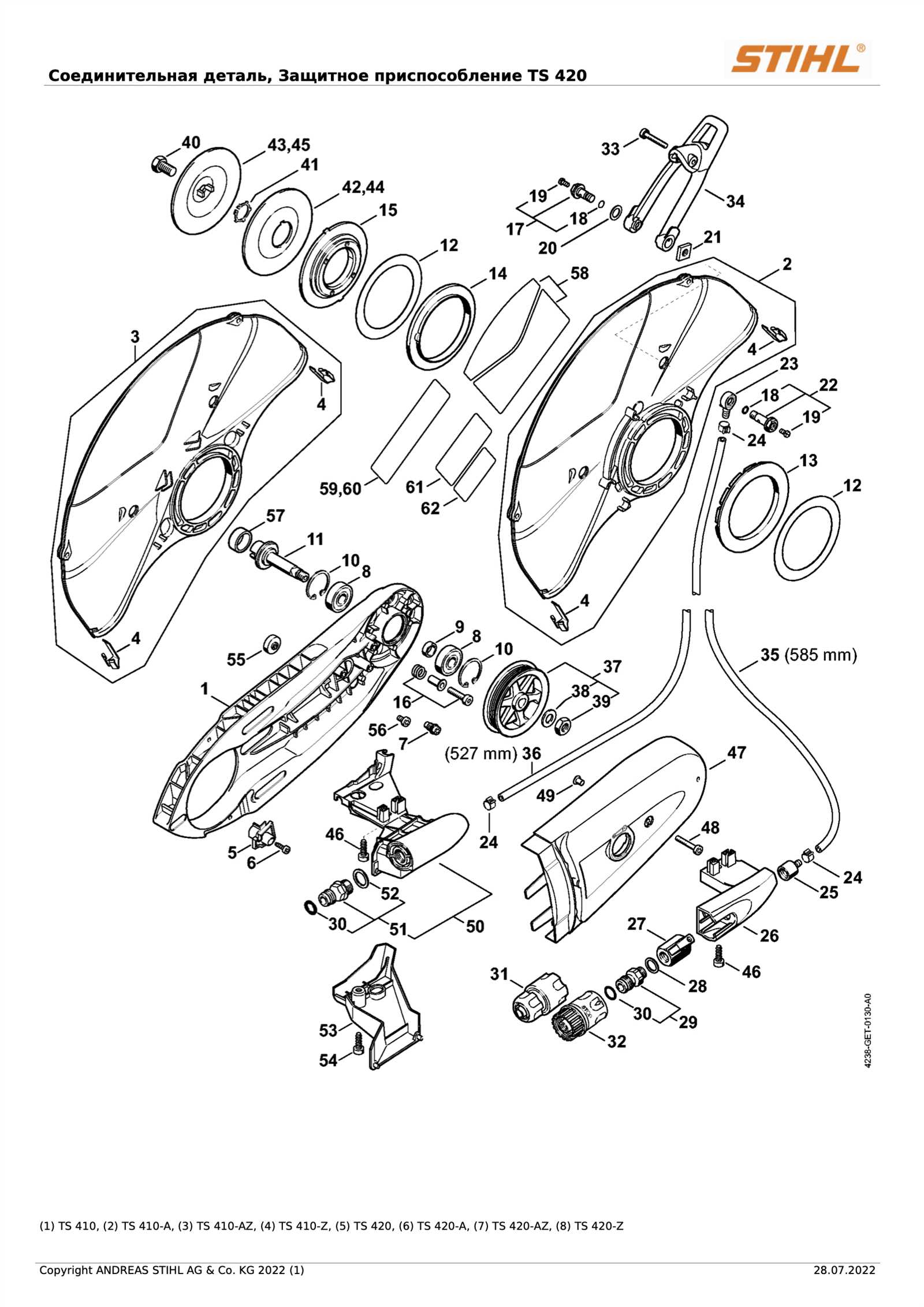

Understanding the Ts 400 Parts Diagram for Effective Repairs

The intricate world of machinery often requires a deeper exploration of its fundamental elements. For enthusiasts and professionals alike, grasping the layout and function of each individual segment can significantly enhance both maintenance and operational efficiency. This section delves into the essential building blocks that form the backbone of Ts series equipment.

When tackling any mechanical system, having a clear visual representation of its internal structure is invaluable. By breaking down the assembly into its key constituents, users can more effectively identify issues, source replacements, and understand the interactions between different components. This not only fosters a more comprehensive knowledge but also empowers individuals to troubleshoot with confidence.

Ultimately, familiarity with the configuration of these vital elements paves the way for improved performance and longevity of the machinery. Whether for repair or enhancement, a thorough understanding serves as a foundation for any endeavor involving this machinery, ensuring optimal functionality and reliability.

