Understanding the Shimano Brake Parts Diagram for Better Maintenance

The intricate design of cycling mechanisms is essential for optimal performance and safety. A well-structured layout can significantly enhance the riding experience by ensuring all elements work in harmony. This section aims to provide insights into these configurations, helping enthusiasts grasp their significance.

By examining the various components involved, readers will uncover how each piece contributes to the overall functionality. Detailed representations can serve as a valuable resource for both novices and experienced riders looking to refine their understanding.

Furthermore, a comprehensive overview of these structures allows for better maintenance practices and informed decisions during upgrades. As we delve deeper into the specifics, the ultimate goal is to empower cyclists with knowledge that enhances their connection to their equipment.

Understanding Shimano Brake Systems

This section explores the intricacies of advanced stopping mechanisms commonly found in cycling equipment. By examining their components and functionality, one can appreciate the engineering behind reliable deceleration and control. Knowledge of these systems is essential for maintenance and optimal performance.

Components play a crucial role in ensuring effective operation. Key elements work in harmony to provide responsiveness, making it imperative to understand each piece’s contribution. Regular checks can prevent issues and enhance safety.

Maintenance is vital for longevity. Familiarity with assembly and disassembly processes empowers users to address wear and tear, ensuring that every ride remains smooth and secure. Investing time in understanding these systems ultimately leads to a better cycling experience.

