Understanding the Components of a Brake Booster Diagram

In modern automobiles, the enhancement of control during operation is largely dependent on a sophisticated network of mechanisms. This intricate assembly plays a crucial role in ensuring a seamless driving experience, allowing for better handling and responsiveness. A comprehensive look at these components reveals the importance of each element in contributing to overall vehicle efficiency.

By examining the various elements involved in this assistance framework, we gain insight into how they function together. The arrangement of these components not only facilitates smoother operation but also enhances safety features. Understanding their layout and interaction is essential for anyone interested in automotive technology.

This exploration aims to dissect the fundamental pieces that constitute this vital system. By visualizing their organization, one can appreciate the engineering prowess involved in automotive design and maintenance. A detailed overview will shed light on the interconnectivity and functionality that ensures optimal performance on the road.

Understanding Brake Booster Functionality

The mechanism that enhances the force applied to the stopping system is vital for safe vehicle operation. By amplifying the driver’s input, it ensures that the vehicle can come to a halt efficiently and with minimal effort. This technology is particularly important in modern automobiles, where the demands for effective stopping power have increased significantly.

At its core, this device utilizes vacuum pressure to multiply the force exerted by the driver on the pedal. When the pedal is pressed, air pressure changes inside the mechanism, creating a difference that activates a diaphragm. This action not only reduces the physical effort needed but also allows for a more responsive and controlled braking experience.

Moreover, the integration of this component contributes to overall vehicle safety. By allowing for quicker stopping times, it plays a crucial role in preventing accidents and enhancing driver confidence. Understanding its operation and maintenance is essential for anyone seeking to ensure their vehicle performs optimally.

