Drive Gear: This component helps

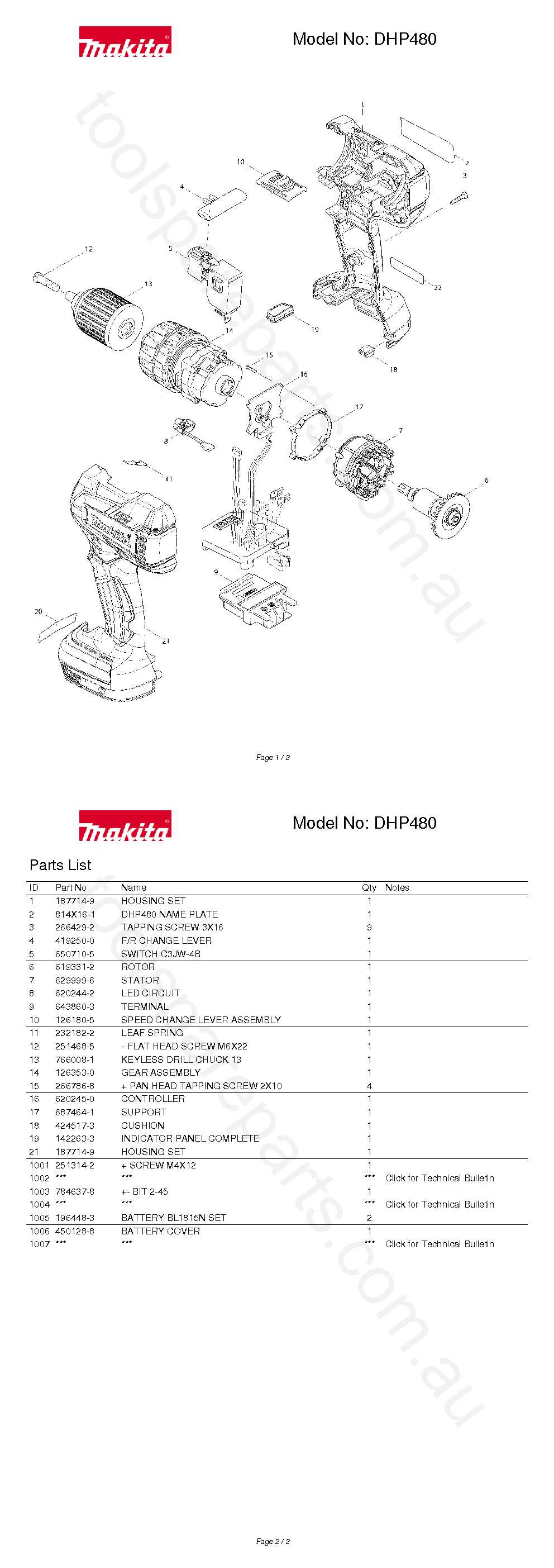

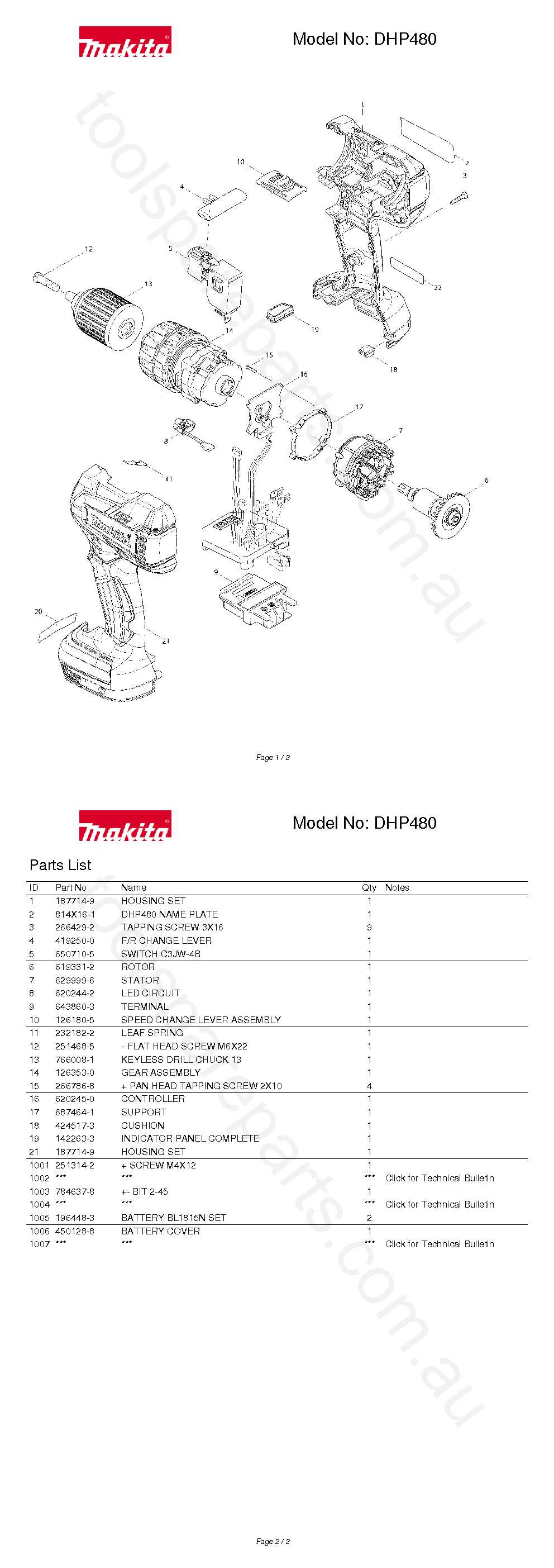

Key Features of the Motor Assembly

The motor assembly plays a critical role in ensuring smooth operation and power delivery. Its design incorporates various components working in unison to generate the necessary torque and speed for different tasks. Understanding the key elements of this system is essential for maintaining and optimizing performance.

Enhanced Durability

The motor unit is engineered for long-term use, with reinforced parts that can withstand heavy workloads. The durable materials used in its construction reduce wear and tear, contributing to the longevity of the tool. This focus on resilience ensures consistent output under demanding conditions.

Efficient Power Transfer

One of the standout characteristics of this motor assembly is its efficiency in transferring energy. The internal mechanisms are fine-tuned to minimize energy loss, ensuring that the power generated is used effectively. This allows for more precise control and reduces unnecessary strain on the system.

