Bosch 4100 Parts Diagram Overview

Exploring the intricacies of mechanical assemblies can greatly enhance one’s ability to troubleshoot and maintain equipment effectively. A comprehensive understanding of the arrangement and function of individual elements within a system is essential for anyone looking to optimize performance and longevity.

In this section, we will delve into a detailed representation that illustrates the various components and their respective roles. Such visual aids serve not only as a reference but also as a crucial tool for both novice and experienced users alike, facilitating a deeper grasp of operational mechanics.

By examining the interconnected nature of these pieces, readers can gain insights into potential issues and solutions. This knowledge empowers users to carry out repairs confidently and make informed decisions regarding maintenance practices, ensuring that their machinery operates smoothly and efficiently.

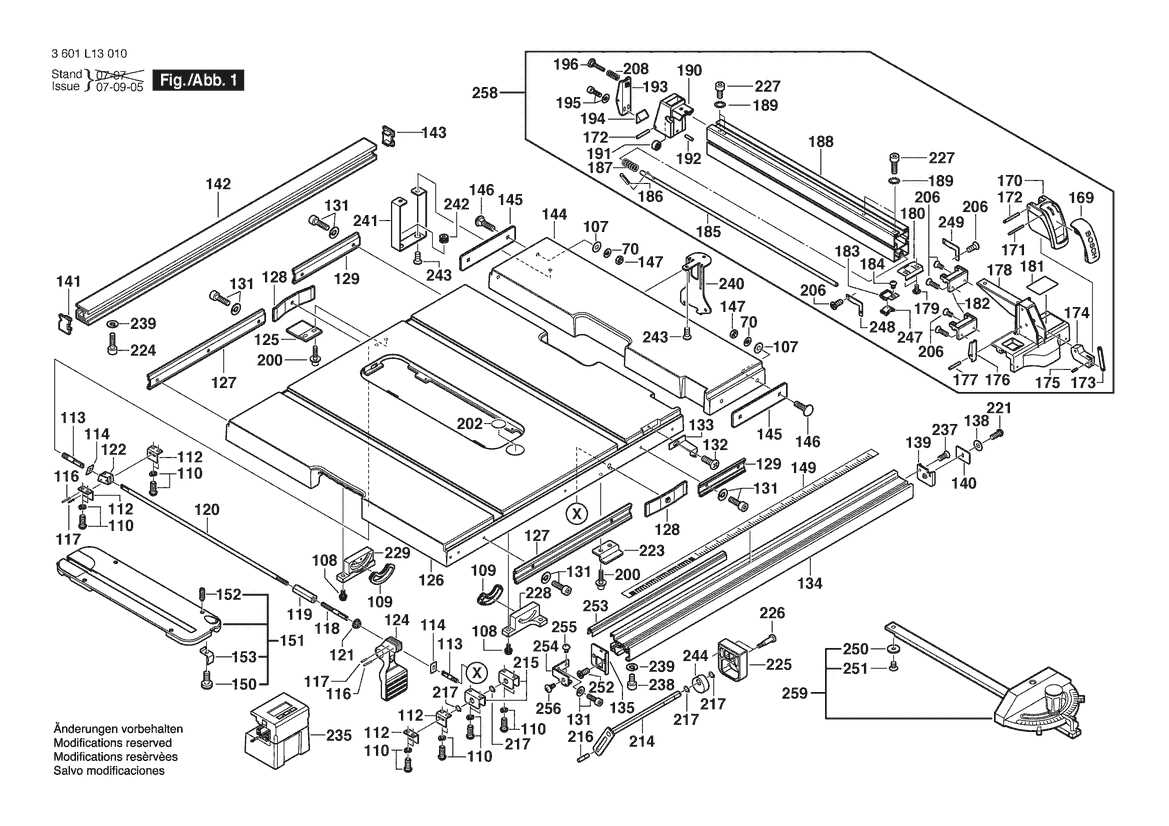

Understanding the Bosch 4100 Parts Diagram

Comprehending the intricacies of a machine’s assembly is crucial for both maintenance and troubleshooting. Visual representations that detail the components of a device can significantly enhance one’s ability to identify issues and perform repairs effectively. By examining such illustrations, users can gain valuable insights into how each part interacts and contributes to overall functionality.

