Daisy 853 Parts Breakdown and Diagram

In any intricate mechanical system, the arrangement and interaction of its various components play a crucial role in ensuring proper functionality. Whether you are a professional or an enthusiast, gaining insight into the specific elements that make up the structure allows for a better understanding of how each part contributes to the overall performance.

To fully appreciate the engineering behind such a system, it’s essential to examine the detailed layout of its individual segments. This examination not only enhances your technical knowledge but also provides the foundation for effective maintenance, troubleshooting, and customization.

Exploring the various sections of a mechanical assembly can uncover a wealth of information, from how certain parts are connected to the system’s operational flow, to identifying areas that might require improvement or repair. With a clear visual representation of the system’s architecture, every piece becomes more than just a part – it transforms into a vital contributor to the whole.

Essential Components of Daisy 853

The key elements of this model play a crucial role in its overall functionality. Each part is designed to work seamlessly with the others, ensuring smooth operation and lasting performance. Understanding the main components can greatly enhance the user’s experience and maintenance of the system.

Power Mechanism: The core of the system, responsible for delivering the necessary energy to the internal components. A reliable power source ensures efficient functioning and prevents disruptions.

Triggering System: This mechanism enables the user to activate the unit. It is carefully calibrated to provide precise control, making the overall experience more responsive and accurate.

Loading Mechanism: This part ensures the proper positioning of materials for optimal performance. It is essential for maintaining the flow of operations without any hitches.

Barrel Assembly: The housing for the internal mechanisms, providing stability and ensuring that all parts work in harmony. The barrel’s design contributes significantly to the durability and reliability of the device.

Sights: The visual aids integrated into the system assist in aiming and provide precision, enabling the user to focus on accuracy during use.

Safety Features: These components are designed to prevent accidents, ensuring that the device is used safely and responsibly. They are critical in providing peace of mind to the operator.

Overview of Key Mechanisms

Understanding the fundamental components and their interaction is essential for mastering the operation of any precision device. These core systems work in unison, ensuring smooth functionality and reliable performance. Each part plays a crucial role in delivering the desired outcomes, whether in terms of accuracy, safety, or ease of use. Exploring how these elements function together provides insight into the overall structure and behavior of the equipment.

Main Operating Systems

At the heart of the mechanism lies a series of interconnected subsystems. These are designed to transfer energy and provide control, ensuring the smooth operation of the entire unit. By analyzing each subsystem’s role, one can gain a deeper appreciation for the precision required in its design and implementation.

Energy Transfer Components

Energy transfer mechanisms are responsible for powering the device, ensuring it performs the intended actions efficiently. These components are typically built for durability and reliability, and their proper maintenance is critical to maintaining performance standards.

| Component | Function | Material |

|---|---|---|

| Trigger Assembly | Initiates action and regulates force output | Steel |

| Spring Mechanism | Stores and releases energy | High-tensile steel |

| Recoil System | Absorbs and distributes energy during discharge | Polymer and metal |