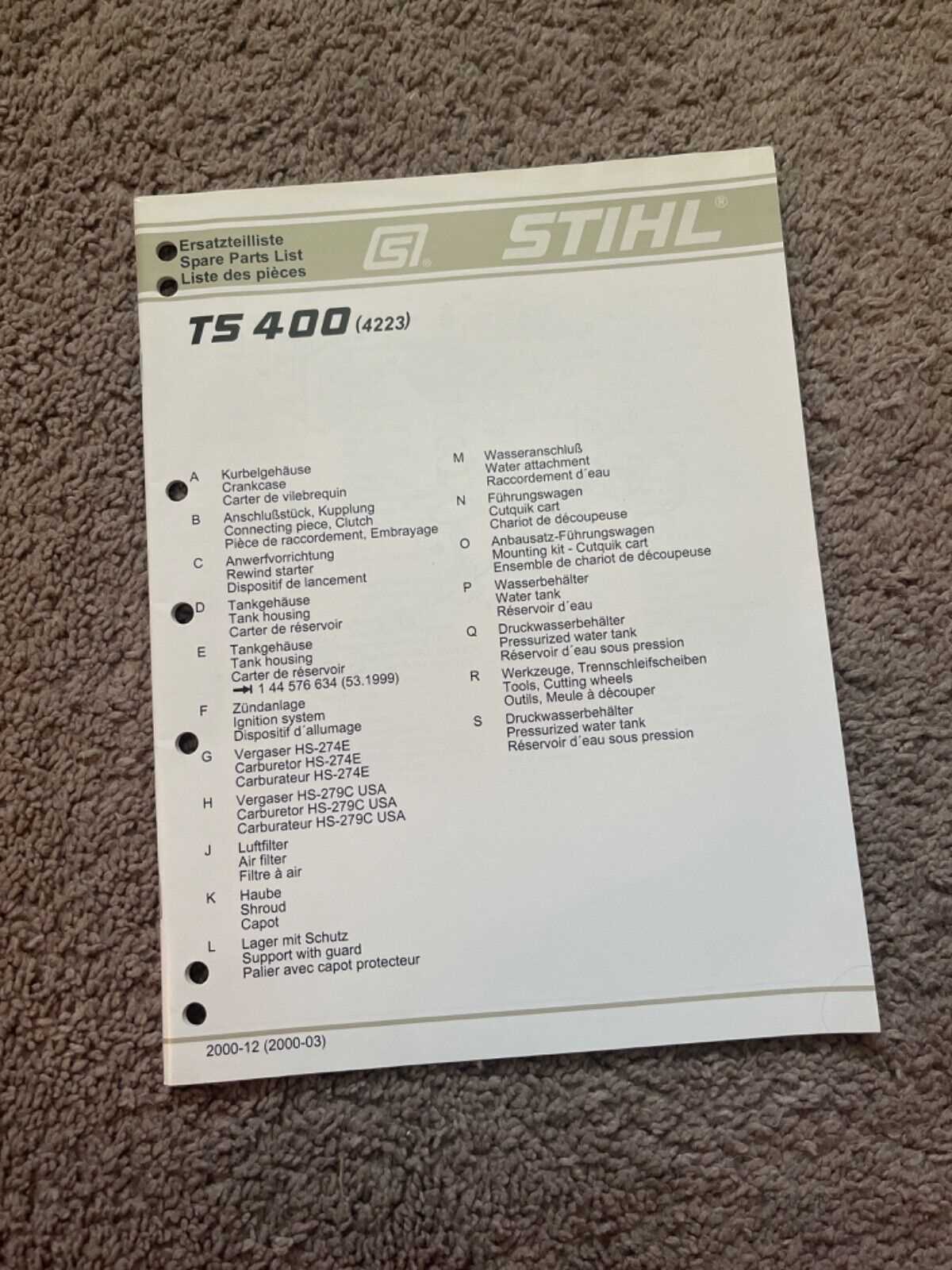

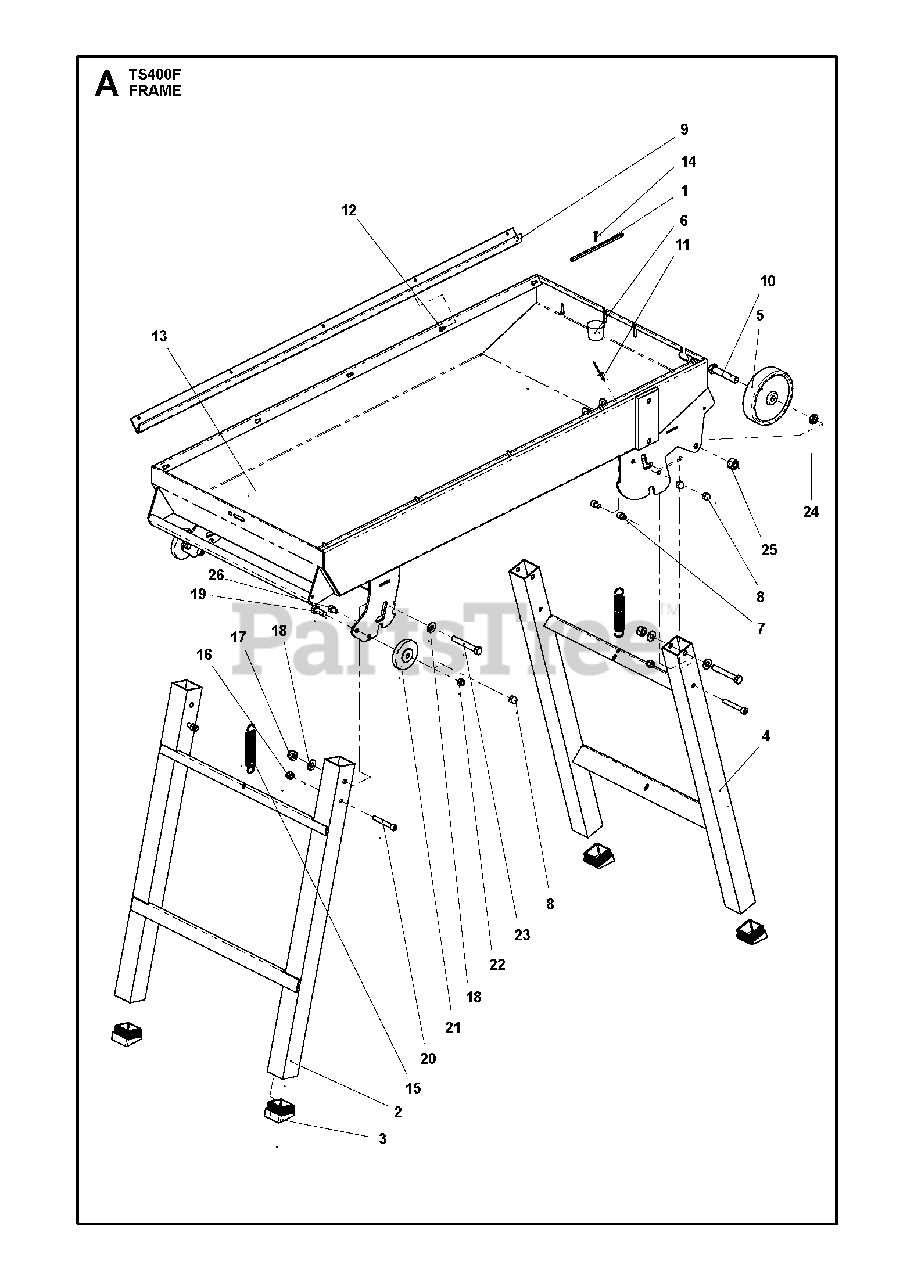

Understanding the Ts 400 Parts Diagram

Comprehending the intricacies of a mechanical assembly is essential for efficient maintenance and repair. A visual representation of components aids in identifying each element’s role within the system, facilitating a deeper understanding of how they interact. This knowledge can significantly enhance both troubleshooting and assembly processes.

Key Components: Familiarizing oneself with the essential elements involved in the machinery is the first step. Each piece serves a specific function, contributing to the overall operation. Knowing the names and purposes of these elements allows users to communicate more effectively when discussing repairs or enhancements.

Maintenance Insights: An illustrative guide not only helps in recognizing individual components but also provides insights into potential issues. By understanding the layout and relationships between elements, operators can anticipate wear and tear, leading to proactive maintenance strategies.

In summary, mastering the visual guide to the assembly leads to improved operational efficiency, reducing downtime and ensuring the longevity of the equipment. With this understanding, users are better equipped to handle both routine checks and unexpected repairs.

Importance of Parts Diagrams

Understanding the structure and components of machinery is essential for effective maintenance and repair. Visual representations serve as valuable tools, enabling users to identify and locate essential elements quickly.

- Enhances clarity in assembly and disassembly processes.

- Facilitates troubleshooting by highlighting potential problem areas.

- Supports efficient ordering of replacement components.

Additionally, these illustrations can improve communication between technicians, ensuring everyone is on the same page regarding repairs or modifications.

- Promotes safety by providing clear guidance.

- Reduces downtime through quick identification of needed items.

- Helps maintain inventory accuracy.

Ultimately, investing time in understanding these visual aids can lead to more efficient operations and prolonged equipment lifespan.