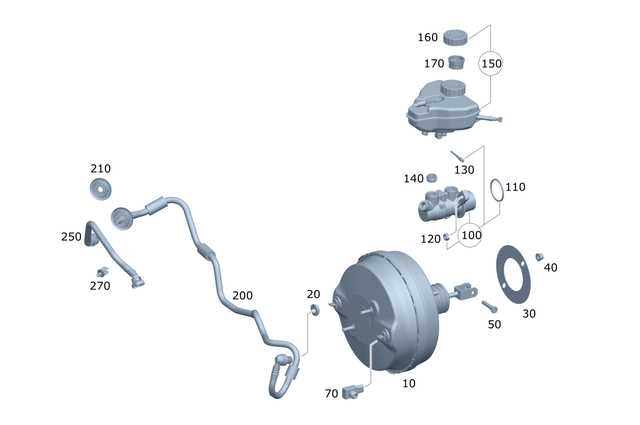

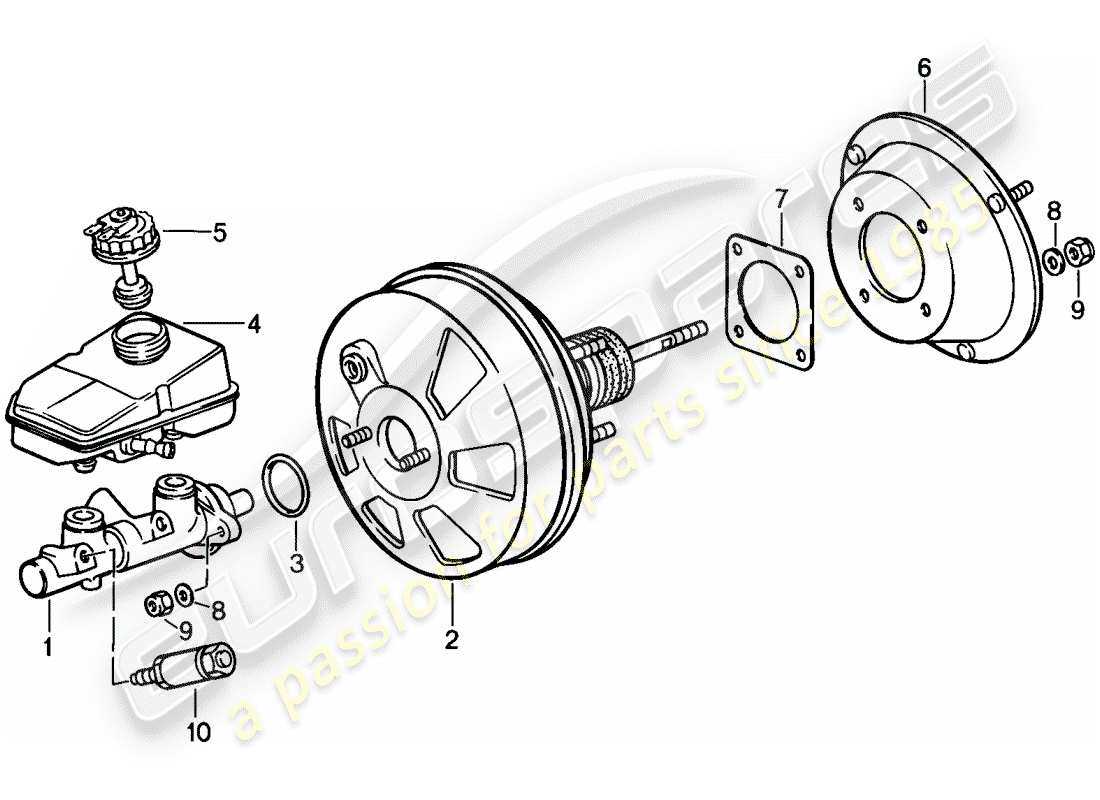

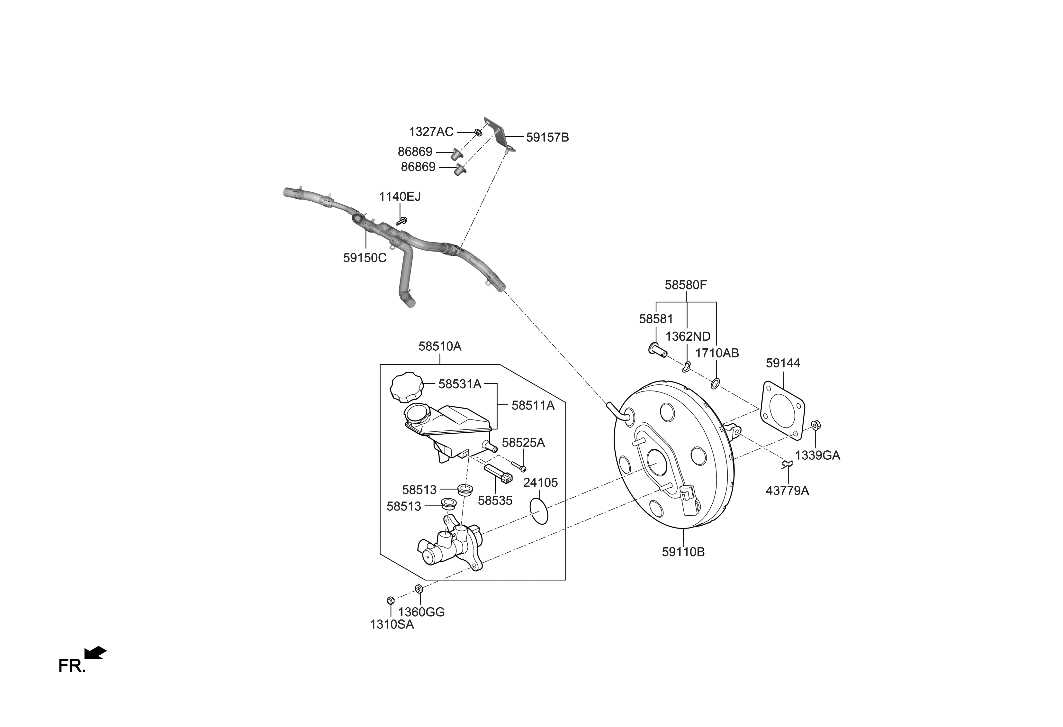

Components of a Brake Booster System

The functioning of a hydraulic amplification system relies on several key elements that work in harmony to enhance the effectiveness of the stopping mechanism. Each component plays a crucial role in ensuring that the vehicle responds effectively to the driver’s commands, resulting in improved safety and control during operation.

