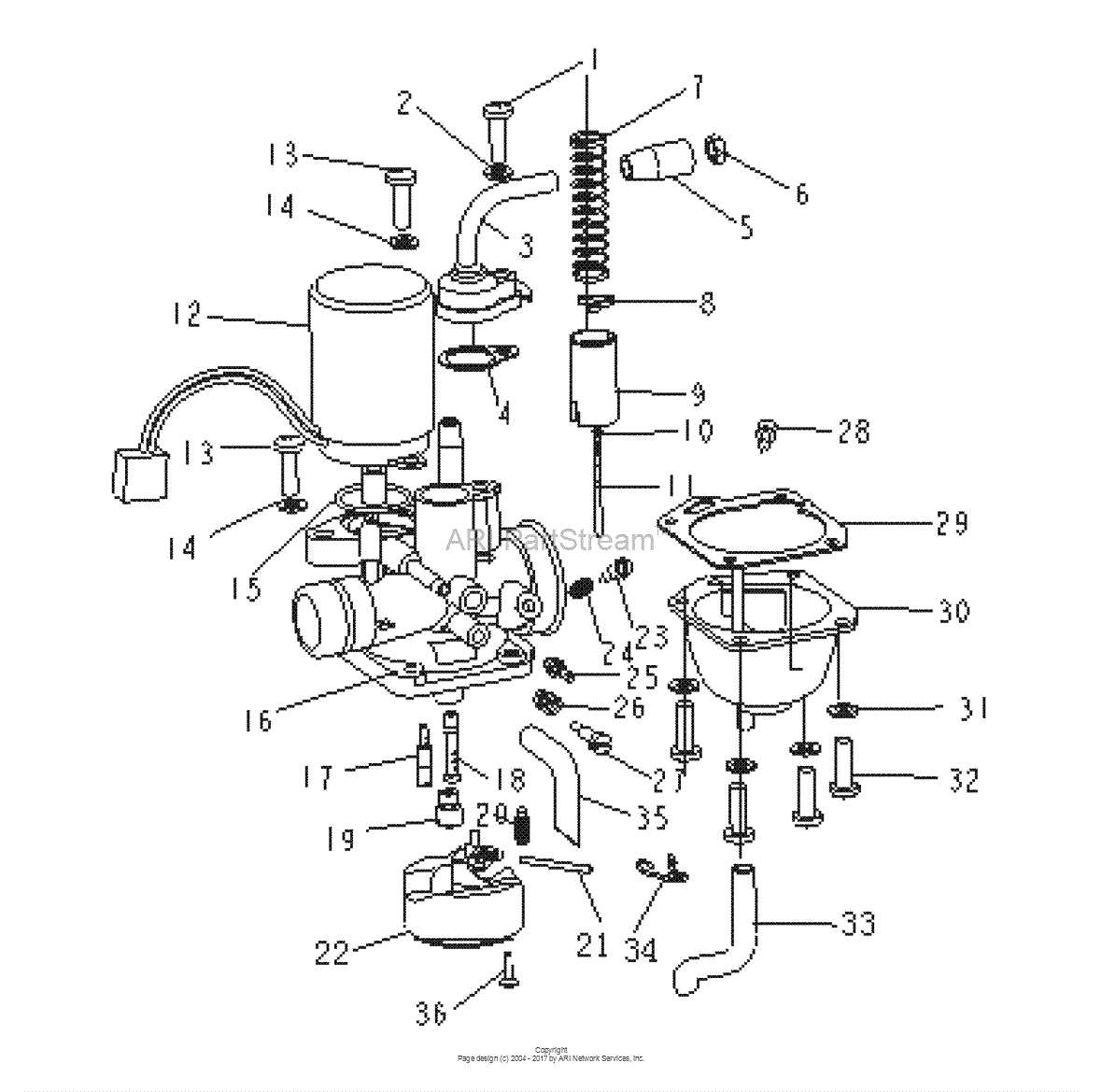

Understanding the Parts Diagram of a Motorized Bicycle Carburetor

The intricacies of small engine fuel systems are crucial for optimal performance and efficiency. Grasping how each component contributes to the overall functionality is key for enthusiasts and builders alike. This section aims to illuminate the fundamental elements that work in harmony to ensure smooth operation.

Exploring the inner workings of these mechanisms can reveal valuable insights into maintenance and troubleshooting. By examining various elements, one can appreciate their roles and interconnections. This knowledge is not only beneficial for repairs but also enhances the experience of customization.

Through this detailed exploration, readers will uncover the ultimate insights into enhancing performance and longevity. Understanding these essential components will empower you to make informed decisions, whether for routine care or innovative upgrades.

