Mansfield 160 Parts Diagram Overview

In the realm of mechanical design, comprehending the intricate components that make up a system is essential for effective maintenance and troubleshooting. By exploring the various elements that contribute to the overall functionality, one can gain insights into how these pieces work in harmony.

Such a detailed exploration not only aids in identifying potential issues but also enhances one’s ability to perform repairs and upgrades. A well-organized visual representation can serve as an invaluable reference for both novice and experienced technicians alike.

Ultimately, having access to a comprehensive overview allows for a deeper appreciation of the engineering behind the machinery. This understanding fosters a greater level of confidence when engaging with the equipment, leading to more efficient and effective operations.

Mansfield 160 Overview

This section provides a comprehensive look at a specific model known for its efficiency and functionality in various applications. The design emphasizes reliability, making it a preferred choice among users seeking durability and performance.

Key Features

The highlighted model boasts a range of innovative attributes, including user-friendly operation and robust construction. These elements contribute to its overall effectiveness, making it suitable for both residential and commercial settings.

Applications

This equipment finds utility in numerous scenarios, catering to a diverse audience. Its versatility allows it to adapt seamlessly to different environments, ensuring optimal results in every use case.

Understanding Parts Diagrams

Visual representations serve as essential tools for comprehending the intricate relationships between various components within a mechanical system. They allow users to identify each element’s function and location, ultimately facilitating efficient assembly, maintenance, and troubleshooting.

The Importance of Visual Guides

- Enhances clarity by showing how components fit together.

- Assists in identifying specific pieces when ordering replacements.

- Streamlines the assembly process by providing a clear reference.

How to Read Visual Representations

- Start by familiarizing yourself with the legend, which explains symbols and labels.

- Identify major sections to understand the overall layout.

- Follow the connections between elements to grasp their interdependencies.