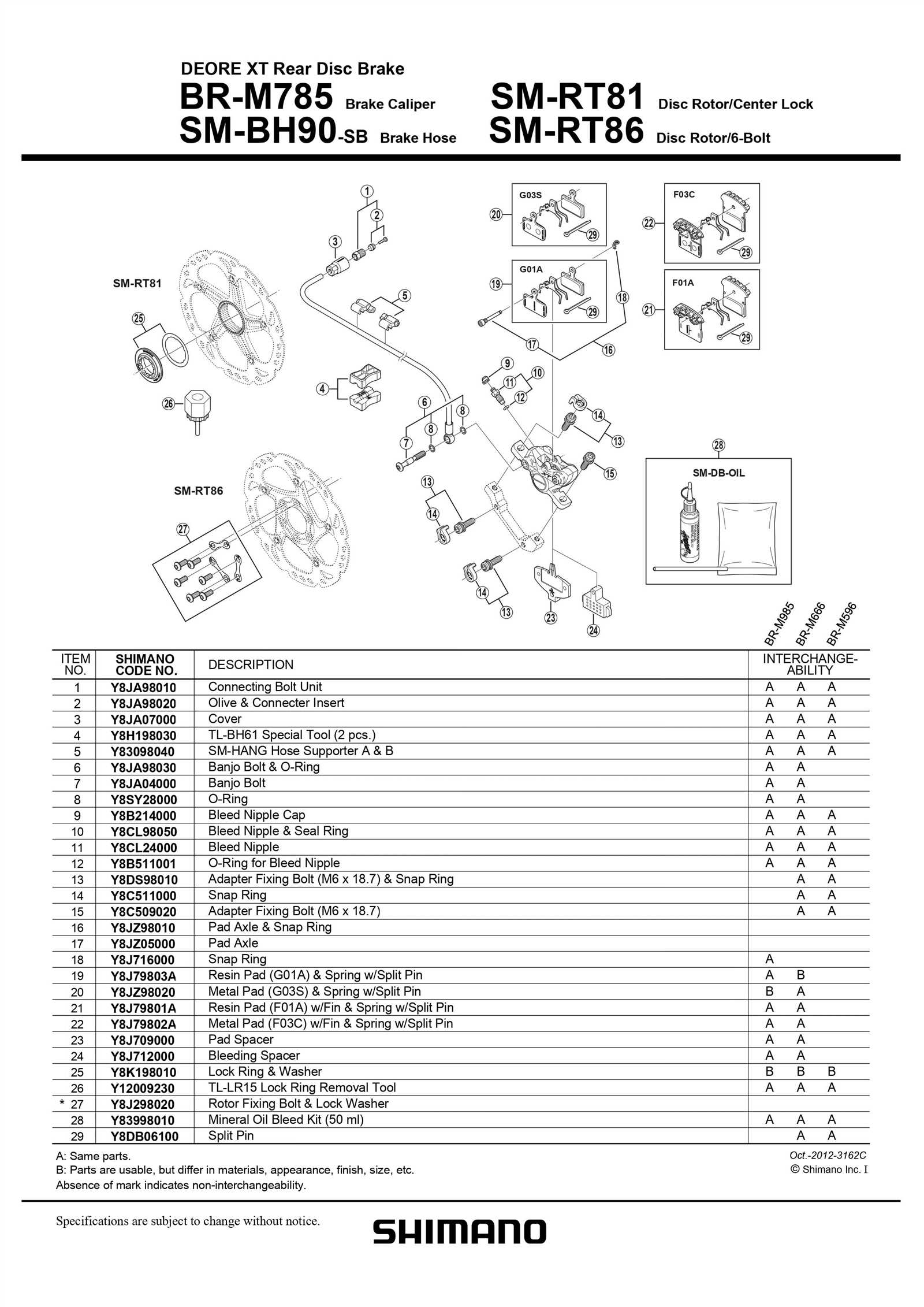

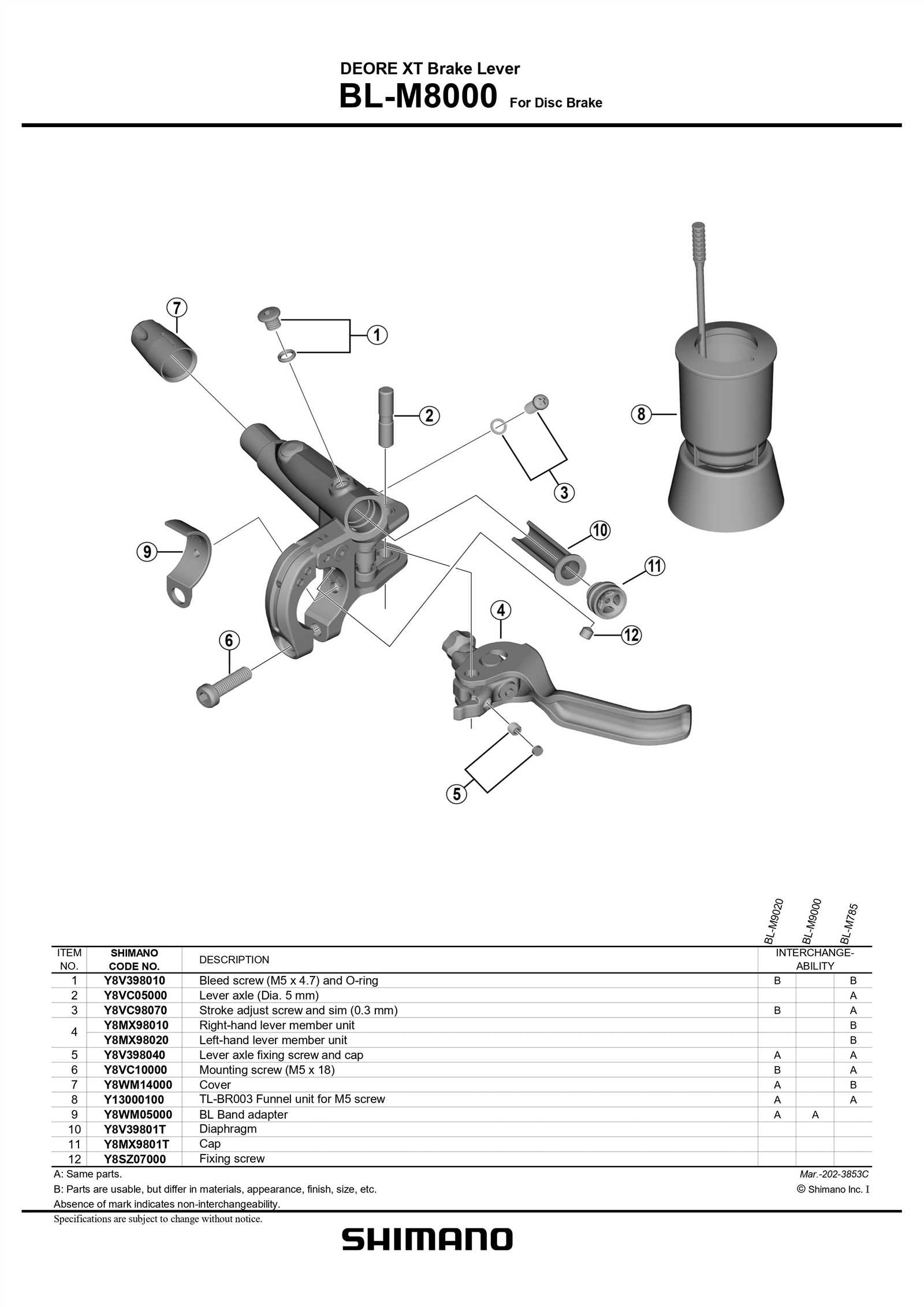

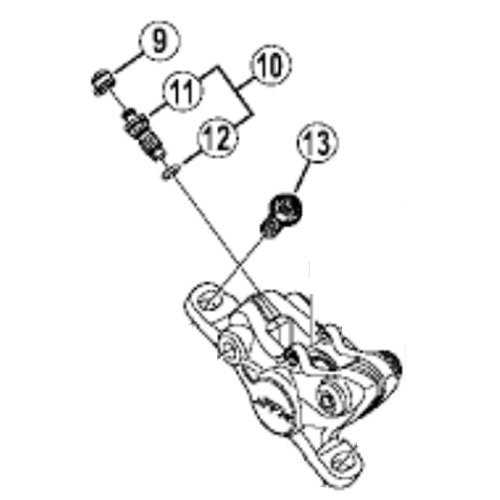

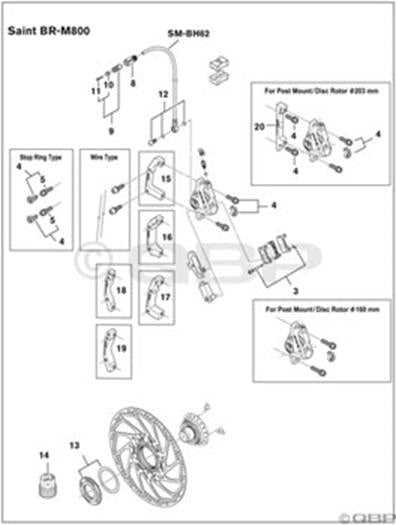

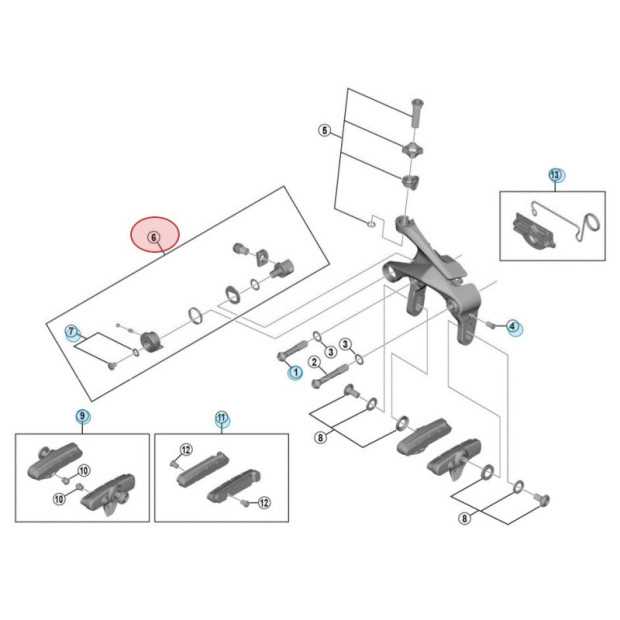

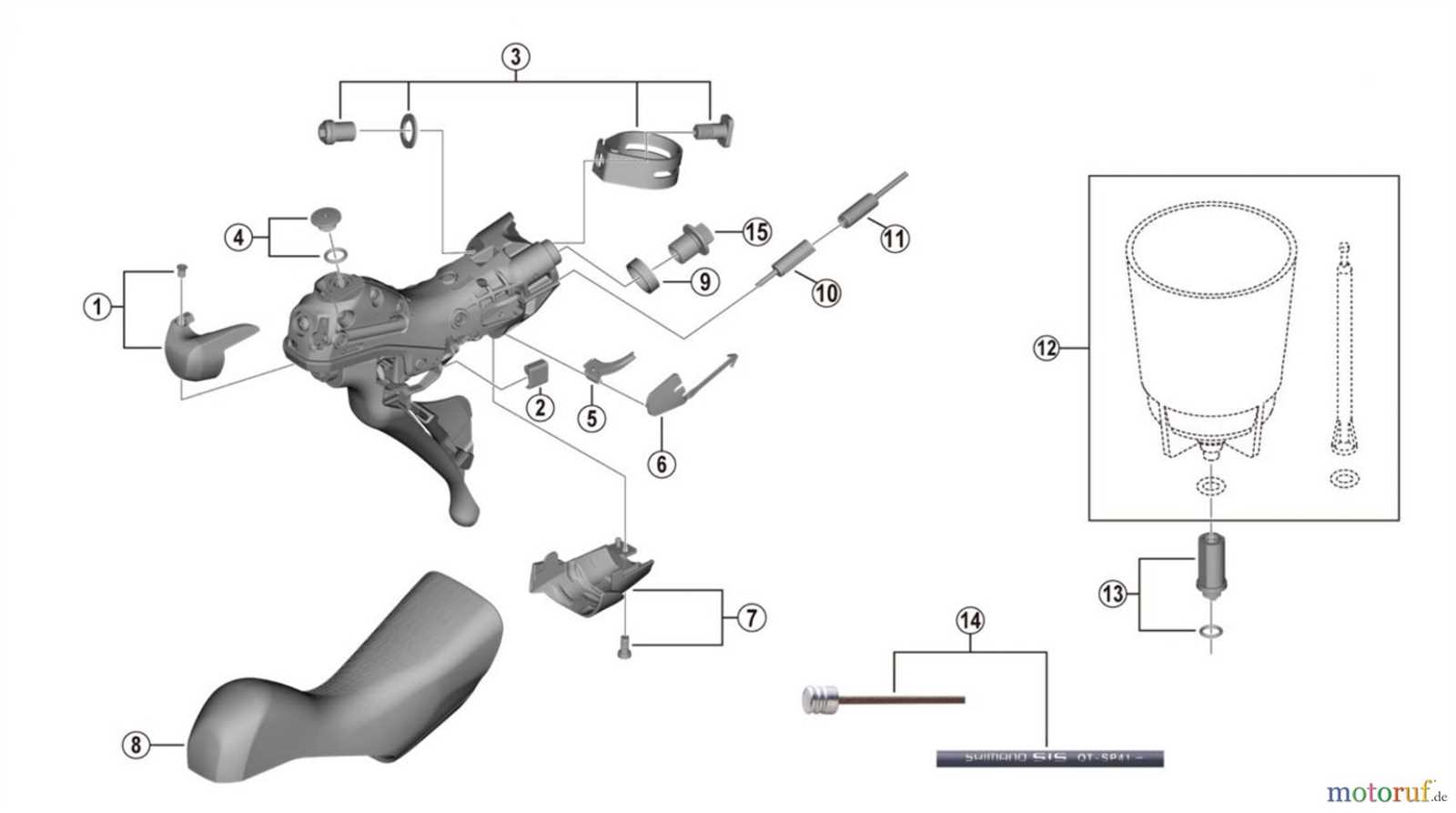

Types of Shimano Brake Components

This section explores the various elements essential for effective stopping mechanisms in cycling. Understanding these components is crucial for maintaining optimal performance and ensuring rider safety.

