Understanding the Cat Backhoe Parts Diagram for Efficient Maintenance

In the world of construction and excavation, the efficiency of equipment relies heavily on the intricate relationship between its various elements. Each component plays a crucial role, contributing to the overall functionality and performance of the machine. A clear comprehension of these elements is essential for operators and technicians alike, ensuring smooth operations and timely maintenance.

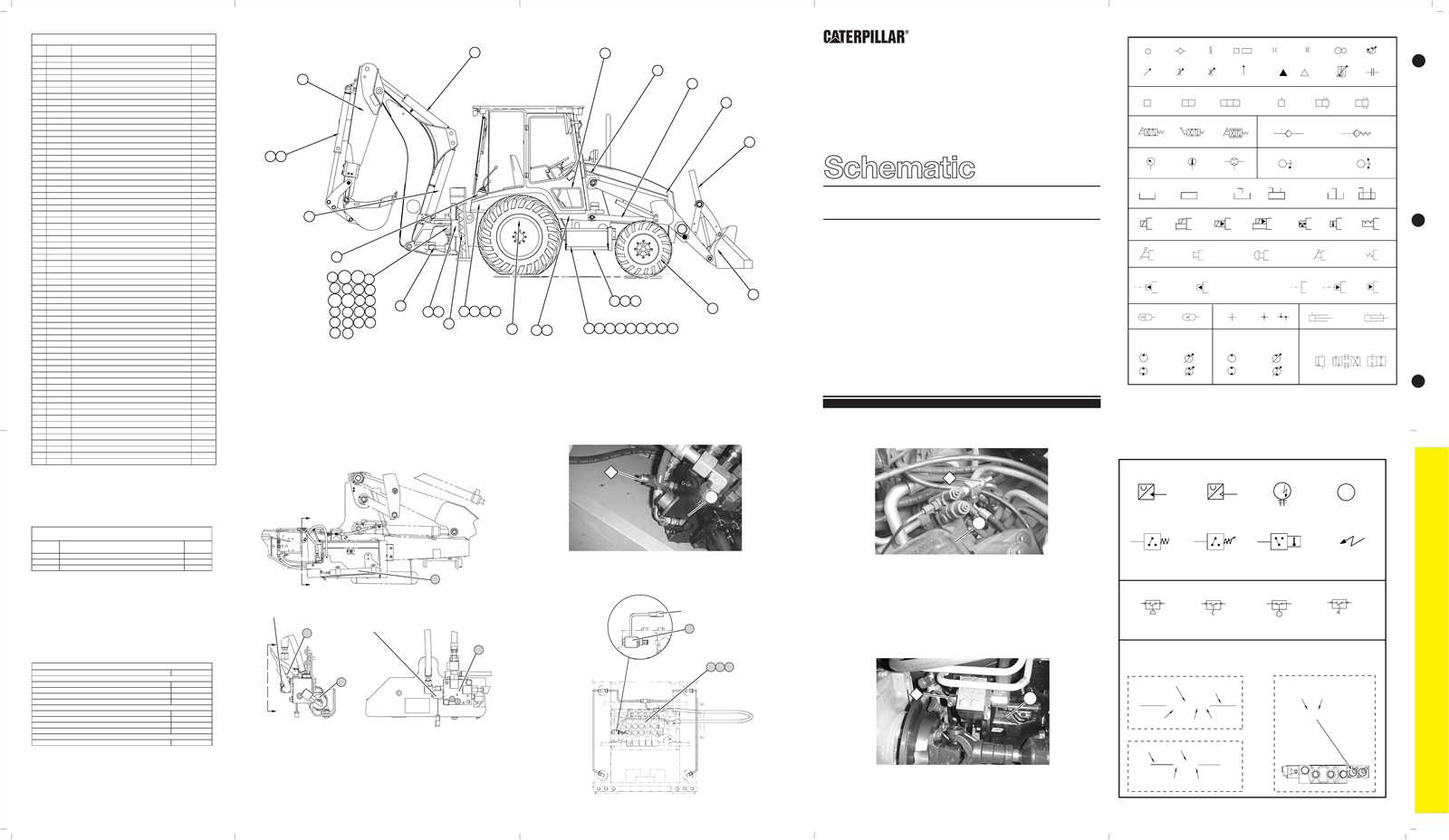

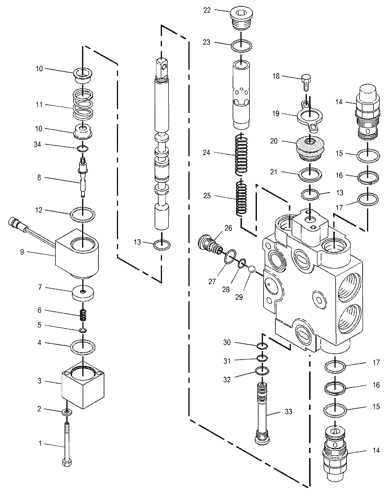

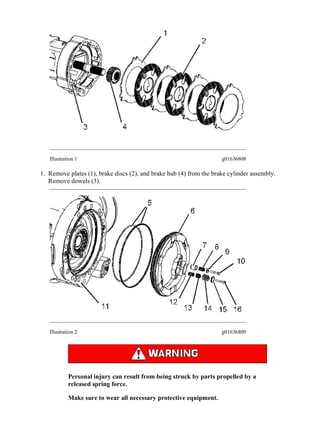

Visual representations of machinery assemblies can serve as invaluable tools for understanding the arrangement and interconnectivity of these components. By studying these illustrations, one can gain insights into how each segment functions independently and as part of a larger system. This knowledge not only aids in effective troubleshooting but also enhances the skills required for optimal operation.

Equipped with this understanding, operators can more effectively diagnose issues, perform necessary repairs, and ultimately prolong the lifespan of their machinery. Engaging with detailed visuals fosters a deeper appreciation for the engineering behind these powerful machines, paving the way for more informed and responsible use in demanding environments.

Understanding Cat Backhoe Components

Exploring the intricate machinery of heavy equipment reveals a complex interplay of various elements that contribute to its functionality. Each component plays a vital role, working in harmony to achieve the ultimate efficiency and performance in demanding environments.

Hydraulic System: This essential mechanism powers movement and operation, allowing for precise control and effective digging capabilities.

Operator’s Cab: Designed for comfort and visibility, the workspace is crucial for the user to monitor tasks and make informed decisions.

Chassis: The robust framework supports all other components, ensuring stability and durability during operation.