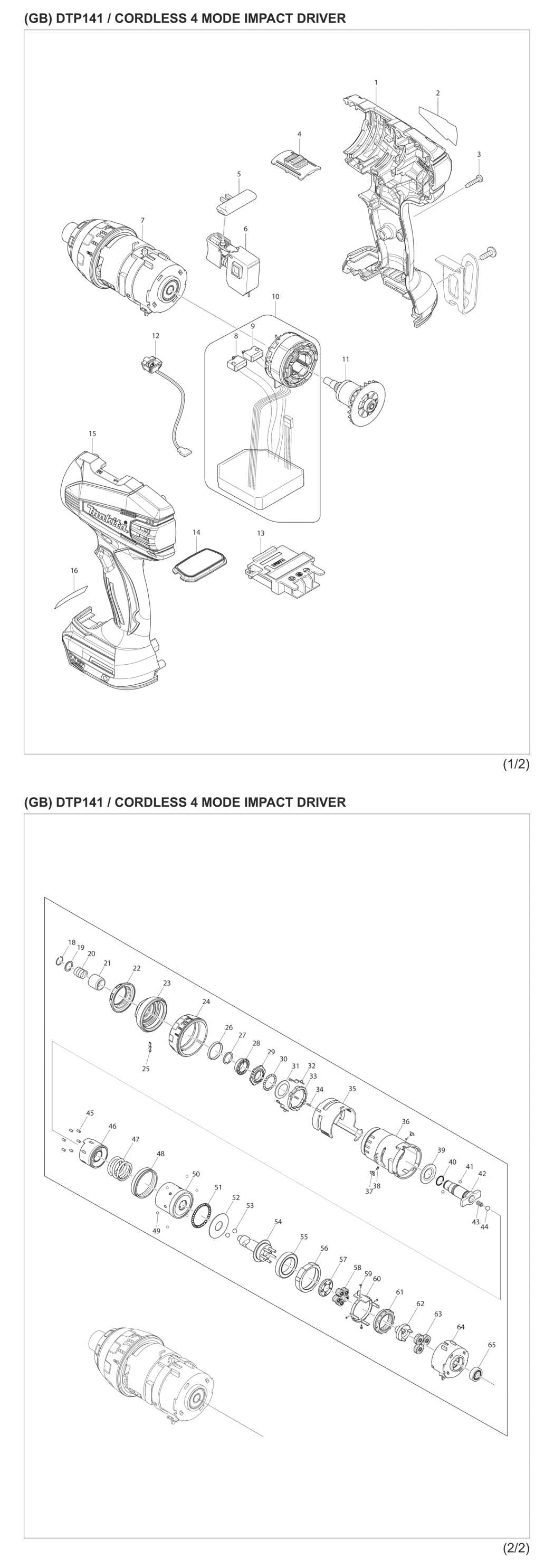

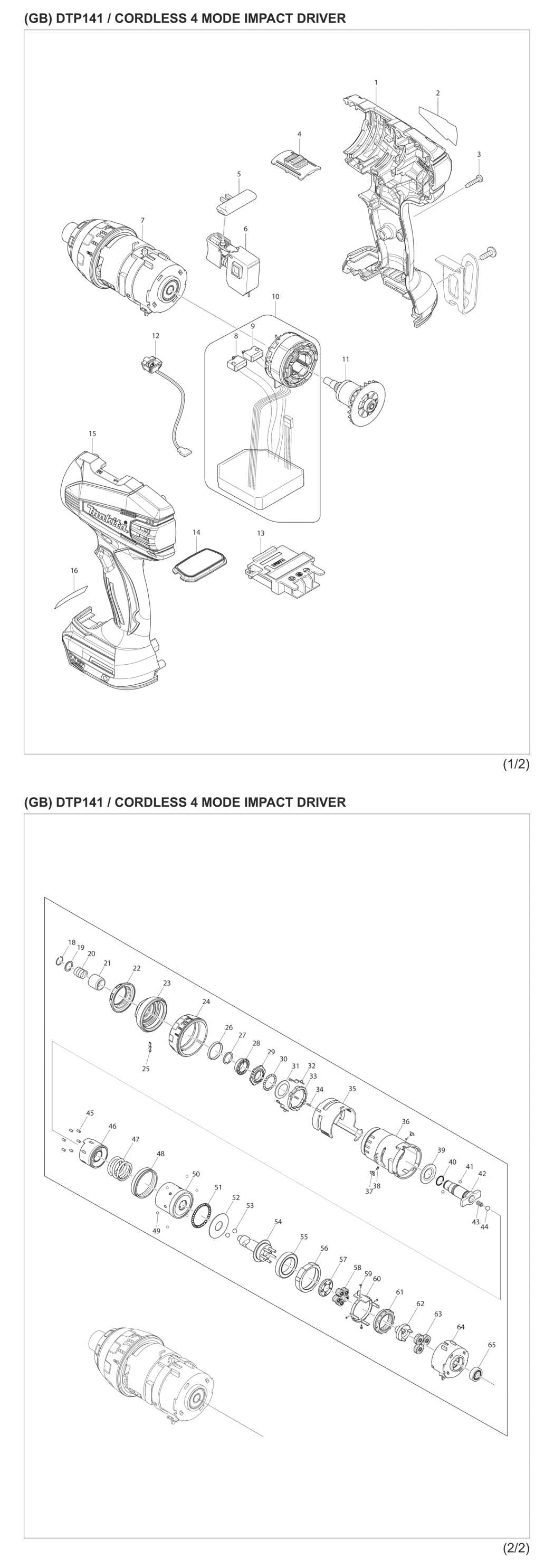

Understanding the Gearbox Structure

The gearbox serves a crucial role in the overall functionality of power tools, translating the motor’s speed into the appropriate torque for various tasks. A thorough comprehension of its structure can greatly enhance operational efficiency and maintenance practices.

Components of the Gear Mechanism

The primary elements within the gearbox include gears, shafts, and bearings. Gears are responsible for adjusting the rotational speed, while shafts transmit the power generated by the motor. Bearings facilitate smooth movement and support the gears, ensuring longevity and reliability.

