Craftsman GT3000 Parts Diagram and Maintenance Guide

Every garden tractor is made up of various essential elements that work together to ensure smooth operation and performance. Knowing the internal layout and how each part interacts can be crucial for maintaining and repairing your equipment.

Whether you’re dealing with issues related to performance, or simply conducting routine maintenance, having a clear overview of the internal mechanisms can save time and prevent future problems. A well-detailed breakdown of the various elements involved can provide valuable insight into how your machine functions.

In this guide, we will explore the individual elements of your machine, offering a closer look at its core components. This knowledge will empower you to handle both simple fixes and more complex repairs with confidence.

Understanding the Craftsman GT3000 Components

The key to maintaining and optimizing your lawn tractor lies in a solid grasp of its essential components. Each element plays a crucial role in the machine’s overall performance and efficiency, working together to ensure smooth operation. Without a clear understanding of these components, even simple repairs or upgrades can become challenging.

Engine: The engine serves as the heart of the machine, providing the power needed to drive and operate attachments. Regular maintenance is necessary to keep it running smoothly and prevent breakdowns.

Transmission: This critical system transfers power from the engine to the wheels, ensuring the machine moves at the desired speed and direction. A well-functioning transmission guarantees efficient operation, especially on varying terrain.

Blades: The cutting system consists of blades responsible for trimming grass.

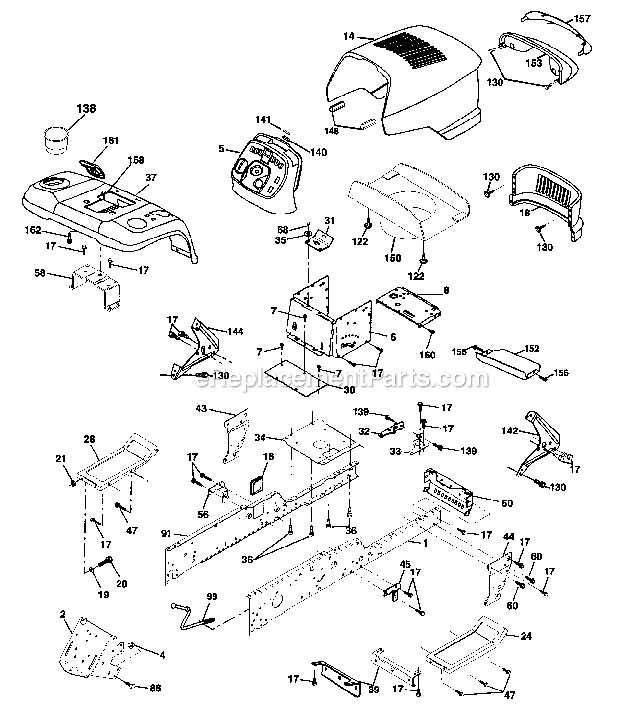

Main Assemblies of the Craftsman GT3000

The structure of this versatile garden machine consists of several essential systems, each playing a crucial role in ensuring optimal performance. Understanding these core assemblies will help in maintaining and repairing the equipment efficiently, allowing users to address issues quickly and ensure the longevity of the machine.

Chassis and Frame

The framework forms the backbone of the vehicle, providing support for all other components. Built from sturdy materials, it offers durability and stability during operation. The frame is designed to absorb the stress and vibration that occur during heavy-duty tasks, ensuring smooth and steady handling.

Engine and Transmission

The powertrain is the heart of the vehicle. It includes the motor, which delivers the necessary energy to power the machine, and the transmission, which controls speed and torque. Together, they ensure efficient performance across various terrains and tasks

