Understanding the Rolair Compressor Parts Diagram for Efficient Repairs

In the realm of machinery, comprehending the intricate arrangement of essential elements is crucial for optimal performance and maintenance. Every device is a complex system, where each component plays a vital role in ensuring functionality and efficiency. This understanding not only aids in troubleshooting but also enhances the ability to make informed decisions during repairs or upgrades.

Visualization of these assemblies can significantly streamline the process of identifying issues and improving overall operation. A clear representation of how each section interacts with the others enables users to grasp the mechanics behind their equipment. By dissecting these elements, one can gain valuable insights into their respective roles and the importance of proper upkeep.

Furthermore, an organized view of the configuration assists both novices and seasoned professionals alike. It transforms abstract concepts into tangible knowledge, allowing for a more profound appreciation of the technology at hand. This exploration is essential for anyone looking to enhance their expertise and ensure longevity in their equipment’s performance.

Understanding Rolair Compressors

This section explores the functionality and design of a well-regarded brand in the field of pneumatic tools. Known for their reliability and efficiency, these devices play a crucial role in various applications, from powering equipment to facilitating specific tasks in workshops and job sites.

Key Features

These machines are engineered to deliver consistent performance, featuring robust construction and advanced technology. Their ability to generate and store high-pressure air makes them indispensable for tasks that require a steady airflow. Additionally, they are designed with user-friendliness in mind, ensuring that both novices and experienced users can operate them effectively.

Maintenance and Care

To ensure longevity and optimal performance, regular maintenance is essential. Users should familiarize themselves with the essential components and understand how to troubleshoot common issues. This knowledge not only enhances efficiency but also helps in avoiding costly repairs.

Investing in a quality device ensures that you have a reliable ally in your projects, providing the power and support needed for a wide range of applications. Understanding the intricacies of this equipment can significantly impact your productivity and satisfaction.

Importance of Compressor Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and troubleshooting. Visual representations of these elements play a vital role in guiding users through the complexities of their equipment. They facilitate a clearer comprehension of how individual pieces interact, enabling users to identify issues and implement solutions efficiently.

Enhanced Troubleshooting

By referring to visual layouts, technicians can quickly locate the source of a malfunction. This expedites the repair process, minimizing downtime and associated costs. A detailed illustration serves as a roadmap, making it easier to follow the flow of operations and pinpoint anomalies.

Improved Maintenance Practices

Regular upkeep is essential for the longevity of any machine. Diagrams assist in highlighting critical areas that require attention, ensuring that maintenance tasks are not overlooked. They also provide insights into the proper assembly and disassembly procedures, promoting best practices among users.

| Benefit | Description |

|---|---|

| Quick Identification | Visual aids enable rapid locating of components and issues. |

