Comprehensive Guide to John Deere 116 Parts Diagram

In the realm of agricultural equipment, a comprehensive grasp of the various elements that make up these complex machines is crucial for effective maintenance and repair. Familiarity with each component not only ensures optimal performance but also prolongs the lifespan of the machinery.

By delving into the intricate arrangements and interconnections of these essential features, operators can enhance their understanding of how their equipment functions. This knowledge is invaluable for troubleshooting issues and facilitating timely repairs, ultimately leading to improved productivity in the field.

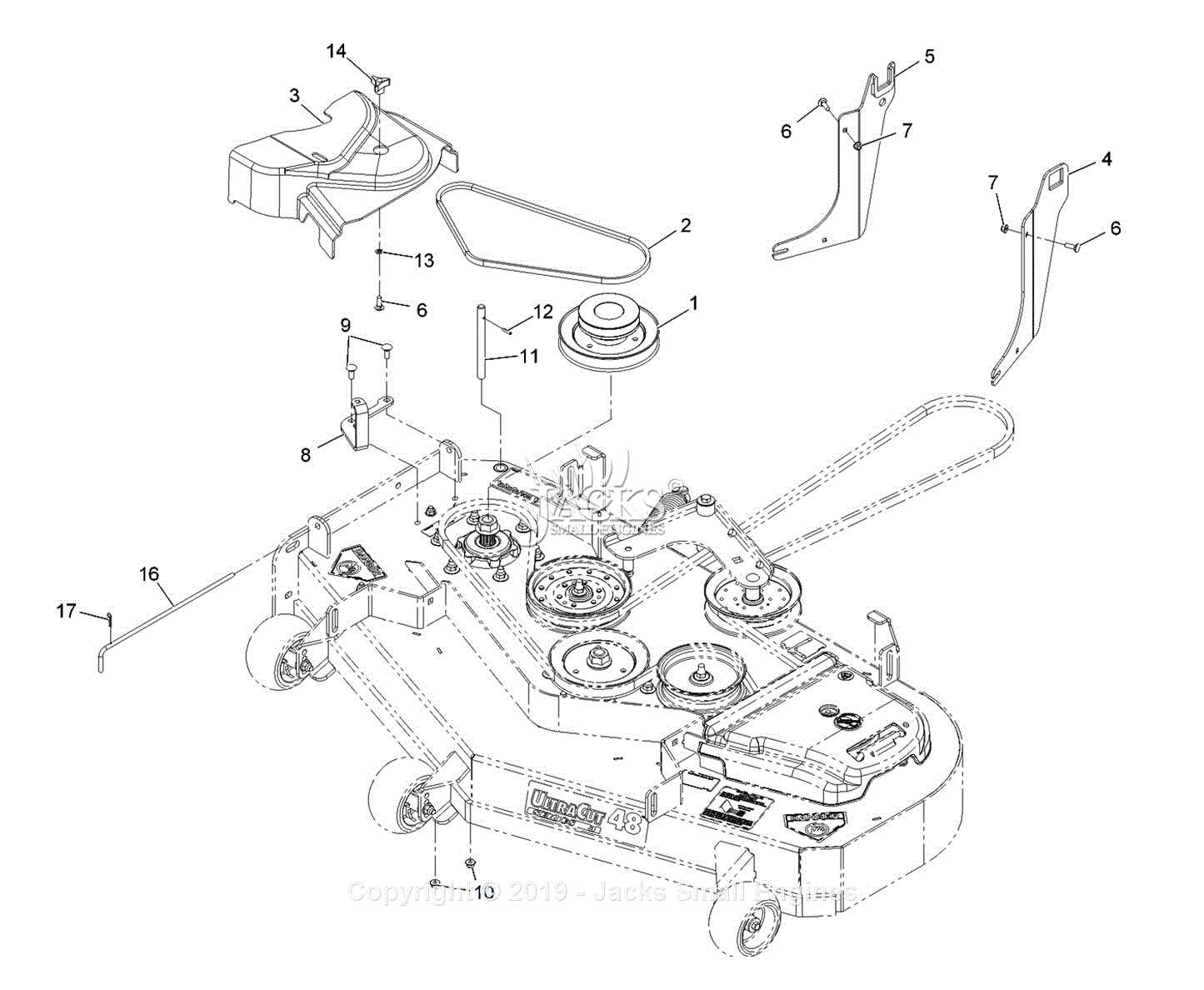

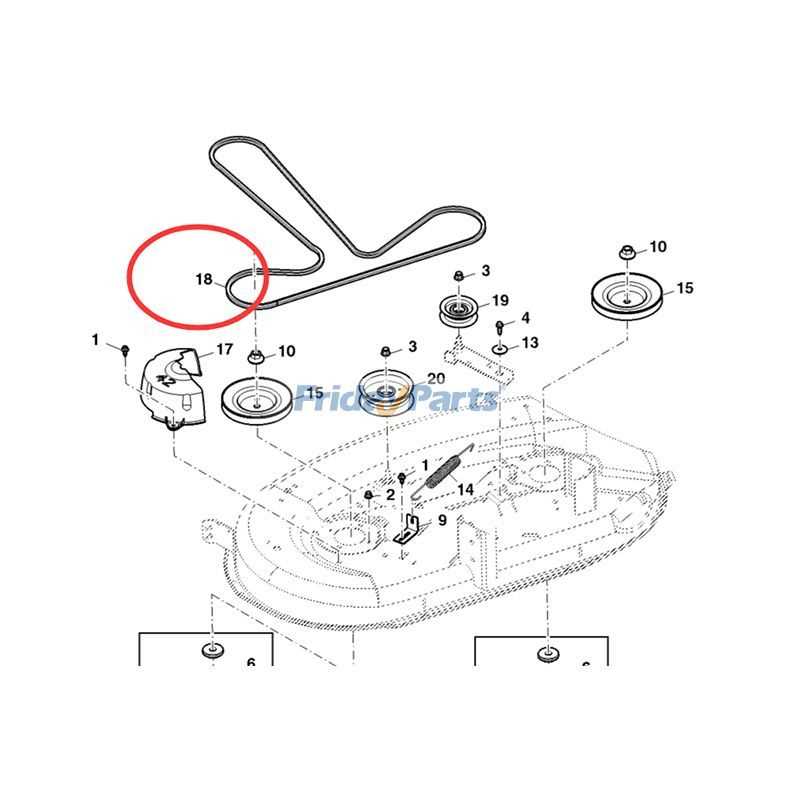

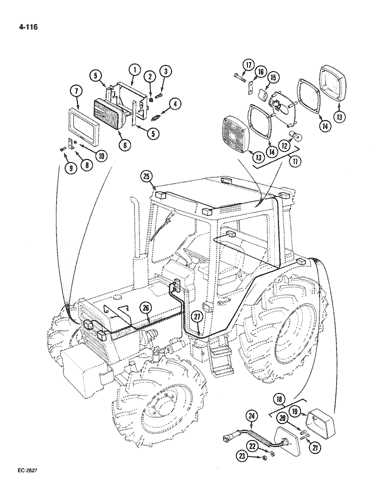

In this section, we will explore the visual representation of the mechanical components, providing insights into their specific roles and relationships. Such an overview will aid users in identifying necessary replacements and making informed decisions regarding maintenance and upgrades.

Understanding John Deere 116 Parts

Gaining insight into the components of agricultural machinery is essential for optimal performance and maintenance. Knowing how each element functions and interacts can significantly enhance the longevity and efficiency of your equipment. This section delves into the various segments that constitute this specific model, providing clarity on their roles and importance.

Key Components

- Engine Assembly

- Transmission System

- Hydraulic Mechanism

- Control Panel

- Chassis Structure

Each of these elements plays a crucial role in the overall operation of the machinery. Understanding their specific functions can help in troubleshooting and performing necessary repairs.

Maintenance Tips

- Regularly check fluid levels to ensure proper operation.

- Inspect belts and hoses for signs of wear.

- Keep components clean to prevent buildup that can affect performance.

- Refer to the manufacturer’s guidelines for part replacements.

By following these maintenance tips and familiarizing yourself with the essential components, you can ensure that your equipment remains in peak condition, ready to tackle any task efficiently.