Bucket: The primary tool for excavation, its design varies based on the specific tasks it needs to perform, highlighting versatility.

Understanding these key components is essential for optimal operation and maintenance, ensuring longevity and efficiency in any project.

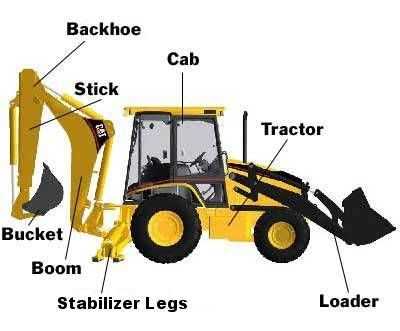

Essential Parts of a Backhoe

The functionality of an excavating machine relies on several key components that work in harmony. Each element plays a crucial role in ensuring efficiency and performance, enabling operators to tackle a variety of tasks with precision.

Power Train: This vital system includes the engine and transmission, providing the necessary force to mobilize and operate the equipment effectively.

Loader Bucket: Located at the front, this scoop is designed for lifting and moving materials, making it indispensable for loading tasks.

Excavator Arm: The extended arm allows for digging and trenching, offering flexibility in reaching various depths and angles.

Hydraulic System: This intricate network powers the movement of the different attachments, ensuring smooth operation and control during work.

Chassis: The sturdy frame provides stability and support, allowing the machine to endure heavy loads while maintaining balance.

Stabilizers: These elements ensure that the equipment remains secure during operation, enhancing safety and precision when digging or lifting.

Functionality of Backhoe Attachments

The diverse tools that can be connected to excavation machinery significantly enhance its versatility and efficiency. Each implement serves a unique purpose, enabling operators to tackle a wide range of tasks with precision and ease.

Digging attachments are primarily designed for excavating soil, while grading tools help in leveling surfaces and managing materials. The utility of these implements extends to lifting heavy objects, breaking through hard surfaces, and even performing fine landscaping work.

Furthermore, specialized attachments like hydraulic thumbs or augers allow for greater adaptability in various job sites, enabling operators to seamlessly transition between different functions without the need for multiple machines.