Familiarity with these visuals allows for quicker identification of components, aiding in both assembly and disassembly processes. Additionally, having a solid grasp of the elements involved fosters confidence in making informed decisions regarding repairs and replacements.

| Component Name | Description | Function |

|---|---|---|

| Base | The foundation of the tool | Supports all other components |

| Motor | Electric power source | Drives the operational functions |

| Table | Flat surface for workpieces | Provides stability during use |

| Blade | Cutting tool | Performs the actual cutting |

| Guard | Safety cover for the blade | Protects user from injuries |

Ultimately, a thorough understanding of the assembly and its components is invaluable for ensuring optimal performance and longevity of the device. Regular reference to these illustrations can make the maintenance process more efficient and effective.

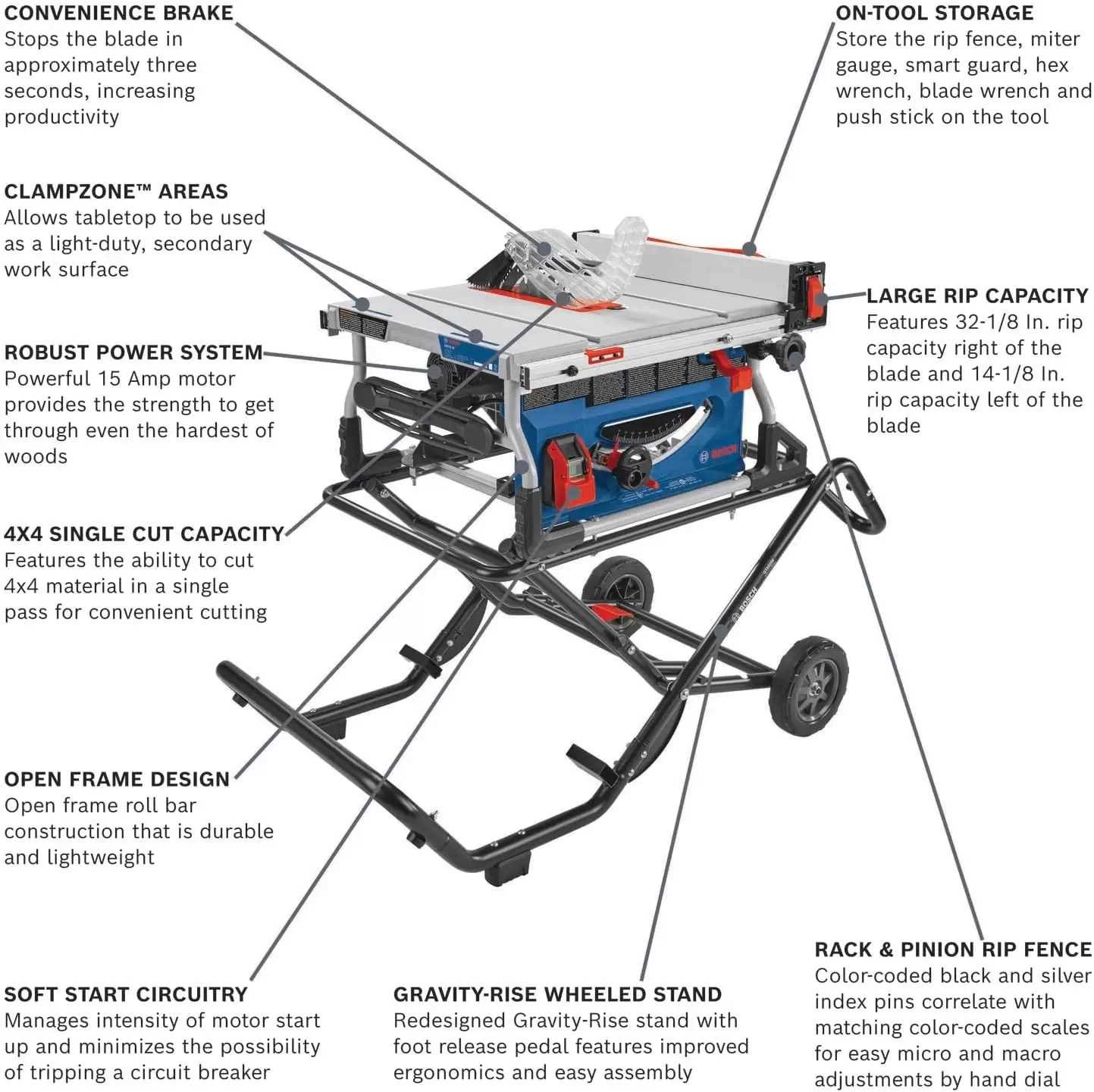

Key Components of the Bosch 4100

This section explores the essential elements that contribute to the functionality and performance of a well-known table saw model. Each component plays a significant role in ensuring precision, safety, and ease of use for woodworking enthusiasts and professionals alike.

| Component | Description |

|---|---|

| Motor | Drives the blade, providing the necessary power for cutting through various materials. |

| Table Surface | A flat area that supports the workpiece, allowing for accurate cuts and stability. |

| Blade Assembly | Includes the saw blade and its mechanisms, crucial for achieving different cut types. |

| Fence System | Ensures straight cuts by guiding the material along the edge of the blade. |

| Safety Guard | Protects the user from accidental contact with the rotating blade during operation. |

| Stand | Supports the entire unit, providing stability and the appropriate working height. |

