Understanding the Components of Scott SCBA Mask Parts Diagram

In environments where air quality poses a significant risk, understanding the intricate elements of respiratory protection systems is vital. These sophisticated devices are designed to safeguard individuals from harmful particulates and gases, ensuring safety during critical operations. A comprehensive grasp of their construction and functionality enhances both efficiency and effectiveness in protective measures.

Exploring the various sections of these safety apparatuses reveals how each component contributes to the overall performance. From filtration units to harness systems, the interplay of these elements is crucial for optimal operation. This knowledge empowers users to make informed decisions regarding maintenance and upgrades, ultimately leading to enhanced safety standards.

Furthermore, delving into the schematic representation of these devices can illuminate the essential roles played by each part. By understanding how the individual pieces fit together, users can better appreciate the engineering behind these life-saving tools. Ultimately, a thorough familiarity with respiratory systems is essential for anyone involved in safety-critical professions.

Overview of Scott SCBA Masks

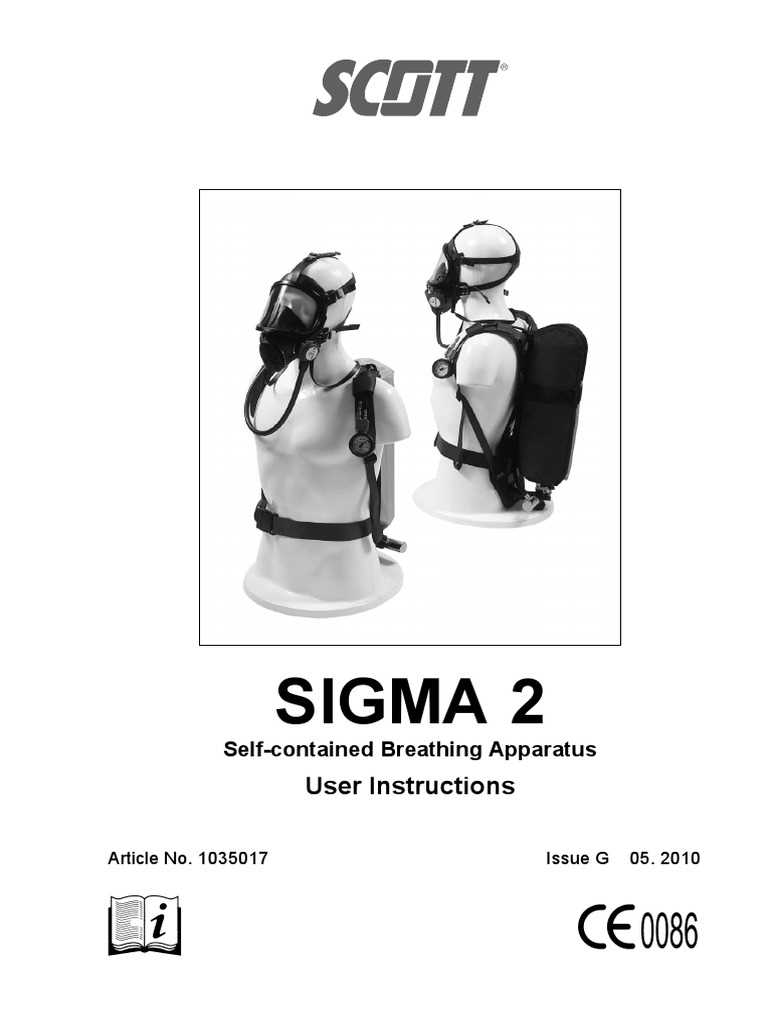

This section provides a comprehensive look at advanced respiratory protection equipment designed for hazardous environments. Such apparatus plays a critical role in ensuring the safety and health of users, allowing them to operate effectively in situations with poor air quality or toxic substances.

Key Features and Benefits

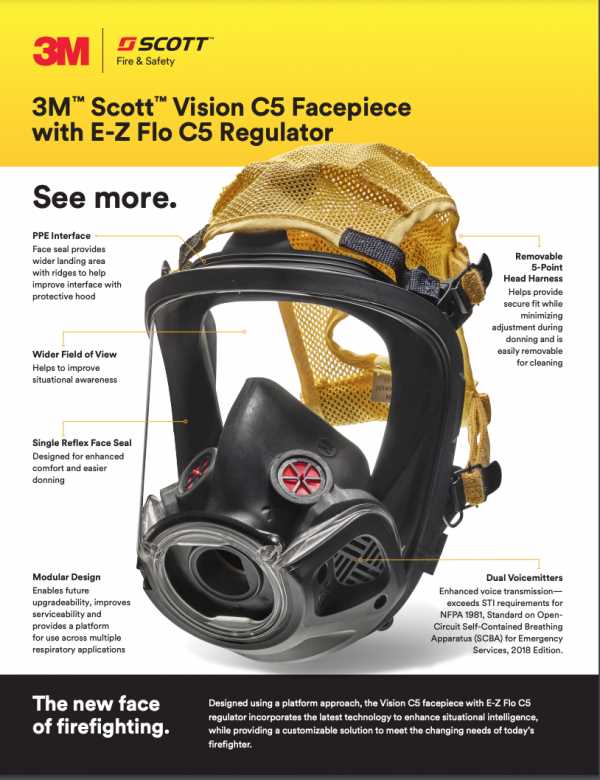

The equipment is engineered with multiple essential components that enhance usability and safety. Features such as ergonomic design and lightweight materials contribute to user comfort during extended wear. Moreover, the integration of state-of-the-art filtration systems ensures a reliable supply of clean air, which is vital in emergency scenarios.