Importance of Proper Assembly

Correct assembly of the gearbox components is vital for optimal performance. Misalignment or improper fitting can lead to increased wear and tear, resulting in potential failures. Regular inspection and understanding the intricate design can help in early detection of issues, ultimately extending the lifespan of the equipment.

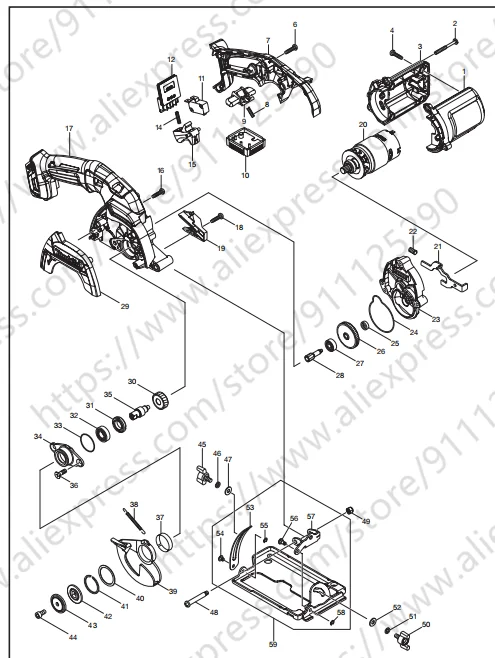

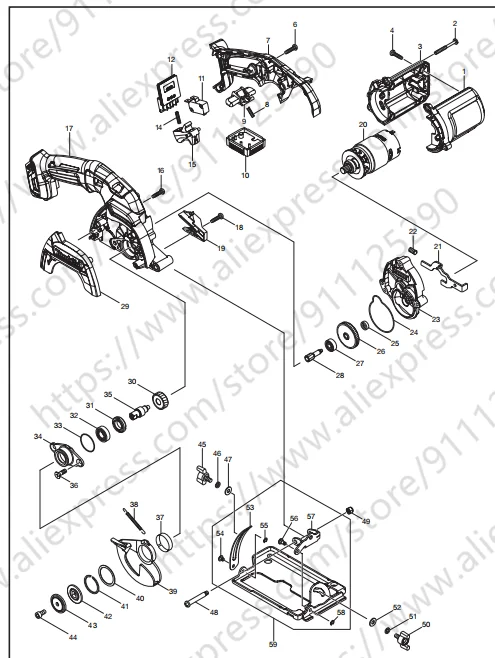

Trigger Mechanism and Its Role

The trigger mechanism is a crucial component in various power tools, serving as the interface between the user and the tool’s operation. This system enables precise control over the tool’s functions, allowing for a tailored response to different tasks. Understanding its workings can significantly enhance both efficiency and safety during use.

Functionality of the Trigger System

This mechanism operates by regulating the power delivery to the tool’s motor. When engaged, it translates the user’s input into actionable commands, thereby determining the speed and force of the tool’s operation. A well-designed trigger ensures smooth operation and minimizes the risk of accidental activation, enhancing overall user experience.

Importance of Maintenance

Regular maintenance of the trigger mechanism is essential for optimal performance. Over time, wear and tear can lead to reduced responsiveness or malfunction. Ensuring that the trigger system is free from debris and lubricated can prolong its lifespan and maintain the efficiency of the tool. Proper care not only improves functionality but also contributes to user safety.

