Explore the Husqvarna 445 Parts Diagram for Ultimate Understanding

When it comes to maintaining the efficiency and longevity of your outdoor power equipment, having a clear grasp of its inner workings is essential. A comprehensive visual representation of its components can greatly enhance your ability to perform repairs and replacements with confidence.

By examining an illustrated overview, enthusiasts and professionals alike can delve into the specifics of each individual element. This not only aids in identifying issues but also ensures that every piece functions optimally for the ultimate performance.

In this guide, you will find a detailed exploration of the essential parts, their functions, and how they interact within the machinery. Armed with this knowledge, you can tackle maintenance tasks effectively and keep your equipment running smoothly.

Understanding Husqvarna 445 Parts

Familiarity with the components of your outdoor equipment is essential for effective maintenance and repair. Each element plays a crucial role in ensuring optimal performance and longevity. Recognizing how these pieces interact can help you troubleshoot issues and make informed decisions about replacements or upgrades.

Key Components

The primary elements include the engine assembly, fuel system, and cutting mechanism. Each part has specific functions that contribute to the overall efficiency of the machine. The engine, for example, is the heart of the system, providing the necessary power, while the fuel system ensures a smooth and reliable flow of energy. The cutting mechanism is vital for performance, influencing how well the device handles various tasks.

Maintenance Tips

Overview of Husqvarna 445 Chainsaw

This powerful cutting tool is designed for both professional and occasional users, providing an excellent balance of performance and usability. It features a robust engine that delivers impressive cutting speed, making it ideal for various tasks such as trimming, felling trees, and firewood preparation.

Key Features

Among its notable attributes are an ergonomic design and lightweight construction, which enhance user comfort during extended use. The advanced air injection system minimizes filter maintenance, allowing for longer operational intervals. Additionally, its easy start mechanism ensures quick and hassle-free ignition, even in challenging conditions.

Performance and Reliability

Engineered for durability, this model offers consistent performance across a range of applications. Its sharp chain and bar combination enables precise cuts, while the built-in safety features, such as the chain brake and low kickback design, provide added security for the user. This makes it a trustworthy choice for both seasoned professionals and newcomers to the world of forestry and landscaping.