Applications and Usage

This protective gear is predominantly utilized by first responders, industrial workers, and individuals operating in confined spaces. The adaptability of the equipment allows for a wide range of applications, from firefighting to chemical handling. Proper training and familiarization with the device are crucial for maximizing its effectiveness and ensuring user safety in critical situations.

Key Components of SCBA Masks

Understanding the essential elements of respiratory protective gear is crucial for ensuring safety and effectiveness in hazardous environments. Each component plays a significant role in providing breathable air, comfort, and protection against various contaminants.

Air Supply System

The air supply system is fundamental, delivering clean, breathable air from a cylinder. It includes regulators and valves that control the flow, ensuring a steady supply during use.

Facepiece and Sealing Mechanism

The facepiece serves as the interface between the user and the environment. Its sealing mechanism is vital for preventing any contaminants from entering, allowing for a secure and comfortable fit on different facial structures.

Understanding the Functionality of Parts

Exploring the various components of a respiratory protection device reveals their critical roles in ensuring user safety and efficiency. Each element is meticulously designed to work in harmony, providing essential features that enhance overall performance and reliability.

| Component | Function |

|---|---|

| Facepiece | Provides a secure seal and protects the user’s face while ensuring clear visibility. |

| Filters | Remove contaminants from the air, ensuring clean breathing. |

| Exhalation Valve | Allows exhaled air to escape, preventing heat and moisture buildup. |

| Head Harness | Secures the device in place, allowing for comfortable long-term wear. |

| Regulator | Controls airflow, ensuring adequate oxygen supply under varying conditions. |

Importance of Proper Maintenance

Ensuring the longevity and reliability of safety equipment is essential for optimal performance in hazardous environments. Regular upkeep not only enhances functionality but also significantly reduces the risk of malfunctions during critical situations. Implementing a systematic maintenance routine is vital for user safety and equipment efficacy.

| Maintenance Activity | Frequency | Benefits |

|---|---|---|

| Inspection for Wear | Monthly | Identifies potential failures |

| Cleaning and Sanitizing | After Each Use | Prevents contamination |

| Functional Testing | Quarterly | Confirms operational integrity |

| Replacement of Worn Components | As Needed | Ensures optimal performance |

Common Issues with SCBA Masks

Properly functioning respiratory protection is essential for safety in hazardous environments. However, users often encounter various challenges that can compromise the effectiveness of these devices. Understanding these common issues can help ensure optimal performance and user safety.

Seal Integrity

A secure fit is critical for preventing contaminants from entering the breathing zone. Over time, the sealing surfaces may wear down or become damaged, leading to leaks. Regular inspection for cracks or deformities in the sealing elements is vital. Users should ensure proper fitting techniques are applied to achieve the best seal possible.

Breathing Resistance

Increased resistance during inhalation can be a significant concern. This may arise from blockages in the filtration system or degradation of internal components. Regular maintenance, including cleaning and replacing filters, can mitigate this issue. Additionally, users should be aware of any changes in airflow during use, as this may indicate underlying problems.

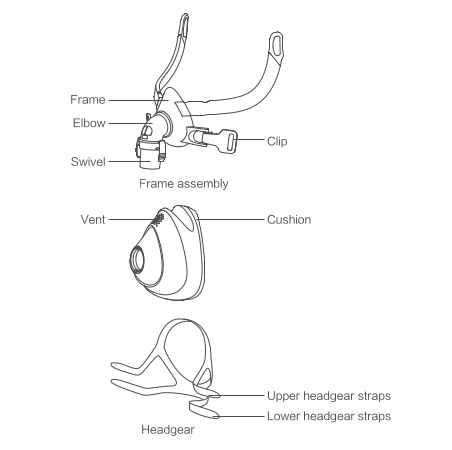

Identifying Parts in the Diagram

Understanding the various components illustrated in the visual representation is crucial for effective operation and maintenance. Each element plays a significant role in ensuring functionality and safety during use. Familiarity with these elements enhances both the efficiency of the equipment and the safety of the user.

First and foremost, it is essential to recognize the primary features, including the secure fitting system, which ensures a snug attachment to the face. This aspect is vital for maintaining an airtight seal, thereby providing optimal protection.

Additionally, the air supply mechanism deserves attention, as it is responsible for delivering breathable air to the user. Understanding how this component works in conjunction with the filtration system can help prevent potential hazards during operation.

