Ultimate Guide to 4L60E Parts Blow Up Diagram

The intricate mechanisms within automotive transmissions play a crucial role in ensuring optimal performance and reliability. By exploring the various elements that contribute to their operation, we can gain valuable insights into how these systems function as a whole.

Each component serves a specific purpose, working in harmony to facilitate smooth gear shifts and maintain the overall efficiency of the vehicle. Recognizing the significance of these individual elements can ultimately aid in troubleshooting and enhancing the longevity of the transmission.

In this section, we will delve into the different segments of the transmission assembly, providing a comprehensive overview that highlights their relationships and interdependencies. This knowledge empowers both enthusiasts and professionals alike to better understand and maintain their vehicles.

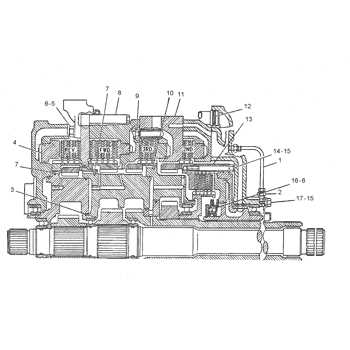

Understanding the 4L60E Transmission

The automatic gearbox in question is renowned for its versatility and widespread application in various vehicles. Its design incorporates multiple components that work harmoniously to ensure efficient power transfer from the engine to the wheels, facilitating smooth acceleration and shifting. This system is essential for achieving optimal performance and reliability.

| Component | Function |

|---|---|

| Torque Converter | Transfers power from the engine, allowing the vehicle to move without stalling. |

| Planetary Gear Set | Provides various gear ratios for different driving conditions. |

| Clutch Packs | Engage and disengage gears to facilitate smooth shifting. |

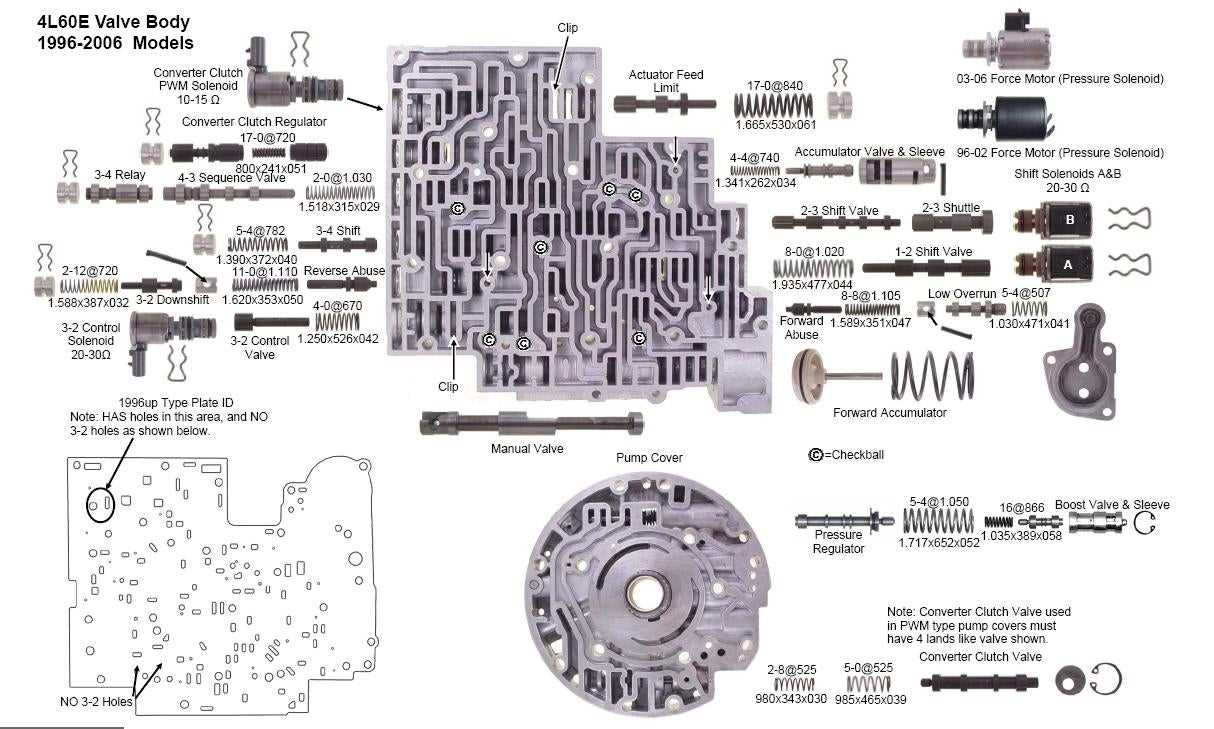

| Valve Body | Controls fluid flow and pressure, managing shifting operations. |

Understanding the intricacies of this transmission system allows enthusiasts and mechanics alike to appreciate its engineering and troubleshoot effectively when issues arise. With proper knowledge, one can ensure longevity and peak performance from this critical automotive component.