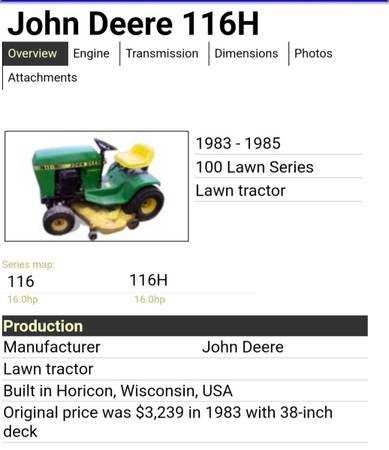

Overview of John Deere 116 Model

This section provides a comprehensive look at a popular agricultural machine, known for its efficiency and versatility in various farming tasks. The model is designed to meet the needs of both small-scale and larger operations, ensuring that users can achieve optimal performance across different terrains and conditions.

Key Features

- Powerful engine for enhanced productivity

- User-friendly controls for ease of operation

- Durable construction for long-lasting use

- Versatile attachments available for diverse applications

Applications

- Crop cultivation and soil preparation

- Landscaping and maintenance of green spaces

- Transporting materials across farms

- Assisting in harvesting processes

With a reputation for reliability, this machine remains a preferred choice among agricultural professionals, ensuring efficiency in various tasks while minimizing downtime and maintenance costs.

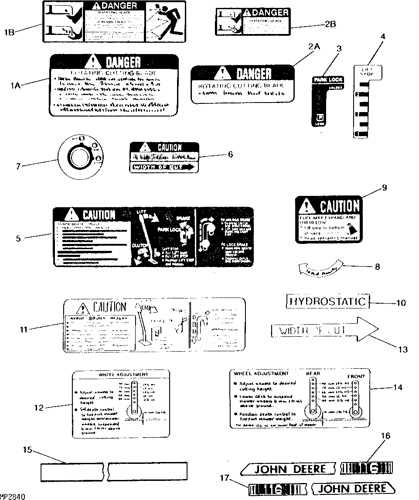

Importance of Parts Diagrams

Understanding the components of machinery is crucial for efficient maintenance and repair. Visual representations play a vital role in this process, allowing users to quickly identify each element and its function. These illustrations serve as essential tools for technicians and owners alike.

Utilizing these visual guides offers numerous advantages:

- Enhanced Clarity: Diagrams simplify complex structures, making it easier to comprehend how parts interact.

- Streamlined Repairs: Technicians can locate specific components swiftly, reducing downtime during maintenance.

- Accurate Ordering: Knowing the exact names and positions of components helps in ordering replacements correctly.

- Informed Upgrades: Users can assess which parts may require enhancements for improved performance.

Moreover, these visuals facilitate training for new personnel, ensuring they grasp the essential functions of various elements within the machinery. This foundational knowledge can lead to more effective troubleshooting and repairs.

In summary, visual guides are indispensable for anyone involved in the upkeep and operation of machinery. They not only enhance understanding but also promote efficiency and accuracy in maintenance tasks.

Common Parts for John Deere 116

This section highlights essential components frequently associated with a popular agricultural machine. Understanding these elements is crucial for maintenance and repair, ensuring optimal performance and longevity.

Among the fundamental components, the engine assembly stands out, as it powers the entire unit. Regular checks and timely replacements can prevent major issues.

The cutting deck is another vital section, impacting the efficiency of operations. Keeping blades sharp and free of debris enhances the machine’s effectiveness.

Transmission gears play a significant role in delivering power to the wheels, allowing for smooth maneuverability across various terrains. Proper lubrication and inspection can prolong their lifespan.

Additionally, the electrical system, including the battery and wiring, is essential for starting and operating the equipment. Ensuring connections are secure and free from corrosion will help maintain reliable functionality.

Lastly, wheels and tires provide stability and traction, making them crucial for effective operation. Regular inspection for wear and tear will contribute to safer and more efficient performance.