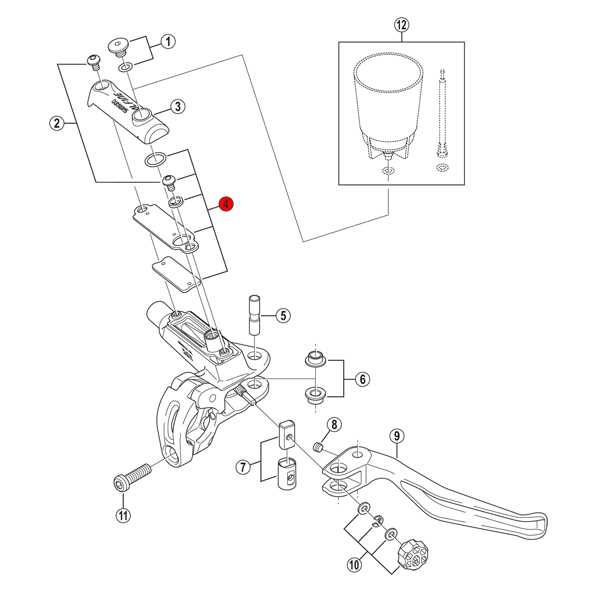

Calipers and Lever Systems

Calipers play a vital role in the overall functionality, providing the necessary force to engage the friction material. Lever systems enhance user control, allowing for precise adjustments based on rider preference and environmental conditions.

Friction Materials and Hoses

Friction materials, commonly made from compounds designed for durability, directly impact the performance and feel of the system. Additionally, hoses are essential for fluid transmission, contributing to the responsiveness of the entire assembly.

Common Issues with Brake Parts

Understanding the typical challenges that arise with stopping mechanisms is essential for maintaining optimal performance. Various factors can lead to malfunctions, affecting overall safety and functionality.

- Wear and Tear: Over time, components can degrade due to regular use, leading to decreased efficiency.

- Noise: Unusual sounds during operation often indicate misalignment or insufficient lubrication.

- Leaking Fluid: Any signs of fluid leakage can signal a serious issue requiring immediate attention.

- Overheating: Excessive heat can cause fading, resulting in a loss of stopping power.

Addressing these problems promptly can enhance the lifespan of the system and ensure safe operation.

- Regular Inspection: Frequently check for visible signs of wear.

- Proper Maintenance: Follow the recommended guidelines for upkeep to prevent issues.

- Timely Replacement: Replace any worn-out components to maintain effectiveness.

By staying vigilant and proactive, users can mitigate risks and enjoy a more reliable experience.