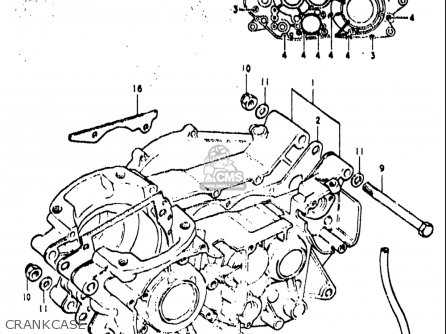

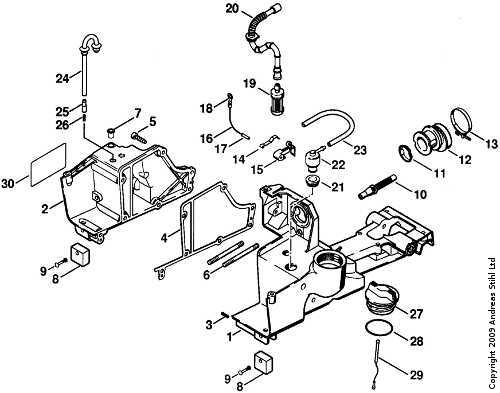

Key Components of the Ts 400

The Ts 400 features several essential elements that contribute to its overall functionality and efficiency. Understanding these crucial components can enhance user experience and maintenance practices.

Engine: The powerhouse of the device, it ensures optimal performance and reliability during operation.

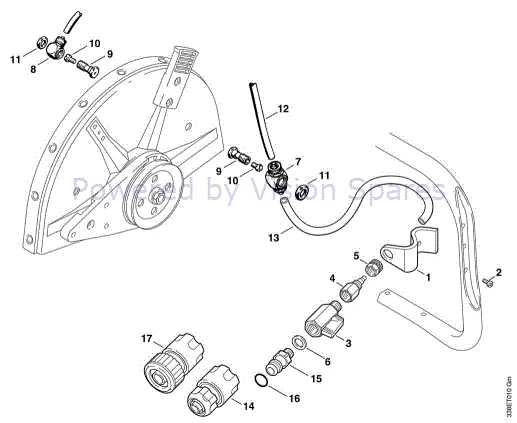

Fuel System: This system plays a vital role in delivering the right mixture of fuel and air, crucial for efficient combustion.

Cylinder: The cylinder houses the piston, facilitating the conversion of fuel energy into mechanical work.

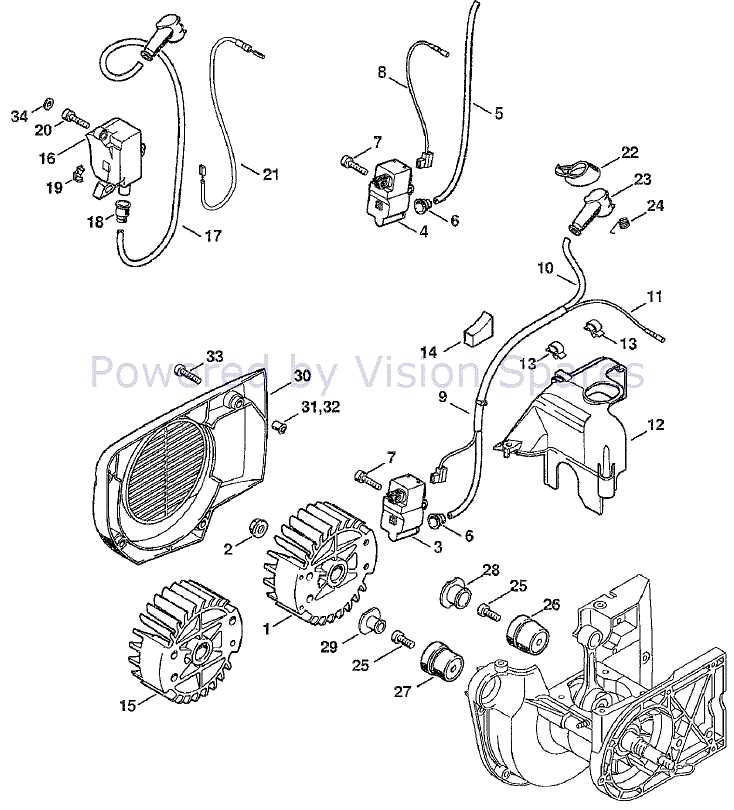

Ignition System: Responsible for initiating combustion, this component ensures smooth starts and consistent operation.

Cooling System: It prevents overheating, maintaining optimal temperatures during prolonged use.

Drive Mechanism: This component transfers power from the engine to the working parts, enabling effective operation.

Delving into these key aspects provides insights into the device’s functionality and highlights areas for potential improvements or upgrades.