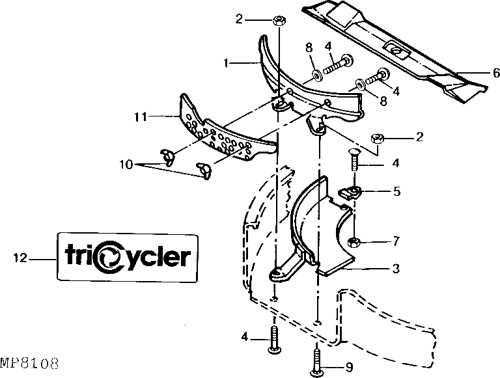

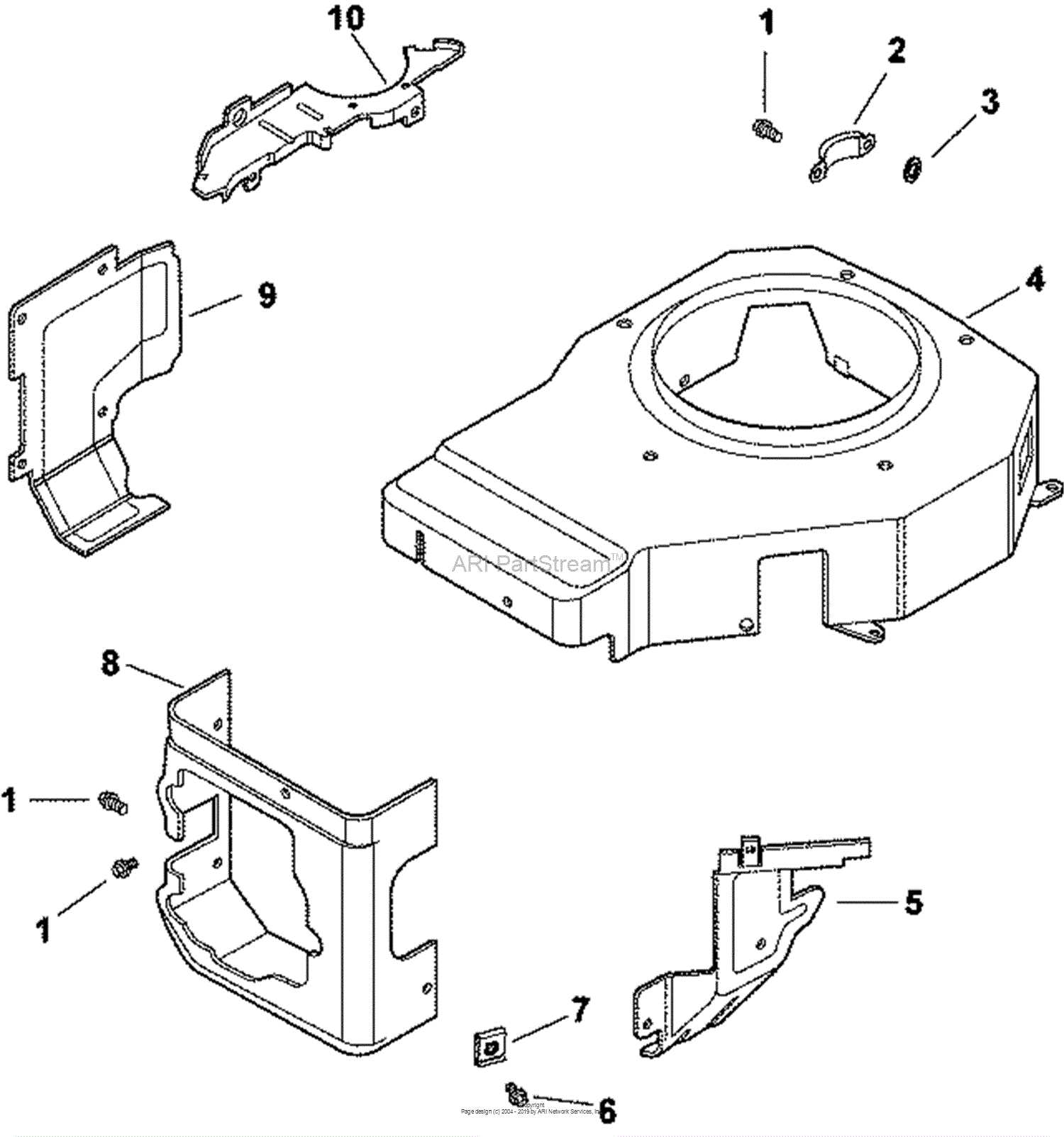

How to Read Parts Diagrams

Understanding visual representations of components is essential for anyone looking to maintain or repair machinery. These illustrations provide a clear layout of various elements, allowing users to identify and locate each piece efficiently. By mastering this skill, you can streamline the maintenance process and enhance your overall knowledge of the equipment.

Begin with the Legend: Most illustrations include a legend or key that explains symbols and numbers associated with each element. Familiarizing yourself with these references is crucial for accurate interpretation.