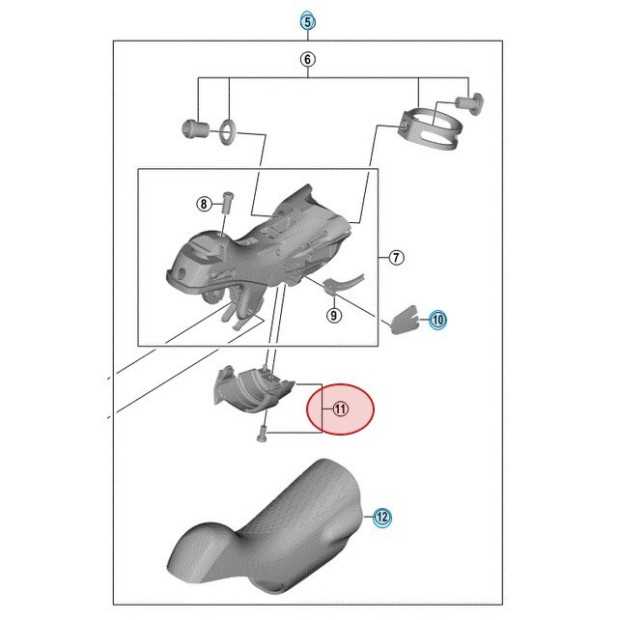

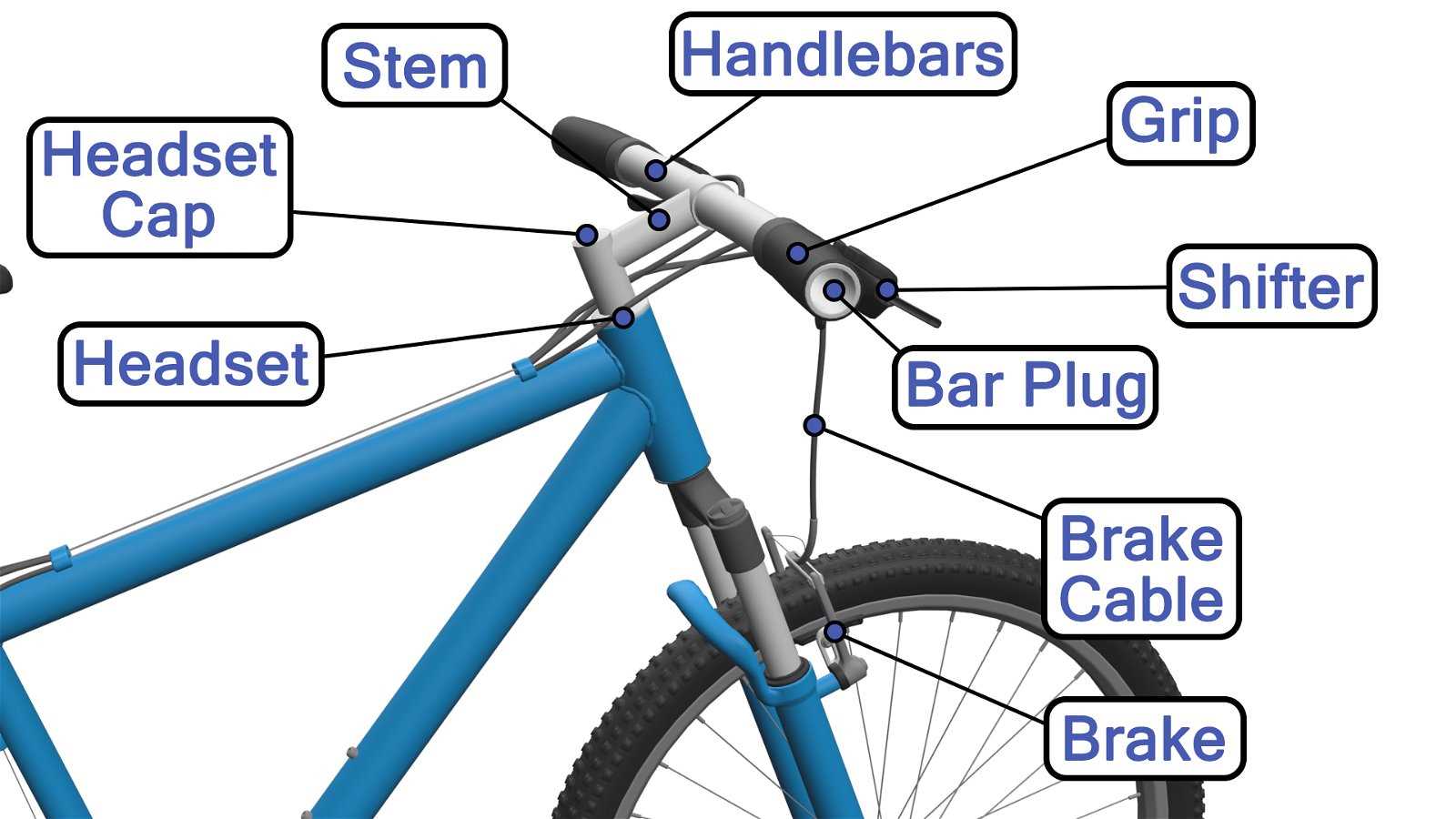

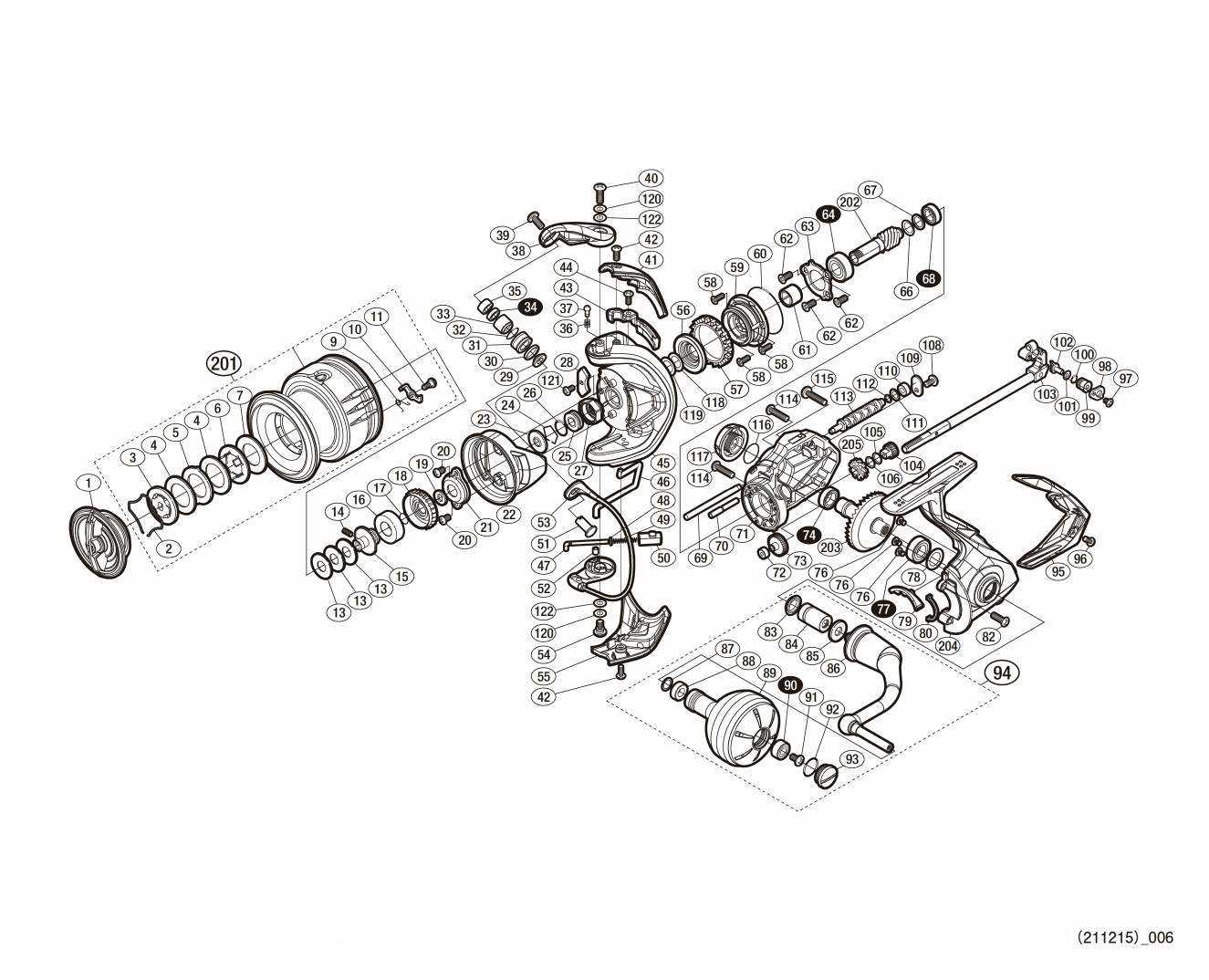

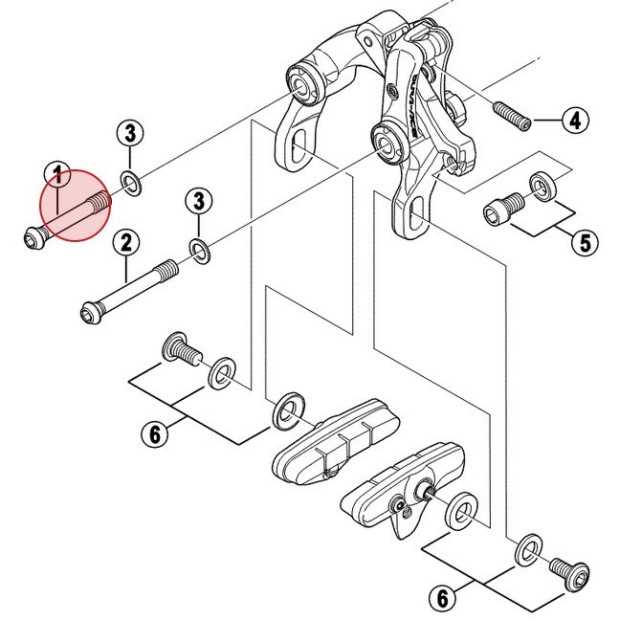

How to Read Brake Diagrams

Understanding the intricacies of technical illustrations can enhance your ability to maintain and repair various mechanisms. These visuals serve as valuable tools, guiding you through the assembly and functionality of different components. To effectively interpret these representations, familiarity with their structure and the symbols used is essential.

Begin by familiarizing yourself with the key elements, such as the legend or key that explains each symbol. These guides often highlight crucial aspects like orientation, dimensions, and connections. Pay close attention to how components are labeled; this helps in identifying parts and their respective functions within the system.

As you delve deeper, look for any annotations or notes that may provide additional insights into assembly techniques or maintenance tips. Taking the time to analyze each element will ultimately empower you to tackle repairs with confidence and precision.