Moreover, the visibility elements, such as the viewing lens, are crucial for situational awareness. Clear visibility allows for better navigation and decision-making in challenging environments.

Lastly, being aware of the maintenance indicators can significantly aid in ensuring that the equipment remains in peak condition. Regular checks and familiarity with these signals can prevent malfunctions and ensure reliable performance.

Safety Features of Scott SCBA

Ensuring the safety of individuals in hazardous environments is paramount, and advanced respiratory protection systems play a crucial role in achieving this. These systems are designed with various innovative features that enhance user protection, comfort, and operational efficiency. Understanding these safety elements is essential for maximizing effectiveness in challenging conditions.

Advanced Respiratory Protection

The core function of these devices is to provide a reliable supply of breathable air, shielding users from harmful gases and particulate matter. Equipped with high-performance filtration systems, they ensure that only clean air reaches the user, significantly reducing the risk of respiratory issues during critical operations.

Ergonomic Design and User Comfort

Comfort is vital for maintaining focus and performance in demanding situations. The ergonomic design of these protective systems includes adjustable straps and lightweight materials that minimize fatigue during extended use. Additionally, features such as anti-fog visors and communication systems facilitate clear visibility and effective teamwork, enhancing overall operational safety.

How to Replace Worn Components

Maintaining the functionality of protective respiratory equipment is essential for safety. Over time, certain elements can deteriorate, leading to reduced efficiency and potential hazards. Understanding how to identify and replace these components is crucial for ensuring optimal performance.

Begin by regularly inspecting your gear for signs of wear, such as cracks, tears, or discoloration. If any part appears compromised, it should be replaced promptly to avoid failure during use. Familiarize yourself with the specific components that are prone to wear and the recommended replacement intervals.

| Component | Signs of Wear | Replacement Steps |

|---|---|---|

| Facepiece Seal | Cracks, brittleness | 1. Remove the old seal. 2. Clean the area. 3. Apply a new seal carefully. |

| Filter Element | Clogging, discoloration | 1. Unscrew the filter. 2. Dispose of the old filter. 3. Install the new filter securely. |

| Head Harness | Fraying, loss of elasticity | 1. Detach the old harness. 2. Align the new harness. 3. Attach and adjust for a secure fit. |

Always follow the manufacturer’s instructions when replacing components. Keeping a maintenance log can also help track the condition of your equipment and schedule timely replacements, ensuring reliability when it matters most.

Regulatory Standards for SCBA Equipment

The effectiveness and safety of respiratory protective gear are governed by a variety of regulatory frameworks designed to ensure user safety in hazardous environments. These standards establish essential performance criteria, testing protocols, and maintenance guidelines to guarantee that equipment can withstand extreme conditions and provide adequate protection against harmful agents.

Organizations such as the National Institute for Occupational Safety and Health (NIOSH) and the Occupational Safety and Health Administration (OSHA) play pivotal roles in setting these benchmarks. Compliance with these regulations not only enhances the reliability of respiratory devices but also instills confidence among users regarding their safety during critical operations.

Furthermore, continuous updates to these standards reflect advancements in technology and changing industry needs. Regular assessments and certifications ensure that equipment remains effective over time, contributing to the overall safety culture in various sectors, from firefighting to industrial work.

Comparative Analysis with Other Brands

In the realm of respiratory protective equipment, evaluating the features and performance of different manufacturers is essential for making informed choices. This section explores how one leading brand stacks up against its competitors in terms of design, functionality, and user satisfaction.

Durability is a critical factor when assessing various options. While some brands prioritize lightweight materials, others focus on robust construction, ensuring longer service life and resilience under demanding conditions.

Comfort also plays a vital role in user experience. Comparing the ergonomic designs and adjustable features can highlight significant differences, impacting how effectively individuals can use their equipment over extended periods.

Moreover, performance in critical situations varies significantly across brands. Evaluating airflow efficiency, visibility, and ease of maintenance provides insight into which options offer the ultimate protection and usability for professionals in hazardous environments.

Ultimately, understanding these distinctions empowers users to select the most suitable equipment for their specific needs, enhancing safety and operational effectiveness.

Training for Effective SCBA Use

Proper preparation and instruction are essential for maximizing the effectiveness of respiratory protective equipment. Comprehensive training ensures users can operate their gear safely and efficiently in various situations. This involves understanding the device’s components, functionalities, and maintenance, as well as practicing emergency protocols.

| Training Component | Description |

|---|---|

| Equipment Familiarization | Learning about the different components and their roles in ensuring safety. |

| Operational Techniques | Practicing the correct procedures for donning and doffing the equipment. |

| Emergency Drills | Simulating emergency scenarios to enhance response times and decision-making skills. |

| Maintenance Practices | Understanding the importance of regular inspections and upkeep of the gear. |

Ongoing education and practice are vital for maintaining proficiency and readiness. By committing to regular training, users can ensure they are equipped to handle any challenges that may arise while using respiratory devices.