Common Failure Points in 4L60E

Understanding the frequent failure areas in this transmission system is essential for effective maintenance and longevity. Many issues arise from wear and tear, improper fluid levels, or overheating, which can lead to significant performance degradation.

One major concern is the failure of the torque converter, which can cause shuddering and slipping during operation. Additionally, worn clutches may result in delayed engagement or slipping under load. Another critical point is the valve body, where a malfunction can disrupt fluid flow and lead to erratic shifting behavior.

Heat buildup is a common culprit, often linked to inadequate cooling systems, which can damage internal components. Finally, electronic control issues can also arise, leading to incorrect operation of the transmission, making it vital to monitor and address any diagnostic trouble codes promptly.

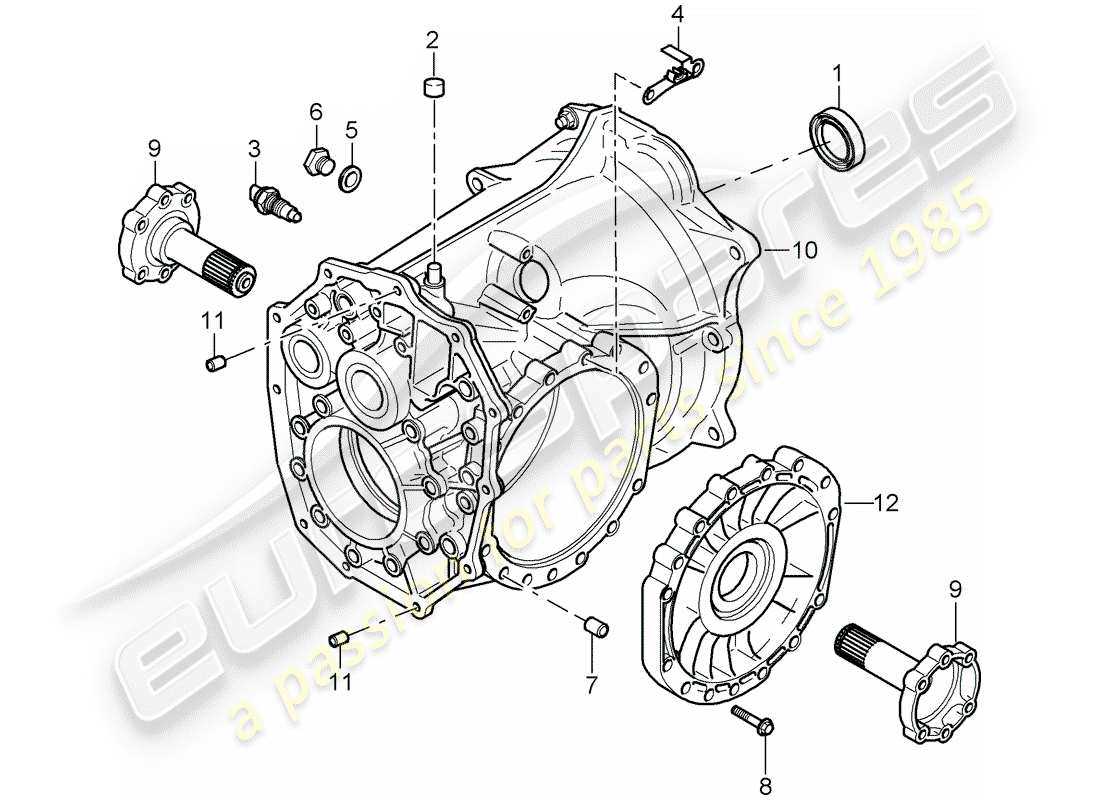

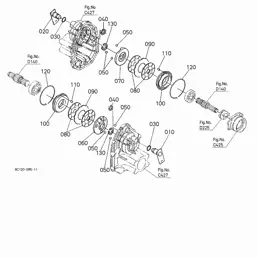

Importance of a Blow-Up Diagram

A visual representation of mechanical components plays a crucial role in understanding the assembly and function of complex systems. It serves as a detailed guide, enhancing clarity and enabling efficient repair or modification. By breaking down each element, it allows for an ultimate comprehension of how parts interact and operate together.

