John Deere CX15 Parts Diagram Overview

In the realm of agricultural equipment, having a comprehensive grasp of the various components is essential for effective maintenance and operation. This section delves into the intricate structure of a particular model, offering insights into its numerous elements and their respective functions. By familiarizing oneself with these components, operators can enhance their knowledge and efficiency in managing their machinery.

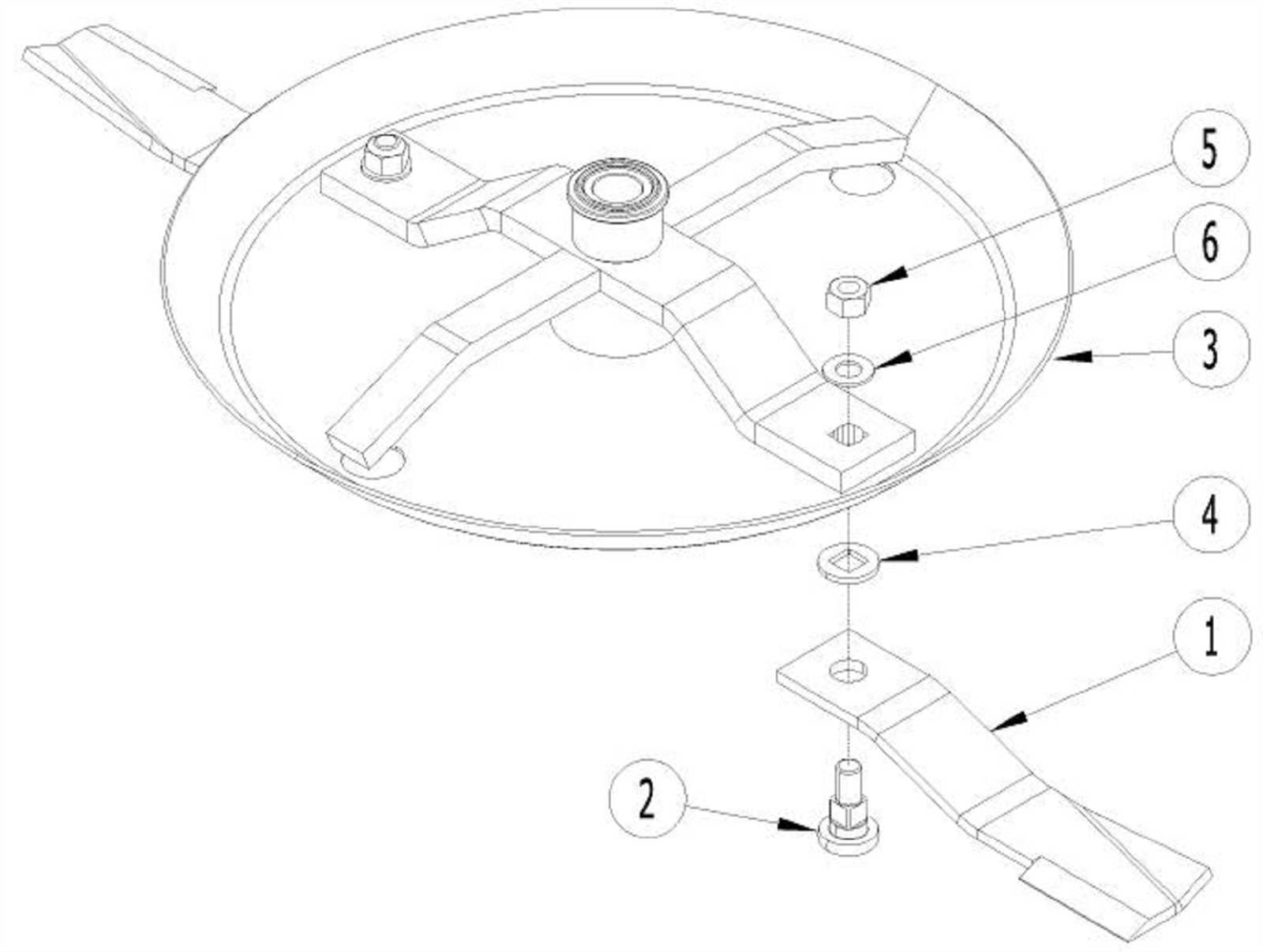

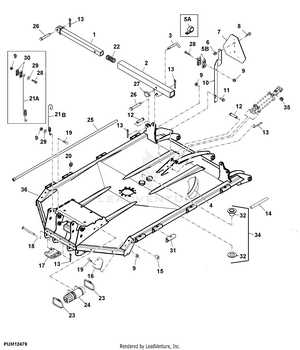

Visual representations of these components play a crucial role in understanding how each part interacts within the overall system. Through detailed illustrations, users can easily identify the arrangement and relationships between different elements. This clarity aids in troubleshooting issues and streamlining repairs, ultimately leading to a more productive experience in the field.

Moreover, having access to clear and concise illustrations fosters a deeper appreciation for the engineering behind modern agricultural machines. By examining the layout and function of each component, users can make informed decisions regarding maintenance and upgrades, ensuring their equipment remains in optimal condition.

