Understanding the Honda Civic Door Parts Diagram

When it comes to vehicle functionality, the significance of the access mechanism cannot be overstated. This essential feature ensures both convenience and security, playing a crucial role in everyday use. A comprehensive look at the elements involved reveals their intricate design and interrelation, contributing to the overall performance of the automobile.

Exploring the various components reveals a complex network that works harmoniously to provide seamless operation. Each segment serves a distinct purpose, from the structural framework to the intricate locking mechanisms. Understanding these individual roles enhances appreciation for the engineering behind modern vehicles.

By examining a detailed representation of these elements, one can grasp the assembly’s layout and operational dynamics. Such insights are invaluable for maintenance and troubleshooting, empowering enthusiasts and professionals alike to ensure optimal functionality and longevity of the vehicle’s access system.

Understanding Honda Civic Door Components

Grasping the elements that make up vehicle entrances is crucial for both maintenance and repair. Each component plays a specific role in functionality and security, contributing to the overall performance of the vehicle. Familiarity with these components can aid in troubleshooting issues and enhancing the driving experience.

Framework: The structure provides essential support, ensuring that the assembly operates smoothly and maintains integrity. It is vital for safeguarding the internal mechanisms while providing a sturdy barrier against external elements.

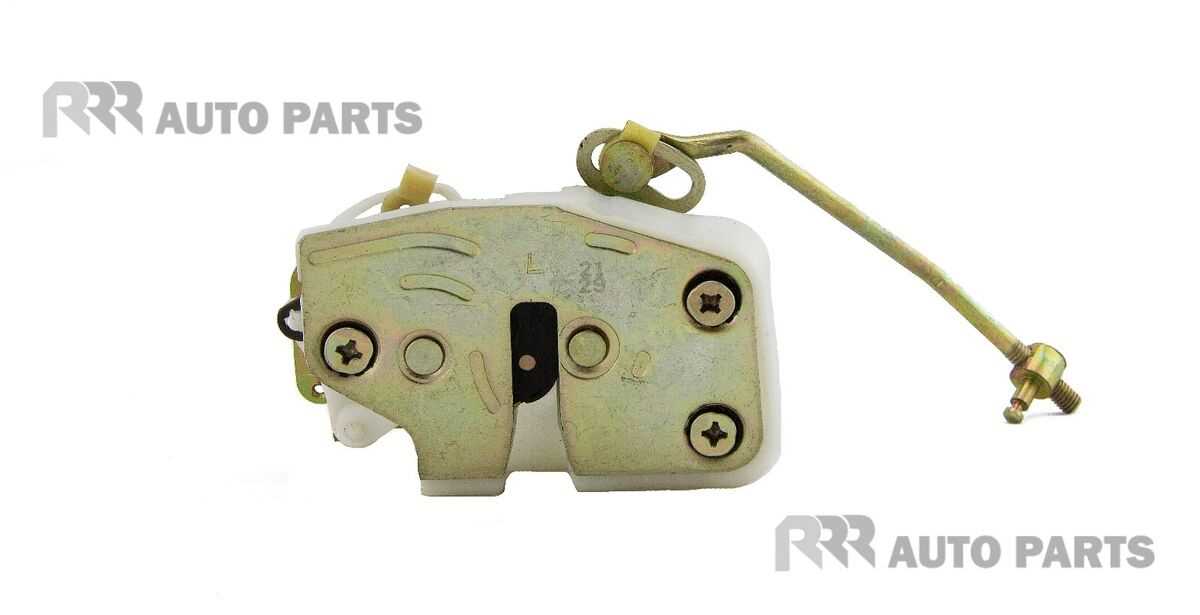

Locking Mechanism: This element is critical for the safety of passengers and belongings. Understanding how it operates can help in diagnosing problems related to security features and accessibility.

Window Assembly: The system that allows for the opening and closing of glass panels is essential for ventilation and visibility. Knowledge of its components can aid in resolving issues related to movement or blockage.

Sealings and Weatherstrips: These components protect the interior from water and debris, ensuring a comfortable environment. Their condition is crucial for maintaining insulation and minimizing noise during travel.

Handle Mechanism: The handle is the primary means of accessing the vehicle’s interior. Understanding its design and function can facilitate repairs or replacements when necessary.

