John Deere L110 Steering Components Overview

To ensure seamless functionality and precise control in any machine, attention to key mechanisms responsible for movement is crucial. These interconnected elements allow for effective management of direction, providing the operator with confidence and ease. A clear understanding of how these components work together can greatly improve both performance and longevity.

With a focus on critical elements, this section delves into the intricate network of parts that work harmoniously to deliver precise movement. Knowing the role of each component and how it contributes to the system’s overall functionality can help maintain consistent and reliable use over time.

In the following section, we’ll explore how these pieces fit together, allowing for optimal maneuverability. The focus will be on ensuring that all parts are well-aligned and function in sync to provide the best possible experience.

John Deere L110 Steering Overview

The mechanism responsible for directional control in this model is crucial for smooth operation and precision. This system ensures the user can maneuver effectively and handle different terrains with ease. By focusing on reliability and ease of use, the design of the control system makes it accessible for both novice and experienced operators.

Key features include:

- Durable construction designed for long-lasting performance.

- Responsive handling to adapt to a variety of terrains.

- Simple maintenance routines to ensure consistent functionality.

Understanding how this system works and the components that contribute to its efficiency can significantly enhance the overall user experience. Proper care and regular checks are recommended to maintain the system in optimal condition

Components of the Steering System

In any vehicle, the mechanism responsible for controlling direction plays a critical role in ensuring smooth and precise navigation. Various elements work together to translate the driver’s input into movements that guide the machine accurately on its course. These components are designed to provide stability, responsiveness, and control under different operating conditions.

Key elements within this mechanism include joints, rods, and gears, all of which collaborate to transmit motion from the operator’s controls to the wheels. Each part must be well-maintained and aligned to guarantee seamless functionality and prevent any disruptions during use. Over time, these components can wear out, leading to reduced precision, which is why regular inspection and maintenance a

How to Identify Worn Steering Parts

Recognizing when components related to your vehicle’s direction control are worn out is crucial for maintaining safety and performance. Over time, these elements may experience wear due to frequent use or rough conditions, which can lead to reduced maneuverability and potential hazards. Understanding the key signs of deterioration helps ensure timely maintenance.

- Loose movement: If you notice excessive play or looseness while attempting to turn, this is a common indicator that certain pieces need inspection or replacement.

- Unusual noises: Squeaking, clunking, or grinding sounds while adjusting the direction suggest that some connections are either misaligned or wearing down.

- Une

Common Steering Problems and Solutions

Issues with the handling of a vehicle can arise due to various mechanical factors, leading to difficulties in maneuvering or reduced control. Understanding the root causes behind these difficulties is essential for ensuring smooth and safe operation. Various components involved in the turning mechanism may experience wear over time, and addressing them promptly can prevent further complications.

One of the frequent concerns is excessive play or looseness when turning. This can often

Maintaining Your L110 Steering Mechanism

Regular care of your vehicle’s directional control system is essential to ensure smooth operation and prolonged lifespan. Keeping all components in optimal condition prevents wear and tear, while also maintaining safety and efficiency. A well-functioning control system allows for precise movement, providing comfort during use.

Key Components to Monitor

Over time, various elements of the control assembly can become loose or worn out, requiring adjustments or replacement. Ensure that connections are tightened and inspect moving parts regularly to avoid unexpected failures. Pay attention to any unusual noises or stiffness when making turns, as these can indicate deeper issues.