Key Hydraulic System Elements

The hydraulic system in heavy machinery plays a crucial role in facilitating movement and power transfer. Understanding its main components is essential for effective operation and maintenance. Each element contributes to the overall functionality, ensuring that the machine operates smoothly and efficiently.

| Component | Description |

|---|---|

| Pump | Generates hydraulic pressure to enable fluid movement throughout the system. |

| Actuator | Transforms hydraulic energy into mechanical motion for various functions. |

| Valve | Regulates fluid flow and directs it to different parts of the system as needed. |

| Reservoir | Stores hydraulic fluid and allows for its circulation within the system. |

| Filter | Cleans the hydraulic fluid, preventing contamination and ensuring optimal performance. |

Importance of the Boom Structure

The boom is a critical component in heavy machinery, serving as the primary tool for lifting and maneuvering. Its design and integrity directly influence the machine’s performance and efficiency in various tasks.

A well-constructed boom allows for enhanced reach and stability, enabling operators to execute tasks with precision. Understanding the significance of this structure helps in maintaining optimal functionality and preventing costly repairs.

| Feature | Importance |

|---|---|

| Reach | Extends operational capabilities |

| Stability | Ensures safety during operations |

| Durability | Reduces maintenance needs |

| Flexibility | Adapts to various tasks |

Exploring the Dipper Arm Design

The dipper arm is a crucial component in excavation machinery, playing a pivotal role in digging and material handling. Its design intricacies significantly influence performance, stability, and operational efficiency. By examining the various elements of this essential arm, one can appreciate how engineering advancements enhance functionality and reliability.

Key Features of the Dipper Arm

This component typically features a robust construction that balances strength and flexibility. The angle of articulation is meticulously crafted to optimize reach and digging depth, ensuring that the machine can tackle a variety of tasks effectively. Additionally, the integration of hydraulic systems allows for precise control, making the dipper arm adaptable to different work environments.

Material Selection and Durability

Material choice is fundamental to the durability of the dipper arm. High-strength alloys are often employed to withstand the stresses of heavy usage while minimizing weight. This careful selection process not only enhances longevity but also contributes to the overall performance of the equipment, ensuring that it can endure rigorous working conditions.

Role of the Loader Bucket

The loader bucket serves as a vital attachment in construction machinery, enabling the efficient handling of various materials. This component is designed to scoop, lift, and transport heavy loads, playing a crucial role in enhancing productivity on job sites. Its versatility makes it an essential tool for tasks ranging from excavation to material transfer.

Functions and Applications

Primarily, the bucket is utilized for digging and loading soil, gravel, and other aggregates. Its robust construction allows it to withstand significant wear and tear, making it suitable for demanding environments. Additionally, it can be equipped with different cutting edges to optimize performance based on the specific material being handled. This adaptability facilitates a wide range of applications, including landscaping, road construction, and site preparation.

Impact on Efficiency

By streamlining the process of moving materials, the loader bucket significantly contributes to overall operational efficiency. Its design enables quick attachment and detachment, allowing operators to switch between tasks seamlessly. This capability reduces downtime and maximizes productivity, making it an indispensable asset in any heavy machinery fleet.

Backhoe Stabilizer Features Explained

Understanding the essential components that enhance stability during excavation tasks is crucial for optimal performance. These features not only ensure safety but also improve efficiency on various terrains, making them invaluable for operators.

Key Attributes of Stabilizers

The primary function of these supports is to provide a stable base while the machine is in operation. Key attributes include:

| Feature | Description |

|---|---|

| Extendable Arms | Allow for adjustment based on the job’s requirements, enhancing reach and stability. |

| Heavy-Duty Construction | Built from robust materials to withstand demanding conditions and ensure longevity. |

| Quick Deployment | Designed for fast setup, reducing downtime and increasing operational efficiency. |

Benefits of Effective Stabilization

Utilizing advanced stabilization mechanisms provides numerous benefits, including increased safety for operators and workers, reduced risk of machine tipping, and improved accuracy in digging operations. Ultimately, investing in high-quality stabilization features pays off through enhanced productivity and reduced maintenance costs.

Engine Specifications for Backhoes

The performance of heavy machinery is significantly influenced by the characteristics of their power units. Understanding the technical details of these engines is crucial for optimizing efficiency and ensuring reliability in demanding tasks. Key specifications often include power output, torque ratings, and operational efficiency, which together contribute to the overall effectiveness of the equipment.

Power Output: The total horsepower of an engine directly affects its ability to perform various functions. High-output engines are designed to handle strenuous workloads, providing the necessary strength for lifting and moving heavy materials.

Torque Ratings: Torque is essential for tasks requiring strong pulling or lifting capabilities. Engines with higher torque ratings can generate more force at lower RPMs, making them ideal for operations that require quick responses and sustained power.