Understanding Carburetor Basics

The mechanism responsible for mixing air and fuel in an engine is crucial for its efficient operation. This process ensures optimal combustion, directly impacting performance and efficiency. Grasping the fundamentals of this assembly aids in diagnosing issues and enhancing engine functionality.

| Component | Function |

|---|---|

| Venturi | Creates a vacuum to draw fuel into the airstream. |

| Throttle Valve | Regulates air and fuel flow to the engine. |

| Float Chamber | Maintains a consistent fuel level for steady operation. |

| Jet | Controls the amount of fuel delivered into the airstream. |

Components of a Motorized Bicycle Carburetor

This section explores the essential elements that contribute to the efficient operation of an engine’s fuel delivery system. Understanding these components helps in diagnosing issues, performing maintenance, and enhancing overall performance.

Main Elements

The main components play a crucial role in regulating the air-fuel mixture, ensuring optimal combustion within the engine. Each element works in harmony to deliver power and efficiency.

| Component | Description |

|---|---|

| Throttle Valve | Controls the amount of air entering the system, influencing power output. |

| Float Chamber | Maintains a consistent level of fuel for proper delivery to the engine. |

| Jet | Regulates the flow of fuel, allowing for precise mixing with air. |

| Needle Valve | Controls fuel flow into the float chamber, ensuring balance. |

Supporting Features

In addition to the main components, various supporting features enhance functionality. These elements ensure stability and reliability during operation, contributing to a smoother experience.

| Feature | Function |

|---|---|

| Choke | Richens the fuel mixture for easier starting in cold conditions. |

| Air Filter | Prevents contaminants from entering the fuel system, maintaining cleanliness. |

| Fuel Line | Transports fuel from the tank to the delivery mechanism. |

How Carburetors Function in Engines

Understanding the role of these essential components in internal combustion engines reveals how they create the optimal mixture of air and fuel for combustion. This mixture is critical for efficient engine performance, fuel economy, and emission control.

Key Functions

- Air-Fuel Mixture Regulation: The primary task is to mix air and fuel in the correct proportions. This balance is vital for effective combustion.

- Atomization: The system atomizes the fuel, turning it into a fine mist that enhances combustion efficiency.

- Throttle Control: Adjusting airflow regulates engine power output, allowing for acceleration or deceleration as needed.

Working Principle

The operation of these components is based on the principles of fluid dynamics and pressure differentials. When air flows through, it creates a vacuum that draws fuel into the airflow. The following steps outline the process:

- Air enters through an intake, where it is drawn into the mixing chamber.

- A drop in pressure due to the venturi effect allows fuel to be sucked into the air stream.

- The air-fuel mixture travels through the engine, where it ignites, producing energy.

This seamless interaction between airflow and fuel ensures that engines run smoothly and efficiently, highlighting the importance of maintaining these components for optimal performance.

Common Types of Carburetors Explained

Understanding the various types of fuel mixing devices is essential for optimizing performance and efficiency in various engines. Each design has unique characteristics that cater to specific needs, making it important to choose the right one for your application.

Constant Velocity Variants

These models maintain a consistent airflow, allowing for smoother operation across a wide range of speeds. They adjust the fuel flow based on the velocity of the incoming air, providing a balanced mixture that enhances throttle response.

Slide Mechanism Types

Featuring a simple design, these versions utilize a sliding mechanism to control airflow. They offer quick throttle response and are commonly found in smaller engines, making them popular among enthusiasts seeking an engaging driving experience.

Identifying Carburetor Parts and Their Roles

Understanding the components within an engine’s fuel delivery system is essential for optimal performance. Each element has a specific function, contributing to the overall efficiency and effectiveness of fuel and air mixture delivery.

Main Components

The central elements include the float chamber, which regulates fuel levels, and the throttle valve, which controls air flow. Each of these components plays a crucial role in maintaining the correct mixture for combustion.

Additionally, elements such as jets and emulsion tubes influence the fuel delivery process, while the choke helps in starting the engine under various conditions. Recognizing these features enables better troubleshooting and maintenance.

Symptoms of Carburetor Issues

Identifying problems with the fuel-air mixing device is crucial for maintaining optimal engine performance. Several signs may indicate that the system is not functioning correctly, leading to inefficiencies and potential damage.

Common indicators include irregular idling, where the engine may stall or struggle to maintain a steady speed. Additionally, excessive smoke from the exhaust can signify improper fuel mixture. Unusual sounds, such as backfiring or popping, also suggest that the device is not working as intended.

Furthermore, poor acceleration or difficulty starting the engine are further clues that warrant immediate attention. Observing these symptoms early can help prevent more severe complications down the line.

Importance of Proper Carburetor Maintenance

Maintaining the efficiency of a fuel delivery system is crucial for optimal performance and longevity of any engine. Regular upkeep not only ensures smooth operation but also prevents potential issues that could lead to costly repairs or replacements. Understanding the significance of this maintenance can greatly enhance overall functionality.