Lubrication and Adjustments

Consistent lubrication of moving joints and pivot points is crucial

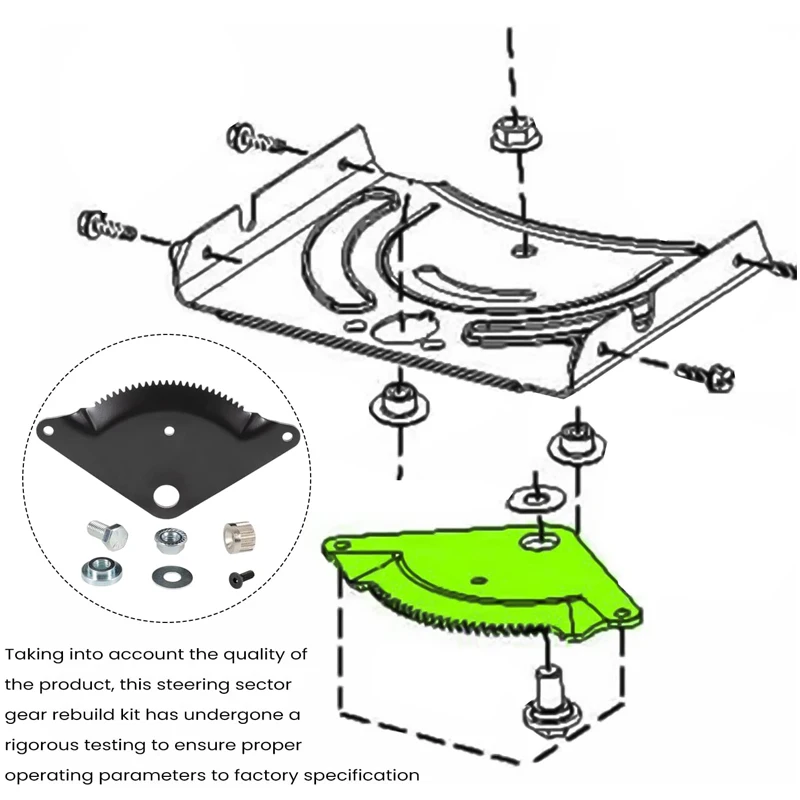

Steering Linkage Assembly Guide

This section provides a comprehensive overview of the components involved in the assembly of the directional control mechanism. Understanding how these elements work together is essential for effective maintenance and troubleshooting.

Follow these steps to ensure proper installation:

- Gather all necessary tools and components for the assembly.

- Identify each component and familiarize yourself with its function.

- Begin by connecting the primary linkage to the frame, ensuring a secure fit.

- Attach the intermediate rods, making sure they are aligned correctly to prevent binding.

- Finally, secure the secondary linkage to complete the assembly process.

Regular inspection of the assembly is crucial for optimal performance. Look for signs of wear and tear, and replace any components as necessary to maintain smooth operation.

- Ensure all fasteners are tightened to the manufacturer’s specifications.

- Lubricate moving parts regularly to reduce friction.

- Monitor for any unusual noises that may indicate misalignment.

By following these guidelines, you can effectively manage the assembly and maintenance of the directional control mechanism, ensuring reliability and longevity.

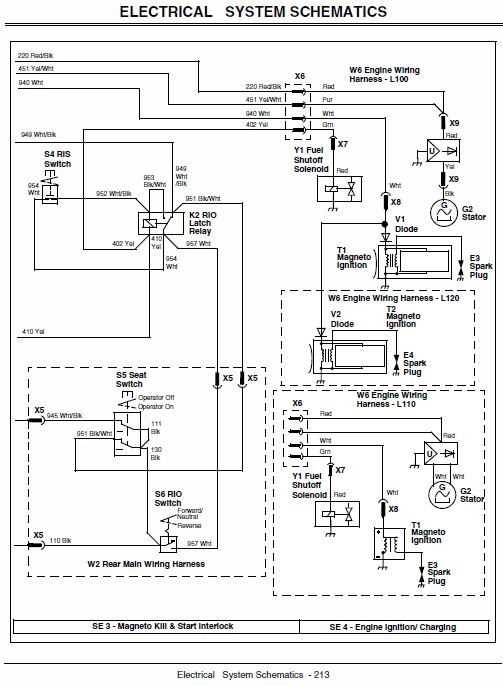

Step-by-Step Steering Wheel Removal

Removing the control wheel from a vehicle can be a straightforward task if approached with the right tools and techniques. This section provides a detailed guide to facilitate the process, ensuring that you can accomplish it efficiently and safely.

Before starting, gather the necessary tools, including a socket set, a wrench, and a steering wheel puller. Ensure the vehicle is parked on a level surface and that the battery is disconnected to prevent any electrical issues during the removal process.

Step Action 1 Remove the center cap, if applicable, to access the securing bolt. 2 Loosen and remove the main bolt securing the wheel to the shaft using the socket set. 3 Carefully detach any attached components, such as the horn wire, ensuring no damage occurs. 4 Utilize a steering wheel puller to gently extract the wheel from the column without causing harm. 5 Once removed, inspect the shaft for any wear or damage before proceeding with reinstallation or replacement. Following these steps will help ensure a successful removal process, allowing for further repairs or adjustments as needed. Always refer to the specific service manual for detailed information relevant to your particular model.

Replacing Tie Rods on John Deere L110

Maintaining proper functionality in your equipment’s handling system is crucial for optimal performance. One common maintenance task involves the replacement of connecting rods, which can significantly affect maneuverability. This section outlines the necessary steps for effectively executing this procedure.

Step Description 1 Gather the required tools, including a wrench set, pliers, and replacement rods. 2 Safely lift the machine using jack stands to access the undercarriage. 3 Locate the existing rods and inspect them for wear or damage. 4 Remove the damaged rods by loosening the connecting bolts with a wrench. 5 Install the new rods, ensuring they are securely fastened. 6 Lower the machine and test the connections to confirm proper operation. Following these steps will help ensure your machinery operates smoothly and reliably. Regular maintenance and timely replacements are essential for extending the lifespan of your equipment.

Steering Gearbox Inspection Tips

Regular evaluation of the control mechanism is essential for ensuring optimal performance and safety. Proper maintenance can prevent larger issues and prolong the lifespan of the equipment. Below are some practical guidelines for inspecting this crucial component.