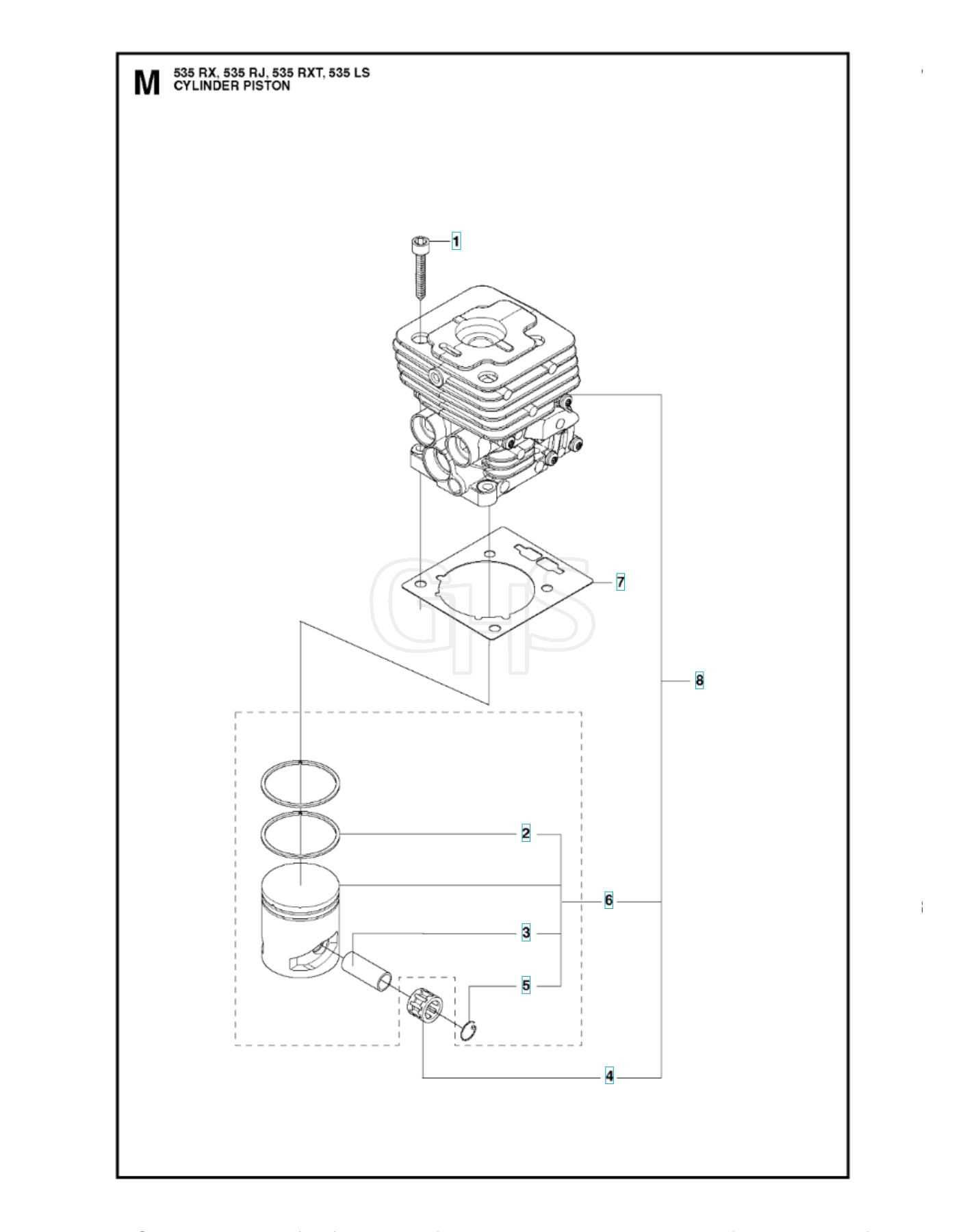

Main Components of the Chainsaw

The functioning of a cutting tool relies on several key elements that work in harmony to achieve optimal performance. Understanding these components is essential for effective maintenance and operation, ensuring safety and longevity.

| Component | Description |

|---|---|

| Engine | The power source that drives the saw, typically a two-stroke engine. |

| Bar | The metal blade that guides and supports the chain during cutting. |

| Chain | A loop of linked segments that rotates around the bar, performing the cutting action. |

| Fuel Tank | Stores the fuel necessary for the engine to operate. |

| Oil Tank | Contains lubrication oil that keeps the chain and bar functioning smoothly. |

| Handle | Provides a grip for the user, ensuring control and safety during operation. |

| Trigger | Controls the engine’s power and chain speed, allowing for precise cutting. |

