Understanding the Case IH 2188 Parts Diagram for Efficient Repairs

In the world of modern farming, the efficiency and reliability of machinery play a crucial role in ensuring optimal productivity. Understanding the intricate network of components that make up these machines is essential for maintenance and operation. Each piece contributes to the overall functionality, and knowing how they fit together can greatly enhance the longevity and performance of the equipment.

Farm machinery operates under rigorous conditions, making it vital for operators to familiarize themselves with the various elements that comprise their equipment. By gaining insights into the arrangement and relationships between different sections, users can effectively troubleshoot issues and perform necessary repairs. This knowledge not only saves time and money but also empowers individuals to take better care of their investments.

Moreover, having access to detailed visual representations of these components can be invaluable for both seasoned professionals and newcomers to the agricultural sector. Such illustrations provide clarity and ease in understanding complex machinery, allowing for more informed decisions regarding maintenance and upgrades. In this context, we delve into the specifics of a particular model, highlighting its essential components and their respective functions.

Understanding Case IH 2188 Components

Grasping the intricacies of agricultural machinery is essential for optimal performance and maintenance. Each machine is composed of various elements that work in unison, ensuring efficiency in the field. Familiarity with these components not only aids in troubleshooting but also enhances the overall productivity of operations.

When examining the core components, it’s beneficial to categorize them into distinct groups:

- Powertrain: This includes the engine and transmission systems, which are crucial for driving the machine.

- Harvesting Mechanisms: These parts are responsible for the cutting and gathering of crops, playing a pivotal role in the harvesting process.

- Conveyance Systems: These components transport materials throughout the machine, ensuring smooth operation and reducing downtime.

- Control Systems: These allow the operator to manage various functions, improving precision and ease of use.

- Frame and Structure: The backbone of the machine, providing support and stability during operation.

Understanding these categories helps in identifying specific elements for maintenance or replacement. Regular inspection and knowledge of each part’s function can lead to increased longevity and better performance in the field.

To delve deeper into each section, consider focusing on:

- Common issues associated with each component.

- Maintenance tips for longevity and reliability.

- Upgrades or modifications that can enhance performance.

This knowledge empowers operators to take informed actions, ultimately contributing to successful agricultural practices.

Overview of Case IH 2188 Model

This section provides a comprehensive overview of a specific agricultural machinery model, emphasizing its design, functionality, and efficiency. Recognized for its robust construction and advanced technology, this machine plays a vital role in modern farming operations, ensuring optimal performance and productivity.

Key Features

The featured model is equipped with several innovative characteristics that enhance its operational capabilities. From its powerful engine to its sophisticated harvesting technology, each element contributes to streamlined agricultural processes.

| Feature | Description |

|---|---|

| Engine Power | High horsepower rating for improved efficiency. |

| Cutting Width | Wide cutting platform allowing for faster harvesting. |

| Grain Handling | Advanced systems for effective grain management. |

Operational Benefits

The model is designed to enhance productivity while minimizing downtime. Its user-friendly interface and intuitive controls make it accessible for operators of varying experience levels. Furthermore, maintenance requirements are simplified, ensuring that the machinery remains in peak condition throughout its operational lifespan.

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and repair. Visual representations of these elements not only enhance comprehension but also streamline the troubleshooting process. By clearly illustrating the relationship between various parts, these aids serve as invaluable resources for both professionals and enthusiasts alike.

Facilitating Efficient Repairs

One of the primary advantages of these visual aids is their ability to simplify complex assembly structures. When mechanics encounter an issue, having access to a detailed illustration allows them to quickly identify the necessary components for repair. This efficiency reduces downtime and helps maintain optimal performance.

Enhancing Learning and Training

For those new to machinery maintenance, these visuals provide an accessible entry point for understanding how different parts interact. Educational tools that utilize graphical representations foster a deeper learning experience. They encourage hands-on practice and reinforce theoretical knowledge, ultimately leading to more skilled technicians.

In conclusion, the significance of visual resources in the maintenance of machinery cannot be overstated. They not only support quick repairs but also contribute to the development of a knowledgeable workforce.

Key Features of the 2188 Machine

This advanced agricultural equipment is designed to enhance efficiency and productivity in the field. Its innovative design incorporates several crucial elements that contribute to its exceptional performance, making it a preferred choice among farmers and operators.

Powerful Engine: At the heart of this machinery lies a robust power unit, providing ample horsepower to tackle various tasks. This strength ensures smooth operation even in challenging conditions.

Efficient Harvesting System: The harvesting mechanism is optimized for speed and accuracy, allowing for quick and effective collection of crops. This feature minimizes losses and maximizes yield.