One of the key aspects of ensuring peak performance lies in the cleanliness and proper adjustment of various components. Over time, deposits and contaminants can accumulate, leading to poor fuel flow and inefficient combustion. By prioritizing maintenance, you can avoid these pitfalls and keep your engine running smoothly.

| Benefits of Regular Maintenance | Consequences of Neglect |

|---|---|

| Improved fuel efficiency | Increased fuel consumption |

| Smoother engine operation | Rough idling and stalling |

| Extended lifespan of components | Frequent breakdowns and repairs |

| Enhanced performance | Loss of power and acceleration |

In conclusion, regular attention to these systems is essential for maintaining performance, preventing issues, and ultimately ensuring a more enjoyable experience. Prioritizing maintenance can lead to significant improvements and save time and resources in the long run.

Tools Required for Carburetor Repair

Effective maintenance and repair of engine fuel systems necessitate a variety of specialized instruments. Having the right tools ensures that the process is smooth and efficient, allowing for precise adjustments and replacements.

- Screwdrivers: A set of flathead and Phillips screwdrivers is essential for loosening and tightening screws.

- Wrenches: Adjustable wrenches and socket sets are necessary for handling nuts and bolts of various sizes.

- Needle-nose Pliers: These help in gripping small components and reaching into tight spaces.

- Fuel Line Cutters: Specialized cutters make it easy to work with fuel lines without causing damage.

- Cleaning Brushes: Small brushes aid in removing debris and buildup from intricate areas.

- Gasket Scraper: This tool is vital for removing old gaskets and ensuring a clean surface for new ones.

In addition to these essentials, having a few extra items can enhance the repair experience:

- Torque Wrench: Ensures that bolts are tightened to the correct specifications.

- Compressed Air Canister: Useful for blowing out dirt and residue from hard-to-reach spots.

- Multimeter: Essential for diagnosing electrical issues within the system.

Equipped with these tools, anyone can approach the task of maintenance and troubleshooting with confidence and precision.

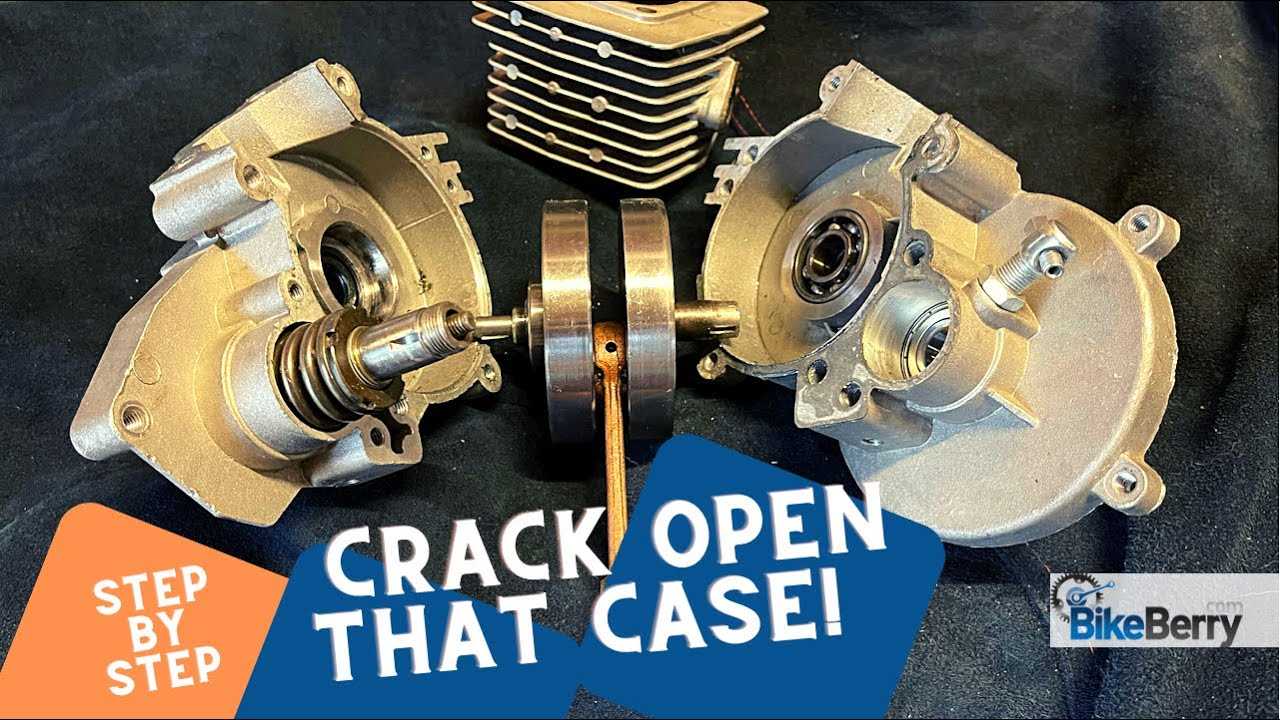

Step-by-Step Carburetor Assembly Guide

Assembling an essential fuel delivery component requires precision and attention to detail. This guide will walk you through the process of reassembling the various elements, ensuring optimal performance and reliability. Follow these instructions carefully to achieve a successful assembly.