Benefits of Visual Representation

- Enhances understanding of intricate assemblies.

- Facilitates identification of individual components.

- Streamlines the repair and replacement process.

- Improves communication among technicians.

Applications in Maintenance

- Quick reference for troubleshooting.

- Training tool for new mechanics.

- Assists in inventory management of components.

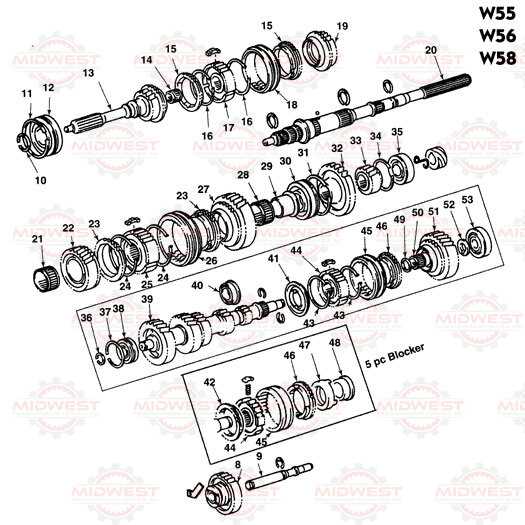

Key Components of the 4L60E

The transmission system is a crucial element in the functioning of a vehicle, ensuring that power is effectively transmitted from the engine to the wheels. Understanding its primary elements is essential for maintenance and performance tuning.

- Torque Converter: This component allows the engine to continue running while the vehicle is stationary, providing a smooth transition between power and movement.

- Planetary Gear Set: Responsible for the different gear ratios, this assembly enables the vehicle to accelerate smoothly and efficiently.

- Clutch Packs: These components engage and disengage gears as needed, allowing for seamless shifting and maintaining optimal performance.

- Valve Body: Acting as the brain of the transmission, the valve body directs hydraulic fluid to the appropriate components, controlling gear shifts based on various factors such as speed and throttle position.

- Transmission Oil Pump: This pump circulates transmission fluid throughout the system, ensuring that all parts receive adequate lubrication and cooling.

- Output Shaft: This element transfers power from the transmission to the drive shaft, ultimately propelling the vehicle forward.

Each of these components plays a vital role in the overall efficiency and functionality of the transmission, highlighting the complexity and engineering involved in modern automotive technology.

How to Read the Diagram

Understanding visual representations of mechanical assemblies is essential for effective analysis and repair. These illustrations provide a detailed view of the components and their interrelationships, allowing you to grasp the functionality and potential failure points. This section will guide you through the key aspects to consider when interpreting such illustrations.

When examining the layout, it’s crucial to identify the main elements and their corresponding labels. Each part typically has a specific code or number that relates to its description in the accompanying documentation. Recognizing these symbols and their meanings will enhance your comprehension and allow you to troubleshoot more efficiently.

| Symbol | Description |

|---|---|

| A | Main Shaft |

| B | Clutch Pack |

| C | Gear Assembly |

| D | Sealing Ring |

| E | Fluid Pump |

Pay attention to the flow of fluid within the system, as arrows often indicate movement direction. This can provide insight into how pressure is managed and how various components interact during operation. Recognizing these flows is vital for diagnosing issues related to performance or efficiency.

Lastly, always cross-reference the visual with the service manual or technical guide. This ensures you have a comprehensive understanding of the system’s intricacies and can identify any discrepancies or areas that require further investigation. Familiarity with the visual layout will ultimately lead to more effective maintenance and repairs.

Visualizing Transmission Assembly Process

Understanding the assembly of a complex system is crucial for both mechanics and enthusiasts. This section explores the various stages involved in bringing together components to create a functional mechanism, highlighting the importance of each step in ensuring optimal performance.

Key Stages in Assembly

- Preparation of Components

- Sequential Integration

- Quality Control Checks

- Final Assembly and Testing

Importance of Each Step

- Preparation: Ensuring all components are ready reduces assembly time.

- Integration: Methodical placement of each element guarantees a cohesive unit.

- Quality Control: Regular inspections prevent future malfunctions.

- Testing: Final assessments confirm that the assembly meets performance standards.

Identifying Parts from the Diagram

Understanding the various components illustrated in a schematic is crucial for effective diagnostics and repairs. By recognizing each element, one can better assess functionality and identify potential issues.

Here are some key steps to aid in identification:

- Familiarize yourself with common terminology related to automotive components.

- Study the layout carefully to comprehend how elements interconnect.

- Use reference materials, such as manuals or online resources, for detailed descriptions.