By comprehensively understanding these elements, vehicle owners can ensure optimal functionality and longevity of their automobiles. This knowledge is invaluable for effective maintenance and addressing any challenges that may arise.

Key Parts of the Honda Civic Door

This section provides an overview of essential components associated with the vehicle’s entry system. Understanding these elements is crucial for maintenance and repairs, ensuring optimal functionality and security.

| Component | Description |

|---|---|

| Handle | Facilitates the opening and closing mechanism, providing easy access to the interior. |

| Locking Mechanism | Ensures security by allowing the user to secure the entryway when not in use. |

| Window Regulator | Controls the movement of the glass panel, enabling it to be raised or lowered as needed. |

| Weather Strip | Seals gaps to prevent water and air leaks, enhancing insulation and comfort. |

| Hinge | Allows for the swinging motion, connecting the entryway to the vehicle frame. |

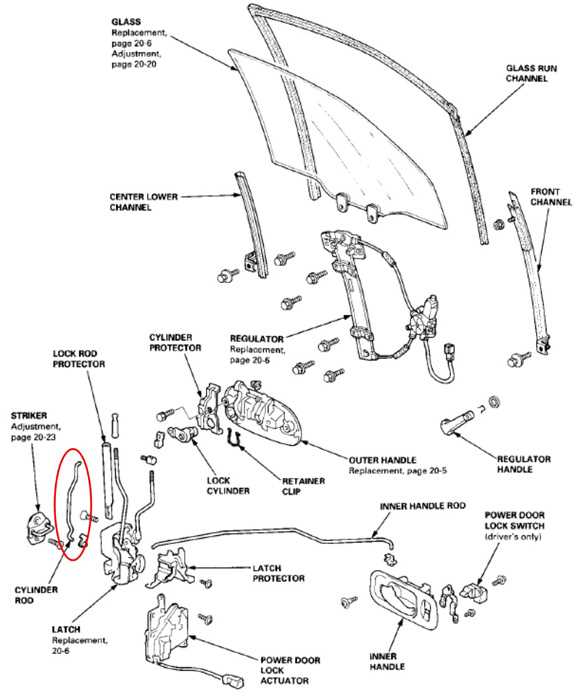

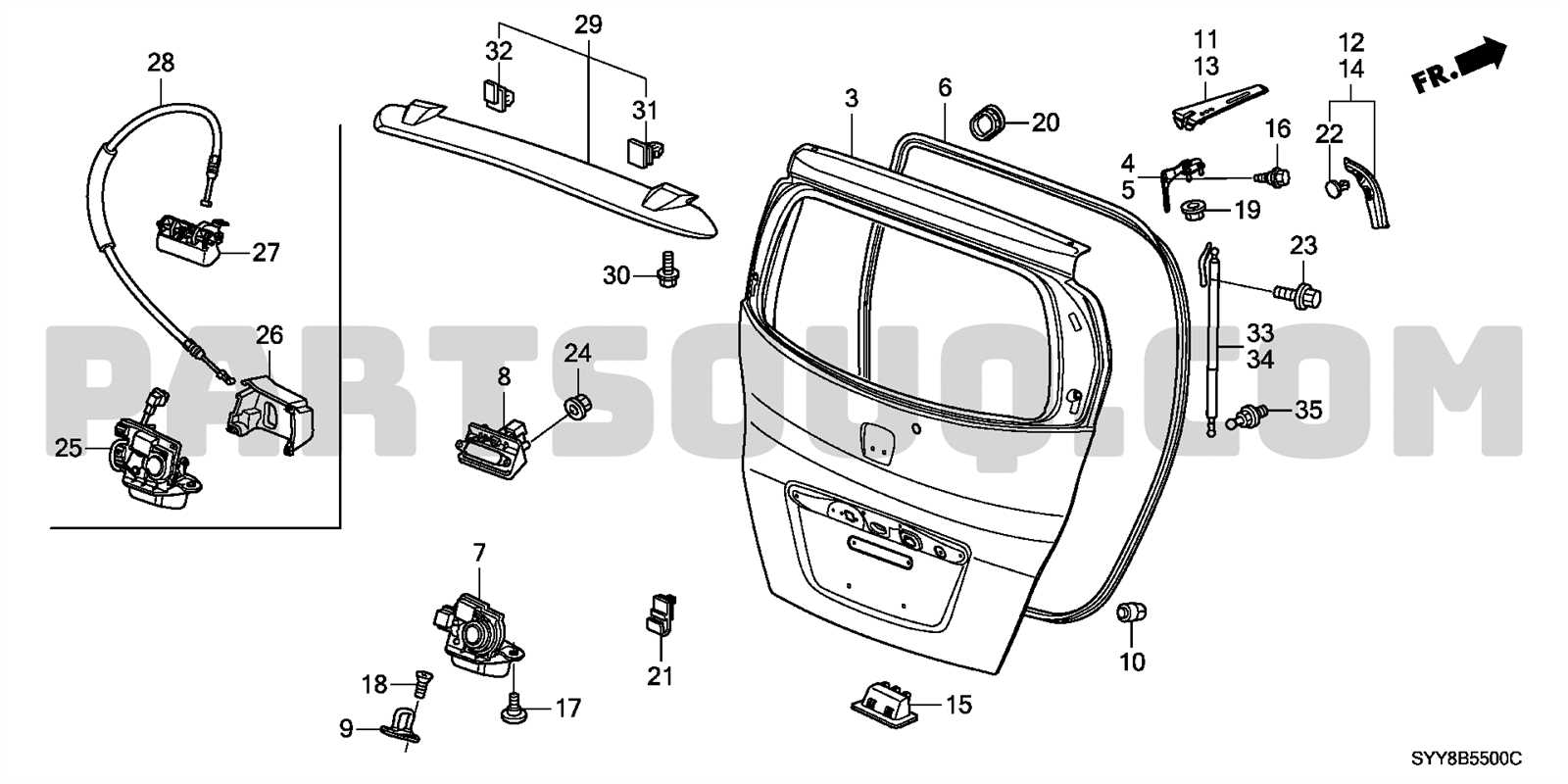

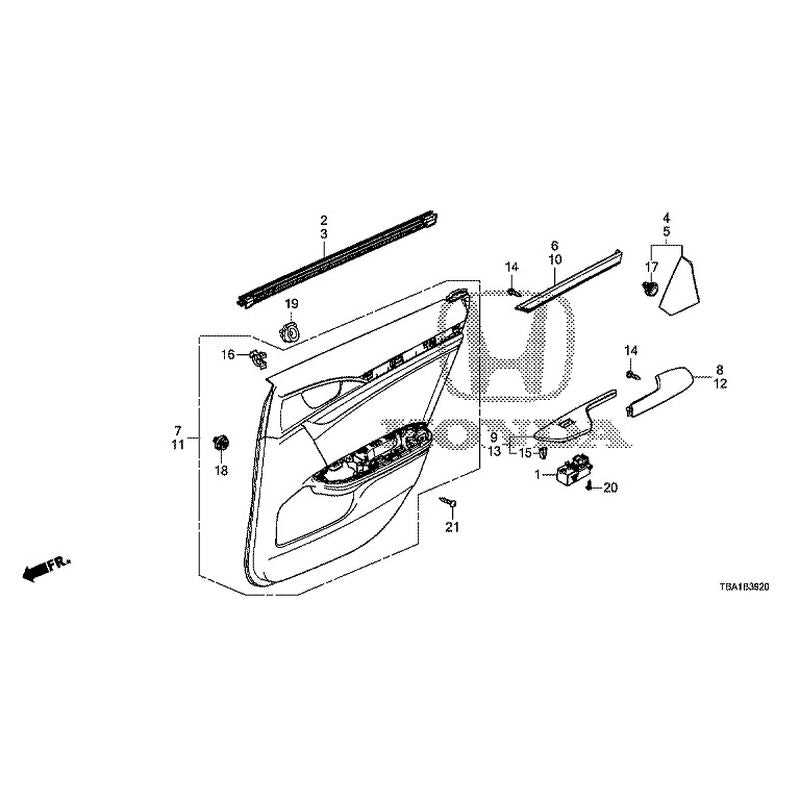

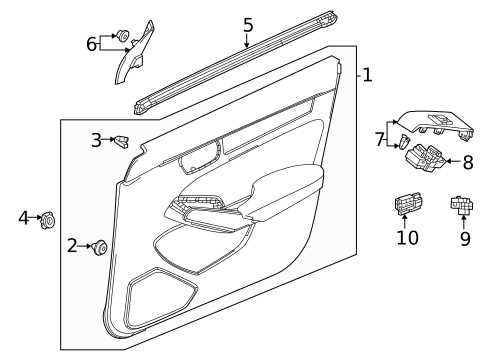

Importance of Door Assembly Diagrams

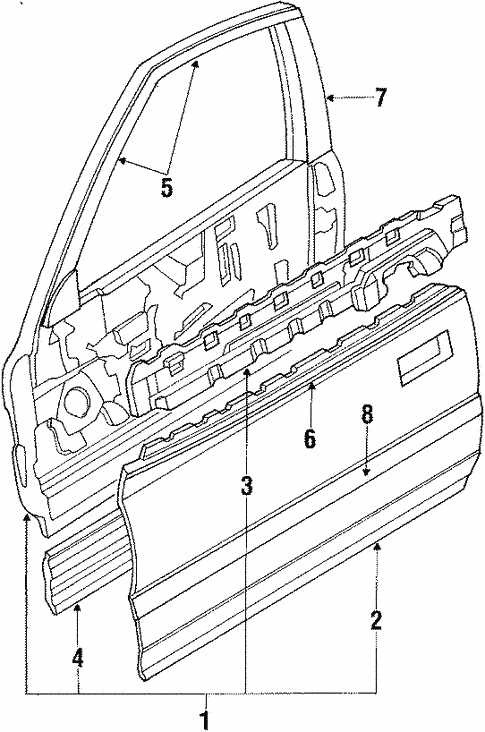

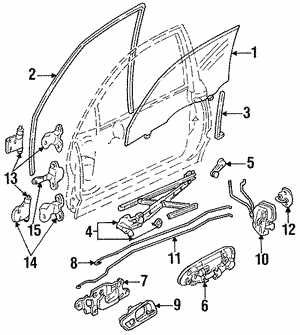

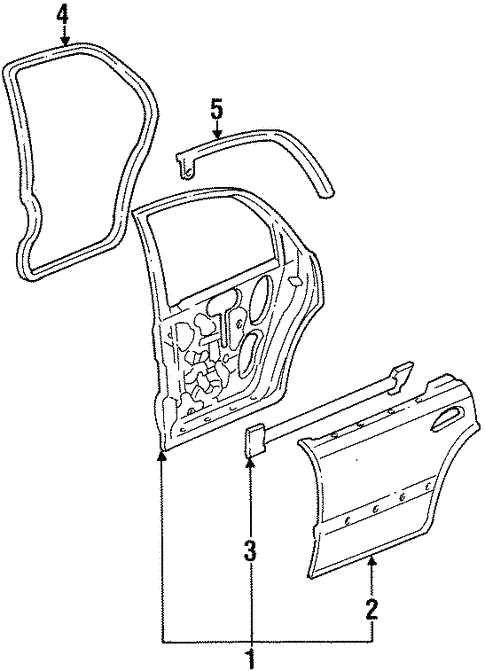

Understanding the layout and components of vehicle entry systems is crucial for effective maintenance and repair. Detailed illustrations provide a comprehensive view of how individual elements interact, enabling technicians and enthusiasts to address issues more efficiently. The clarity offered by these visuals significantly enhances troubleshooting processes, leading to quicker resolutions and reduced downtime.

Benefits of Visual References

Visual references serve multiple purposes, from facilitating proper assembly to assisting in identifying potential problems. When mechanics can easily locate each component, they can ensure that everything is functioning as intended. This ultimately leads to safer and more reliable vehicle operation.

Enhanced Learning Experience

For those new to automotive repair, these schematics serve as educational tools. They break down complex systems into manageable parts, allowing learners to grasp the intricacies of vehicle construction. By studying these diagrams, individuals can develop a solid foundation of knowledge, which is essential for future repairs and modifications.

| Feature | Benefit |

|---|---|

| Clear Component Layout | Facilitates easier identification and replacement |

| Step-by-Step Guidance | Reduces the risk of errors during assembly |

| Educational Tool | Enhances understanding of vehicle systems |

How to Read a Door Parts Diagram

Understanding an illustration of automotive components can greatly simplify the repair and maintenance process. These visual guides provide a detailed layout of each element, helping users identify and locate specific items quickly. Familiarity with the symbols and notations used in these illustrations is crucial for effective interpretation.