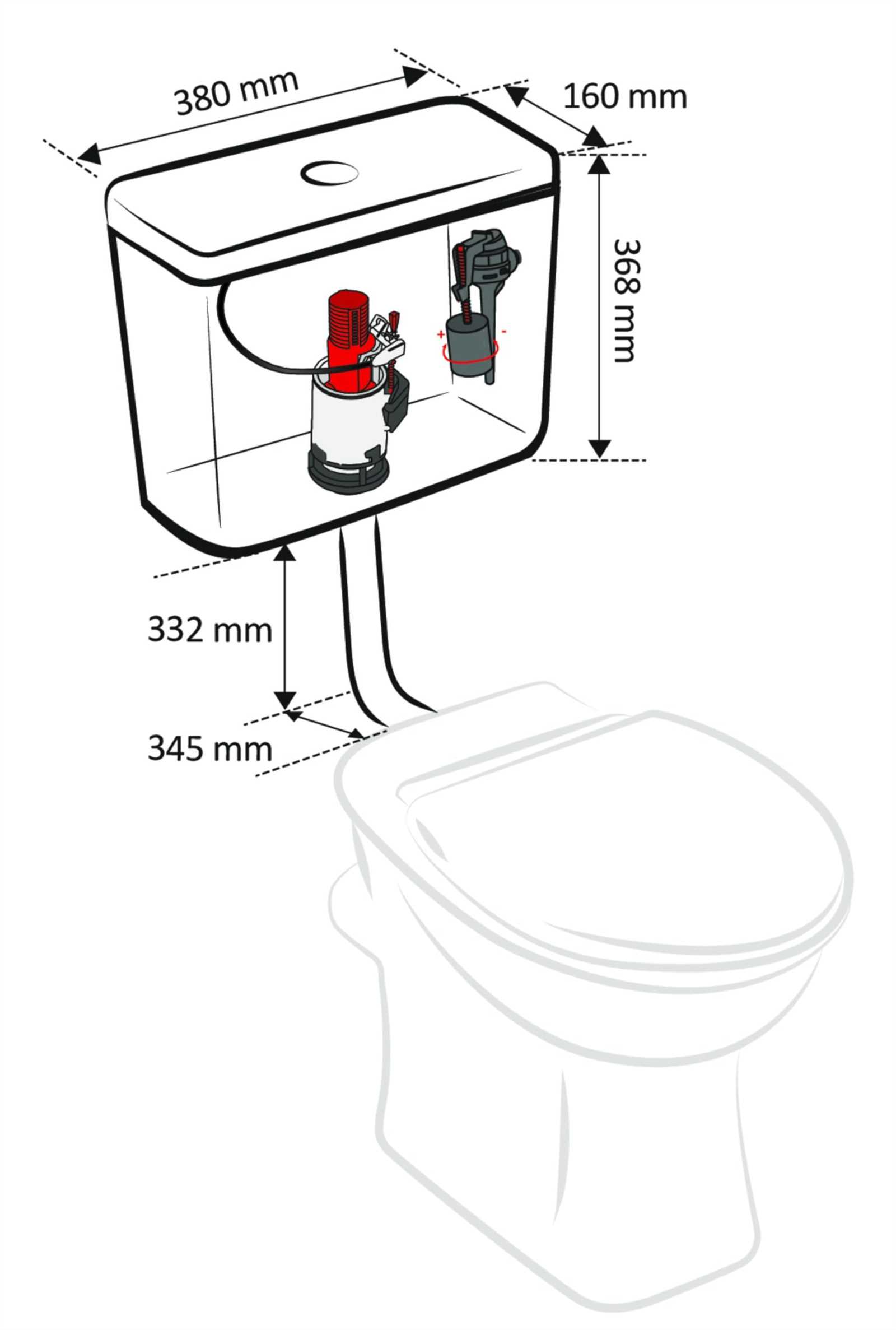

Key Components of Mansfield 160

This section explores the essential elements that contribute to the functionality and efficiency of a specific model in the plumbing industry. Understanding these crucial components enhances maintenance and troubleshooting efforts.

Main Features

- Body Structure

- Sealing Mechanisms

- Flow Control Valves

- Flush Mechanism

Operational Elements

- Water Supply Connections

- Drainage Outlets

- Adjustable Components

- Installation Accessories

Importance of Accurate Diagrams

Precise visual representations play a crucial role in various fields, providing clarity and enhancing understanding. When dealing with complex systems, having a well-detailed schematic is essential for effective communication and efficient problem-solving. Accurate illustrations ensure that all components are correctly identified and understood, which can significantly impact the overall functionality of any system.

Facilitating Communication

Well-crafted visuals serve as a universal language, bridging gaps between different stakeholders. They allow for clear discussions among technicians, engineers, and designers, minimizing the chances of misinterpretation. Effective communication reduces errors and streamlines workflows, leading to more successful outcomes.

Enhancing Troubleshooting and Maintenance

Detailed representations are invaluable during troubleshooting and maintenance processes. When issues arise, having a reliable reference helps technicians quickly pinpoint problems and execute repairs efficiently. Timely interventions can save both time and resources, emphasizing the necessity of maintaining accurate and up-to-date visuals in any operational context.

Common Issues with Mansfield 160

In the realm of plumbing fixtures, certain challenges frequently arise that can hinder functionality and performance. Understanding these common complications is crucial for ensuring efficient operation and maintaining overall satisfaction. This section explores prevalent problems encountered by users and offers insights for troubleshooting.

Frequent Leaks

One of the most common issues faced is the occurrence of leaks. These may stem from faulty seals or improper installation. Regular maintenance and timely repairs can significantly mitigate water wastage and prevent further damage.

Flush Inconsistencies

Another prevalent concern is inconsistent flushing. Users often report issues with incomplete flushing or weak performance. Addressing the issue usually involves checking the water supply and ensuring all components are functioning as intended.

How to Read Diagrams Effectively

Understanding visual representations can greatly enhance your ability to interpret complex information. By familiarizing yourself with the symbols, lines, and annotations used, you can quickly grasp the underlying structure and functions presented. This skill is invaluable in various fields, from engineering to art, as it allows you to analyze and communicate ideas with clarity.

Start by identifying the key components and their relationships within the illustration. Pay attention to legends and notes that provide context, as these often contain crucial insights. Breaking down the visual into smaller parts can help you piece together the overall concept more easily.

Practice is essential; the more you engage with these visuals, the more intuitive your understanding will become. Utilize resources that encourage exploration of different styles and layouts, enabling you to develop a flexible approach to reading representations. Ultimately, mastering this skill will enhance your efficiency in problem-solving and project execution.

Maintenance Tips for Optimal Performance

Ensuring peak functionality requires regular attention and care. By adhering to specific practices, one can significantly enhance the lifespan and efficiency of equipment.

- Regular Cleaning: Remove dirt and debris to prevent wear and tear.

- Check for Wear: Inspect components for signs of damage or degradation.

- Lubrication: Apply appropriate lubricants to moving parts to minimize friction.

- Fluid Levels: Monitor and maintain proper fluid levels to ensure smooth operation.

- Scheduled Inspections: Conduct periodic assessments to identify potential issues early.

Implementing these strategies will help achieve the ultimate performance and reliability of your equipment.