Additionally, consider the following tips:

- Pay attention to unique shapes and sizes of the components.

- Note any color coding that may indicate specific functions.

- Look for numbers or labels that correspond to parts lists.

By employing these strategies, you can confidently navigate the complexities of the schematic and enhance your understanding of the system’s architecture.

Maintenance Tips for Longevity

Ensuring the durability of your transmission requires regular attention and care. By implementing effective maintenance practices, you can significantly extend the lifespan and performance of your vehicle’s components. This guide outlines key strategies to maintain optimal functionality and prevent costly repairs.

Regular Fluid Checks

Maintaining the right fluid levels is crucial for the smooth operation of your system. Insufficient or contaminated fluid can lead to overheating and damage. Check fluid levels regularly and replace them according to the manufacturer’s recommendations.

Routine Inspections

Conducting periodic inspections can help identify potential issues before they escalate. Look for signs of leaks, unusual noises, or performance changes. Early detection can save time and money in repairs.

| Maintenance Task | Frequency |

|---|---|

| Fluid Level Check | Every 3,000 miles |

| Fluid Change | Every 30,000 miles |

| Inspection for Leaks | Monthly |

| Noise Check | During each drive |

Upgrades for Improved Performance

Enhancing the functionality of your transmission can lead to a remarkable boost in vehicle efficiency and responsiveness. By implementing specific modifications, you can achieve a balance between power and reliability, ultimately elevating your driving experience.

Essential Modifications

Consider integrating high-performance components that can withstand increased power demands. These enhancements often focus on durability and heat dissipation, ensuring your system operates smoothly even under stress.

| Upgrade Type | Description |

|---|---|

| High-Performance Torque Converter | Improves power transfer and efficiency. |

| Shift Kit | Enhances shift timing and firmness. |

| Stronger Clutches | Provides better engagement and longevity. |

Final Considerations

When selecting upgrades, it’s crucial to assess compatibility with your existing system. Thoughtful choices can significantly enhance overall performance and extend the lifespan of your transmission.

Typical Symptoms of Component Failure

Understanding the common indicators of malfunction within a transmission system can help diagnose issues before they escalate. Recognizing these signs early on is crucial for maintaining performance and preventing extensive damage.

Common Warning Signs

Unusual noises, such as grinding or whining, often signal underlying problems. Additionally, slipping gears or unexpected shifts can indicate that components are not functioning as intended.

Performance Issues

Delayed engagement when shifting or a noticeable decrease in acceleration may also suggest component wear. If any of these symptoms are present, it’s essential to delve deeper into the system to pinpoint the ultimate cause.

Repairing or Replacing Damaged Parts

When it comes to maintaining the efficiency of a transmission system, addressing wear and tear is crucial. Whether it’s due to excessive stress, age, or environmental factors, damaged components can lead to serious operational issues. Understanding the options available for restoration or substitution can ensure optimal performance and longevity.

Assessment of Damage

Before deciding on a course of action, a thorough evaluation of the condition of the components is necessary. Consider the following steps:

- Visual inspection for cracks, wear, or deformation.

- Functional tests to identify performance issues.

- Consulting service manuals for specifications and tolerances.

Repair Options

If the damage is minor, repairs might be feasible. Common methods include:

- Welding: Suitable for metal components with structural failures.

- Resurfacing: Effective for parts with surface wear, restoring their original shape.

- Sealing: Useful for preventing leaks in gaskets or seals.

Each repair method has its pros and cons, and it’s essential to evaluate whether a repair will offer a lasting solution or if a replacement would be more prudent in the long run.

Replacement Considerations

In cases where damage is extensive, replacing the components may be the best option. Key points to consider include:

- Choosing high-quality replacements that meet or exceed original specifications.

- Considering remanufactured or aftermarket options for cost savings.

- Ensuring proper installation to avoid future issues.

Ultimately, making informed decisions about repair or replacement will contribute significantly to the overall efficiency and reliability of the transmission system.

Resources for Further Study

For those seeking to deepen their understanding of automotive components and their intricacies, numerous resources are available. These materials provide valuable insights into the mechanisms and functions of various systems, ensuring a well-rounded knowledge base for enthusiasts and professionals alike.

Books authored by industry experts often serve as a solid foundation, covering both theoretical concepts and practical applications. Additionally, online forums and communities foster discussions where individuals can share experiences and solutions related to specific challenges.

Video tutorials and workshops offer visual and hands-on learning opportunities, making complex ideas more accessible. Lastly, manufacturer websites frequently publish technical manuals and guides that are indispensable for anyone looking to gain comprehensive knowledge about these systems.