| Efficiency | Streamlines the repair and maintenance processes. |

| Training | Facilitates the onboarding of new technicians with clear visuals. |

| Longevity | Encourages proactive maintenance, extending equipment lifespan. |

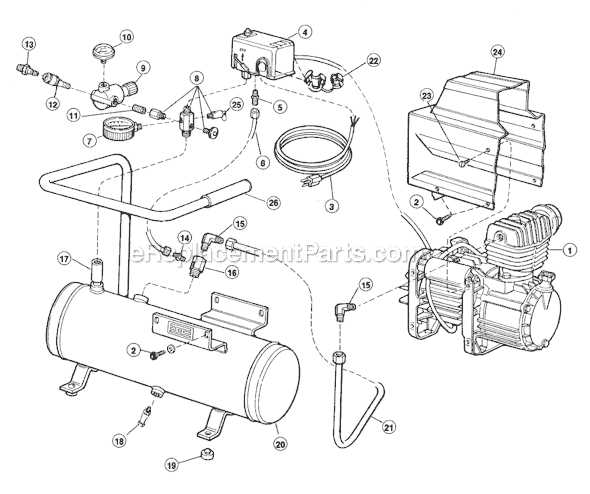

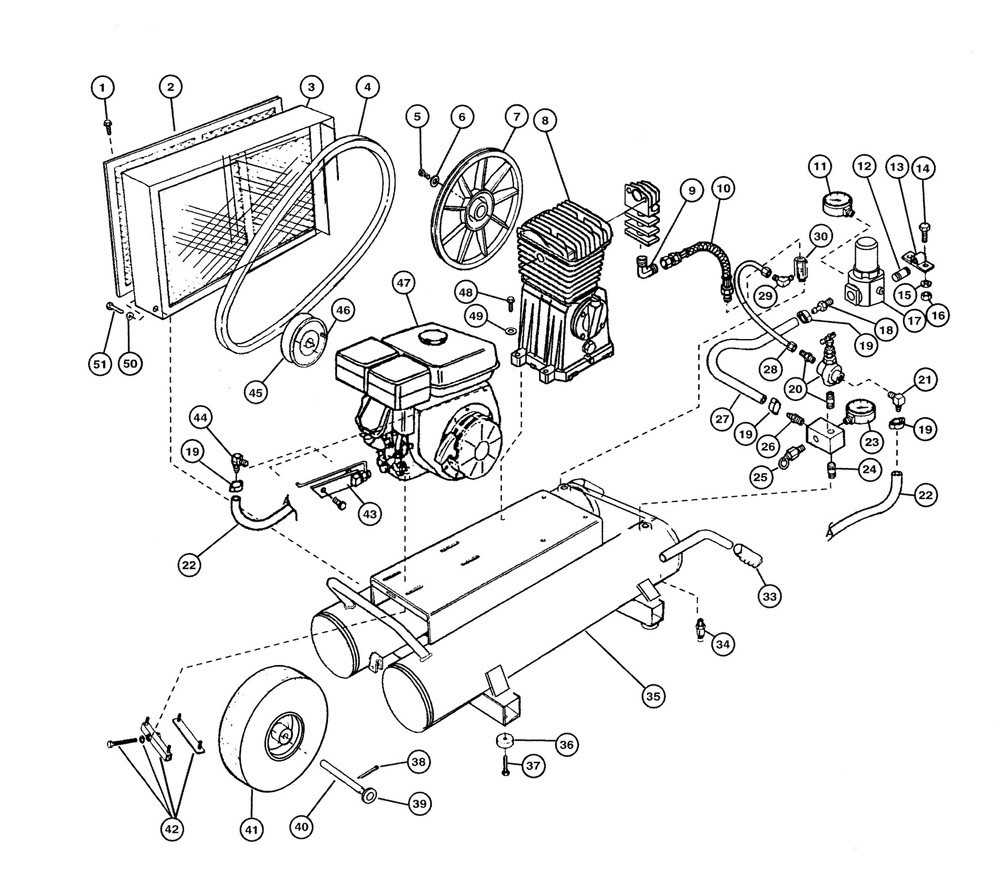

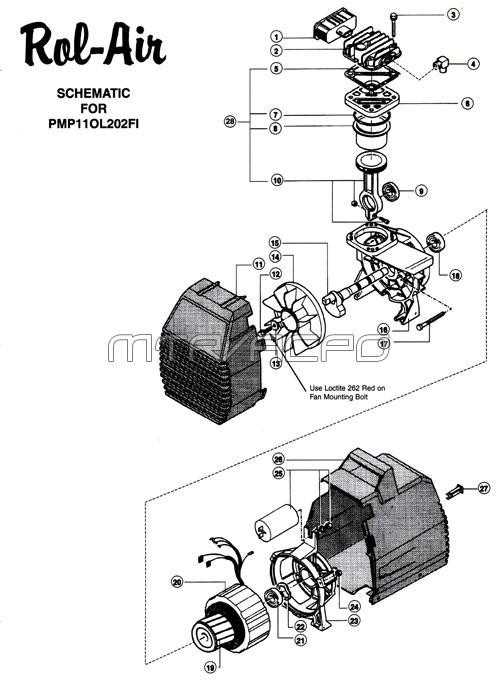

Common Components of Rolair Compressors

Understanding the key elements of an air pressure device is crucial for efficient operation and maintenance. Each unit consists of various essential components that work together to ensure optimal performance and longevity. Below are some of the primary elements typically found in these systems.

Motor: The motor serves as the heart of the unit, providing the necessary power to operate the entire mechanism. It converts electrical energy into mechanical energy, driving the other components.

Pump: This vital element is responsible for generating air pressure. It compresses the air and delivers it to the storage tank, playing a crucial role in the overall functionality.

