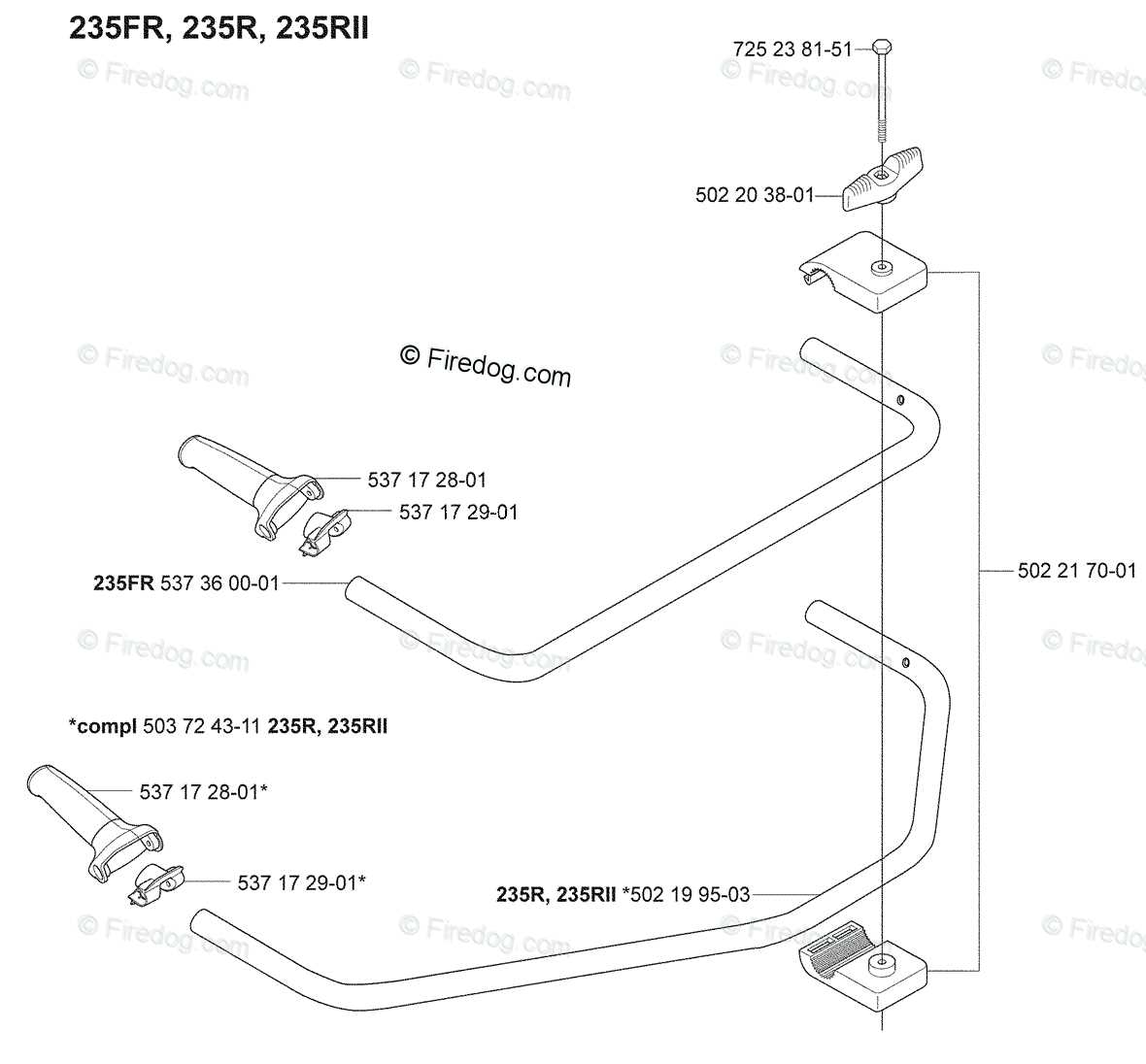

- Handle Assembly: Provides control and comfort during use, designed for ergonomic handling.