This section aims to provide a comprehensive understanding of a particular agricultural implement known for its durability and efficiency. It highlights key components, their functionalities, and how they contribute to the overall performance of the machinery. By gaining insight into these elements, users can make informed decisions regarding maintenance and upgrades.

Key Features and Benefits

The implement is designed to enhance productivity in various farming tasks. Its robust construction ensures longevity, while the innovative design facilitates ease of use. Users can expect improved operational efficiency and reduced downtime due to the high-quality materials and engineering involved in its creation.

Essential Components Breakdown

| Component Name | Functionality |

|---|---|

| Frame | Provides structural support and stability. |

| Cutter Bar | Responsible for cutting through vegetation effectively. |

| Drive Shaft | Transfers power from the engine to the cutting components. |

| Bearings | Ensure smooth rotation and minimize friction. |

| Blades | Designed to deliver precision cuts and maintain sharpness. |

Key Features of CX15 Model

The model offers a blend of advanced functionalities and robust construction, designed to meet the diverse needs of users. With its innovative design and efficient performance, this machine stands out in its category, providing exceptional reliability and versatility.

Equipped with a powerful engine, it ensures optimal productivity while maintaining fuel efficiency. The machine’s ergonomic design enhances operator comfort, making extended work sessions more manageable. Additionally, its durable frame is engineered to withstand rigorous tasks, contributing to long-lasting performance.

This model includes various attachments and implements that allow for multi-functional use, making it suitable for different applications. Furthermore, the ease of maintenance and accessibility of components simplify service procedures, ensuring minimal downtime and enhancing operational efficiency.

Importance of Parts Diagrams

Visual representations of components play a crucial role in maintenance and repair tasks. They serve as a comprehensive guide, enabling users to identify individual elements and understand their functions within a system. This clarity can significantly enhance efficiency and accuracy during servicing.

Facilitating Efficient Repairs

Having a visual reference aids technicians in quickly locating and replacing faulty components. This efficiency minimizes downtime and helps in maintaining productivity. Moreover, a detailed illustration can simplify complex assembly processes, ensuring that each part is correctly positioned.

Enhancing Understanding

- Visual aids provide clarity on how different components interact.

- Users can familiarize themselves with various elements without needing extensive technical knowledge.

- They serve as valuable training tools for new technicians, expediting their learning process.

In conclusion, visual representations are indispensable tools that support effective maintenance and repair, making them essential for both experienced and novice users alike.

Understanding Each Component’s Role

In any complex machinery, each element plays a crucial part in ensuring the overall functionality and efficiency of the system. Recognizing the significance of each section can lead to better maintenance practices and improved operational performance. This understanding enables operators and technicians to make informed decisions when troubleshooting issues or upgrading parts.

The Importance of Functionality

Every individual piece contributes uniquely to the machine’s performance. For instance, some components may be responsible for power transmission, while others might focus on enhancing stability or improving maneuverability. A comprehensive understanding of these roles allows users to optimize the machine’s capabilities, ensuring it operates at peak performance.

Maintenance and Longevity

Regular examination of each segment is vital for extending the life of the equipment. Recognizing signs of wear or malfunction in specific components can prevent larger issues from arising. By being aware of how each part functions, operators can implement timely maintenance, enhancing both reliability and productivity.

How to Use the Parts Diagram

Understanding the visual representation of components is essential for efficient maintenance and repair of machinery. This guide will help you navigate the illustration effectively, ensuring you can identify and locate the necessary elements with ease.

Here are some key steps to make the most out of the visual representation:

- Familiarize Yourself: Spend some time getting acquainted with the layout and symbols used in the illustration.

- Identify Major Sections: Look for the main categories that group related components together, such as the engine, transmission, and chassis.

- Locate Specific Elements: Use the reference numbers or labels provided to pinpoint the parts you need.

- Cross-Reference with Manuals: Check any accompanying documentation to get detailed descriptions and specifications for each item.

- Consult with Experts: If you’re unsure about certain components, seek advice from knowledgeable individuals or online forums.

By following these steps, you can enhance your understanding of the machinery and ensure that repairs and replacements are carried out effectively.

Common Maintenance Practices

Regular upkeep is essential to ensure optimal performance and longevity of machinery. Implementing effective maintenance routines helps prevent unexpected breakdowns and extends the lifespan of equipment. Here are some widely accepted practices to consider:

- Perform routine inspections to identify any signs of wear or damage.

- Keep the equipment clean to avoid debris buildup that can lead to malfunctions.

- Regularly check fluid levels, including oil, coolant, and hydraulic fluids, and top them off as needed.

- Replace filters and fluids according to the manufacturer’s recommendations to maintain efficiency.

Additionally, consider scheduling professional servicing to address more complex issues. Adopting a proactive approach to maintenance will not only improve performance but also enhance safety during operation.

- Inspect belts and hoses for cracks or fraying, replacing them as necessary.

- Sharpen blades regularly to ensure effective cutting performance.

- Check tire pressure and tread depth to ensure proper traction and handling.