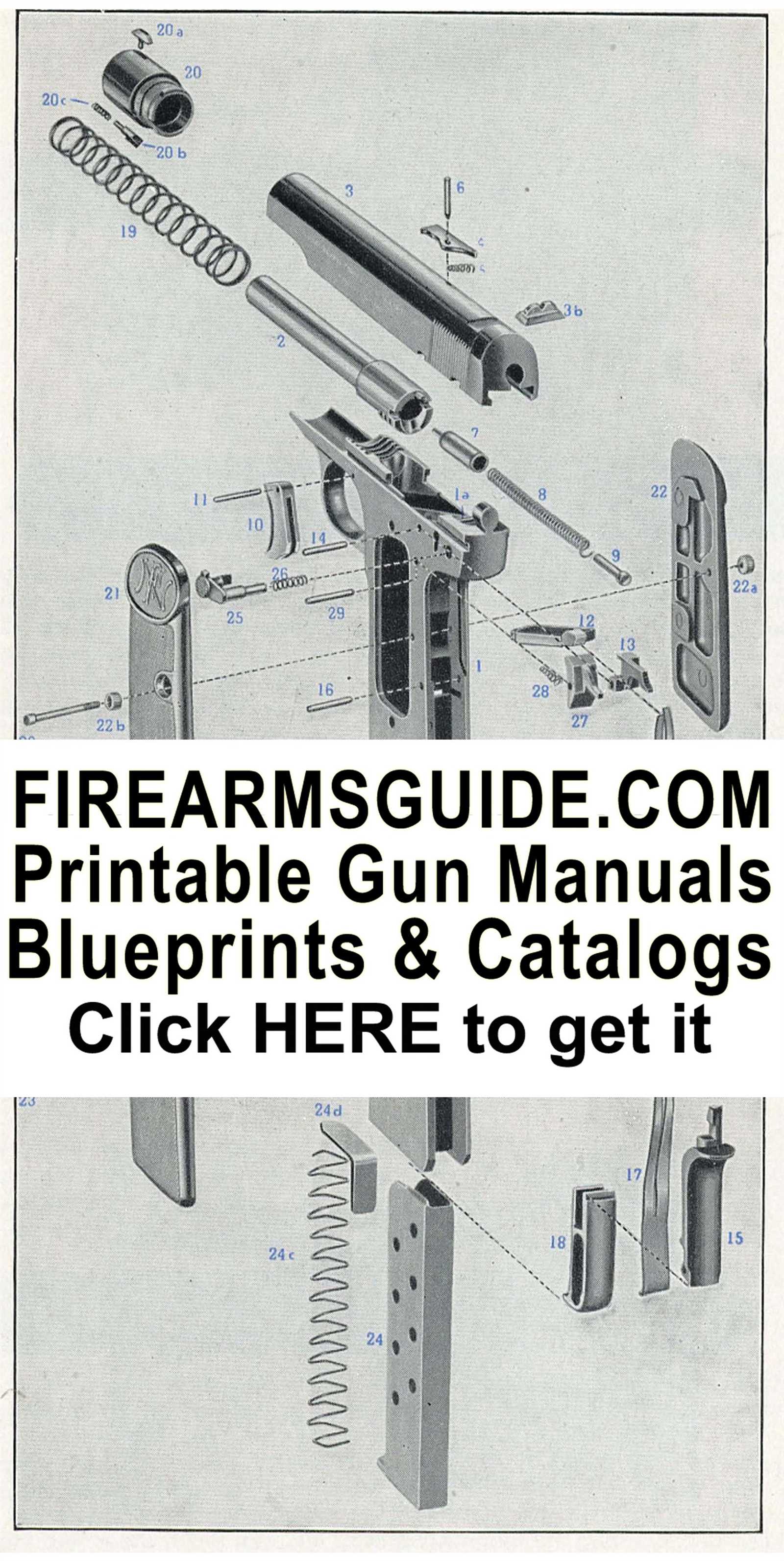

Detailed Diagram Analysis

This section provides an in-depth look at the visual representation of the components that make up the assembly. It aims to highlight how each individual element interacts within the whole structure, focusing on key features and their roles in the overall functioning. Understanding this layout is crucial for anyone looking to gain a clear perspective on how the pieces fit together to form a complete unit.

By examining the visual model, we can break down the relationships between different sections and identify the key connections that enable efficient performance. The goal is to offer a comprehensive view that makes it easier to understand the system as a whole.

| Part Number | Description | Function |

|---|---|---|

| 001 | Main Frame | Supports and houses the internal components |

| 002 | Trigger Mechanism | Activates the release mechanism for action |

| 003 | Compression Spring | Provides tension for the trigger mechanism |

| 004 | Rear Sight | Helps with aiming and target alignment |

| 005 | Barrel | Guides the projectile during its travel |

Understanding the Internal Assembly

In this section, we will delve into the core structure of the mechanical system, examining how each component is strategically arranged for optimal performance. The internal layout plays a crucial role in the overall functionality, with each piece designed to work in harmony with others to ensure smooth operation.