- Safety Features: Incorporate mechanisms like chain brakes and safety switches to protect the user.

Familiarity with these components enhances the user’s ability to troubleshoot and perform routine maintenance effectively.

Assembly and Disassembly Guide

This section provides essential instructions for the proper assembly and disassembly of your equipment, ensuring efficient maintenance and repairs. Understanding how components fit together is crucial for troubleshooting and optimizing performance.

General Steps for Disassembly

- Start by disconnecting any power sources to prevent accidents.

- Carefully remove any coverings or protective panels to access internal parts.

- Document the arrangement of components, taking notes or pictures for reference.

- Use appropriate tools to detach screws, bolts, or clips without damaging parts.

- Handle all components with care to avoid unnecessary wear or breakage.

Steps for Assembly

- Refer to the documentation or notes taken during disassembly for guidance.

- Begin by placing the main components in their designated positions.

- Secure each part using the correct fasteners, ensuring a snug fit.

- Replace any coverings or protective panels once all components are reassembled.

- Reconnect power sources and perform a thorough check to ensure everything operates smoothly.

Maintenance Tips for Longevity

Proper upkeep is essential for enhancing the lifespan of any equipment. Regular attention to various components can prevent wear and tear, ensuring optimal performance over time. Implementing a consistent maintenance routine not only safeguards your investment but also promotes efficiency during use.

Regular Cleaning

Cleaning is a fundamental aspect of maintenance. Remove debris and dirt from the exterior and interior parts. Pay special attention to areas prone to accumulation, as this can hinder functionality. Utilizing appropriate cleaning solutions and tools will help maintain a polished appearance while preventing damage.

Periodic Inspections

Conducting regular inspections allows for the early detection of potential issues. Check for any signs of wear, loose components, or unusual sounds during operation. Addressing minor problems promptly can avert more significant complications in the future. Keeping a maintenance log can also help track performance and identify patterns that may require attention.

Common Issues and Solutions

When working with outdoor machinery, users often encounter various challenges that can hinder performance. Identifying these issues early can save time and ensure smooth operation. This section outlines some prevalent problems and their effective remedies, helping users maintain optimal functionality.

Starting Difficulties

One of the most frequent concerns is trouble initiating the machine. This can stem from a variety of factors, including fuel blockage or spark plug malfunction. Ensuring that fuel lines are clear and the spark plug is in good condition can often resolve this issue. Regular maintenance checks can prevent these starting complications.

Excessive Vibration

Another common issue is excessive vibration during operation, which can lead to user discomfort and potential damage to the equipment. This may be caused by loose components or misalignment. Tightening all bolts and ensuring proper alignment can significantly reduce vibration levels. Implementing routine inspections will help maintain stability and enhance user experience.

Replacement Parts Availability

Access to essential components is crucial for maintaining the functionality and longevity of equipment. Ensuring that users can easily obtain necessary replacements enhances the overall performance and reliability of their machines. Availability of these items plays a significant role in minimizing downtime and optimizing efficiency.

Where to Find Components

Components can typically be sourced from various outlets, including authorized retailers, online marketplaces, and local repair shops. Authorized vendors often provide quality assurance and compatibility guarantees, ensuring that replacements meet the required standards.

Considerations for Purchasing

When selecting replacements, it is important to verify compatibility with your equipment model. Additionally, consider the quality of the components, as this can affect the overall performance. Investing in reliable replacements can lead to better efficiency and reduced maintenance issues in the long run.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor equipment, having the right instruments at hand is essential. Proper tools not only facilitate the repair process but also ensure that the job is completed efficiently and effectively. Below are some essential items that will assist in troubleshooting and repairing various components of your equipment.

Basic Hand Tools

Every repair kit should include a selection of basic hand tools. A set of wrenches and screwdrivers in various sizes is crucial for loosening and tightening bolts and screws. Additionally, pliers are indispensable for gripping and manipulating small parts. These tools form the foundation of any repair effort, allowing for straightforward access to internal components.