Identify Key Components: Look for major sections within the visual. Often, the largest parts will be positioned prominently, serving as the foundation for smaller items. Recognizing these primary elements helps in understanding how everything fits together.

Trace Connections: Pay attention to lines and arrows that indicate relationships between different components. These connections often represent how pieces interact, providing insight into assembly and disassembly processes.

Consult Additional Resources: If certain symbols or parts are unclear, don’t hesitate to seek further information. Manufacturer manuals, online forums, or community groups can offer valuable insights to enhance your understanding.

Practice Makes Perfect: Like any skill, reading these visuals becomes easier with practice. Regularly working with different representations will improve your ability to quickly and accurately identify components.

Tools Needed for Repairs

When it comes to performing maintenance and fixing machinery, having the right tools at your disposal is essential for efficiency and effectiveness. A well-equipped toolkit not only facilitates the repair process but also ensures safety and accuracy. Below is a list of indispensable instruments that will help you tackle various tasks with confidence.

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening or loosening nuts and bolts. |

| Screwdrivers | Essential for driving screws and performing intricate adjustments. |

| Pliers | Helpful for gripping, twisting, and cutting wire. |

| Socket Set | Facilitates easier access to hard-to-reach fasteners. |

| Torque Wrench | Ensures that fasteners are tightened to the specified torque. |

| Hammer | Used for driving nails or adjusting components. |

| Multimeter | Measures electrical properties and assists in diagnosing issues. |

Equipping yourself with these tools will prepare you for a range of repair tasks, allowing you to maintain and enhance the functionality of your equipment.

Where to Find Replacement Parts

When it comes to maintaining machinery, sourcing the correct components is essential for ensuring optimal performance and longevity. A variety of avenues exist for acquiring the necessary items, catering to different preferences and requirements.

Online Retailers

Shopping online has become a popular choice for many. Numerous platforms offer an extensive selection of components, often with competitive pricing. Consider the following options:

- Dedicated machinery parts websites

- Large e-commerce platforms

- Specialty shops focusing on agricultural equipment

Local Suppliers

For those who prefer a more hands-on approach, local suppliers can be invaluable. They provide the advantage of immediate access and personalized service. Look into these resources:

- Authorized dealers for direct access to official components

- Local repair shops that might have spare items

- Farm and machinery expos that often feature vendors

Regardless of the method chosen, ensuring compatibility with your equipment should be a priority to avoid future issues.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. By implementing effective maintenance practices, you can significantly extend its operational lifespan and enhance performance. Here are some essential tips to keep your machinery running smoothly.

- Regular Inspections: Conduct routine checks to identify any wear or damage early on.

- Keep it Clean: Remove dirt, debris, and residue to prevent buildup that can affect functionality.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear.

- Check Fluids: Regularly monitor and replace oils, coolant, and other fluids as necessary.

By adhering to these practices, you can help ensure optimal performance and reduce the likelihood of costly repairs.

- Follow Manufacturer Guidelines: Always refer to the recommended maintenance schedule and guidelines provided by the manufacturer.

- Store Properly: When not in use, keep your equipment in a dry, sheltered location to protect it from the elements.

- Use Quality Parts: When replacements are needed, choose high-quality components that meet or exceed original specifications.

Consistency in maintenance will not only enhance efficiency but also ensure reliability over the long term.

Typical Issues with John Deere 116

Common challenges faced by users of this well-known brand’s equipment can range from mechanical failures to maintenance oversights. Understanding these issues can help enhance performance and longevity.

- Engine Problems:

- Starting difficulties due to battery issues.

- Overheating from coolant leaks or blocked cooling fins.

- Transmission Issues:

- Shifting problems caused by worn components.

- Slippage when under load, often due to fluid contamination.

- Electrical Failures:

- Malfunctions in the ignition system affecting performance.

- Faulty wiring leading to inconsistent operation of accessories.

- Hydraulic System:

- Leaks in hoses or connections resulting in decreased power.

- Slow response times due to dirty filters or low fluid levels.

- Wear and Tear:

- Excessive wear on blades affecting cutting efficiency.

- Corrosion of metal parts leading to premature failures.

Proactive maintenance and timely repairs can mitigate many of these common issues, ensuring smooth operation and reliability in the long run.