By following these guidelines, operators can keep their machinery in peak condition, ensuring reliable performance throughout its operational life.

Identifying Replacement Parts Easily

Understanding how to find the right components for your machinery is essential for maintaining optimal performance. With a variety of options available, knowing where to look and what to consider can simplify the process. This section will provide insight into efficient methods for identifying the necessary components to ensure your equipment runs smoothly.

Utilizing Online Resources

The internet offers a wealth of resources for identifying essential components. Manufacturer websites often have detailed catalogs, including specifications and compatibility information. Additionally, online forums and communities can be valuable for advice and recommendations from other users who have faced similar challenges.

Consulting with Experts

Reaching out to professionals in the field can also enhance your ability to locate the correct items. Technicians and equipment dealers typically possess extensive knowledge about various models and their corresponding components. By leveraging their expertise, you can ensure you are selecting the right solutions for your specific needs.

Resources for CX15 Parts

Finding the right components for your equipment can be essential for its optimal performance and longevity. Various sources provide valuable information and options for acquiring the necessary items. This section highlights some useful avenues to explore when searching for essential elements for your machinery.

Online Retailers: Numerous e-commerce platforms specialize in agricultural and industrial supplies. These sites often feature extensive catalogs, allowing you to search by model or type, making it easier to locate specific items that suit your needs.

Manufacturer Websites: Visiting the official sites of equipment manufacturers can provide access to detailed catalogs, including specifications and compatibility information. These resources can also direct you to authorized dealers and service centers that offer genuine products.

Local Dealerships: Establishing a relationship with local dealers can be beneficial. They typically have a thorough understanding of the equipment and can provide personalized assistance, including recommendations for reliable components and maintenance services.

Forums and Community Groups: Engaging with online communities dedicated to machinery can offer insights from experienced users. These platforms often feature discussions on where to find specific items, recommendations, and tips on installation and maintenance.

Instructional Videos: Many enthusiasts and professionals share valuable tutorials on platforms like YouTube. These videos can guide you through the process of identifying components and demonstrate how to replace or maintain them effectively.

Benefits of Genuine John Deere Parts

Utilizing authentic components for your machinery brings numerous advantages that contribute to improved performance and longevity. These high-quality items are specifically designed to meet the exact specifications required for optimal operation, ensuring that your equipment runs smoothly and efficiently. Investing in these reliable components can lead to reduced downtime and enhanced productivity, allowing you to complete tasks with confidence.

Quality Assurance

When you choose authentic components, you are guaranteed superior quality and reliability. These items undergo rigorous testing and adhere to strict manufacturing standards, which helps to maintain the integrity of your machinery. This level of quality not only enhances functionality but also minimizes the risk of unexpected failures, ensuring that your equipment remains operational for longer periods.

Compatibility and Performance

Genuine components are designed to work seamlessly with your machinery, ensuring compatibility and optimal performance. Unlike generic alternatives, which may lead to fitting issues or performance problems, authentic items ensure that all parts function harmoniously together. This compatibility not only improves overall efficiency but also contributes to fuel savings and lower maintenance costs over time.

Tips for Accurate Repairs

Achieving precision in maintenance tasks requires careful attention to detail and a systematic approach. Whether you are working on machinery or equipment, following specific guidelines can enhance the effectiveness of your repair efforts. This section provides essential advice to ensure your repairs are conducted accurately and efficiently.

1. Gather Essential Tools: Before starting, assemble all necessary tools and materials. Having everything within reach minimizes interruptions and keeps you focused on the task.

2. Refer to Documentation: Always consult reliable documentation or manuals for reference. These resources often contain critical information on specifications, assembly instructions, and troubleshooting techniques.

3. Take Detailed Notes: Document your process as you work. Notes about the steps taken, parts removed, or any unusual observations can be invaluable for future reference or for others who may work on the equipment later.

4. Inspect Components Thoroughly: Before reassembling, inspect all components for wear, damage, or misalignment. Identifying potential issues at this stage can prevent problems down the line.

5. Test After Repair: Once repairs are complete, conduct a thorough test to ensure everything functions correctly. Testing helps confirm that all adjustments were made accurately and that the equipment is safe to use.

By adhering to these tips, you can enhance the reliability of your repairs and extend the lifespan of your machinery.

FAQs About CX15 Parts

This section aims to address common inquiries related to components and accessories associated with the CX15 model. Understanding these elements can enhance user experience and maintenance efficiency.

Here are some frequently asked questions:

-

What are the most common components that require replacement?

Typical items that often need changing include:

- Blades

- Belts

- Filters

- Hydraulic hoses

-

How do I know when to replace a component?

Indicators for replacement may include:

- Visible wear and tear

- Decreased performance

- Unusual noises during operation

-

Where can I find high-quality replacements?

High-quality replacements can typically be sourced from:

- Authorized dealers

- Reputable online retailers

- Specialty equipment suppliers

-

Are there maintenance tips for prolonging the life of components?

Effective maintenance strategies include:

- Regular inspections

- Cleaning after use

- Adhering to the manufacturer’s guidelines

For any further questions or specific concerns, consulting a professional or referring to the user manual is highly recommended.