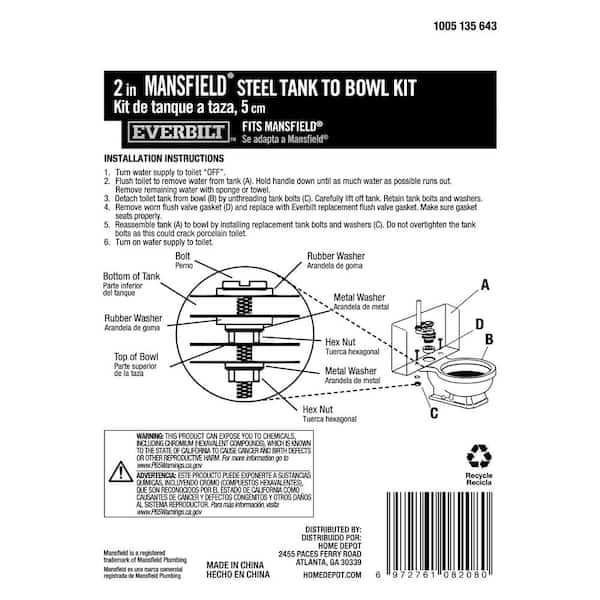

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a straightforward process with the right approach. Understanding where to search and what resources to utilize is essential in ensuring you find exactly what you need without unnecessary delays. Whether you’re a professional or a DIY enthusiast, having a reliable strategy will save you time and effort.

Online Resources are one of the most convenient ways to discover the necessary components. Numerous websites specialize in offering extensive catalogs, making it easy to browse through options based on your specific requirements. Always check for detailed specifications and compatibility to ensure you select the right item.

Local Retailers also play a vital role in your search. Building a rapport with suppliers can lead to valuable insights about availability and alternatives that may not be listed online. Visiting physical stores allows you to examine products firsthand and consult with knowledgeable staff who can provide recommendations tailored to your situation.

In addition, community forums and social media groups dedicated to your equipment type can be invaluable. Engaging with fellow users often yields suggestions on where to find hard-to-locate items, along with tips on installation and maintenance. Sharing experiences helps create a supportive network that can enhance your overall knowledge.

Lastly, keeping track of your equipment’s model number and specifications simplifies the search process significantly. When you have this information at hand, you can quickly narrow down options and avoid any confusion. With these strategies in mind, you’ll be well-equipped to find what you need efficiently.

Tools Needed for Repairs

When undertaking any repair task, having the right equipment is essential for achieving optimal results. Proper tools not only facilitate the process but also ensure safety and efficiency. Understanding which instruments are necessary can make all the difference between a successful repair and a frustrating experience.

Essential Hand Tools

Basic hand tools are the backbone of any repair project. Screwdrivers, wrenches, and pliers are crucial for assembling and disassembling components. Additionally, a sturdy hammer can be invaluable for adjustments, while a reliable measuring tape aids in precise alignments.

Power Tools for Efficiency

For more extensive repairs, power tools significantly enhance productivity. A drill is essential for making holes, while a saw can expedite cutting tasks. Using a sander can help achieve a smooth finish, making the entire process faster and more effective.

Comparing with Other Models

In the realm of machinery, evaluating various models against one another provides valuable insights into performance, efficiency, and usability. By analyzing different designs, users can identify unique features, advantages, and potential drawbacks that may influence their decision-making process.

One key aspect to consider is the design philosophy of each unit. While some prioritize compactness and ease of use, others focus on durability and power. For instance, certain alternatives might incorporate advanced materials that enhance longevity, whereas others may offer simpler maintenance procedures that appeal to users seeking convenience.

Moreover, performance metrics such as speed, energy consumption, and output quality can vary significantly among models. This diversity allows users to select the option that best aligns with their operational needs, whether it involves high-volume tasks or precision work.

Additionally, accessories and compatibility with existing equipment can be crucial factors. Some machines boast a wider range of attachments and upgrades, providing flexibility for users with evolving requirements. In contrast, others may be more limited in scope but excel in specific applications.

Ultimately, thorough comparisons enable users to make informed choices, ensuring they select the most suitable machine for their specific tasks and environments.

FAQs About Mansfield 160 Parts

This section addresses common inquiries regarding components and their functionalities. Understanding these elements can greatly enhance the experience of maintaining and utilizing plumbing fixtures.

| Question | Answer |

|---|---|

| What should I do if a component is leaking? | Check for worn-out seals or gaskets and replace them if necessary. Tightening connections may also resolve minor leaks. |

| How can I identify the right replacement for a broken part? | Refer to the manufacturer’s specifications or part numbers. Consulting an expert at a local hardware store can also be helpful. |

| Are there universal components available? | Some parts are designed to fit a variety of models, but it’s essential to verify compatibility to ensure proper function. |

| How often should components be inspected? | Regular inspections every six months are recommended to catch any wear and tear before they lead to significant issues. |

| What tools do I need for basic repairs? | A standard toolkit with wrenches, screwdrivers, and pliers should suffice for most maintenance tasks. |