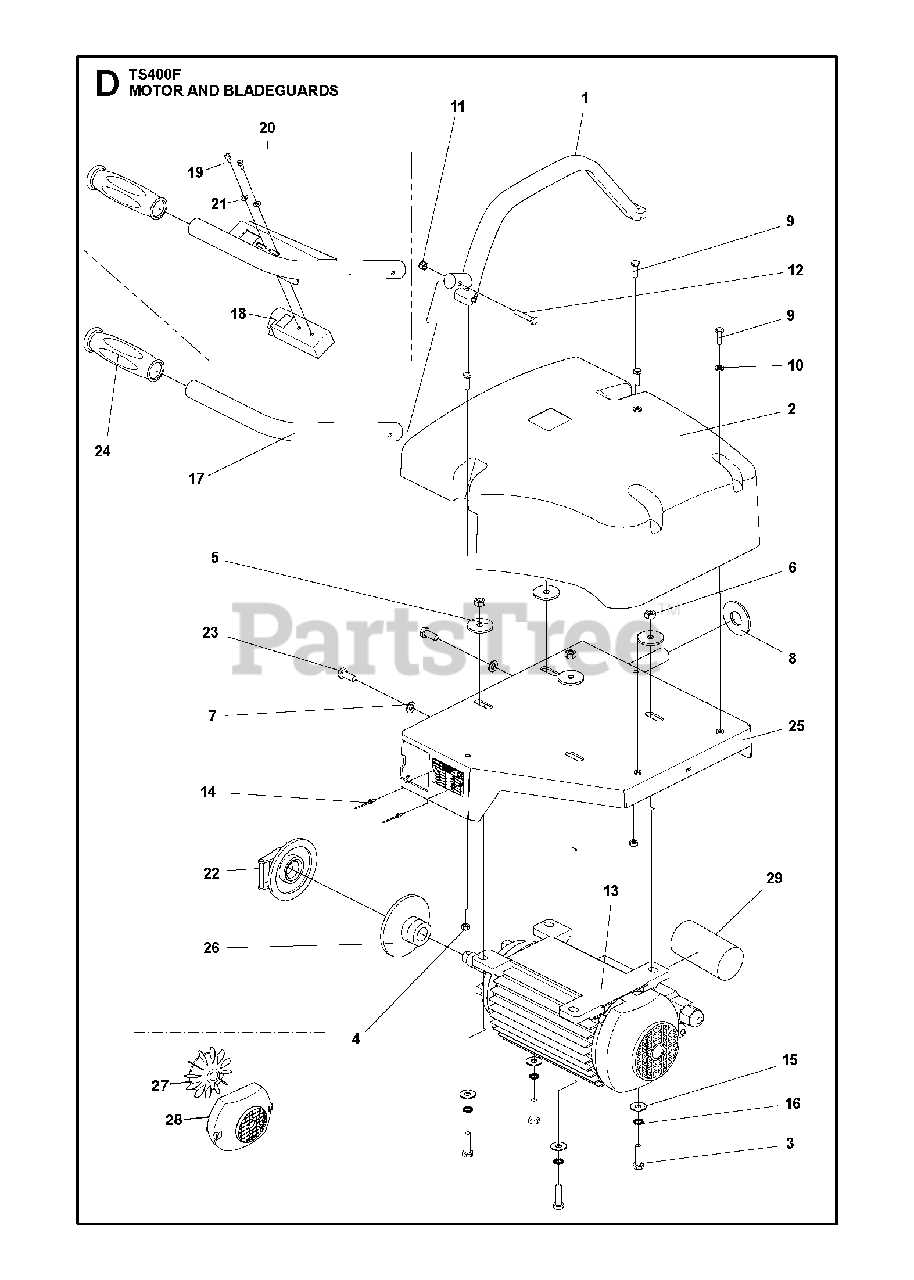

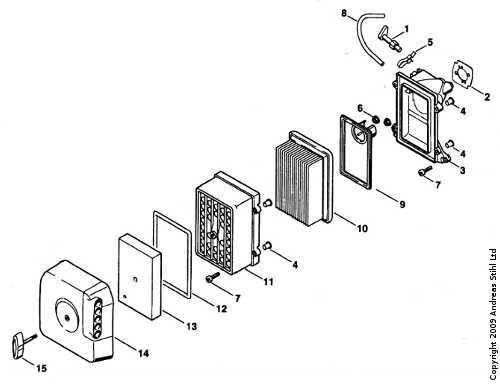

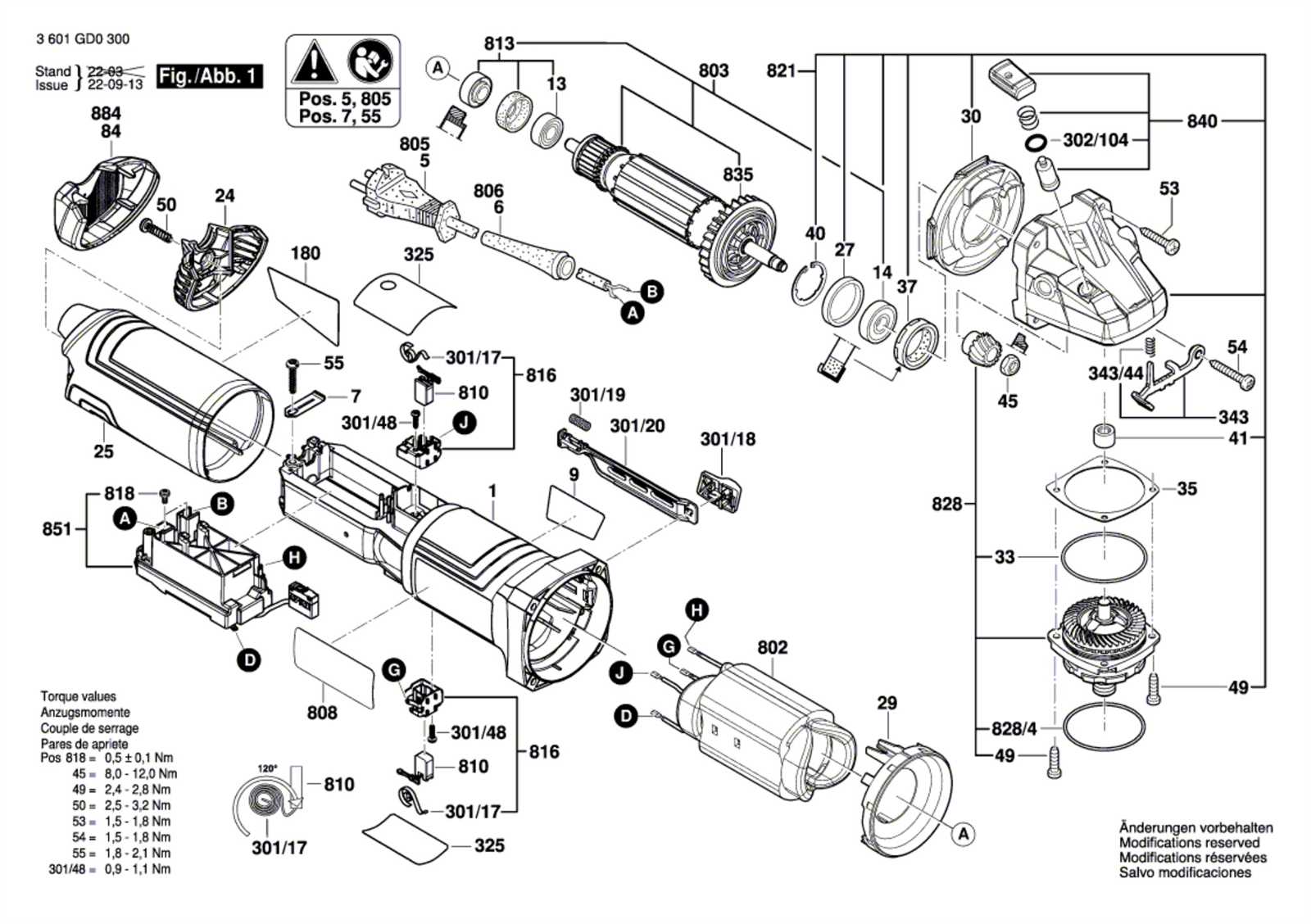

How to Read a Parts Diagram

Understanding the layout of components is crucial for effective maintenance and repair. Familiarity with the schematic representation allows for quicker identification and troubleshooting of individual elements within a system.

Identifying Key Components

Start by locating the main sections in the illustration. Each segment typically represents a specific area or function, making it easier to isolate issues. Use the accompanying labels to connect the visual elements with their descriptions.

Utilizing Reference Numbers

Reference numbers often accompany each component, guiding you to relevant details in a parts list. Cross-referencing these numbers with documentation can enhance your understanding and ensure accurate replacements.

Common Issues with Ts 400 Parts

When working with the Ts 400 model, users often encounter a variety of challenges that can impact performance and longevity. Understanding these common problems can help in effective maintenance and troubleshooting, ensuring smooth operation.

Wear and Tear

One of the most frequent issues stems from general wear and tear. Components may degrade over time due to constant use, leading to decreased efficiency. Regular inspection and timely replacement of these elements can prevent further complications and costly repairs.

Compatibility Problems

Another concern is the compatibility of replacement elements. Using non-original or substandard components can result in improper fitting or functionality, which may cause operational failures. Always ensure that any new parts meet the manufacturer’s specifications to maintain optimal performance.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your equipment requires a dedicated approach to upkeep and care. Regular maintenance not only enhances performance but also significantly extends the lifespan of the machine. Implementing a systematic routine can prevent unexpected breakdowns and costly repairs.