To effectively analyze such a schematic, consider the following steps:

- Identify the Key: Most diagrams include a legend or key that explains the symbols and lines used. Familiarize yourself with this to avoid confusion.

- Examine the Layout: Observe the overall structure. Components are often arranged logically, reflecting their physical relationships.

- Look for Annotations: Pay attention to any accompanying notes or labels. These often provide additional information about the function or specifications of each item.

- Follow the Connections: Trace lines or arrows that indicate how different components interact or connect. Understanding these relationships is essential for troubleshooting.

- Use a Reference: If possible, consult a repair manual or online resource for context on the diagram. This can enhance your understanding of the system as a whole.

By following these guidelines, you will improve your ability to interpret automotive illustrations, making repairs and maintenance tasks more manageable.

Common Issues with Door Mechanisms

The functionality of entry barriers is crucial for both security and convenience. However, various challenges can arise that hinder their operation, often leading to frustration for users. Understanding these common problems can assist in effective troubleshooting and maintenance.

Mechanical Failures

One frequent issue involves mechanical components that may wear out over time. This can result in difficulty opening or closing the access points. Such failures often stem from the degradation of hinges, latches, or locking systems.

Electrical Malfunctions

In modern access systems equipped with electronic features, electrical malfunctions can create significant obstacles. Problems such as faulty wiring or malfunctioning sensors can lead to inoperability of electronic locks or window mechanisms, complicating the user experience.

| Issue Type | Description | Possible Solution |

|---|---|---|

| Mechanical Wear | Components may become stiff or broken. | Inspect and replace worn parts. |

| Electrical Failure | Faulty wiring can disrupt functionality. | Check connections and replace damaged wires. |

| Alignment Problems | Misalignment can prevent proper closure. | Adjust hinges and frames to realign. |

Replacing Honda Civic Door Parts

Maintaining the functionality of vehicle entry mechanisms is essential for both security and convenience. Over time, various components may wear out, necessitating replacement to ensure smooth operation. This section outlines the process and considerations involved in substituting these elements effectively.

Tools and Materials Needed

Before commencing the replacement procedure, gather the necessary tools and materials to ensure a seamless experience. Below is a list of common items you may require:

| Tool/Material | Description |

|---|---|

| Screwdriver | Used for removing screws securing the components. |

| Wrench Set | Necessary for loosening and tightening bolts. |

| Replacement Component | New part to be installed, specific to the vehicle model. |

| Lubricant | To ensure smooth movement of moving elements. |

Steps for Replacement

Follow these steps to replace the worn-out components effectively:

1. Start by disconnecting the battery to avoid any electrical issues.

2. Carefully remove the panel covering the entry mechanism using a screwdriver.

3. Identify the damaged component and detach it from its mounting.

4. Install the new element by reversing the removal process, ensuring it is securely fastened.

5. Reattach the panel and reconnect the battery, testing the functionality to confirm the repair was successful.

Tools Needed for Door Repairs

Repairing vehicle entryways requires a specific set of instruments to ensure efficiency and precision. Having the right tools on hand not only simplifies the process but also enhances the quality of the repairs. This section outlines the essential equipment necessary for tackling various issues associated with vehicle access points.

Essential Hand Tools

A variety of hand tools is crucial for disassembling and reassembling components. Commonly needed items include screwdrivers, wrenches, and pliers. These tools help in loosening screws and bolts, as well as manipulating smaller elements within the assembly. Additionally, a trim removal tool can be invaluable for preventing damage to the vehicle’s interior when accessing hidden fasteners.

Power Tools and Accessories

In some cases, power tools may be required to expedite the repair process. An electric drill is particularly useful for making precise holes or removing stubborn screws. Furthermore, a rivet gun can assist in fastening components that require a more secure connection. Always ensure that you have the appropriate safety gear, such as goggles and gloves, when using power tools to protect against potential hazards.

Identifying Door Parts by Model Year

Understanding the components of a vehicle’s access structure is essential for maintenance and repair. Each model year often features unique characteristics, making it crucial to recognize the variations in design and function. This section provides insights into identifying these elements based on specific production years.