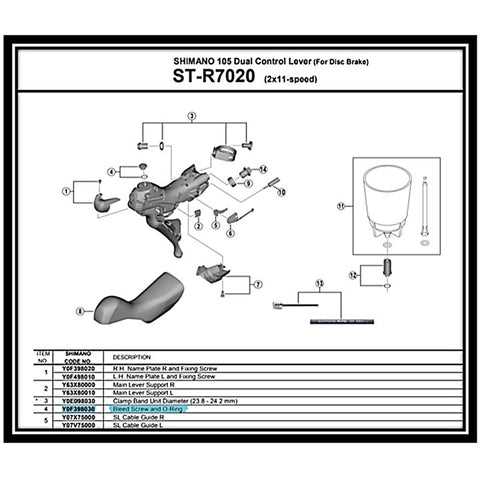

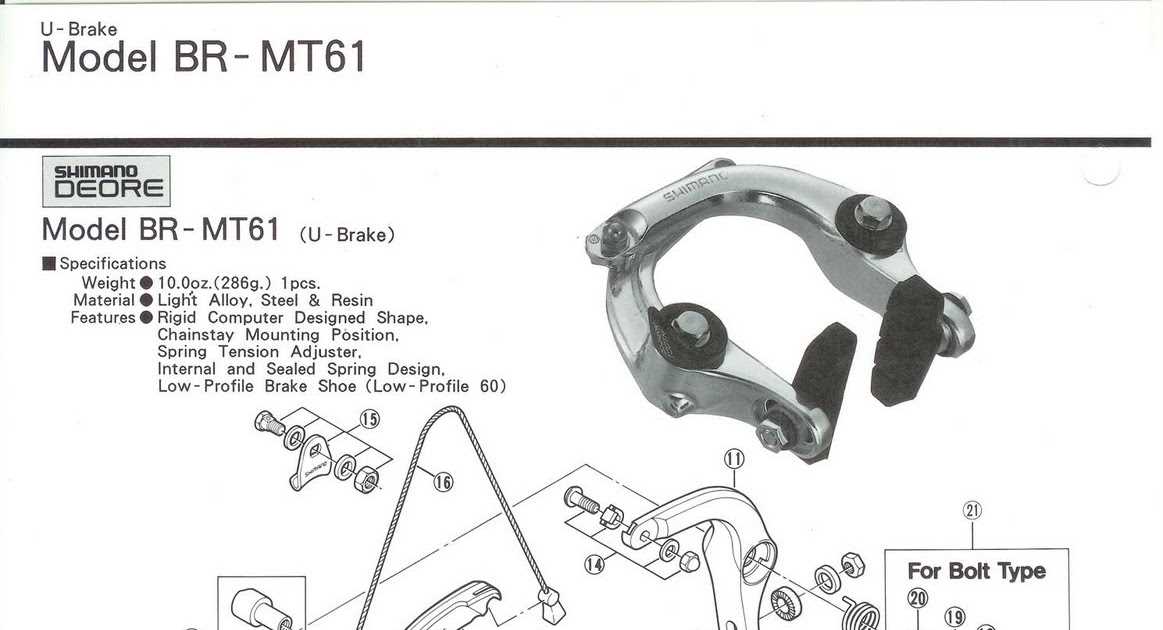

Identifying Shimano Brake Models

Recognizing different models within the realm of cycling components can significantly enhance your maintenance and upgrade endeavors. Understanding the characteristics and features associated with each design allows for better compatibility and performance optimization.

When it comes to distinguishing various models, consider the following aspects:

- Design Type: Examine the overall structure and mechanism. Different types might include hydraulic, mechanical, or cable-actuated systems.

- Color and Finish: Many manufacturers use distinct color schemes or finishes that can help in identification.

- Model Numbers: Look for engraved numbers or markings that usually indicate the specific model.

- Lever Shape: The shape and ergonomics of the lever can vary, providing clues about the model.

- Pad Composition: Different models often utilize specific materials for their pads, affecting performance and durability.

To further refine your identification process, consult documentation or online resources that provide detailed information on various models. Engaging with communities or forums can also yield valuable insights and tips from experienced cyclists.

Tools Needed for Brake Maintenance

Maintaining your stopping system is essential for optimal performance and safety. Having the right equipment can make this process straightforward and efficient. Below is a list of essential tools that will assist you in keeping everything in top condition.

First and foremost, a quality set of wrenches is crucial for loosening and tightening various components. A torque wrench is particularly useful for ensuring that everything is secured to the manufacturer’s specifications. Additionally, a set of screwdrivers in different sizes will help you access hard-to-reach areas.

Next, a specialized cleaning solution and brush are vital for removing dirt and grime. This step is important for maintaining functionality and longevity. A lubricant specifically designed for your system is also necessary to keep moving parts operating smoothly.

Finally, having a multi-tool that combines several functions can be a great asset for quick adjustments on the go. With these tools in hand, you’ll be well-equipped to ensure your system operates safely and effectively.

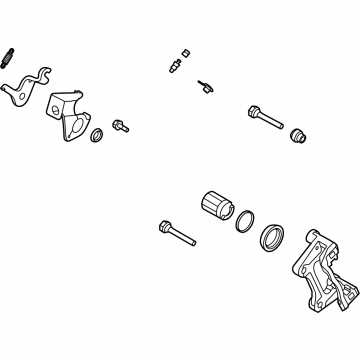

Steps for Replacing Brake Parts

Replacing essential components of your stopping system is crucial for maintaining optimal performance and safety. This process involves careful preparation and execution to ensure a successful outcome. Below are the steps to effectively carry out this task.

1. Gather Necessary Tools and Components: Before you begin, make sure you have all the required tools such as wrenches, screwdrivers, and any new components needed for the replacement. Having everything on hand will streamline the process.

2. Prepare the Vehicle: Ensure the vehicle is parked on a flat surface and engage the parking brake. This will provide stability while you work. If applicable, remove the wheel to access the components easily.

3. Remove the Old Components: Carefully detach the existing elements that need replacement. This may involve unscrewing bolts or unclipping parts. Take note of the arrangement for accurate reassembly.

4. Install New Components: Position the new items into place following the arrangement of the old ones. Ensure that everything is aligned properly to avoid any functional issues.

5. Secure and Test: Once installed, tighten all bolts and fasteners to the manufacturer’s specifications. Afterward, conduct a test to verify that everything operates smoothly and efficiently.

6. Reassemble and Clean Up: If you removed any wheels or covers, put them back in place. Clean the workspace and properly dispose of any old components.

By following these steps, you can ensure that your vehicle’s stopping mechanism functions effectively, contributing to a safer driving experience.

Importance of Regular Brake Checks

Maintaining optimal performance of your stopping mechanism is crucial for safety and reliability. Regular inspections can prevent unforeseen issues, ensuring smooth operation and longevity of the system.

Benefits of Routine Inspections

- Enhanced safety during operation.

- Increased lifespan of components.

- Improved overall performance and responsiveness.

- Early detection of wear and tear, saving costs on repairs.

Key Areas to Focus On

- Checking fluid levels and quality.

- Inspecting the effectiveness of the mechanism.

- Examining wear on key components.

- Ensuring proper alignment and adjustments.

Upgrading Shimano Brake Systems

Enhancing your stopping mechanisms can significantly improve your overall riding experience. Whether you are looking to increase responsiveness, reduce weight, or enhance durability, exploring available upgrades can yield impressive results. Understanding the components involved and their compatibility is essential for achieving optimal performance.