Advanced Control Systems: Equipped with user-friendly controls, operators can easily adjust settings for different conditions. This adaptability enhances overall functionality and user experience.

Durable Construction: Built with high-quality materials, this equipment is designed to withstand the rigors of agricultural work. Its resilience ensures longevity and reliability, reducing maintenance costs.

Enhanced Operator Comfort: The spacious cabin and ergonomic layout provide a comfortable working environment. Features such as climate control and adjustable seating further enhance the operator’s experience during long hours of use.

Overall, this machine combines power, efficiency, and comfort, making it an indispensable asset for modern farming operations.

Common Replacement Parts for 2188

Maintenance and repair of agricultural machinery often require the replacement of various components to ensure optimal performance and longevity. Understanding which elements frequently need attention can help operators keep their equipment running smoothly and efficiently. Here, we highlight some of the most commonly needed replacements that enhance functionality and reliability.

Key Components

Essential elements that often require replacement include filters, belts, and bearings. These components play a vital role in the operation of the machinery, affecting everything from engine performance to overall efficiency. Regular inspection and timely replacement can prevent more significant issues down the line.

Wear and Tear Items

Items such as augers, feeder houses, and concaves also experience significant wear and tear during operation. Addressing these parts promptly ensures that the machinery continues to perform at its best, reducing downtime and increasing productivity. Operators should keep a close eye on these components to identify any signs of deterioration early on.

Locating Parts Diagrams Online

Finding detailed illustrations of machinery components can greatly enhance maintenance and repair efforts. The availability of these visual guides online facilitates a smoother process for technicians and DIY enthusiasts alike. This section aims to provide insights into where to locate these valuable resources effectively.

Utilizing Manufacturer Websites

One of the most reliable sources for component illustrations is the official website of the manufacturer. These platforms often offer comprehensive resources, including technical manuals and visual aids. Users can usually access specific models and their related parts by navigating through their catalog or support sections.

Online Forums and Communities

Engaging with online communities dedicated to machinery can yield beneficial results. Members often share resources, including visual guides and personal experiences. Websites and forums provide a platform for users to request and exchange information, making it easier to find specific illustrations that may not be readily available elsewhere.

In addition, third-party websites may host collections of resources, including user-generated content that can be incredibly helpful for locating the right visuals for your equipment. Always verify the credibility of these sources to ensure accuracy and reliability.