Key elements of this system include the mechanisms responsible for powering the device, as well as the supporting structures that ensure stability and precision. These components are carefully engineered to withstand repeated use while maintaining accuracy and reliability.

By understanding how the parts interconnect, users can gain a better appreciation of the device’s durability and the thought behind its design. Whether it’s for maintenance or simple curiosity, knowing the internal structure can enhance both the user experience and the device’s longevity.

Functional Parts Breakdown

This section provides a detailed analysis of the key components and their specific roles within the mechanism. Understanding the function of each individual element is essential for proper operation and maintenance. By examining the core sections and their interconnections, users can gain insight into the structure and performance of the system as a whole.

Key Components and Their Functions

The system is composed of various essential units, each with a unique task that contributes to the overall functionality. These components work in harmony, ensuring smooth performance and precision in action. For example, the power source provides the necessary energy, while the triggering mechanism enables controlled operation. Each part has been designed to fulfill a particular role, which is critical for maintaining efficiency and reliability.

Maintenance and Care

Regular upkeep of these units is vital for ensuring long-lasting operation. Cleaning and inspecting the individual elements can prevent wear and tear, allowing for continued high performance. It is important to be aware of the specific maintenance requirements for each section, as neglecting any component could lead to malfunction or reduced efficiency.

Exploring the Role of Each Part

Every element within a mechanical system serves a vital function that contributes to its overall performance and efficiency. Understanding how each component interacts with the others allows for better maintenance, repair, and customization. In this section, we delve into the specific duties and significance of the individual pieces that make up the complete mechanism.

Key Components and Their Functions

Each part is designed with precision, ensuring that when assembled, the device operates smoothly. From the main structure to the smaller, intricate elements, every piece is critical for optimal functioning. A properly calibrated assembly ensures longevity and minimizes wear and tear over time, allowing the user to maximize the performance without unnecessary interruptions.

Understanding Assembly and Interaction

The way the pieces fit together is just as important as the materials used. The interaction between parts determines not only the device’s durability but also its efficiency. Whether it’s the energy transfer between connected elements or the balance of force across the structure, each component must function cohesively to achieve the desired outcome.

Assembly Instructions

Follow these step-by-step instructions to correctly assemble the components of your device. Each stage requires attention to detail to ensure proper functionality and safety. It’s essential to verify that all parts are in good condition before starting the assembly process.

Step 1: Preparing the Components

Begin by organizing all the individual elements. Make sure that each item is free from damage and matches the provided list. Lay out everything in a clean, spacious area to help streamline the assembly process.

Step 2: Assembling the Core Structure

Start by attaching the main frame elements together. Secure the components with the appropriate fasteners, ensuring they are tightly fixed. This forms the foundation for the rest of the assembly.

Step-by-Step Guide to Reassembly

Reassembling a mechanical device requires precision and an understanding of how its components fit together. The process involves carefully following each stage to ensure that all parts are correctly positioned and securely fastened. This section will walk you through the necessary steps, ensuring a smooth and efficient reassembly process.

Start by laying out the parts in an organized manner. Ensure that all components are present and undamaged. A clean, flat surface is ideal for assembly, as it allows for easy handling and prevents loss of small pieces.

| Step | Description |

|---|---|

| 1 | Inspect all components for any wear or damage before beginning reassembly. |

| 2 | Start with the core mechanism and position it correctly within the housing or main structure. |

| 3 | Attach any smaller parts, ensuring they are aligned and fit snugly. |

| 4 | Securely fasten all components using the appropriate fasteners, checking for tightness at each stage. |

| 5 | Test the assembly by gently operating the mechanism to ensure proper function and stability. |

Once all steps are completed, perform a final inspection to confirm that every component is in place and functioning as expected. Any misalignments or loose parts should be addressed immediately to avoid future issues.

Common Wearable Parts

In any mechanical system, certain components undergo frequent use and wear due to constant interaction with other elements. These components are essential for the device’s performance, and their longevity can impact overall efficiency. Understanding the key parts that experience regular stress can help in maintaining and optimizing the system for a prolonged service life.