Step-by-Step Repair Process

Repairing machinery requires a systematic approach to ensure that each component is addressed thoroughly. This section outlines a comprehensive guide to troubleshooting and fixing issues, helping you restore functionality efficiently and effectively.

1. Identify the Issue: Begin by observing the equipment for any unusual sounds, vibrations, or performance drops. Take notes on specific symptoms to guide your repair process.

2. Gather Necessary Tools: Ensure you have all essential tools at hand, including wrenches, screwdrivers, and diagnostic devices. Having everything ready will streamline your efforts.

3. Consult the Manual: Reference the service manual for detailed information about components and their specifications. Understanding the layout and function of each part is crucial for effective repairs.

4. Disassemble as Needed: Carefully remove covers and components to gain access to the problematic area. Keep track of screws and parts to avoid misplacing them during reassembly.

5. Inspect and Diagnose: Examine the components closely for wear, damage, or malfunction. Use your notes from step one to pinpoint the exact source of the issue.

6. Replace or Repair Parts: Depending on your findings, either replace damaged components or perform necessary repairs. Ensure that all replacements are compatible with the machinery.

7. Reassemble: Once repairs are complete, carefully reassemble the machine. Follow your disassembly notes to ensure no parts are overlooked.

8. Test the Equipment: After reassembly, conduct a thorough test to confirm that the issue has been resolved. Monitor for any recurring problems during operation.

9. Document the Process: Finally, make notes of what was done, including any parts replaced and observations made during the repair. This information will be invaluable for future maintenance.

Upgrading Components for Efficiency

Enhancing machinery performance through the replacement or improvement of specific elements can lead to significant gains in productivity. By focusing on optimizing these critical components, operators can achieve smoother operation, reduced downtime, and increased output, ultimately leading to more efficient workflows.

Key Areas for Improvement

- Engine Enhancements: Upgrading fuel injectors or air filters can result in better combustion and higher efficiency.

- Hydraulic System: Installing advanced hydraulic components can improve responsiveness and power delivery.

- Transmission: Upgrading to a more modern transmission system can enhance speed and torque management.

Benefits of Upgrading

- Increased Performance: Optimized components lead to better overall performance, allowing for more demanding tasks.

- Cost Efficiency: Improved fuel efficiency and reduced wear can lower operational costs.

- Longevity: Quality upgrades can extend the lifespan of equipment, resulting in fewer replacements.

Customer Reviews and Experiences

Feedback from users plays a crucial role in understanding the quality and performance of machinery. Customers often share insights that can help prospective buyers make informed decisions. Their experiences provide a glimpse into reliability, efficiency, and overall satisfaction with the product.

Common Themes in Feedback

- Reliability: Many users highlight the dependability of the equipment, noting its consistent performance even in challenging conditions.

- Ease of Use: Several reviews mention the straightforward operation, making it accessible for both seasoned operators and newcomers.

- Maintenance: Users appreciate the design that allows for easy upkeep, reducing downtime and enhancing productivity.

- Customer Support: Positive remarks about responsive service teams often surface, providing peace of mind for users who may require assistance.

User Experiences

- One user shared a story of successfully using the equipment for several seasons without major issues, emphasizing its durability.

- Another mentioned the intuitive controls, which made it easy for their family members to operate the machinery, fostering a collaborative work environment.

- A customer praised the efficient fuel consumption, leading to reduced operational costs over time.

Overall, the shared experiences of users reveal a general satisfaction with the machinery, underscoring its value in various applications.

Comparative Analysis with Other Models

This section aims to explore the similarities and differences between a specific agricultural machine and its counterparts in the market. By evaluating various characteristics such as functionality, durability, and efficiency, we can gain insights into how this particular model stands against other offerings.

When comparing machinery, one must consider the performance metrics that define each unit’s effectiveness. Factors such as power output, fuel efficiency, and ease of maintenance often serve as key indicators of a model’s reliability and operational cost. Furthermore, examining user feedback and industry reviews can highlight the strengths and weaknesses of different machines.

Another important aspect is the design philosophy behind each model. While some manufacturers prioritize advanced technology and automation, others may focus on simplicity and ease of use. This divergence in approach can significantly influence the user experience and overall satisfaction.

In summary, a thorough comparative analysis not only provides valuable insights into one particular machine but also helps potential buyers make informed decisions based on a holistic view of the market landscape.