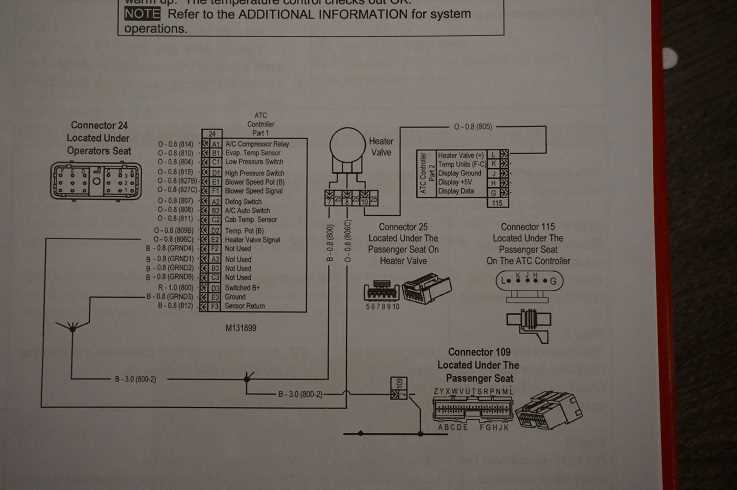

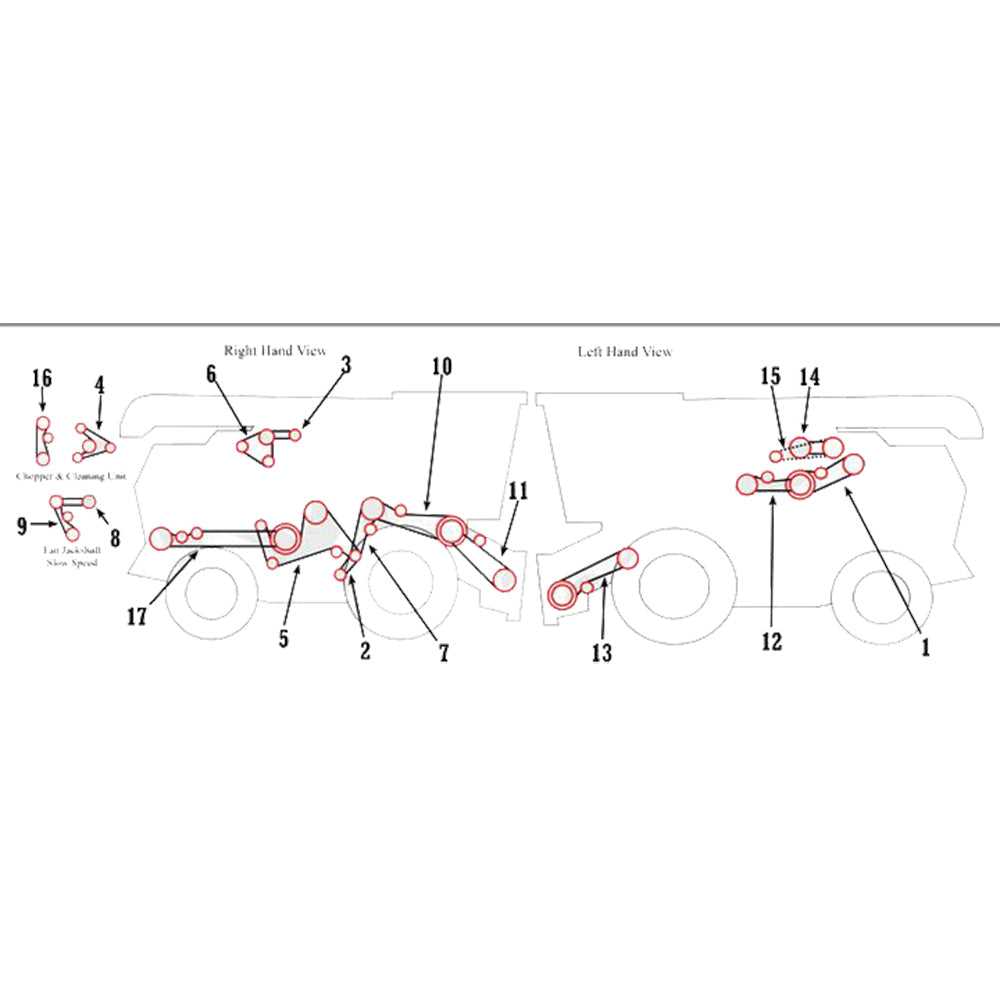

Interpreting the Parts Diagram

Understanding a schematic representation of components is crucial for effective maintenance and repair. Such visuals provide a detailed overview of each element’s location and function, enabling users to identify parts quickly and efficiently. Grasping the layout and symbols used can significantly enhance one’s ability to address issues and perform necessary interventions.

To navigate these illustrations effectively, it’s important to familiarize yourself with the common elements included. Below is a brief overview of typical features found within these visuals:

| Feature | Description |

|---|---|

| Reference Numbers | Each component is usually marked with a unique identifier for easy cross-referencing. |

| Labels | Textual descriptions provide insight into the function and specifications of each part. |

| Connection Lines | Lines indicate how components interact and are interconnected, showing flow or electrical pathways. |

| Legend | A key explaining the symbols and notations used in the visual representation. |

By carefully studying these features, one can gain a clearer understanding of the entire assembly, making troubleshooting and repairs more manageable and efficient.

Top Suppliers for Case IH Parts

Finding reliable sources for agricultural machinery components is essential for maintaining optimal performance. Numerous vendors specialize in high-quality replacements and accessories, ensuring that operators can keep their equipment running smoothly. Below are some of the top suppliers renowned for their exceptional service and product range.

| Supplier Name | Location | Specialization |

|---|---|---|

| Farm Equipment Co. | Illinois, USA | Aftermarket solutions and accessories |

| Agricultural Supply Group | Texas, USA | OEM components and tools |

| Harvest Machinery Parts | Ontario, Canada | Wear parts and critical spares |

| Rural Equipment Specialists | Ohio, USA | Maintenance kits and upgrades |

| Agri-Tech Solutions | Florida, USA | Custom parts and modifications |

These suppliers are well-regarded for their quality offerings and commitment to customer satisfaction, making them valuable resources for anyone in the agricultural sector.

Maintenance Tips for 2188 Owners

Proper upkeep of your harvesting equipment is essential for ensuring optimal performance and longevity. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency during operation. Below are some key strategies to keep your machine running smoothly.