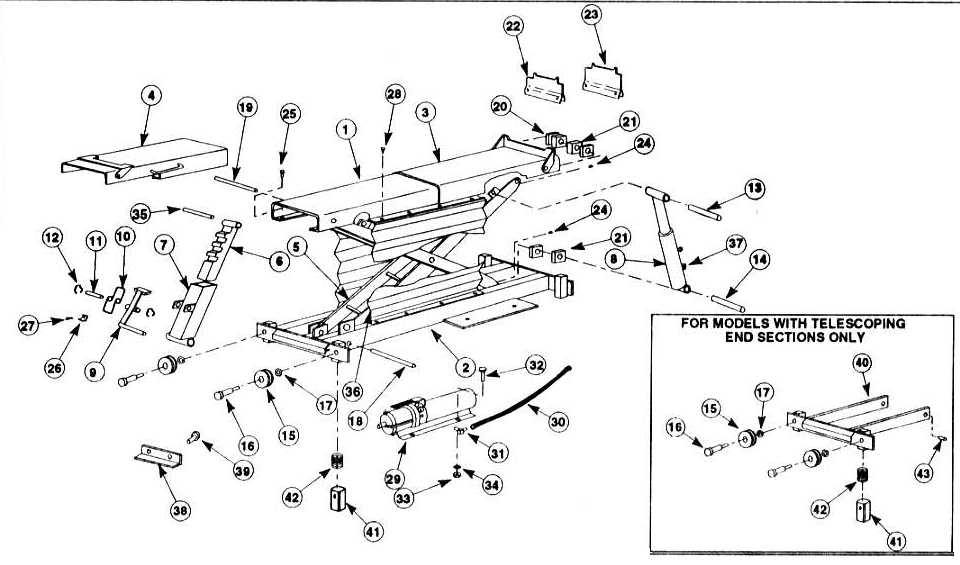

Tank: The storage vessel holds compressed air until it is needed for various applications. The size and capacity of this component can significantly affect the performance and efficiency of the system.

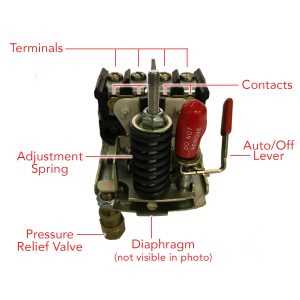

Regulator: This device controls the pressure level, ensuring that the output remains consistent and suitable for the intended tasks. Proper regulation prevents damage to tools and ensures safety during operation.

Filter: To maintain clean air output, a filtration system removes contaminants and moisture from the air before it reaches the tools. This is essential for preventing wear and tear on equipment.

Hoses and Fittings: These connections facilitate the transport of compressed air from the tank to the tools. Quality hoses and fittings are necessary to ensure efficient airflow and prevent leaks.

Recognizing these essential components aids in better maintenance and troubleshooting, ultimately enhancing the efficiency and lifespan of the equipment.