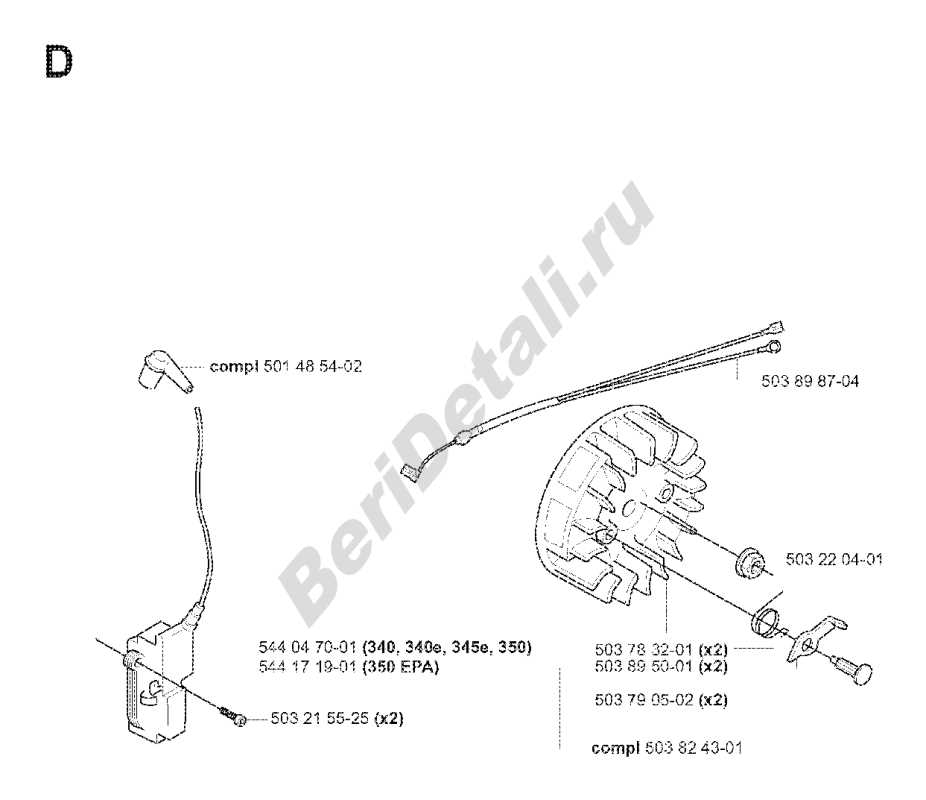

Importance of Parts Diagram

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. A visual representation allows users to quickly identify each element, facilitating troubleshooting and replacement processes. This clarity not only enhances operational knowledge but also minimizes downtime.

Moreover, such illustrations serve as invaluable references for both novice and experienced technicians, ensuring that repairs are executed accurately. By highlighting the relationship between various components, users can delve into the intricacies of the equipment, ultimately leading to improved performance and longevity.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Provides a clear view of how parts interact, aiding in comprehension. |

| Efficient Repairs | Streamlines the process, reducing the time needed for fixes. |

| Prevention of Errors | Minimizes the risk of incorrect assembly or replacements. |

| Resource for Training | Serves as a tool for educating new technicians. |

How to Read the Diagram

Understanding an assembly illustration is crucial for effective maintenance and repair. This visual guide breaks down components and their interconnections, allowing users to identify and locate parts efficiently. Mastery of this tool enhances your ability to troubleshoot and ensure optimal functionality.

Key Elements of the Illustration

Each segment of the visual representation typically includes labels, numbers, and references. Familiarizing yourself with these aspects will streamline the repair process.

Interpreting Symbols and Labels

Symbols used in the illustration often denote specific components, while accompanying labels provide essential details. Pay attention to these elements to grasp the overall layout.

| Symbol | Description |

|---|---|

| A | Engine assembly |

| B | Fuel system |

| C | Cutting mechanism |

Common Replacement Parts Explained

Understanding the essential components of outdoor power equipment is crucial for maintaining optimal performance. Regular wear and tear can necessitate the replacement of certain elements to ensure longevity and efficiency. This section delves into the most frequently replaced components, highlighting their functions and the signs that indicate they may need to be swapped out.

Key Components

- Chain: A vital part of cutting equipment, the chain experiences significant wear due to friction. Signs of damage include dullness or broken links.

- Guide Bar: This component supports the chain and can become worn down over time. Look for uneven wear or bending as indicators for replacement.

- Air Filter: Responsible for filtering out dirt and debris, a clogged air filter can hinder engine performance. Regular checks can prevent issues.

- Fuel Filter: Ensures that clean fuel reaches the engine. A dirty filter can cause starting problems or stalling.

- Spark Plug: Essential for ignition, spark plugs can wear out and affect starting and performance. A check every few months is advisable.

Maintenance Tips

- Regularly inspect components for wear and damage.

- Follow the manufacturer’s guidelines for maintenance schedules.

- Use quality replacement parts to ensure compatibility and longevity.

- Keep the equipment clean to reduce wear on all components.

Tools Needed for Maintenance

Regular upkeep of your equipment requires a selection of essential instruments to ensure optimal performance and longevity. Understanding which tools are necessary will streamline the maintenance process and help avoid potential issues down the line.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For tightening or loosening screws during assembly or repairs. |

| Wrench Set | To adjust nuts and bolts securely. |

| Oil Can | For lubricating moving parts to reduce friction. |

| Brush | To clean debris from components. |

| Safety Gear | Protective equipment like gloves and goggles to ensure safety during maintenance. |

Identifying Wear and Tear

Recognizing signs of deterioration in machinery components is essential for maintaining optimal performance and longevity. Regular inspections can help identify issues early, preventing further damage and costly repairs.

Common Signs of Deterioration

Look for specific indicators that suggest wear on various parts:

| Indicator | Description |

|---|---|

| Cracks | Visible fractures can weaken structural integrity. |

| Rust | Corrosion often signifies prolonged exposure to moisture. |

| Worn Edges | Edges that are rounded or missing material can affect functionality. |

| Discoloration | Changes in color can indicate overheating or chemical damage. |

Preventative Measures

To extend the life of components, implement a routine maintenance schedule that includes cleaning, lubrication, and timely replacements of worn parts.

