Understanding Walbro Carburetor Parts Diagram

In the realm of small engine mechanics, a precise understanding of fuel delivery systems is essential for optimal performance and efficiency. These systems play a crucial role in the proper functioning of various machinery, ensuring that the engine receives the right mixture of air and fuel for combustion. Familiarity with the intricate elements involved can greatly enhance maintenance practices and troubleshooting efforts.

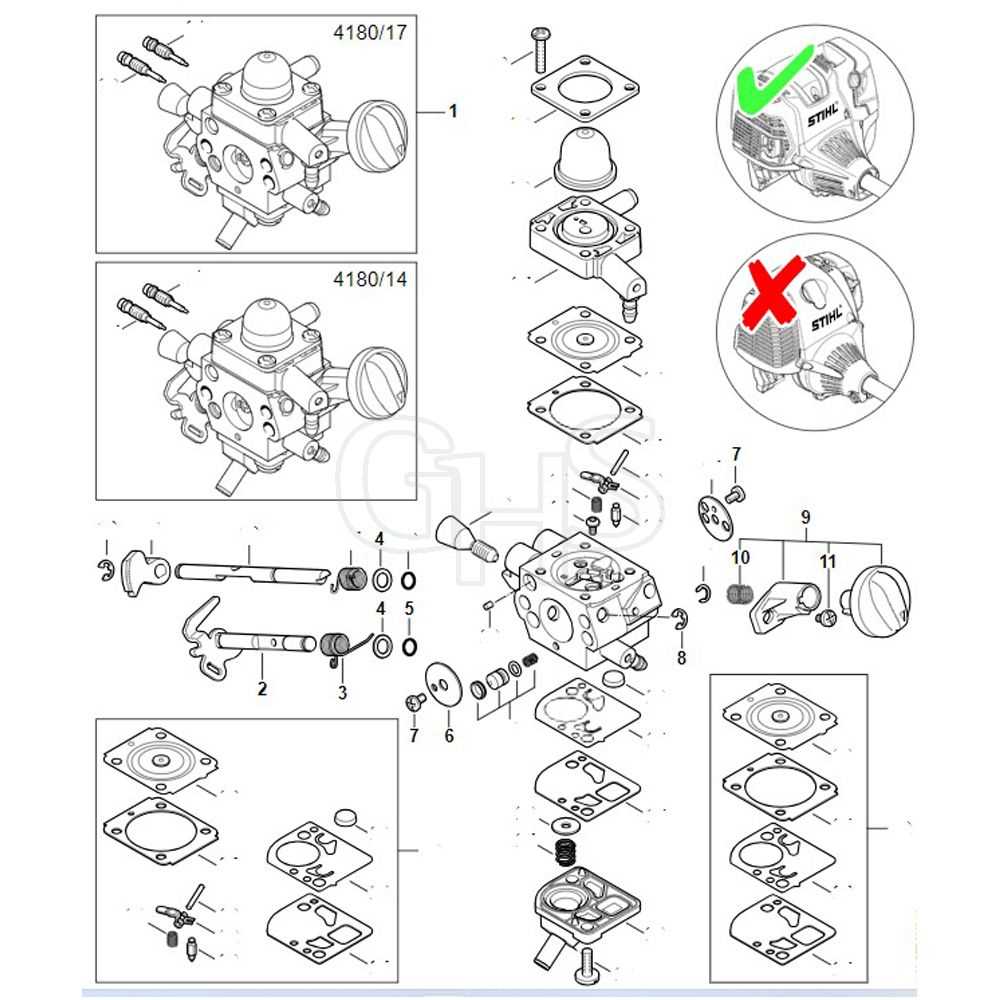

Exploring the intricate layout of these essential components reveals how each element interacts to facilitate smooth operation. From metering devices to flow pathways, each section serves a distinct purpose, contributing to the overall functionality of the system. A comprehensive breakdown not only aids in repairs but also empowers users to make informed decisions regarding upgrades and modifications.

Visual representations of these assemblies can significantly simplify the learning process. By examining these illustrations, one can quickly identify each component’s role and position, leading to a deeper understanding of how they work together harmoniously. This knowledge is invaluable for both novice and experienced users looking to enhance their skills in engine maintenance.

Understanding Walbro Carburetor Basics

When it comes to the intricate mechanisms that control fuel and air mixtures in small engines, a solid grasp of their fundamental components and operation is essential. This understanding not only enhances performance but also aids in effective troubleshooting and maintenance.

Key Components and Their Functions

The assembly consists of several critical elements that work in harmony. The throttle regulates the airflow, while the fuel delivery system ensures the right mixture reaches the combustion chamber. Additionally, adjustment screws allow for fine-tuning to accommodate various environmental conditions and engine requirements.