Specialized Equipment

In some cases, specialized equipment may be required to address specific issues. For instance, a torque wrench ensures that bolts are tightened to the correct specifications, preventing damage from over-tightening. Furthermore, a multimeter can be useful for diagnosing electrical problems, allowing for accurate assessments of power flow and component functionality.

Identifying Genuine Parts

Ensuring the quality and longevity of your equipment hinges on the use of authentic components. Recognizing the key features of original elements can prevent unnecessary complications and enhance performance. It’s essential to distinguish between genuine items and imitations, which may compromise functionality and safety.

Key Features to Look For

When assessing authenticity, examine the packaging and labeling closely. Genuine products often come in well-designed packaging that includes clear branding and detailed information about the manufacturer. Additionally, look for certification marks or seals that indicate compliance with industry standards.

Benefits of Using Authentic Components

Utilizing original items not only ensures optimal performance but also prolongs the lifespan of your equipment. Authentic components are engineered to meet specific requirements, resulting in improved efficiency and reduced wear. By investing in quality, you protect your equipment and maintain its value over time.

Wiring and Electrical Diagrams

This section focuses on the essential layouts and connections that facilitate the proper functioning of electrical systems in equipment. Understanding these configurations is crucial for troubleshooting and maintenance, ensuring that each component operates seamlessly within the overall framework.

Understanding Circuit Layouts

The arrangement of wires and connections forms the backbone of any electrical setup. Each path must be meticulously planned to guarantee efficient energy flow. By analyzing these configurations, users can identify potential issues and enhance the performance of their devices.

Importance of Accurate Connections

Properly executed connections are vital for safety and functionality. Misaligned or faulty links can lead to malfunctions or damage. Regular reviews of electrical schematics are recommended to uphold the integrity of the system and to ensure that all parts operate at their ultimate potential.

Safety Precautions During Repairs

When undertaking maintenance or repairs on any equipment, adhering to safety measures is crucial to prevent accidents and ensure efficient operation. Proper precautions not only protect the individual performing the work but also safeguard the equipment from potential damage.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes gloves to shield hands from sharp edges, goggles to protect eyes from debris, and sturdy footwear to prevent injuries. Always ensure that your clothing is fitted and avoids any loose fabric that could get caught in moving parts.

Work Environment Safety

Maintaining a clean and organized workspace is vital. Clear away any unnecessary tools and materials that could create hazards. Additionally, ensuring proper lighting can help avoid mistakes and enhance visibility. Always disconnect power sources before starting any repairs to prevent electrical hazards.

Upgrades and Modifications Options

Enhancing the performance and functionality of your equipment can lead to improved efficiency and satisfaction. Various upgrades and modifications can tailor your machine to better suit your needs, whether for recreational use or professional tasks.

- Engine Upgrades: Consider enhancing the engine for increased power output.

- Cutting Attachments: Different attachments can be used for varied cutting tasks.

- Handle Modifications: Ergonomic handles can improve comfort during extended use.

- Fuel System Enhancements: Upgrading the fuel system can lead to better fuel efficiency.

By exploring these options, you can create a more efficient and user-friendly experience with your machine, making it more versatile for different applications.

Manufacturer’s Service Recommendations

To ensure optimal performance and longevity of your equipment, it is essential to adhere to the manufacturer’s suggested maintenance practices. Regular upkeep not only enhances functionality but also minimizes the risk of unexpected breakdowns. Following these guidelines will help maintain the reliability and efficiency of your machinery.

Routine Maintenance Tasks

Implementing a schedule for routine maintenance is crucial. This includes tasks such as cleaning, inspecting, and lubricating various components. Regular checks can identify potential issues before they escalate into significant problems.

| Maintenance Task | Frequency |

|---|---|

| Inspect fuel and oil levels | Before each use |

| Clean air filter | Every 25 hours of operation |

| Sharpen cutting blades | As needed |

| Check spark plug | Every 50 hours of operation |

Seasonal Preparation

Preparing your equipment for different seasons is essential for optimal operation. This may involve specific adjustments and protective measures to ensure it can handle varying weather conditions effectively.