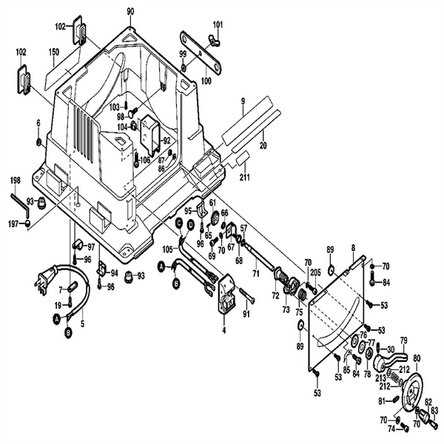

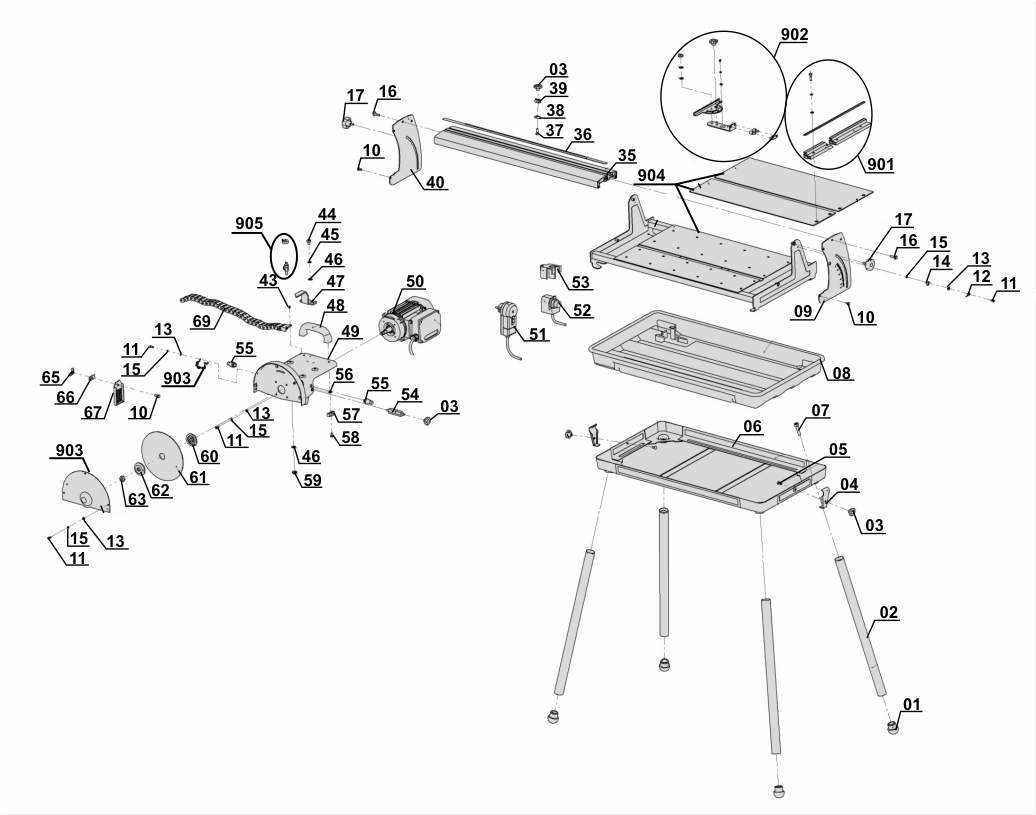

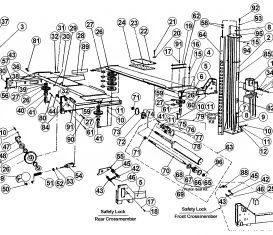

How to Read the Parts Diagram

Understanding a component illustration is essential for efficient maintenance and repair tasks. This visual representation provides a clear overview of the various elements involved in the machinery, making it easier to identify and locate specific parts. By familiarizing yourself with the layout and symbols used, you can streamline the process of disassembly and reassembly.

First, take note of the legend or key, which often accompanies the illustration. This section outlines the symbols and numbering system used to reference different components. Familiarizing yourself with this key will help you decode the information presented.

Next, observe how the parts are arranged. Typically, they are organized logically, either by assembly order or function. Pay attention to groupings, as they can indicate which components interact with each other. This insight is crucial for troubleshooting and ensuring proper reassembly.

Additionally, look for any annotations or notes that may provide further context. These could include installation tips, torque specifications, or troubleshooting advice. Such details can be invaluable when you encounter challenges during repairs.

Finally, ensure you cross-reference the illustration with the user manual or repair guide. This will help reinforce your understanding and provide additional clarity on any complex assemblies. By following these steps, you can effectively utilize the visual representation to enhance your repair efforts.

Common Issues with Bosch 4100 Parts

When working with various tools, users often encounter specific challenges that can hinder performance and efficiency. These issues can stem from wear and tear, improper maintenance, or manufacturing defects. Identifying and addressing these problems is crucial for ensuring the longevity and reliability of the equipment.

One frequent concern involves the misalignment of components, which can lead to inaccurate cuts and decreased operational effectiveness. Users may also experience difficulties with power loss, often linked to electrical connections or faulty switches. Additionally, components may become loose or damaged over time, resulting in vibrations or unusual noises during use.

Another common issue is the degradation of consumable elements, which can affect overall functionality. Regular inspection and timely replacement of these parts are essential for optimal performance. Finally, users may face challenges with assembly or disassembly, particularly if proper guidelines are not followed, leading to potential damage or safety hazards.

Where to Find Replacement Parts

Locating suitable components for your equipment can significantly enhance its longevity and performance. There are various avenues to explore when searching for high-quality replacements, ensuring you get the right fit for your specific model. From authorized retailers to online marketplaces, understanding your options will help streamline the process.