Main Elements

Understanding the fundamental components helps in grasping how this system operates. The following elements are essential for optimal performance:

| Component | Function |

|---|---|

| Vacuum Chamber | Generates the necessary pressure difference to amplify force. |

| Diaphragm | Separates different pressures and facilitates the movement of the actuator. |

| Actuator | Converts the amplified force into mechanical movement to engage the stopping mechanism. |

| Input Rod | Transmits the driver’s input to the actuator for engagement. |

Additional Components

In addition to the primary elements, there are other auxiliary parts that contribute to the overall efficiency and reliability of the system. These components help to maintain functionality and ensure the system operates smoothly under various conditions:

| Auxiliary Component | Role |

|---|---|

| Check Valve | Prevents backflow and maintains pressure within the chamber. |

| Spring | Helps return the actuator to its original position after use. |

| Mounting Bracket | Secures the system to the vehicle’s structure. |

Common Issues with Brake Boosters

Understanding the typical challenges that can arise in the hydraulic assist systems is crucial for maintaining optimal vehicle performance. Various factors can lead to malfunctions, impacting overall safety and drivability. Identifying these common issues early can help prevent more severe complications and costly repairs.

One prevalent problem is air leakage within the system. When seals deteriorate or become compromised, air can infiltrate, resulting in decreased efficiency and increased pedal effort. Drivers may notice a spongy feel or an unresponsive pedal, indicating that the system is not functioning correctly.

Another frequent issue involves fluid contamination. Debris or moisture in the hydraulic fluid can lead to corrosion and blockages, disrupting the system’s operation. Regular maintenance and fluid checks can help mitigate these risks and ensure smooth functioning.

Additionally, wear and tear on components can cause a loss of assist, making it challenging to achieve the desired stopping power. It’s important to monitor the age and condition of these elements to avoid sudden failures while driving.

Lastly, electronic malfunctions in modern vehicles can also affect the hydraulic assist systems. Software glitches or sensor failures may prevent proper engagement, leading to unpredictable behavior when applying the brakes. Keeping the vehicle’s software updated is essential for avoiding such issues.

How to Diagnose Brake Booster Problems

Identifying issues with your vehicle’s assistance system is crucial for safe driving. Problems can manifest through various symptoms, and recognizing them early can prevent further complications. This section outlines key steps to assess whether the assistance mechanism is functioning correctly.

First, observe the pedal response. If you notice that the pedal feels hard or requires excessive force to engage, this could indicate a malfunction. Additionally, pay attention to any unusual sounds, such as hissing or whistling, when the pedal is pressed. These noises may signal air leaks within the system.

Next, check for performance inconsistencies. If the vehicle experiences a longer stopping distance or pulls to one side during braking, it may suggest that the assistance function is compromised. A consistent reduction in stopping efficiency warrants further investigation.

Another important step is to inspect the vacuum source. Ensure that the vacuum line is intact and free from obstructions. Any damage or leaks in this line can directly impact the system’s operation, leading to potential hazards.

Lastly, test the vehicle at low speeds. A noticeable increase in pedal effort or a lack of responsiveness during slow maneuvers can be a clear indicator of underlying issues. If any of these symptoms are present, it is advisable to consult a qualified technician for a comprehensive evaluation and necessary repairs.

Importance of Proper Maintenance

Regular upkeep of vehicle components is crucial for ensuring optimal performance and safety on the road. Neglecting this aspect can lead to reduced efficiency, increased wear and tear, and potentially hazardous situations. Understanding the significance of thorough care can help drivers make informed decisions regarding their automotive needs.