Start by regularly inspecting all components for wear and tear. This proactive measure helps identify potential issues before they escalate. Cleanliness is crucial; debris and dust can lead to inefficiency, so make it a habit to keep the machinery clean and free from obstructions.

Lubrication is another key aspect. Using the appropriate oils or greases as specified in the manual reduces friction and wear, thereby enhancing operational efficiency. Additionally, always ensure that any filters are replaced or cleaned according to the manufacturer’s recommendations to maintain optimal airflow and performance.

Pay close attention to the operating conditions. Avoid excessive loads and harsh environments that could strain the machine. Lastly, keep a detailed log of all maintenance activities. This record will help track the history and performance trends, allowing for informed decisions on future upkeep and repairs.

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. Ensuring that you use high-quality, reliable items can make all the difference in your machinery’s functionality. This section will guide you on where to locate these essential supplies.

Authorized Dealers

One of the most reliable ways to find authentic components is through authorized distributors. These suppliers are officially recognized and typically offer a wide range of genuine items. Benefits of purchasing from them include:

- Guaranteed authenticity

- Expert advice and support

- Warranty on items purchased

Online Retailers

Another convenient option is to explore reputable online platforms. Many websites specialize in selling genuine components and often provide detailed descriptions and specifications. When shopping online, consider the following tips:

- Check for customer reviews to gauge reliability.

- Ensure the site has a secure payment system.

- Look for return policies and customer support options.

By utilizing these resources, you can confidently acquire the necessary components to keep your equipment in top shape.