Authorized Dealers

One of the most reliable sources for obtaining components is through certified dealers. These establishments often carry a wide selection of original items tailored to specific models. Additionally, purchasing from authorized vendors typically guarantees that you are receiving genuine merchandise, which can be crucial for maintaining the integrity of your machinery.

Online Marketplaces

The internet provides a vast array of platforms where you can search for the necessary replacements. Websites dedicated to tools and equipment often feature comprehensive catalogs, allowing you to compare prices and find the exact items you need. User reviews and ratings can also guide you in selecting reputable suppliers, ensuring that your purchase meets your expectations.

Tools Needed for Assembly and Repair

When embarking on the journey of assembly or maintenance of machinery, having the right tools is crucial for efficiency and precision. The proper equipment not only simplifies the process but also ensures safety and longevity of the device. Below is a comprehensive list of essential tools that will assist in both assembly and repair tasks.

Essential Tools

| Tool | Purpose |

|---|---|

| Screwdriver Set | For fastening and loosening screws of various sizes. |

| Wrench Set | Used to tighten or loosen nuts and bolts. |

| Allen Keys | For hexagonal screws, common in many mechanical assemblies. |

| Pliers | For gripping, twisting, and cutting wires or small components. |

| Measuring Tape | To ensure accurate measurements during assembly. |

Safety Equipment

In addition to the primary tools, safety equipment should never be overlooked. Protective gear like gloves and goggles is essential to prevent injuries during any assembly or repair tasks. Ensuring safety allows for a more focused and effective working environment.

Step-by-Step Assembly Guide

This section provides a detailed guide to effectively assembling your equipment. Following these steps will ensure that all components fit together seamlessly, resulting in optimal performance and longevity. Each stage is designed to be straightforward, allowing even those with minimal experience to achieve success.

Preparation

- Gather all necessary tools and components.

- Clear a workspace to facilitate easy assembly.

- Review the instruction manual for an overview of the assembly process.

Assembly Steps

- Begin with the base unit. Secure the stabilizers to ensure a sturdy foundation.

- Attach the main body, aligning it with the pre-drilled holes.

- Install any necessary connectors or brackets to support the structure.

- Proceed to add any additional features or accessories as specified.

- Conduct a thorough check of all connections and fastenings to ensure everything is secure.

Completing these steps will help you assemble your device efficiently, allowing you to move on to its usage without delay.

Maintenance Tips for Bosch 4100

Ensuring the longevity and efficiency of your equipment requires regular attention and care. By following some essential maintenance practices, you can keep your tool in optimal working condition and enhance its performance.

- Regular Cleaning: Dust and debris can accumulate, affecting performance. Clean the surface and components after each use to prevent build-up.

- Check for Wear: Periodically inspect the moving parts for signs of wear or damage. Replace any worn components promptly to avoid further issues.

- Lubrication: Apply appropriate lubricants to ensure smooth operation of moving parts. Follow manufacturer guidelines for specific lubrication points.

- Calibration: Regularly check and calibrate settings to maintain accuracy. This ensures precision in your projects.

- Storage: Store the equipment in a dry, protected area when not in use. Use covers or cases to shield it from dust and moisture.

By adhering to these maintenance tips, you can extend the lifespan of your tool and ensure reliable performance for years to come.

Comparing Bosch 4100 with Similar Models

This section explores the differences and similarities between a specific cutting tool and its counterparts in the market. Understanding these nuances can help potential buyers make informed decisions based on their needs and preferences. By examining features, performance, and user feedback, one can better appreciate the strengths and weaknesses of each option available.

Feature Comparison

When assessing various models, it’s essential to consider key characteristics such as power output, portability, and versatility. Many competing tools offer comparable motor strength, but the design and ease of use can vary significantly. Features like adjustable cutting angles and safety mechanisms are crucial, as they enhance the overall user experience and efficiency during operations.

User Feedback and Performance

User reviews provide valuable insights into real-world performance and reliability. While some models excel in precision and durability, others may lag behind in customer satisfaction due to design flaws or inconsistent quality. Analyzing feedback can reveal trends that highlight which tools best meet the expectations of both hobbyists and professionals in various settings.