Key Components Subject to Frequent Wear

- Seals and Gaskets – Often subjected to compression, leading to degradation over time.

- Springs – Vital for maintaining tension, but can lose their strength with repeated cycles.

- O-rings – Prone to wear from friction and environmental factors, requiring regular checks for leaks.

- Trigger Mechanism – Components in the firing or activation system are highly sensitive to constant use.

Maintaining Performance

Regular inspection and timely replacement of these frequently worn components can help in sustaining optimal functionality. Neglecting maintenance could lead to operational failure or reduced efficiency, impacting overall performance.

Identifying Frequently Replaced Components

When maintaining mechanical devices, certain elements often require replacement due to wear or damage. Understanding which components are most likely to fail can help owners avoid unexpected downtime and ensure smooth operation. Regularly replacing these key parts keeps the equipment functioning optimally and extends its lifespan.

Seals and O-rings are common components that deteriorate over time, especially if exposed to harsh conditions or frequent use. Their ability to prevent leaks is crucial, making them a top priority for replacement.

Springs also tend to lose their strength after repeated use. They play an essential role in the mechanism’s movement and performance, and a weakened spring can affect overall efficiency.

Seating pads and trigger mechanisms are frequently impacted by mechanical stress. These components are often subjected to significant force and, as a result, may need replacement to ensure proper function and safety.

By paying attention to these frequently replaced items, owners can maintain optimal performance and prevent costly repairs or malfunctions.

Replacement Tips for Major Components

When it comes to maintaining and restoring your device, knowing how to replace key elements is essential. Over time, certain parts may wear out or become damaged, and understanding the proper procedure for their substitution can prolong the lifespan and ensure optimal functionality. This section will guide you through the replacement process for crucial components.

1. Safety First: Always ensure the device is disconnected from any power source before starting any repairs. This simple step prevents potential electrical hazards and allows you to work more comfortably and securely.

2. Choosing Compatible Replacements: When sourcing new parts, it is important to select those that match the specifications of the original components. Using incompatible replacements could result in poor performance or even damage to the device.

3. Handle with Care: Be cautious when removing and installing parts. Fragile components such as springs or small pins should be handled with precision to avoid unnecessary breakage. Use appropriate tools to ease the process and protect both the device and the replacement parts.

4. Proper Alignment: Ensure that each component is correctly aligned before securing it in place. Misalignment can affect the overall performance and may cause further complications down the road.

5. Test After Replacement: Once the new components are installed, test the device to ensure everything is functioning properly. It’s important to confirm that all replacements work as expected before returning the device to regular use.

Choosing Compatible Parts for Repairs

When performing maintenance or restoring a device, selecting the right components is essential to ensure functionality and longevity. Understanding the specifications and compatibility of each item is crucial for achieving optimal performance and avoiding issues during reassembly.

It is important to reference reliable sources that provide accurate measurements, features, and designs for the individual elements. Opting for high-quality replacements that match the original materials can help maintain the integrity of the equipment, especially when addressing common wear and tear.

In addition, checking for manufacturer recommendations and using trusted suppliers can further prevent complications. Proper installation of these elements not only extends the lifespan of the device but also ensures safe and effective use over time.

Maintenance Recommendations

To ensure optimal performance and longevity of your equipment, regular upkeep is essential. Proper maintenance helps prevent malfunctions and extends the lifespan of key components. Below are some key practices to follow for keeping your device in top condition.

- Regularly clean and inspect all moving parts to prevent wear and tear.

- Lubricate components as recommended to reduce friction and prevent rusting.

- Check for any loose connections or fasteners, tightening them as needed.

- Replace worn or damaged elements promptly to avoid further damage.

In addition to routine maintenance, always store the equipment in a dry, cool environment to avoid exposure to extreme conditions that may compromise its functionality.

- Use protective covers when storing to avoid dust and debris accumulation.

- Store in a location where temperature fluctuations are minimal.