Maintaining these essential elements not only extends their lifespan but also enhances the overall functionality of the vehicle. Routine checks can identify issues before they escalate, allowing for timely interventions that save both time and money. Furthermore, a well-maintained system contributes to a smoother driving experience, improving comfort and control.

Drivers should prioritize regular inspections and service routines to ensure that all components operate as intended. This proactive approach fosters reliability, minimizes unexpected breakdowns, and ultimately supports safer journeys. Emphasizing maintenance is not merely a recommendation but a vital practice for any responsible vehicle owner.

Identifying Signs of Wear and Tear

Recognizing the indicators of deterioration in mechanical systems is crucial for maintaining optimal functionality and safety. Regular inspections can reveal issues before they escalate into serious problems, ensuring the longevity of the components involved.

Common Symptoms to Look For

- Unusual noises during operation, such as hissing or grinding sounds.

- Inconsistent performance, including a noticeable decrease in responsiveness.

- Fluid leaks around the system, which may indicate compromised seals or connections.

- Visible cracks or wear on the exterior surfaces of components.

Monitoring Performance Changes

- Keep track of any changes in response time; delays can signal deeper issues.

- Observe for any vibrations that weren’t present before, as these can indicate misalignment or wear.

- Regularly check the pressure levels, as fluctuations might point to underlying problems.

- Pay attention to dashboard warning lights that may illuminate during operation.

Types of Brake Boosters Explained

Understanding the various mechanisms that enhance the effectiveness of the stopping system is crucial for vehicle safety and performance. Different designs cater to distinct needs, influencing how the stopping force is applied during operation. This section delves into the primary variations, highlighting their functionalities and applications.

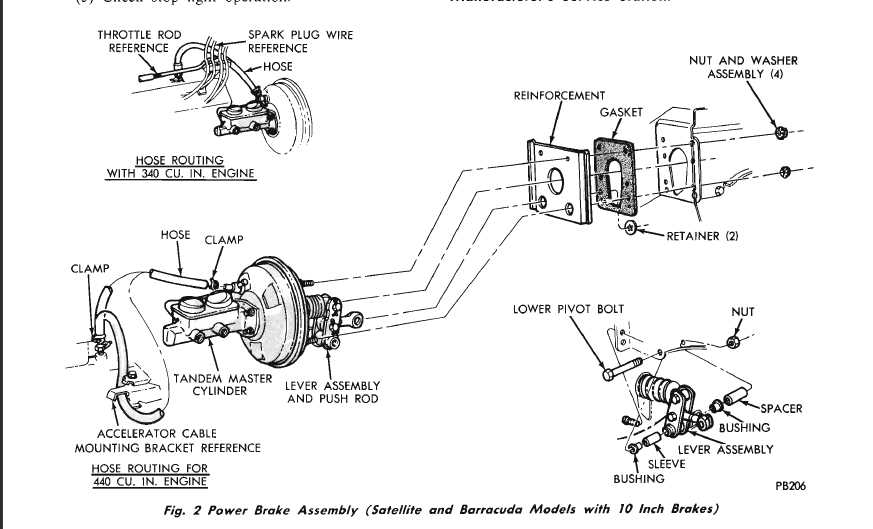

Pneumatic Assist Mechanisms

Pneumatic systems utilize air pressure to amplify the force applied by the driver. This type relies on the vacuum created by the engine, making it a popular choice in many vehicles due to its efficiency and reliability. The design minimizes the physical effort required to engage the stopping system, ensuring smoother deceleration.