Tuning and Maintenance Tips

Proper calibration is crucial for optimal engine performance. Regular inspection and cleaning of the assembly can prevent common issues such as clogging and inefficient fuel flow. Understanding how to adjust the mixture and airflow can lead to significant improvements in power and efficiency.

Key Components of Walbro Carburetors

Understanding the essential elements that facilitate optimal fuel delivery is crucial for effective engine performance. Each of these vital components plays a specific role in ensuring proper mixing of air and fuel, allowing for efficient combustion and smooth operation.

Fuel Delivery Mechanism

The fuel delivery mechanism is responsible for transporting the fuel from the tank to the combustion chamber. This system typically includes a fuel pump and a filter, ensuring that only clean fuel reaches the engine. The design and efficiency of this mechanism are pivotal for maintaining consistent performance.

Air-Fuel Mixture Control

The air-fuel mixture control system regulates the ratio of air to fuel entering the engine. This is achieved through components such as the throttle valve and adjustment screws, which allow for fine-tuning. Proper calibration of this system is essential for optimal power output and fuel efficiency.

How to Read a Parts Diagram

Understanding an assembly illustration is essential for effective maintenance and repair tasks. These visuals serve as a guide, providing an overview of components and their relationships. Familiarity with the layout and symbols can significantly streamline the process of identifying and replacing elements in a system.

Identifying Components

Begin by examining the key that usually accompanies the illustration. This legend explains the symbols and numbers used, offering clarity on what each part represents. Pay close attention to any color coding or shading, as these often indicate different categories or functions within the assembly.

Understanding Connections

Next, focus on how the components interact with one another. Lines connecting different elements typically represent physical connections or pathways. Following these links can help you understand how each piece contributes to the overall functionality, making it easier to troubleshoot issues or perform replacements.

Common Issues with Walbro Carburetors

Understanding the frequent challenges associated with fuel delivery mechanisms can greatly enhance their performance and longevity. Many users encounter a variety of symptoms that indicate underlying issues, ranging from inefficient fuel flow to erratic engine behavior. Identifying these common problems is essential for proper maintenance and optimal functionality.

Fuel Flow Problems

One of the primary concerns relates to inadequate fuel flow, which can manifest in several ways. Blockages, wear, and improper adjustments can impede the fuel’s journey from the tank to the engine, resulting in poor performance.

| Symptoms | Potential Causes |

|---|---|

| Engine stalls or hesitates | Clogged fuel lines or filter |

| Difficulty starting | Faulty pump or incorrect settings |

| Poor acceleration | Dirty or worn components |

Adjustment and Tuning Issues

Improper calibration can lead to suboptimal operation, affecting overall efficiency. Regular tuning is crucial to maintain the correct air-fuel mixture, which is vital for effective combustion and engine response.

Tools Needed for Maintenance

To ensure optimal performance and longevity of your equipment, it’s essential to have the right tools at your disposal. Proper maintenance not only enhances efficiency but also prevents potential issues from escalating. Here’s a guide to the necessary implements for routine care and servicing.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws during disassembly and assembly. |

| Socket Wrench | To remove bolts and nuts securely without stripping them. |

| Pliers | For gripping, bending, and cutting wires or small components. |

| Fuel Line Clamp | To prevent fuel leakage when working on fuel systems. |

| Cleaning Brush | To remove dirt and debris from intricate areas. |

| Compressed Air Canister | For blowing out dust and particles from hard-to-reach spots. |

| Protective Gloves | To ensure safety while handling components and chemicals. |

Having these tools on hand will facilitate effective upkeep and help you tackle maintenance tasks with confidence.

Step-by-Step Repair Process

Undertaking a repair can seem daunting, but breaking it down into manageable steps simplifies the task. This guide outlines a systematic approach to ensure each component is thoroughly examined and restored to optimal functionality.

Start by gathering the necessary tools and materials. This preparation will streamline your workflow and minimize interruptions. A clean, organized workspace is crucial for maintaining focus and ensuring that small parts do not get lost.

Next, disassemble the unit carefully. Pay close attention to the order in which components are removed, as this will aid in reassembly. Taking notes or photos during this process can be beneficial for reference later on.

Once disassembled, inspect each component for wear, damage, or blockages. Cleaning parts with appropriate solvents is essential, as buildup can hinder performance. Replace any damaged elements with new or refurbished ones to guarantee reliable operation.

After the components have been cleaned and inspected, reassemble the unit in the reverse order of disassembly. Ensure all connections are secure and that components fit snugly without forcing them together.

Finally, conduct a thorough test to confirm that everything is functioning as intended. Adjust settings if necessary, and make sure to observe the operation for any irregularities. This final step will help you identify any remaining issues before full usage.

Identifying Replacement Parts

Understanding how to recognize essential components in your equipment is crucial for effective maintenance and repair. Proper identification ensures that you select the correct items for replacement, enhancing performance and longevity.