Customer Reviews and Feedback

Understanding user experiences is essential for evaluating the quality and reliability of any product. Feedback from consumers provides invaluable insights into performance, usability, and overall satisfaction, helping potential buyers make informed decisions. This section delves into various perspectives shared by users, highlighting both positive remarks and areas for improvement.

Positive Experiences

Many users appreciate the durability and efficiency of their tools. They often mention how reliable these devices are for various tasks, praising their robust construction and ease of use. One customer noted that the precision and accuracy greatly enhanced their workflow, making it an indispensable addition to their toolkit.

Areas for Improvement

While feedback is predominantly positive, some users have identified a few drawbacks. Several reviewers expressed concerns regarding the initial setup process, describing it as somewhat complex. Additionally, there were mentions of the need for better instructional materials to assist new users in navigating the features effectively.

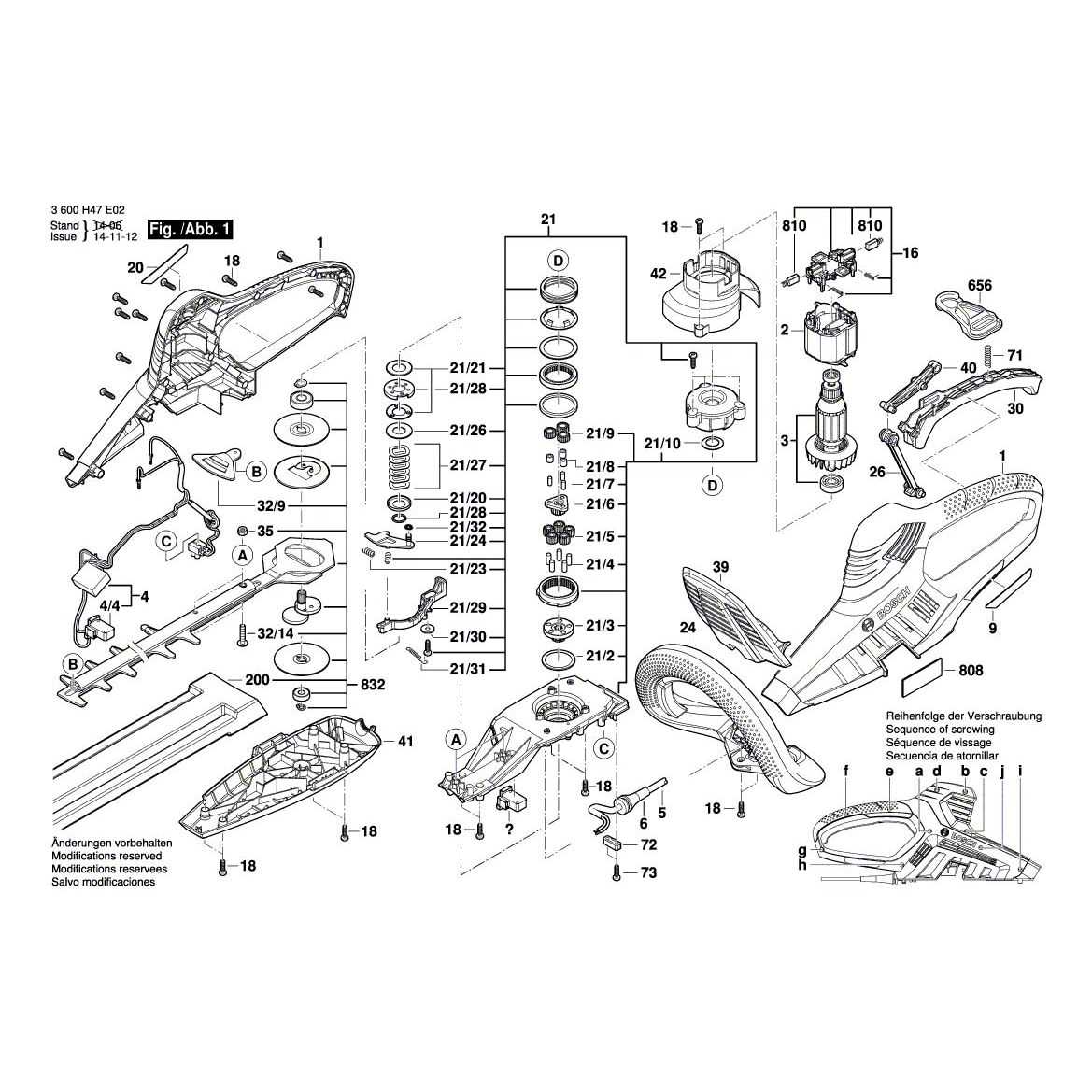

Upgrades and Modifications Available

Enhancing your equipment can significantly improve its performance and longevity. Various upgrades and modifications can transform standard machinery into high-efficiency tools tailored to specific needs. Below are some options that can elevate functionality and user experience.

- Performance Enhancements:

- Installing a more powerful motor for increased cutting speed.

- Upgrading to high-quality blades for improved precision and durability.

- Safety Features:

- Adding a blade guard to prevent accidental contact.

- Incorporating advanced dust collection systems to improve air quality.

- Convenience Modifications:

- Equipping mobile stands for better portability and stability.

- Installing quick-release systems for faster blade changes.

- Custom Accessories:

- Utilizing auxiliary tables for larger workpieces.

- Integrating laser guides for enhanced cutting accuracy.

By selecting the right enhancements, users can create a more effective and enjoyable working environment. Whether for personal projects or professional tasks, these modifications can make a significant difference.

Frequently Asked Questions

This section addresses common inquiries related to the components and assembly of specific machinery. Here, you will find answers that clarify various aspects, helping users better understand the intricacies involved.