Hydraulic Assist Mechanisms

In contrast, hydraulic systems harness fluid pressure to achieve similar outcomes. This method is often favored in high-performance applications, as it can provide quicker responses and greater control under demanding conditions. By using fluid dynamics, these systems enhance the driver’s ability to modulate stopping power effectively.

| Type | Key Features | Common Uses |

|---|---|---|

| Pneumatic | Uses air pressure, efficient and reliable | Standard passenger vehicles |

| Hydraulic | Utilizes fluid pressure, quick response | High-performance cars and racing vehicles |

Role of Vacuum in Brake Boosters

In automotive systems, the influence of a low-pressure environment is crucial for enhancing the efficiency of certain components. This phenomenon allows for a significant reduction in the amount of effort needed by the driver to engage the stopping mechanism. By harnessing this vacuum, vehicles can achieve optimal performance and responsiveness.

How Vacuum Functions

The low-pressure area works by creating a force that amplifies the driver’s input. Here’s how it operates:

- The vacuum is generated by the engine during its operation.

- This low-pressure space is connected to specific components within the system.

- When the driver presses the pedal, the atmospheric pressure outside pushes against a diaphragm.

- The difference in pressure enhances the force applied, resulting in a more effective stopping action.

Benefits of Utilizing Vacuum

Implementing this low-pressure technique offers several advantages:

- Reduced effort required by the driver, leading to increased comfort.

- Enhanced response time when engaging the stopping mechanism.

- Improved safety through more reliable and predictable performance.

- Efficient use of engine power without additional energy consumption.

Overall, the role of a low-pressure environment in these systems cannot be overstated, as it fundamentally transforms how vehicles interact with the driver’s commands, ensuring a smoother and safer driving experience.

Brake Booster Repair vs. Replacement

When faced with issues related to the assistance mechanism in a vehicle’s stopping system, owners often wonder whether to fix the existing unit or to replace it entirely. Each option comes with its own set of advantages and considerations that can impact both safety and budget. Understanding the nuances between refurbishment and total substitution is crucial for making an informed decision.

Benefits of Repair

Choosing to repair can be a cost-effective solution, especially when the malfunction is minor or localized. Repairs often involve replacing specific components rather than the entire assembly, which can significantly reduce labor and material costs. Furthermore, opting for refurbishment allows for the preservation of the original unit, which may be beneficial for maintaining vehicle authenticity. However, it is essential to ensure that the repair is conducted by a qualified technician to guarantee long-lasting results.

Advantages of Replacement

On the other hand, total substitution may be the preferred choice when the system is significantly degraded or has experienced multiple failures. New units often come with warranties, providing peace of mind for the owner. Additionally, modern replacements may incorporate improved technology, leading to better performance and enhanced safety features. While the initial investment is higher, the long-term reliability of a new system may justify the expense.

Ultimately, the decision between repair and replacement should be guided by the specific condition of the unit, financial considerations, and the desired level of performance and safety.

How to Install a New Brake Booster

Replacing an essential component of your vehicle’s hydraulic system can enhance its performance and safety. This process involves several steps that ensure proper installation and functionality. Following a detailed guide will help you achieve a successful replacement, allowing you to regain optimal efficiency on the road.

Preparation Steps

Before starting the installation, gather all necessary tools and materials. It is important to work in a well-ventilated area and have safety gear handy. Begin by disconnecting the vehicle’s battery to prevent any electrical issues. Next, clear the space around the component to allow easy access.

Installation Procedure

Once you are prepared, follow these steps to install the new component:

| Step | Description |

|---|---|

| 1 | Remove the old component by detaching the mounting bolts and disconnecting any connected lines. |

| 2 | Clean the mounting surface to ensure a proper seal for the new unit. |

| 3 | Position the new unit in place, aligning it with the mounting holes. |

| 4 | Tighten the mounting bolts securely, ensuring the component is firmly in place. |

| 5 | Reconnect any lines that were previously detached, making sure there are no leaks. |

| 6 | Reattach the battery and perform a thorough check of the installation. |

After completing these steps, test the vehicle to ensure that everything operates smoothly. Regular maintenance and prompt replacement of worn components will contribute to a safer driving experience.