When searching for the right components, consider the following steps:

- Check the model number: This information is often found on a label or stamped onto the device.

- Consult the manufacturer’s guide: Look for documentation that details the specifications and compatible components.

- Examine the existing elements: Take note of size, shape, and any distinguishing features that can aid in identification.

Additionally, familiarize yourself with common terminologies associated with these components:

- Gaskets: Essential for sealing and preventing leaks.

- Diaphragms: Critical for regulating airflow and fuel delivery.

- Needles: Play a key role in controlling the flow of fuel.

Utilizing these strategies will streamline the process of finding suitable replacements, ensuring your equipment operates efficiently.

Adjusting Fuel Mixture Settings

Fine-tuning the fuel mixture is essential for optimal engine performance and efficiency. The right balance ensures that the combustion process runs smoothly, minimizing emissions and maximizing power. By adjusting the mixture, users can adapt to various operating conditions and enhance the overall reliability of the engine.

Understanding Mixture Components

The mixture comprises two primary elements: fuel and air. Achieving the ideal ratio is crucial, as an overly rich mixture can lead to incomplete combustion, while a lean mixture may cause overheating and engine damage. Adjustments should be made carefully to strike the right balance.

Steps for Adjusting the Mixture

To initiate the adjustment, first locate the relevant screws or knobs on the unit. Turn the adjustment screw slowly while observing engine behavior. A small clockwise turn usually enriches the mixture, while counterclockwise decreases it. Listen for changes in engine sound and monitor performance. Aim for a steady idle and responsive acceleration, which indicates a well-tuned mixture.

Cleaning and Rebuilding Tips

Maintaining optimal performance of small engines often involves a thorough cleaning and refurbishment of their fuel delivery systems. Over time, residue and deposits can accumulate, affecting efficiency and functionality. Understanding how to properly clean and reassemble these components can lead to improved performance and longevity.

Essential Cleaning Techniques

Start by disassembling the unit carefully, taking note of the order and orientation of each element. Use a suitable solvent to remove grime and deposits. Soaking parts in the solution for a few minutes can help loosen stubborn residues. A soft brush or cloth can assist in reaching intricate areas. Ensure all orifices are clear to prevent blockages, which could hinder fuel flow.

Reassembly Tips

When putting everything back together, take your time to avoid misalignment. Use new seals and gaskets to prevent leaks. Lubricate moving parts lightly with a compatible oil to ensure smooth operation. Double-check that all screws and fasteners are tightened to their recommended torque specifications. A systematic approach will enhance reliability and performance, making your equipment ready for action.

Importance of Proper Installation

Ensuring the correct assembly of mechanical components is crucial for optimal performance and longevity. Each element plays a specific role in the overall functionality, and improper placement can lead to inefficiencies or failures. The precision involved in fitting these components directly affects the machine’s ability to operate smoothly.

Correct installation not only maximizes efficiency but also minimizes the risk of damage. When each piece is aligned and secured properly, the likelihood of wear and tear decreases significantly. In contrast, mistakes during the setup process can lead to leaks, misfires, or even catastrophic breakdowns.

Furthermore, attention to detail during assembly ensures that all connections are tight and functional. Regular maintenance becomes more manageable when the initial installation is executed flawlessly, allowing for easier inspections and repairs down the line. Investing time in the proper setup pays off in the long run by enhancing reliability and performance.

Frequently Asked Questions

This section aims to address common inquiries related to the assembly and maintenance of fuel delivery mechanisms. Here, we provide clear and concise answers to help you navigate through any uncertainties you may have.

What are the most common issues encountered with these systems?

Many users experience problems such as poor fuel flow, irregular engine performance, or difficulty in starting. These issues can often be traced back to blockages, wear, or incorrect adjustments. Regular maintenance and proper handling can mitigate these challenges.

How can I ensure proper maintenance?

To maintain optimal performance, it’s essential to keep the components clean and free from debris. Inspecting and replacing worn parts regularly can extend the lifespan of the mechanism. Additionally, following the manufacturer’s guidelines for adjustments and settings will help achieve the best results.

Where to Find Parts and Diagrams

Locating components and schematics for maintenance and repair tasks can significantly enhance your understanding and efficiency. Various resources are available to assist enthusiasts and professionals alike in sourcing the necessary items.

- Manufacturer’s Website: Official websites often provide detailed resources, including schematics and lists of available components.

- Online Retailers: Numerous e-commerce platforms specialize in supplying essential items for various engines and tools. Check for reviews to ensure quality.

- Forums and Community Groups: Engaging with online communities can yield valuable insights and recommendations on where to find specific items.

- Local Repair Shops: Visiting local mechanics or specialty shops can provide access to both components and expert advice.

- Manuals and Guides: Comprehensive manuals often include valuable schematics and part numbers, assisting in the identification of what you need.

Utilizing these resources can streamline your search, making repairs and maintenance more accessible and effective.