Choosing Upgrades

When considering enhancements, it’s crucial to evaluate the specific elements you wish to improve. Upgrading to advanced materials can provide better heat dissipation and longevity, while modifying the lever system can offer improved modulation and feel. Each adjustment plays a role in refining the efficiency and responsiveness of your system.

Installation Tips

Proper installation is vital for any enhancement. Carefully follow manufacturer instructions to ensure a secure fit and optimal functionality. If you’re uncertain, consulting with a professional can prevent potential issues and guarantee that your modifications are executed flawlessly.

Maintenance Considerations

After upgrading, regular maintenance becomes even more important. Keeping components clean and well-lubricated will prolong their lifespan and maintain performance. Regular checks for wear and tear will help you catch any potential problems early, ensuring a smooth ride every time.

Maintaining Brake Performance Over Time

Ensuring optimal functionality of your stopping mechanisms is crucial for safety and efficiency. Over time, various components may wear down or accumulate debris, which can affect responsiveness. Regular maintenance practices can help preserve performance and extend the lifespan of these essential elements.

Periodic inspection is vital. Check for signs of wear, such as discoloration or uneven surfaces. Keeping the area clean from dirt and grime will prevent unnecessary strain on the system. Additionally, lubricating moving parts appropriately can enhance fluidity and responsiveness.

Timely replacement of worn components is essential. Neglecting this can lead to diminished performance and, ultimately, more significant issues. Staying informed about the specific needs of your equipment allows for proactive measures, ensuring a smooth and safe experience every time you engage the system.

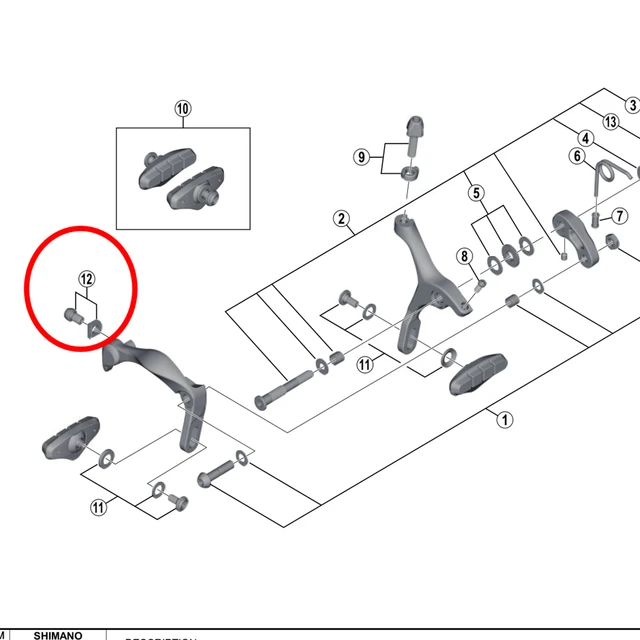

Shimano Brake Adjustment Techniques

Proper alignment and calibration of your stopping mechanism are essential for optimal performance and safety. Ensuring that components are correctly set can enhance responsiveness and provide a smoother riding experience. In this section, we will explore effective methods to fine-tune your system for better functionality.

1. Cable Tension Adjustment: The initial step involves checking the tension of the control lines. Too much slack can result in unresponsive action, while excessive tightness may lead to premature wear. Adjust the tension by turning the barrel adjuster, allowing for precise control over responsiveness.

2. Alignment of Components: Ensuring that all elements are aligned correctly is crucial. Inspect the positioning of the mechanism relative to the wheel and pads. Misalignment can lead to uneven wear or diminished stopping power. Use appropriate tools to reposition any misaligned parts.

3. Pad Positioning: The contact area between the stopping surfaces and the wheel is vital for effective operation. Make sure the pads are properly aligned and have sufficient contact with the rim or rotor. Adjust their positioning to ensure full contact without dragging or excessive clearance.

4. Regular Maintenance: Periodic checks and maintenance can prevent performance issues. Clean the components regularly and replace any worn elements to ensure consistent operation. Keeping everything in good condition enhances longevity and efficiency.

5. Test and Fine-Tune: After making adjustments, conduct test rides to assess performance. Pay attention to responsiveness and any unusual noises. Make incremental adjustments as necessary until the desired feel is achieved.

FAQs About Shimano Brake Parts

This section addresses common inquiries related to components involved in stopping mechanisms, helping users understand their functionality, maintenance, and replacement options. By providing clear answers, we aim to enhance user knowledge and confidence in managing their equipment.

What are the signs that my stopping system needs attention?

Indicators of wear may include unusual noises, decreased responsiveness, or visible damage. If you notice any of these symptoms, it’s advisable to inspect the mechanism promptly.

How often should I replace these components?

The lifespan varies based on usage, conditions, and quality. Regular inspections and following manufacturer guidelines can help determine the appropriate replacement schedule. It’s crucial to prioritize safety and performance.

Maintenance tips: Regular cleaning and lubrication can extend the lifespan of your equipment. Always refer to the user manual for specific maintenance procedures.

Where to Find Replacement Parts

Locating suitable components for your cycling system can be a straightforward task with the right approach. Various sources offer an extensive selection to ensure your equipment functions optimally.

Online Retailers

- Specialized cycling websites

- General e-commerce platforms

- Manufacturer’s official site

Local Shops

- Bike repair stores

- Sporting goods retailers

- Second-hand bicycle shops

Consider checking reviews and recommendations to make informed choices about quality and compatibility.