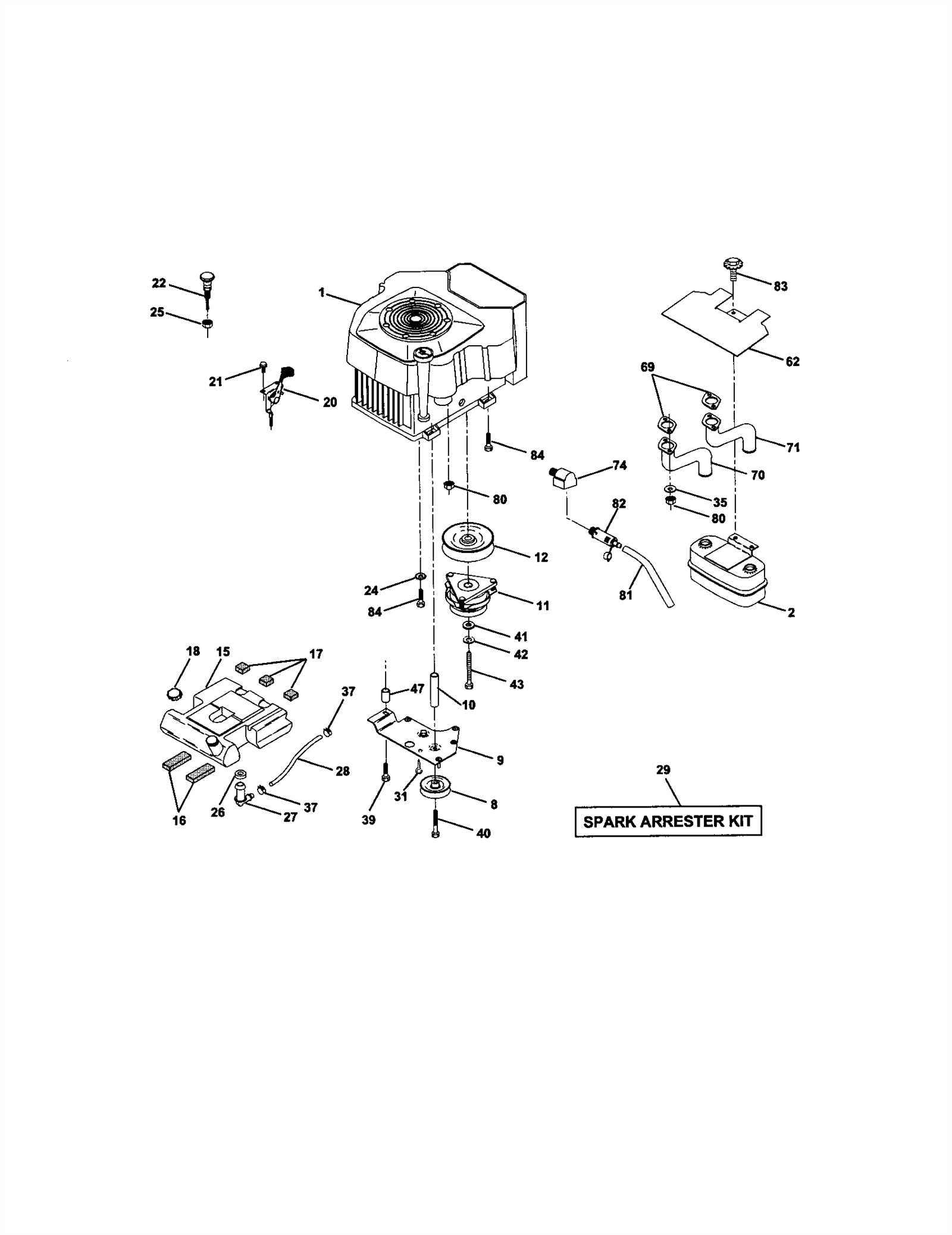

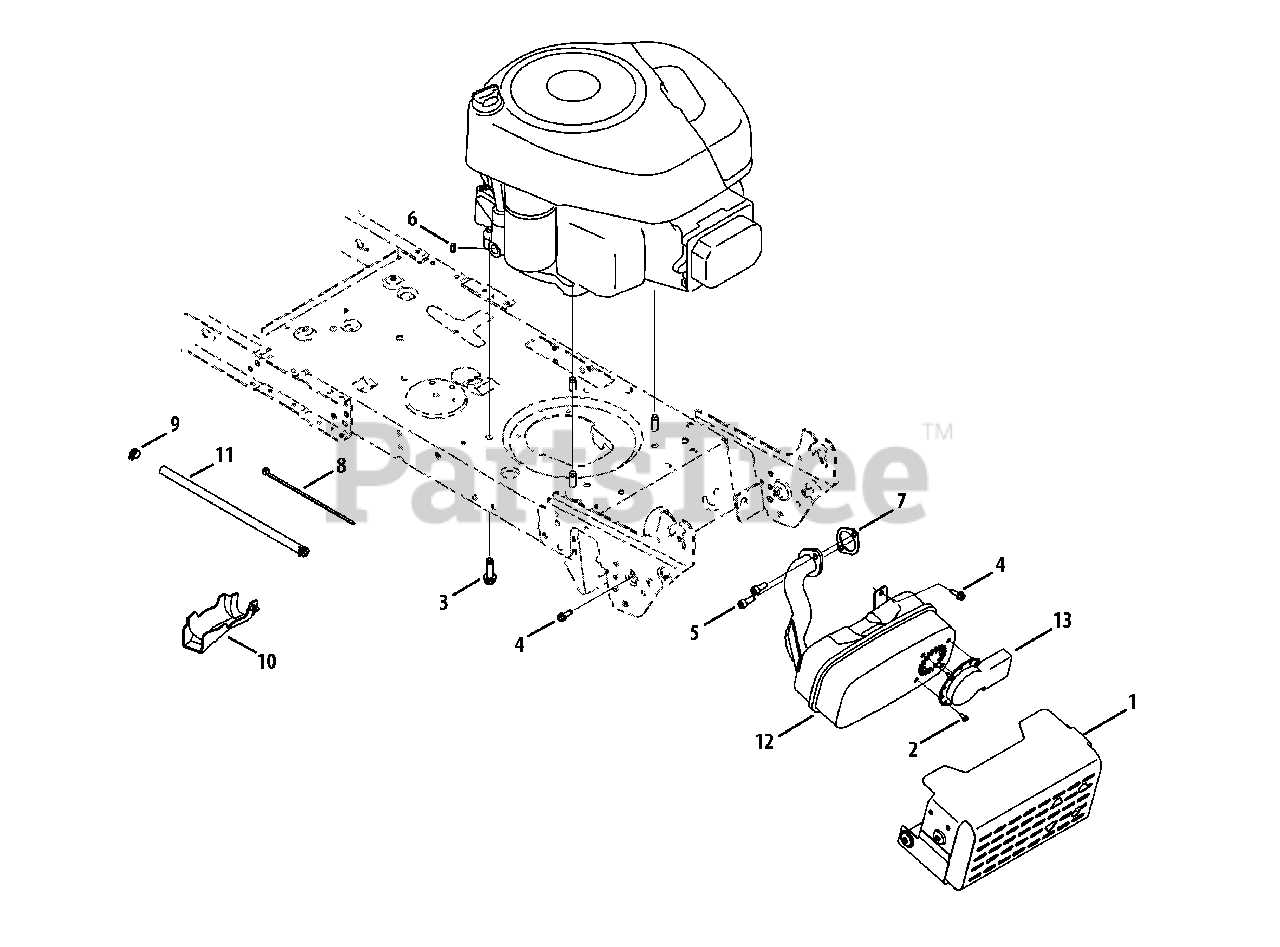

Exploring the Engine System of GT3000

The engine system of this robust lawn tractor is designed for efficiency and durability, providing reliable power for various outdoor tasks. This section will take a closer look at how the core components of the motor work together to deliver high performance, ensuring smooth operation over time. By understanding the key elements involved, you can better appreciate the mechanical design that drives this machine forward.

Core Components of the Powertrain

At the heart of the engine system is the powertrain, which consists of several critical components working in harmony. The motor converts fuel into mechanical energy, enabling the machine to function. Key parts like the crankshaft, pistons, and valves ensure that energy is efficiently transferred from combustion to the wheels, allowing the equipment to operate seamlessly even under heavy loads.

Maintaining Optimal Engine Performance

For the engine to function

Drive Belt and Pulley Configurations

The arrangement of the drive belt and pulley system plays a vital role in ensuring efficient power transmission within the machinery. This setup controls the transfer of motion from the engine to various mechanical components, allowing for smooth operation. Understanding the placement and interaction between these elements is key to maintaining optimal performance.

Drive belts connect the pulleys, creating a continuous loop that transfers energy across different parts of the machine. The proper tension and alignment of the belt are crucial to avoid slippage or excessive wear. Misaligned or worn-out belts can cause inefficient movement or even damage to other components.