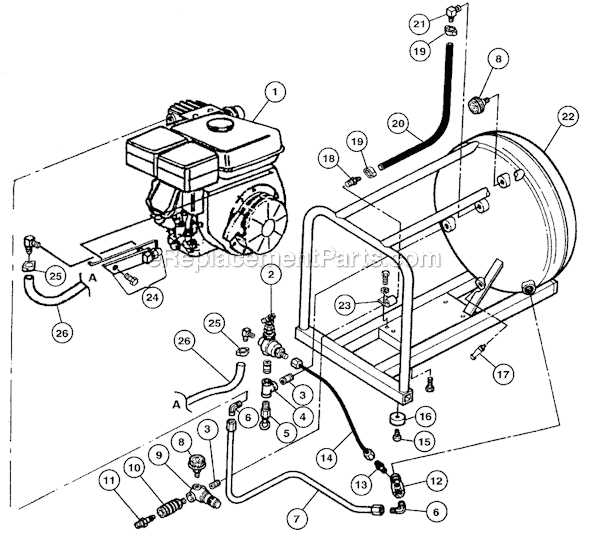

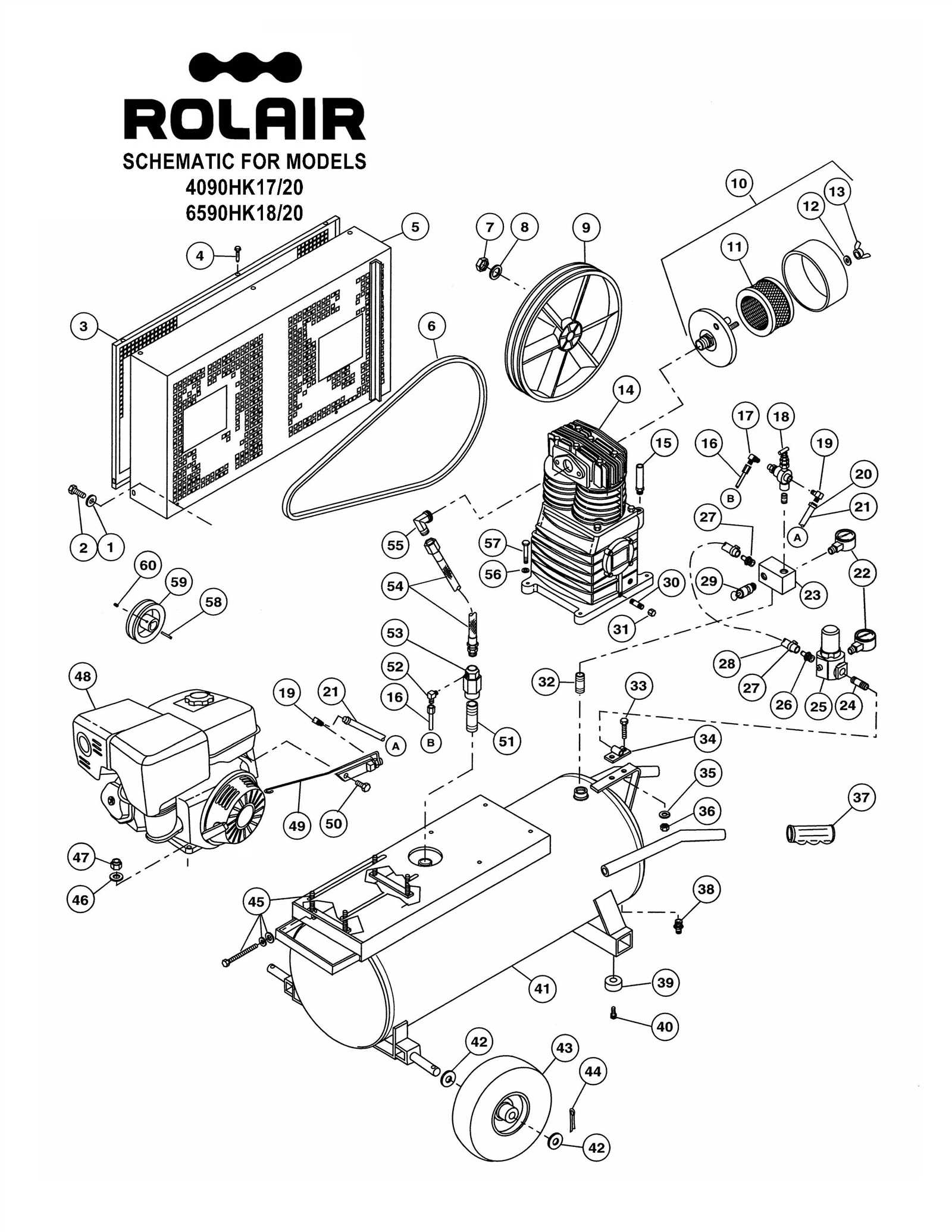

How to Read a Parts Diagram

Understanding a visual representation of components is essential for efficient maintenance and troubleshooting. Such illustrations provide valuable information about the arrangement and functionality of individual elements, enabling users to identify and address issues effectively.

Key Elements to Look For

- Labels: Each item typically has a corresponding label, which may include numbers or letters that reference a list or key.

- Connections: Pay attention to lines or arrows indicating how components are linked or interact with one another.

- Symbols: Familiarize yourself with common symbols that represent various parts, as these can differ by manufacturer.

Steps for Effective Interpretation

- Examine the Legend: Start by reviewing the legend or key, as it provides crucial context for the notations used in the visual.

- Identify Major Sections: Break down the illustration into sections to simplify your understanding of larger systems.

- Cross-reference with Manuals: Utilize user manuals or service guides for additional details on each component’s function.

- Practice: Regularly engage with different visual aids to become more comfortable with their layouts and conventions.

Identifying Key Parts and Functions

Understanding the essential components and their roles is crucial for effective operation and maintenance of any machinery. Each element plays a vital role in ensuring optimal performance and efficiency.

- Motor: Powers the entire system, converting electrical energy into mechanical energy.

- Pump: Compresses the air, increasing its pressure for various applications.

- Tank: Stores the compressed air, providing a reservoir for consistent supply.

- Regulator: Controls the pressure output, ensuring safe and efficient usage.

- Valves: Manage the flow of air, directing it where needed within the system.

Recognizing these critical elements allows users to troubleshoot issues and optimize functionality effectively.