Step 1: Gather Your Tools

Step 2: Organize Components

Lay out all the individual elements in the order they will be assembled. This will help you keep track of each piece and reduce the risk of losing any important items.

Step 3: Start with the Base

Begin by securing the main base. Align it properly with the intake and ensure that any seals are in place to prevent leaks.

Step 4: Install the Float Assembly

Next, carefully place the float mechanism into the designated chamber. Make sure it moves freely and is not obstructed by any other components.

Step 5: Attach the Needle Valve

Connect the needle valve to the float assembly, ensuring it fits snugly. This step is crucial for maintaining the correct fuel level within the chamber.

Step 6: Assemble the Jet System

Insert the jet into its corresponding position, tightening it gently to avoid damage. The jet controls fuel flow, so accuracy here is vital.

Step 7: Finalize with the Cover

Carefully place the cover over the assembled components, securing it with screws. Ensure that all seals are intact to prevent any air leaks.

Step 8: Conduct a Test

Once assembled, perform a thorough check for any loose parts or potential issues. A test run will help confirm that everything operates smoothly.

By following these steps diligently, you can ensure that your assembly is completed correctly, leading to efficient operation in its application.

Upgrading Your Carburetor for Performance

Enhancing the efficiency of your engine can significantly improve its overall performance. One of the most effective ways to achieve this is by focusing on the fuel delivery system. By refining the components that manage air and fuel flow, you can unlock the potential of your power unit, leading to smoother operation and increased power output.

Choosing the Right Components

When considering upgrades, it’s crucial to select high-quality components that are compatible with your engine. Options such as high-flow jets and improved float mechanisms can lead to better fuel atomization, which in turn enhances combustion efficiency. Researching aftermarket alternatives can provide insight into the best products available, ensuring you make informed decisions.

Tuning for Optimal Performance

After installing new components, proper tuning is essential to maximize benefits. Adjusting settings such as air-fuel mixture ratios and idle speed can lead to noticeable gains in responsiveness and power. Regular maintenance and tuning adjustments will help maintain optimal performance, ensuring your engine runs smoothly and efficiently over time.

Common Misconceptions About Carburetors

Many enthusiasts hold several inaccurate beliefs about fuel delivery systems. These misunderstandings can lead to improper maintenance and performance issues. It’s essential to clarify these points to ensure optimal operation and longevity.

One common myth is that these systems only function effectively in certain conditions. In reality, they are designed to adapt to various environments and demands, ensuring reliable performance under most circumstances.

Another misconception is that adjusting these mechanisms is a straightforward task that anyone can handle. While basic tweaks may seem simple, achieving the ultimate efficiency often requires a deeper understanding of their complex workings.

Lastly, many believe that once set up, these systems do not require further attention. However, regular maintenance and fine-tuning are crucial to keep them functioning at their best.

Resources for Further Carburetor Learning

Gaining a deeper understanding of fuel delivery systems is essential for anyone interested in optimizing engine performance. Whether you’re a hobbyist or a professional, numerous materials can enhance your knowledge and skills. Below are some valuable resources to guide you on this journey.

Books: Several comprehensive guides delve into the intricacies of fuel mixing mechanisms, offering insights into their operation and maintenance. Titles like “The Art of Tuning” and “Engine Management: Advanced Tuning” provide essential information for enthusiasts at all levels.

Online Courses: Platforms such as Coursera and Udemy offer courses focusing on engine technology. These classes often include video lectures, quizzes, and interactive forums, fostering a supportive learning environment.

Forums and Communities: Engaging with fellow enthusiasts can be incredibly beneficial. Online forums like Reddit’s r/MechanicAdvice and specialized groups on Facebook serve as platforms for discussion, troubleshooting, and sharing experiences.

YouTube Channels: There are numerous channels dedicated to mechanical systems, providing tutorials, troubleshooting tips, and reviews of tools. Channels like “Engineering Explained” and “The Garage Journal” are excellent starting points.

Manufacturer Websites: Many brands offer resources, including technical documents and troubleshooting guides. Checking the official sites can provide specific information relevant to various systems.

Utilizing these resources will enhance your comprehension and expertise, empowering you to tackle projects with confidence.