Routine Checks

Conducting regular inspections can help identify potential issues before they escalate. Focus on the following areas:

| Component | Check Frequency | Action Required |

|---|---|---|

| Engine Oil | Every 50 hours | Change if dirty or low |

| Air Filters | Every 100 hours | Clean or replace as needed |

| Belt Condition | Every 50 hours | Inspect for wear and tear |

| Hydraulic Fluids | Every 200 hours | Check levels and replace if contaminated |

Seasonal Maintenance

Different seasons may require additional attention to various systems. Preparing your machinery for changes in weather conditions can help prevent issues:

| Season | Recommended Actions |

|---|---|

| Spring | Inspect and clean components after winter storage |

| Summer | Check cooling systems and clean radiators |

| Fall | Perform a thorough inspection before storage |

| Winter | Ensure proper winterization if storing |

How to Order Replacement Parts

When it comes to acquiring components for your machinery, understanding the process is crucial for efficiency and accuracy. Knowing where to look and how to navigate options can save time and ensure you get the right items for your needs.

Follow these steps to simplify your ordering experience:

| Step | Action |

|---|---|

| 1 | Identify the specific component you need. Consult your equipment’s manual or online resources for detailed information. |

| 2 | Check authorized dealers or reputable online platforms. Ensure they provide genuine and compatible items. |

| 3 | Gather necessary details such as model numbers, serial numbers, and descriptions to facilitate accurate ordering. |

| 4 | Request quotes from multiple suppliers to compare prices and availability. |

| 5 | Place your order, ensuring to review all details for correctness before finalizing the transaction. |

By following these guidelines, you can streamline the procurement process and ensure your equipment remains in optimal working condition.

DIY Repairs Using Parts Diagram

Understanding the layout of machinery components can significantly enhance the efficiency of repairs and maintenance. By utilizing a visual representation of various elements, you can quickly identify issues and replace faulty parts without the need for professional assistance. This not only saves time but also reduces costs associated with hiring experts.

Benefits of Visual Reference

A schematic view provides several advantages. It allows for easy location of specific elements, which is particularly useful when dealing with complex systems. Moreover, having a clear guide can minimize the risk of errors during assembly and disassembly, ensuring that each component is correctly positioned.

Common Repairs and Replacement Parts

Many common repairs can be executed effectively with the help of a visual reference. Below is a table outlining frequent issues and the corresponding components that might need replacement:

| Issue | Component |

|---|---|

| Engine Overheating | Cooling Fan |

| Poor Performance | Fuel Filter |

| Hydraulic Leaks | Seals and Hoses |

| Electrical Failures | Wiring Harness |

With the right visual tools and a bit of knowledge, anyone can tackle repairs with confidence. Empower yourself to maintain your machinery effectively by understanding its components and functions.

Understanding Warranty Options

When investing in machinery, knowing your warranty options is crucial for ensuring long-term reliability and protection. Warranties can vary significantly in terms of coverage, duration, and specific conditions, impacting your overall ownership experience. Familiarizing yourself with these options allows for informed decisions that can safeguard your investment.

Types of Warranties

Several types of warranties may be offered, each serving different needs:

- Basic Warranty: Covers defects in materials and workmanship for a specified period.

- Extended Warranty: Provides additional coverage beyond the basic terms, often at an extra cost.

- Powertrain Warranty: Focuses specifically on major components such as the engine and transmission.

- Corrosion Warranty: Protects against rust and corrosion-related issues, usually for a defined period.

Important Considerations

When evaluating warranty options, consider the following:

- Duration: How long does the warranty last, and what does it cover during that time?

- Transferability: Can the warranty be transferred to a new owner if you sell the equipment?

- Exclusions: What types of damages or issues are not covered?

- Service Requirements: Are there specific maintenance practices you must follow to keep the warranty valid?

Understanding these factors can help you select the warranty that best suits your operational needs and provides peace of mind for your investment.

Community Resources for 2188 Owners

For individuals who own this agricultural machine, tapping into community resources can greatly enhance the ownership experience. Engaging with fellow enthusiasts and experts provides invaluable insights, troubleshooting tips, and a platform for sharing experiences. These connections foster a sense of camaraderie among users and can lead to practical solutions for common challenges.

Online Forums and Discussion Groups

Participating in online forums dedicated to machinery enthusiasts allows for the exchange of knowledge and advice. Many platforms feature sections where users can post questions, share modifications, and discuss maintenance techniques. By joining these communities, owners can benefit from the collective wisdom of seasoned operators and gain access to troubleshooting assistance that is specific to their needs.

Local Clubs and Associations

Joining local clubs focused on agricultural machinery can create opportunities for networking and collaboration. These organizations often host events, workshops, and meetups where owners can connect face-to-face. Sharing experiences and learning from others’ successes and challenges can lead to improved performance and longevity of the equipment. Additionally, these groups may offer access to exclusive resources such as discounts on services or parts from trusted vendors.