Maintenance Tips for Rolair Components

Regular upkeep of equipment is essential for optimal performance and longevity. Proper attention to various elements can prevent issues and ensure smooth operation.

- Check for leaks regularly to maintain efficiency.

- Inspect seals and gaskets for wear and tear.

- Keep the unit clean and free of debris to avoid overheating.

- Monitor fluid levels and replace as necessary to ensure lubrication.

Following these guidelines will help maximize the lifespan and effectiveness of your machinery.

Common Issues and Solutions

In the world of pneumatic tools, various challenges can arise that may hinder performance. Understanding these issues and their resolutions is essential for maintaining efficiency and prolonging the lifespan of the equipment.

-

Insufficient Air Pressure:

This issue often stems from leaks or inadequate power supply. To resolve this:

- Inspect all hoses and fittings for leaks.

- Ensure the motor is receiving adequate voltage.

- Check and replace any worn-out components.

-

Overheating:

Excess heat can lead to breakdowns and reduced efficiency. Possible solutions include:

- Allowing the unit to cool down between uses.

- Cleaning any dust or debris from ventilation areas.

- Ensuring that the lubrication system is functioning properly.

-

Noisy Operation:

Unusual sounds may indicate underlying problems. To address noise issues:

- Examine for loose components and tighten as necessary.

- Replace any worn bearings or seals.

- Use vibration-dampening mounts if applicable.

-

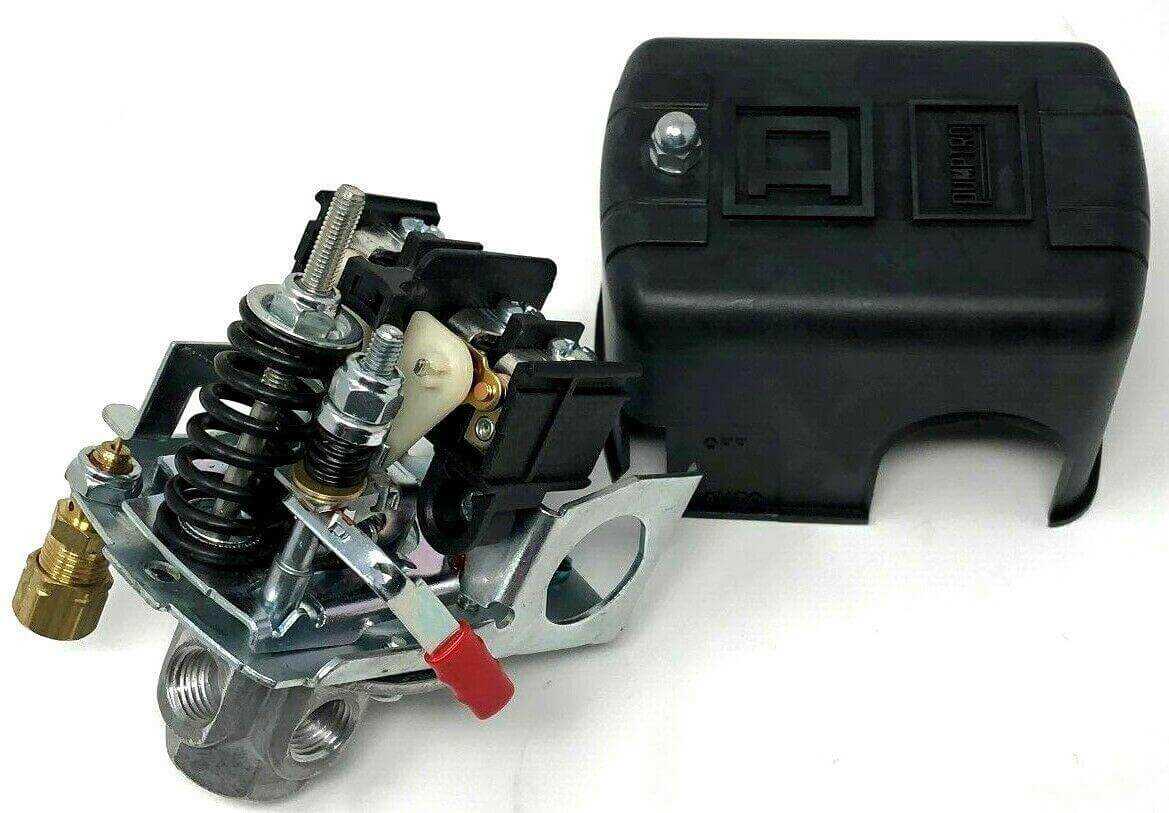

Frequent Start/Stop Cycles:

This can be frustrating and may signal inefficiency. Consider the following solutions:

- Check the pressure switch settings.