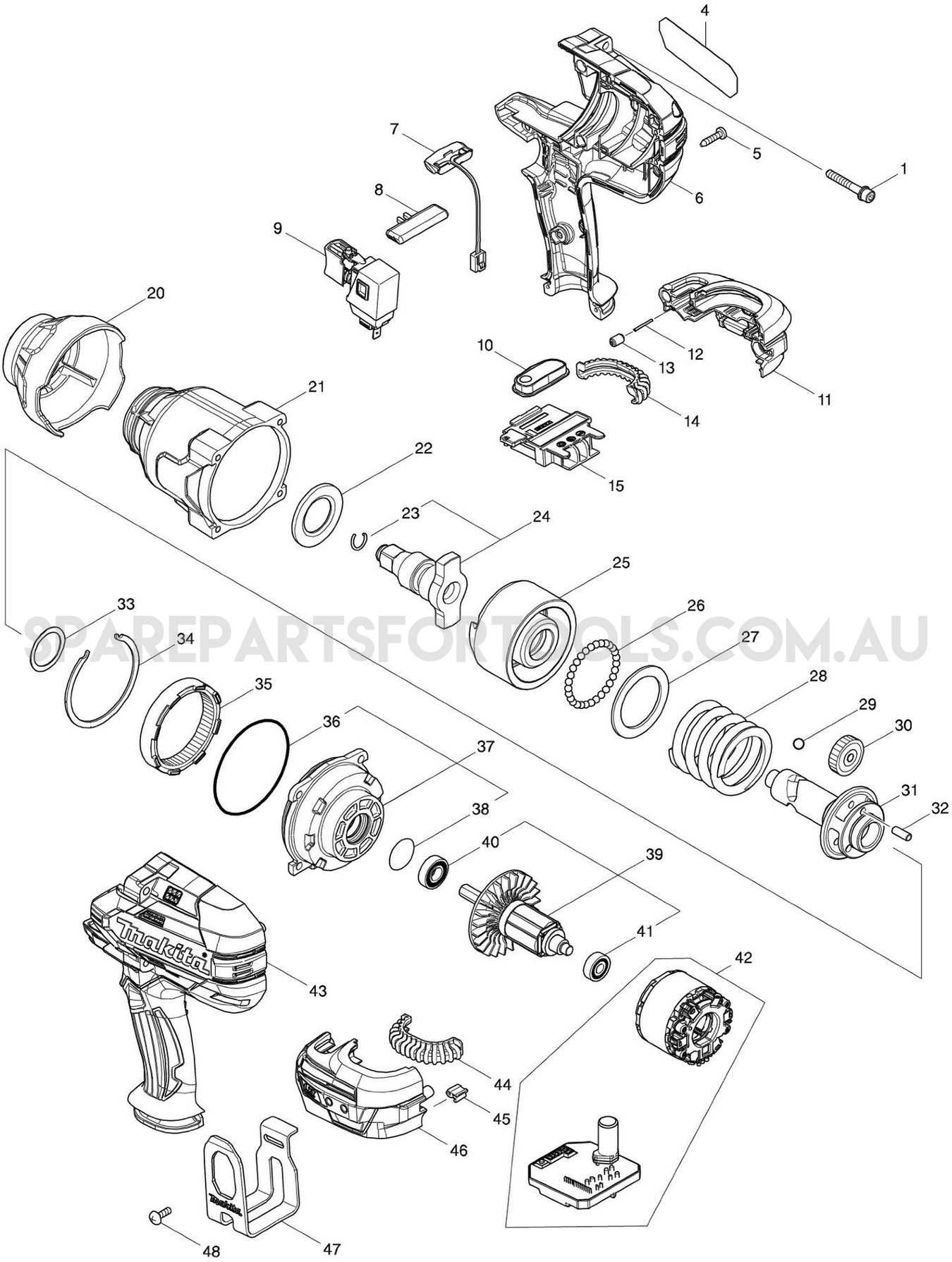

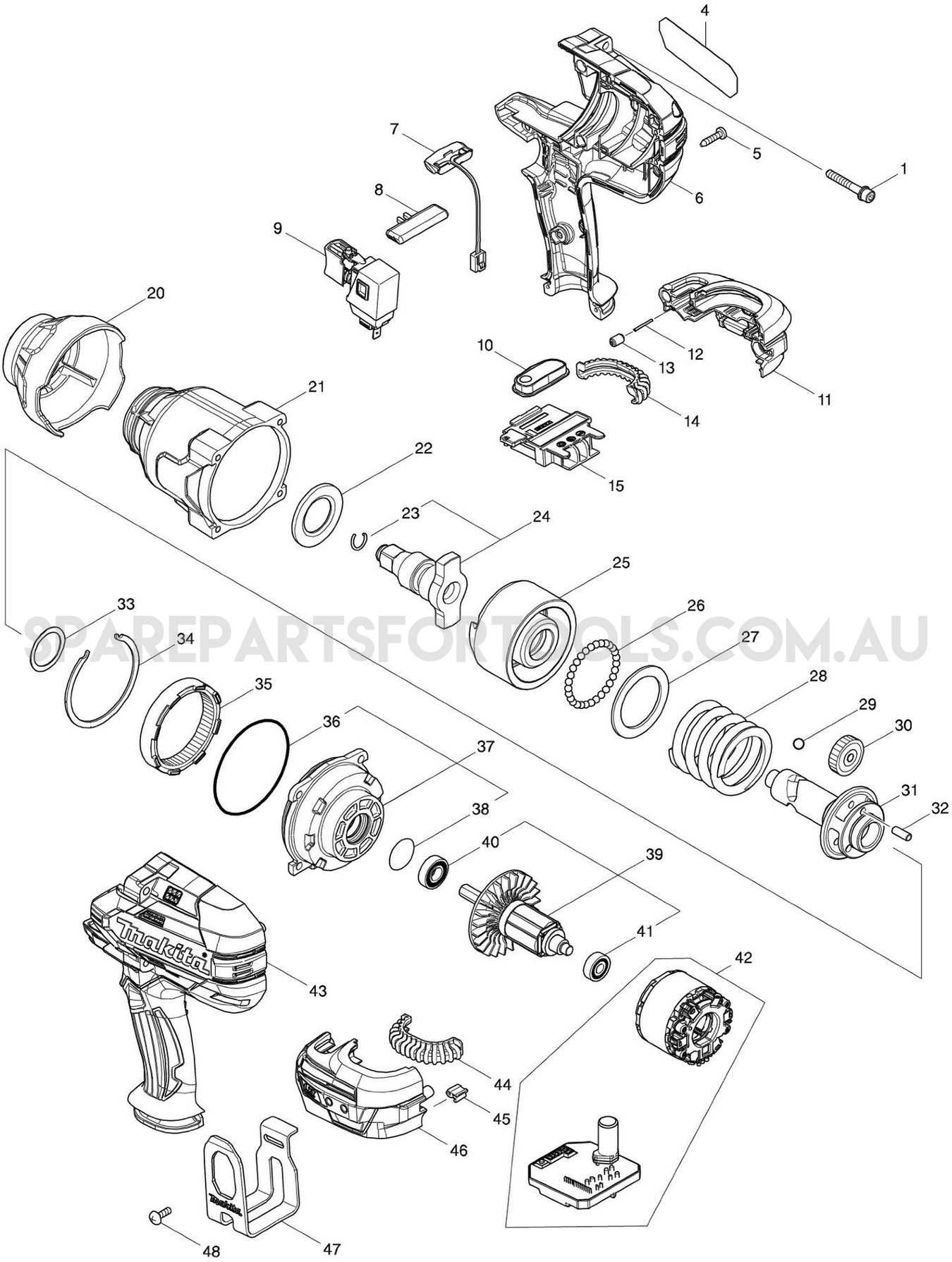

Exploring the Chuck and Its Function

The chuck is a crucial component in power tools, specifically designed to hold and secure various types of bits. This element plays a significant role in ensuring precision and stability during operations, making it essential for effective performance.

Typically found in drills and screwdrivers, the chuck allows for quick and easy bit changes, catering to different tasks and materials. Understanding its mechanics is vital for optimal usage and maintenance.

- Types of Chucks:

- Keyed Chucks: Require a special tool for tightening and loosening.

- Keyless Chucks: Allow for fast bit changes by hand, enhancing convenience.

- Functionality:

- Grip: Ensures a secure hold on the bit, preventing slippage during operation.

- Alignment: Aids in aligning the bit with the workpiece for accurate drilling or driving.

- Maintenance Tips:

- Regularly clean the chuck to remove debris and dust.

- Inspect for wear and tear, replacing it when necessary.

In conclusion, the chuck is an indispensable part of power tools, directly impacting their efficiency and user experience. Proper understanding and care can significantly enhance the functionality of these tools.

Switch Assembly and Control System

The switch assembly and control system are essential components of power tools, allowing for efficient operation and user interaction. These parts work in tandem to regulate the tool’s functions, ensuring optimal performance and safety during use. Understanding the various elements involved in this system can enhance maintenance and troubleshooting efforts.

Key Components

- Trigger Switch: This component enables the user to activate and deactivate the tool, providing precise control over its operation.

- Speed Control Mechanism: It allows for adjustment of the tool’s speed, catering to different materials and applications.