What should I do if I can’t find a specific component?

If you’re having difficulty locating a particular part, consider checking with authorized retailers or online marketplaces that specialize in tools and machinery accessories. It’s also helpful to consult the user manual for part numbers and compatibility information.

How can I ensure I am purchasing the correct replacement?

To guarantee you’re buying the right substitute, refer to the specifications outlined in your equipment’s manual. Cross-referencing part numbers and compatibility with your model is essential to avoid any mismatches.

Are there any maintenance tips to prolong the lifespan of my equipment?

Regular maintenance is crucial. Ensure you clean the machine after each use, lubricate moving parts as recommended, and periodically inspect for wear and tear. Following these practices will enhance performance and longevity.

Where can I find assembly instructions?

Assembly guidelines are typically included in the product manual. Additionally, many manufacturers provide digital copies on their official websites or through customer service channels. Online forums can also offer valuable insights from experienced users.

What are common signs that a component needs replacement?

Watch for indicators such as unusual noises, reduced performance, or visible wear. If you notice any discrepancies during operation, it may be time to evaluate and possibly replace affected parts.

Resources for Bosch 4100 Owners

Owning a high-quality power tool can greatly enhance your woodworking projects. To ensure optimal performance and longevity of your equipment, having access to reliable information and support is essential. This section provides valuable resources for users looking to maintain and troubleshoot their devices effectively.

Online Support and Communities

- Manufacturer’s Official Website: A primary source for manuals, FAQs, and product updates.

- Forums: Join dedicated discussion groups where enthusiasts share tips, modifications, and repair experiences.

- Social Media Groups: Engage with other users for real-time advice and project inspiration.

Repair and Maintenance Guides

- Video Tutorials: Platforms like YouTube offer step-by-step guides for common repairs and maintenance tasks.

- User Manuals: Downloadable resources provide detailed instructions on setup, usage, and troubleshooting.

- Professional Services: Consider local technicians or authorized service centers for more complex issues.