Fuel Efficiency: Modern engines often incorporate advanced technology to enhance fuel economy. Efficient fuel consumption not only reduces operational costs but also minimizes environmental impact, aligning with current sustainability goals.

Emission Standards: Adhering to regulatory requirements is vital for all machinery. Engines must comply with stringent emission norms, which drive manufacturers to innovate and improve their designs, contributing to cleaner air and reduced pollution.

Cooling Systems: Proper temperature regulation is essential for engine longevity. Many units feature sophisticated cooling systems that prevent overheating, ensuring optimal performance during extended use.

Understanding these specifications is essential for operators and maintenance teams, as it empowers them to make informed decisions regarding equipment use, maintenance schedules, and upgrades. Knowledge of engine characteristics leads to enhanced operational efficiency and increased lifespan of the machinery.

Understanding Electrical Systems in Backhoes

Electrical systems play a crucial role in the efficient functioning of heavy machinery, facilitating communication between various components and ensuring optimal performance. A solid grasp of these systems allows operators to troubleshoot issues effectively and maintain their equipment.

Key components of these electrical systems include:

- Battery: Provides the necessary power for starting and running the engine.

- Alternator: Charges the battery and powers electrical accessories while the engine is running.

- Wiring Harness: Connects various electrical components, ensuring proper communication and functionality.

- Sensors: Monitor parameters like temperature, pressure, and fluid levels, relaying critical data to the operator.

To fully comprehend the electrical systems, one should focus on:

- Understanding the basic principles of electricity.

- Familiarizing oneself with the layout and function of each component.

- Learning how to diagnose common electrical problems.

- Regularly inspecting and maintaining electrical connections to prevent failures.

A well-maintained electrical system enhances the longevity and reliability of the equipment, ensuring peak operational efficiency.

Maintenance Tips for Backhoe Parts

Proper care and regular upkeep are essential for ensuring optimal performance and longevity of heavy machinery. By focusing on specific components, operators can prevent breakdowns and enhance efficiency.

| Component | Maintenance Tip |

|---|---|

| Hydraulic System | Regularly check fluid levels and replace filters to prevent contamination. |

| Engine | Change oil and filters at recommended intervals to maintain engine health. |

| Undercarriage | Inspect and clean tracks frequently to avoid wear and tear. |

| Bucket | Sharpen edges and check for cracks to ensure effective digging. |

| Electrical System | Examine wiring and connections regularly to avoid electrical failures. |

Identifying Common Backhoe Issues

Understanding frequent challenges in heavy machinery can significantly enhance operational efficiency and longevity. Early detection of these problems is crucial for maintaining performance and avoiding costly repairs. Here are some prevalent concerns operators may encounter.

Hydraulic Failures: A common issue is inadequate power in hydraulic systems. This may stem from leaks, blockages, or worn components, leading to reduced performance and sluggish operation.

Engine Performance: Variations in engine efficiency can signal deeper issues. Symptoms include unusual noises, decreased power, or trouble starting, indicating potential mechanical or electrical failures.

Structural Wear: Regular inspections are essential to detect signs of fatigue in the frame or attachments. Cracks, excessive rust, or misalignments can compromise safety and functionality.

Electrical Problems: Malfunctions in the electrical system can disrupt operations. Flickering lights, dead batteries, or faulty connections often point to underlying wiring issues that need addressing.

Operational Noise: Unusual sounds during operation should never be ignored. Grinding, clanking, or hissing noises can indicate mechanical wear or the need for lubrication, requiring immediate investigation.

By keeping a vigilant eye on these areas, operators can effectively mitigate issues and ensure smooth functionality in their machinery.

Resources for Backhoe Parts Diagrams

Accessing detailed visuals and manuals for construction machinery is essential for effective maintenance and repairs. Numerous platforms provide comprehensive resources, helping users identify components and their respective functions. These tools facilitate smoother operations and enhance overall machinery performance.

Online forums and specialized websites offer valuable insights from experienced operators and technicians. These communities often share manuals and guides that detail the inner workings of equipment, promoting a collaborative learning environment.

Additionally, manufacturers’ official websites frequently host a wealth of information, including exploded views and assembly instructions. Utilizing these resources can lead to better understanding and quicker troubleshooting.

Moreover, instructional videos and tutorials available on platforms like YouTube can serve as practical guides. Visual aids can greatly enhance comprehension, allowing users to see each element in action.