- Electrical Connectors: These ensure proper connectivity between the switch assembly and the power source, facilitating reliable operation.

- Housing: The protective casing that encases the internal components, safeguarding them from damage and contamination.

Functionality and Maintenance

The functionality of the switch assembly and control system directly impacts the efficiency and longevity of the power tool. Regular inspection and maintenance of these components are crucial for preventing malfunctions. Here are some tips for proper upkeep:

- Check for any signs of wear or damage on the trigger switch and connectors.

- Ensure that the speed control mechanism is functioning smoothly without any resistance.

- Clean the housing regularly to prevent dust and debris buildup.

- Consult the user manual for specific maintenance guidelines related to your tool.

Battery Housing and Power Flow

The structure that encases the energy source is crucial for the efficient functioning of any power tool. This enclosure not only protects the internal components but also facilitates a seamless connection between the energy source and the tool’s motor, ensuring optimal performance during operation.

Energy distribution plays a vital role in the effectiveness of a tool. The flow of power from the energy source to the operational mechanisms is designed to minimize energy loss while maximizing output. Proper alignment and secure connections within the housing ensure that energy transfer occurs without interruptions, allowing the tool to perform at its best.

Maintenance of the battery housing is essential for long-term functionality. Regular checks for wear and tear, along with ensuring the connections are clean and secure, can significantly extend the life of the energy source and improve overall performance. A well-maintained enclosure not only safeguards the energy source but also enhances the efficiency of the tool it powers.

Protective Casing and Durability

When it comes to power tools, the robustness of their protective casing plays a crucial role in ensuring longevity and reliable performance. A well-engineered outer shell not only safeguards the internal components from external impacts but also enhances the overall usability of the tool.

Materials and Design

The choice of materials used in the construction of the casing significantly influences the tool’s resilience. Commonly utilized materials include:

- High-grade plastic: Lightweight yet strong, providing effective shock resistance.

- Metal reinforcements: Adding durability and protection against heavy-duty use.

- Rubberized grips: Enhancing handling and reducing the risk of slippage during operation.

Impact Resistance Features

To further improve durability, many models incorporate specific design elements aimed at absorbing shocks and minimizing wear:

- Reinforced corners: Designed to withstand drops and impacts.

- Weather-resistant coatings: Protecting against moisture and dust ingress.

- Ergonomic shapes: Ensuring comfort while enhancing grip stability.

These features collectively contribute to the reliability and extended lifespan of the tool, making it a valuable investment for both professionals and DIY enthusiasts.

Common Parts Replacements and Maintenance

Regular upkeep of power tools is essential for ensuring optimal performance and longevity. Over time, certain components may wear out and require replacement. Understanding which elements are most susceptible to damage can help users effectively maintain their equipment and avoid costly repairs.

Battery Packs are often among the first items to show signs of decline. Users should monitor their performance and consider replacement if they notice a significant decrease in charge retention. Regular cleaning of battery terminals can also enhance lifespan.

Chuck Mechanisms play a crucial role in securely holding drill bits. If users experience difficulty in tightening or loosening attachments, it may indicate wear and necessitate replacement. Proper lubrication and periodic inspection can help prolong the life of this component.

Brushes are essential for the electric motor’s function. Over time, they can become worn down, affecting tool efficiency. Routine checks can identify the need for replacement, ensuring consistent power delivery and performance.

Incorporating these maintenance practices and being proactive about replacing worn components will lead to enhanced functionality and reliability of the equipment.

Troubleshooting Tips for Makita DHP481

When dealing with power tools, understanding common issues and solutions can enhance the user experience and extend the tool’s lifespan. Identifying problems early on is crucial to maintaining optimal performance and efficiency.

Common Issues and Solutions

One frequent problem users encounter is a lack of power. This may be due to a drained battery or a faulty connection. Ensure that the battery is fully charged and securely attached. If the issue persists, inspect the contacts for any dirt or corrosion that may impede electrical flow.

Performance Optimization

To achieve better performance, regularly check the tool for any signs of wear and tear. Lubrication of moving parts can prevent overheating and reduce friction, enhancing overall functionality. Additionally, keeping the device clean from dust and debris will help maintain its efficiency.