- Visual Examination: Start with a thorough visual inspection. Look for any signs of wear, corrosion, or damage. Ensure that all connections are secure and that there are no loose components.

- Check for Leaks: Examine the surrounding areas for any fluid leaks. Fluid loss can significantly impact the functionality of the mechanism, so addressing leaks promptly is vital.

- Monitor Movement: Operate the control system and observe the mechanism’s movement. It should operate smoothly without any jerking or binding. Listen for any unusual noises that might indicate underlying issues.

- Inspect Fasteners: Ensure all bolts and screws are tightly secured. Loose fasteners can lead to misalignment and increased wear on the mechanism.

- Lubrication Check: Verify that all moving parts are properly lubricated. Insufficient lubrication can lead to friction and accelerated wear, so make sure to apply the appropriate lubricant as needed.

By following these tips, you can maintain the functionality and reliability of the control mechanism, ensuring smooth operation and enhancing the overall performance of the equipment.

Proper Lubrication for Smooth Steering

Maintaining optimal performance of the directional control system is essential for a seamless driving experience. Adequate lubrication minimizes friction between moving components, ensuring smooth operation and prolonging the lifespan of the machinery. This section outlines best practices for applying lubricants to achieve the best results.

Benefits of Proper Lubrication

- Reduces wear and tear on moving elements

- Enhances responsiveness and maneuverability

- Prevents corrosion and rust buildup

- Improves overall efficiency

Lubrication Guidelines

- Choose the appropriate lubricant based on manufacturer recommendations.

- Clean the areas to be lubricated to remove any dirt or old grease.

- Apply the lubricant evenly, ensuring coverage on all necessary components.

- Check for excess lubricant and remove any that could attract dirt.

- Regularly inspect and reapply lubricant as part of routine maintenance.

Alignment Issues and Adjustments

Proper alignment is crucial for the optimal functioning of any machinery. Misalignment can lead to increased wear and tear, reduced efficiency, and even safety hazards. Understanding the common alignment challenges and how to adjust them can enhance performance and prolong the life of the equipment.

One of the most frequent issues arises from incorrect positioning of components, which can cause erratic movement and uneven pressure distribution. Regular inspections should be conducted to identify signs of misalignment, such as uneven tire wear or difficulty in maneuvering.

To correct alignment problems, adjustments may involve repositioning various components to achieve the desired alignment. It is essential to follow the manufacturer’s guidelines during this process to ensure accuracy. Tools such as levels and alignment gauges can aid in achieving precision.

Additionally, environmental factors, such as uneven terrain, can affect alignment over time. Therefore, periodic maintenance and adjustments are necessary to maintain optimal operation. By addressing alignment issues promptly, operators can ensure smooth functionality and avoid costly repairs.

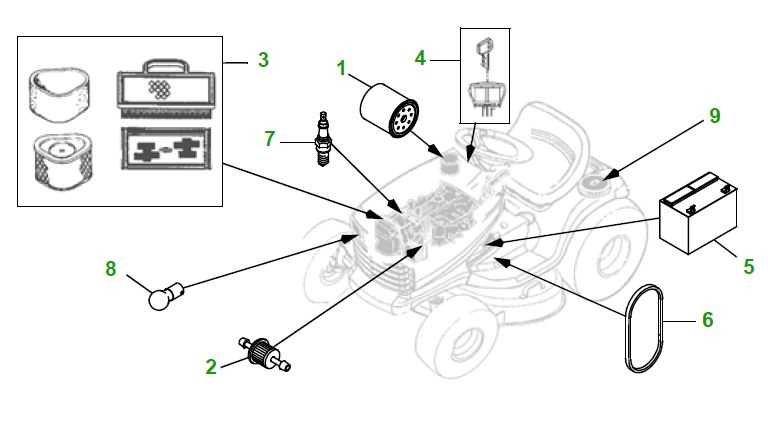

Finding Replacement Parts for L110 Steering

When your lawn tractor experiences difficulties with its directional controls, identifying suitable components is crucial for restoring functionality. Many options are available for obtaining the necessary items, ensuring that your machine can operate smoothly once again.

To assist you in locating the correct components, consider the following approaches:

- Consult the Manufacturer: The original manufacturer’s website often provides valuable resources, including catalogs and contact information for authorized dealers.

- Visit Local Retailers: Local hardware or gardening stores may carry a selection of compatible components or be able to order them for you.

- Online Marketplaces: Websites like eBay or Amazon feature various sellers who offer both new and used items, often at competitive prices.

- Specialized Forums: Joining online communities can connect you with experienced users who may have recommendations or even spare components for sale.

- Repair Shops: Local mechanics or repair shops specializing in lawn equipment might have the necessary items on hand or can assist with sourcing them.

By exploring these avenues, you can effectively find the components needed to restore your machine’s functionality and ensure optimal performance for your outdoor tasks.