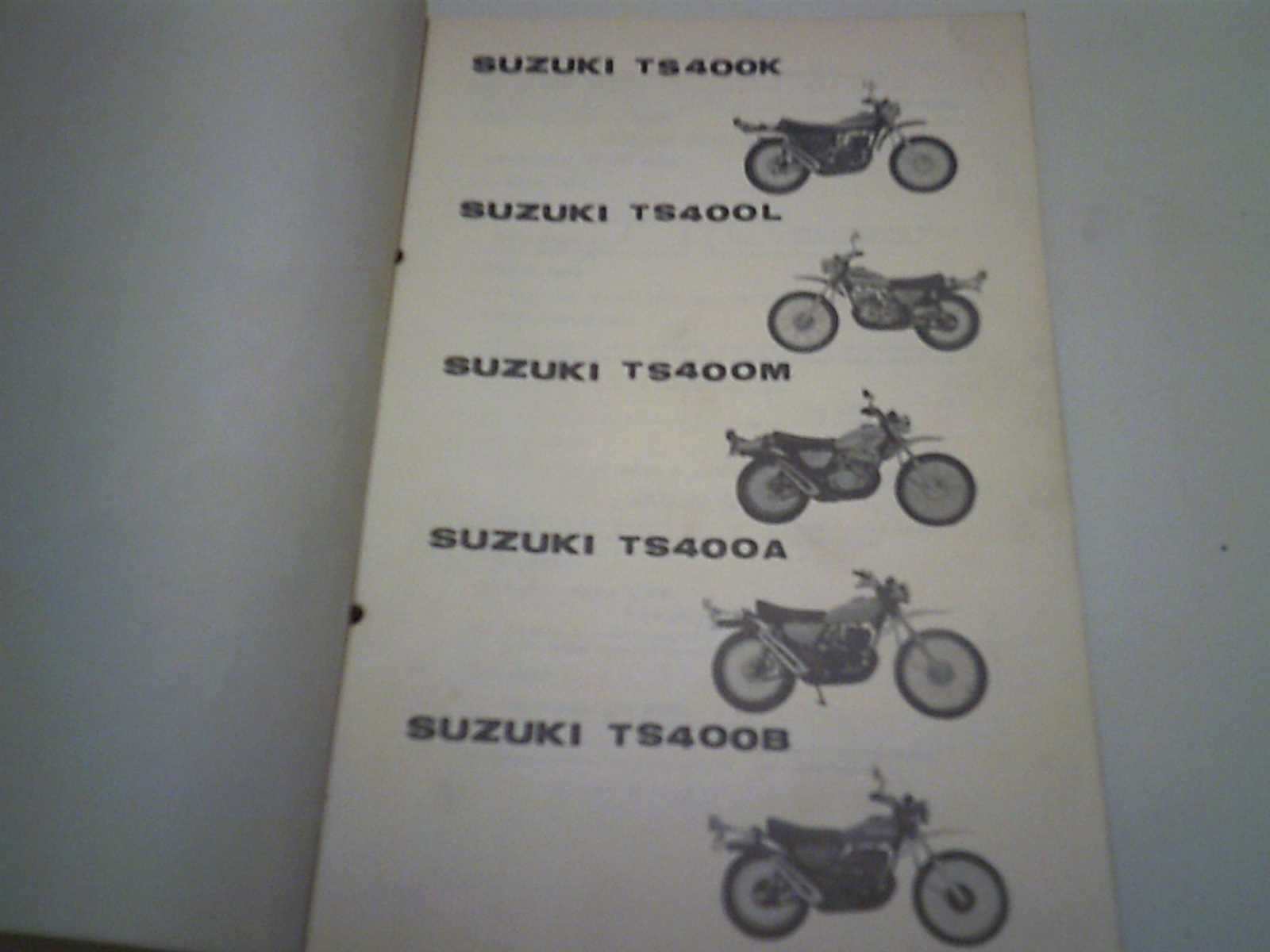

Comparing Ts 400 with Other Models

This section explores the similarities and differences between the Ts 400 and various other units in the same category. By examining key features, performance metrics, and user experiences, we can better understand where the Ts 400 stands in relation to its competitors.

- Design and Build Quality:

- Evaluate the materials used in construction.

- Compare weight and ergonomics for user comfort.

- Power and Efficiency:

- Analyze engine performance across different models.

- Consider fuel consumption and operational efficiency.

- Features and Technology:

- Identify unique functionalities of the Ts 400.

- Assess technological advancements in competing models.

- User Feedback:

- Summarize customer reviews for the Ts 400.

- Compare with feedback on other comparable units.

By analyzing these aspects, potential buyers can make informed decisions when selecting the most suitable tool for their needs.

DIY Repairs Using the Diagram

Engaging in self-repairs can be a rewarding experience, empowering you to tackle issues that may arise with your equipment. Utilizing a detailed schematic allows you to understand the assembly and functionality of components, making it easier to identify what needs attention.

With a clear visual guide, you can methodically disassemble and reassemble machinery, ensuring that each element is correctly positioned. Familiarity with the layout can help you recognize worn or damaged items that require replacement, potentially saving time and money in professional services.

Furthermore, having a reference enhances your troubleshooting skills, enabling you to isolate problems efficiently. Whether it’s a minor adjustment or a more significant overhaul, a comprehensive visual representation serves as an invaluable tool in your repair arsenal.

Tools Needed for Ts 400 Repairs

When it comes to maintenance and fixing your equipment, having the right tools is essential for achieving optimal performance. Proper instruments not only streamline the repair process but also ensure longevity and efficiency in your machinery.

Essential tools include: a reliable wrench set for securing and loosening various components, a screwdriver set with multiple heads to accommodate different screws, and pliers for gripping and manipulating smaller parts. Additionally, having a torque wrench can help in applying the correct amount of force to prevent damage.

Moreover, specialized equipment such as a diagnostic tool can greatly assist in identifying issues early, while a clean workspace with proper storage solutions is vital for organization and safety during repairs.

Online Resources for Ts 400 Owners

For enthusiasts and users seeking to enhance their experience with this model, a plethora of digital platforms provides valuable information and support. From forums and instructional videos to dedicated websites, these resources facilitate a deeper understanding and effective maintenance of the equipment.

Community Forums

Engaging with online communities allows users to exchange tips, troubleshooting advice, and personal experiences. These forums serve as a rich repository of knowledge, helping owners connect and solve issues collaboratively.

Tutorials and Guides

Numerous websites offer comprehensive tutorials and guides, providing step-by-step instructions for various tasks. These resources not only simplify repairs but also empower owners to delve into their equipment with confidence.

Frequently Asked Questions

This section addresses common inquiries related to specific components and their arrangements. Here, we aim to provide clarity and support for those seeking information about their equipment.

What are the most common issues users face?

Users often report challenges with assembly and identifying the correct elements, leading to confusion during maintenance.

Where can I find a reliable reference for components?

It’s recommended to consult official manuals or trusted online resources to ensure accurate information regarding the specific items.

How can I ensure proper maintenance?

Regular inspections and following recommended procedures can greatly enhance the longevity and performance of your equipment.

What should I do if I can’t find a specific element?

If an item is elusive, consider reaching out to customer support or specialized forums for assistance and potential alternatives.

Are there any upgrades available?

Yes, various enhancements are often available that can improve functionality and efficiency, so exploring options is advisable.

Customer Experiences and Reviews

This section explores the insights and feedback shared by users regarding their interactions with the product. Understanding these perspectives can enhance the overall appreciation of its functionality and reliability.

Many users highlight the efficiency and durability of the equipment, often noting how it meets their expectations in various applications. One reviewer mentioned the ease of use, stating that the tool significantly improved their workflow. Others appreciated the responsive customer service, which offered timely solutions to any issues encountered.

However, some feedback pointed out areas for improvement, particularly regarding accessibility of replacement elements. A few users expressed a desire for more detailed documentation to help with maintenance. Overall, the collective experiences indicate a strong satisfaction level, making this equipment a favored choice among enthusiasts and professionals alike.