- Ensure that the tank is not overfilled with moisture.

- Inspect for clogs in the air filter.

By addressing these common problems with effective solutions, users can enhance the performance and reliability of their pneumatic systems.

Choosing Replacement Parts Wisely

When it comes to maintaining your equipment, making informed choices about components is crucial for optimal performance and longevity. Selecting the right alternatives can prevent future issues and ensure efficiency in operation.

Research is key. Before making any purchases, investigate various options available in the market. Look for reputable manufacturers and read reviews to gauge the reliability of each choice.

Compatibility should always be a priority. Ensure that the selected replacements fit seamlessly with your existing setup, as mismatches can lead to decreased functionality and even damage.

Consider cost-effectiveness. While cheaper options may seem appealing, they often compromise quality. Invest in durable items that provide value over time.

Lastly, keep in mind the importance of warranty. Components with a guarantee offer peace of mind, as they typically reflect the manufacturer’s confidence in their durability and performance.

Tools for Compressor Repair and Maintenance

Maintaining and repairing air machinery requires a set of specialized instruments designed to ensure optimal functionality and longevity. Having the right tools can significantly enhance efficiency and accuracy during service tasks.

Essential Tools

- Wrenches: Adjustable and socket types for various fasteners.

- Screwdrivers: Flathead and Phillips for diverse applications.

- Air Pressure Gauge: To monitor and adjust pressure levels accurately.

- Oil Filter Wrench: For easy removal and replacement of filters.

Safety Equipment

- Safety Glasses: To protect eyes from debris and particles.

- Gloves: For hand protection against sharp objects and chemicals.

- Ear Protection: To guard against loud noise levels during operation.

Upgrading Your Rolair Compressor

Enhancing your equipment can significantly boost its efficiency and longevity. By investing in advanced components and technology, you can transform your unit into a high-performance machine. This not only improves functionality but also provides a better return on investment.

Consider the benefits of replacing outdated elements. Upgrades such as improved motors or efficient pumps can lead to enhanced power output and reduced energy consumption. These changes not only optimize performance but also minimize wear and tear on the entire system.

Regular maintenance plays a crucial role in ensuring your machinery operates smoothly. Periodic checks and timely upgrades prevent unexpected breakdowns, allowing you to maintain peak performance. Staying proactive with enhancements can help you avoid costly repairs down the line.

Finally, research and select components that match your specific requirements. Each upgrade should align with your operational goals to achieve the ultimate performance. By choosing wisely, you can create a robust and reliable system that meets all your needs.

Safety Considerations During Repairs

When undertaking maintenance on machinery, ensuring safety is paramount. Proper precautions not only protect the individual performing the work but also safeguard the equipment itself. Understanding the potential hazards and implementing safety measures can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment (PPE) should always be worn. This includes gloves, goggles, and hearing protection as needed. Each of these items plays a crucial role in minimizing exposure to potential dangers, such as sharp edges or loud noises.

Before beginning any repair, it is essential to disconnect the power source. This simple step can prevent unexpected startups, which could lead to serious injuries. Additionally, familiarizing oneself with the specific machinery and its components can aid in identifying potential risks.

It is also wise to work in a well-ventilated area. Many tasks may generate harmful fumes or dust, so ensuring proper airflow can help maintain a safe working environment. Keeping the workspace organized and free of clutter reduces the likelihood of accidents caused by trips or falls.

Lastly, always consult the manufacturer’s guidelines and documentation. These resources provide valuable insights into safe handling and specific precautions necessary for the task at hand. By adhering to these recommendations, individuals can enhance their safety while performing necessary maintenance tasks.

Resources for Further Learning

Expanding your knowledge on machinery components can greatly enhance your understanding and efficiency in maintenance and repairs. There are various avenues available for those eager to delve deeper into this subject.

| Resource Type | Description | Link |

|---|---|---|

| Online Courses | Interactive lessons covering fundamentals and advanced topics in machinery. | Coursera |

| Books | Comprehensive guides offering insights into operational mechanics and troubleshooting. | Amazon |

| Forums | Community discussions providing real-world experiences and solutions. | |

| Webinars | Live sessions hosted by experts sharing latest trends and technologies. | LinkedIn Learning |