Variations Across Model Years

As manufacturers evolve their designs, modifications are frequently implemented to enhance performance, safety, and aesthetics. These changes can affect the shape, size, and materials of the access structure components. For instance, while earlier models may utilize basic mechanical systems, newer versions often incorporate advanced technology, including electronic locking mechanisms and integrated sensors.

Key Identifiers to Consider

When examining components, pay attention to the following identifiers:

- Shape and Size: Different model years can have distinct geometries.

- Material Composition: Variations in materials, such as plastics or metals, can indicate the production period.

- Mounting Points: Changes in the location of fasteners or connectors are crucial for compatibility.

By carefully evaluating these factors, one can effectively identify and source the necessary components for specific model years, ensuring optimal functionality and fit.

Maintenance Tips for Door Functionality

Ensuring optimal operation of your vehicle’s access points is crucial for both safety and convenience. Regular maintenance can prevent common issues, enhance longevity, and improve overall performance. Here are some essential tips to keep in mind.

Regular Lubrication

Applying appropriate lubricants to moving components can significantly reduce friction and wear. Focus on hinges and locking mechanisms, ensuring they move smoothly. Use a silicone-based spray or graphite powder for best results, avoiding sticky substances that can attract dirt.

Inspect and Clean

Routine inspection and cleaning of the surrounding areas are vital. Remove debris and dirt that may accumulate around seals and latches, as they can hinder functionality. Pay attention to rubber gaskets, as they can dry out and crack over time. Regular cleaning will not only maintain aesthetic appeal but also ensure seals remain effective.

Implementing these maintenance practices will lead to a more reliable experience and extend the lifespan of the access mechanisms.

Aftermarket vs. OEM Door Components

When it comes to replacement items for vehicle entry systems, enthusiasts often face a choice between original equipment manufacturer (OEM) solutions and aftermarket alternatives. Each option comes with its own set of advantages and considerations that can significantly impact performance, longevity, and overall satisfaction.

Benefits of OEM Components

Opting for OEM solutions typically provides several advantages:

- Quality Assurance: These components are designed and manufactured to the exact specifications of the vehicle, ensuring a perfect fit and reliable performance.

- Warranty Protection: OEM items often come with warranties that guarantee their longevity, offering peace of mind for the buyer.

- Brand Compatibility: Original items are guaranteed to work seamlessly with existing systems, minimizing the risk of malfunction.

Advantages of Aftermarket Options

On the other hand, aftermarket offerings can also be appealing:

- Cost-Effectiveness: These alternatives are generally less expensive than their OEM counterparts, making them an attractive option for budget-conscious consumers.

- Variety of Choices: Aftermarket solutions come in a wide range of styles and materials, allowing for personalization and enhanced aesthetics.

- Performance Enhancements: Many aftermarket products are designed to improve functionality, such as increased durability or enhanced features.

In summary, the decision between OEM and aftermarket items often boils down to personal priorities, such as budget constraints, performance needs, and aesthetic preferences.

Visual Guides for Door Assembly

Understanding the intricacies of vehicle entryway structure is essential for both enthusiasts and professionals. Visual resources can greatly enhance comprehension of how various components fit together, ensuring efficient assembly and repair processes. These guides typically include illustrations and step-by-step instructions that simplify complex tasks.

Diagrams serve as invaluable tools, offering clear representations of the arrangement and orientation of elements involved in the assembly. By following these visual aids, individuals can pinpoint the exact placement of each component, reducing the likelihood of errors during installation.

Annotated illustrations highlight critical features and connections, making it easier to grasp the function of each element. This attention to detail allows for a more streamlined workflow, whether one is replacing a mechanism or conducting routine maintenance.

In addition, color-coded schematics can further clarify the assembly process, providing a quick reference that aids in the identification of specific items. Such tools empower users to take a hands-on approach, fostering confidence in tackling assembly tasks with precision.

Frequently Asked Questions about Door Parts

This section addresses common inquiries regarding the components associated with vehicle entrances. Understanding these elements can enhance maintenance and repair knowledge, leading to improved functionality and longevity.

Common Questions

- What are the essential elements of a vehicle entrance?

- How do I identify a malfunctioning component?

- What signs indicate that a replacement is necessary?

Maintenance Tips

- Regularly inspect for wear and tear.

- Lubricate moving mechanisms to prevent stiffness.

- Keep seals clean to ensure proper sealing and prevent leaks.