Where to Find Genuine Parts

Ensuring the longevity and optimal performance of your outdoor equipment often requires sourcing authentic components. Genuine items guarantee compatibility and reliability, making maintenance and repairs more straightforward. Here are several avenues to explore when seeking original replacements.

Authorized Dealers

One of the most reliable sources for authentic components is through authorized retailers. They provide:

- Expert guidance on suitable parts for your machinery.

- Assurance of product authenticity and quality.

- Access to warranties and customer support.

Manufacturer’s Website

Visiting the official website of the manufacturer is another excellent option. Here, you can find:

- A comprehensive catalog of available items.

- Information on the latest releases and updates.

- Options for direct online purchasing.

Utilizing these resources will help ensure you obtain the right components, maintaining the performance and safety of your equipment.

Steps for Safe Disassembly

Disassembling machinery requires careful planning and execution to ensure safety and efficiency. By following systematic steps, you can prevent accidents and maintain the integrity of the components involved. The key is to approach the task methodically, ensuring all necessary precautions are taken before proceeding.

Preparation

Begin by gathering all required tools and safety gear. Ensure you have a clean workspace, free of distractions. Read the user manual to understand specific components and mechanisms. Label each part as you remove it to facilitate reassembly later.

Disassembly Process

Start with the outer casing, ensuring that all screws and fasteners are removed. Use appropriate tools to avoid damaging any parts. As you delve deeper into the assembly, take your time, and handle each component with care. If you encounter resistance, reassess your approach instead of forcing parts apart.

Reassembly Tips for Beginners

Reassembling machinery can be a rewarding experience, allowing you to gain a deeper understanding of its inner workings. For those just starting, a few practical tips can make the process smoother and more efficient. Carefully following these guidelines will help ensure that everything fits together correctly and functions as intended.

First, organize all components before you begin. Lay them out systematically to avoid confusion and ensure that no piece is overlooked. Using containers or trays can help keep small items together, reducing the risk of misplacement.

Next, refer to your reference materials frequently. Whether it’s an online guide, a manual, or diagrams, having access to visual aids can clarify how parts fit together. Take notes as you go, which can be invaluable for recalling the order of assembly.

During reassembly, take your time. Rushing can lead to mistakes, such as misaligning components or overtightening screws. Work methodically, checking each step before moving on to the next. If a piece doesn’t seem to fit, reassess rather than forcing it into place.

Lastly, don’t hesitate to seek assistance or watch tutorials. Engaging with more experienced individuals can provide insights and tips that are not immediately obvious. Learning from others can greatly enhance your confidence and skill in putting everything back together.

Common Issues and Troubleshooting

When working with outdoor power equipment, users often encounter a variety of common problems that can affect performance and efficiency. Understanding these issues and knowing how to troubleshoot them can save time and prevent further complications. This section outlines typical challenges and offers practical solutions to ensure smooth operation.

Engine Performance Problems

One of the most frequent issues involves engine performance. Symptoms such as difficulty starting, stalling, or a lack of power can stem from various causes. Fuel quality is crucial; using stale or contaminated fuel can lead to poor combustion. Additionally, check the air filter; a clogged filter restricts airflow and can cause the engine to struggle. Regular maintenance and cleaning can prevent these problems from arising.

Cutting and Trimming Issues

Another area of concern is related to cutting efficiency. If the cutting blade does not operate smoothly or leaves uncut areas, it may indicate dullness or misalignment. Sharpening the blade regularly is essential for optimal performance. Furthermore, ensure that the cutting attachment is securely fastened and properly adjusted to the manufacturer’s specifications. These simple steps can significantly improve the effectiveness of the equipment.

Maintaining Your Chainsaw for Longevity

Proper upkeep is essential for ensuring the long-term performance and reliability of your cutting tool. Regular maintenance not only enhances efficiency but also extends the lifespan of the equipment, allowing you to tackle more tasks with confidence.

To achieve optimal functioning, consider the following maintenance tips:

- Regular Cleaning: After each use, clean the exterior and remove any debris to prevent buildup.

- Chain Tension: Check and adjust the tension frequently to avoid wear and tear on the guide bar.

- Sharpening the Chain: Keep the cutting edges sharp for efficient cutting and to reduce strain on the motor.

- Fuel Quality: Use high-quality fuel and mix oil appropriately to ensure smooth operation.

- Inspection of Components: Regularly check the bar, chain, and other parts for signs of damage or wear.

Implementing these practices will not only enhance performance but also save on costly repairs and replacements in the future.