Pulleys are mounted in specific configurations to guide the belt and adjust the speed and torque of the transmitted power. These configurations vary depending on the design of the system, and each pulley’s size and placement can influence the overall performance. Regular inspection and maintenance of both the belt and pulleys are essential to prevent breakdowns.

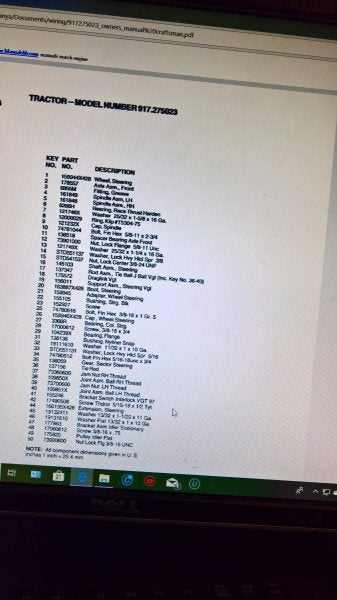

Steering Mechanism Breakdown

The steering system plays a critical role in the maneuverability and control of any machine, ensuring that the operator can direct it smoothly and accurately. A well-functioning steering mechanism guarantees safety and efficiency, allowing for precise navigation, whether in tight spaces or over long distances.

Main Components of the Steering System

The core of the steering assembly consists of several key elements. The steering wheel is connected to the steering shaft, which transfers the rotational motion to the system. This movement is directed through a series of linkages and joints, ensuring the wheels turn in the desired direction. In many cases, an adjustable steering rod is incorporated to accommodate varying alignment needs.

Common Issues and Maintenance

Over

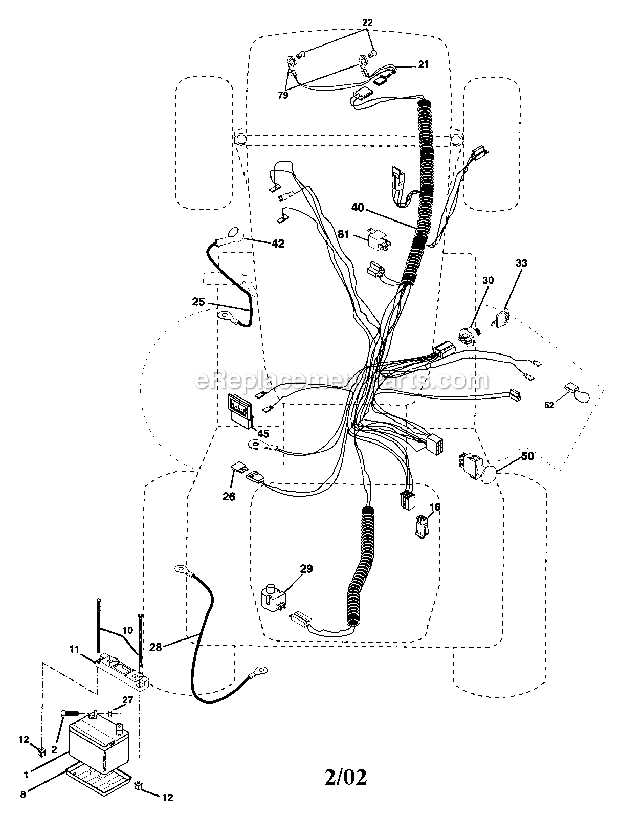

Understanding the Electrical System

The electrical system of a garden tractor plays a crucial role in its overall performance and functionality. This intricate network of components is designed to manage power distribution, ensure smooth operation of the engine, and facilitate various electronic features. A comprehensive understanding of this system is essential for troubleshooting and maintenance, allowing users to maximize efficiency and longevity.

Key Components of the Electrical Network

At the heart of the electrical setup lies the battery, which serves as the primary energy source. It provides the necessary power to start the engine and operate electrical accessories. Additionally, the alternator is responsible for recharging the battery during operation, ensuring a continuous power supply. Other vital components include the ignition system, wiring harnesses, and switches, each contributing to the overall functionality of the machinery.

Troubleshooting Electrical Issues

Identifying and resolving electrical problems can be challenging. Common issues may stem from a dead battery, faulty wiring, or malfunctioning switches. To effectively troubleshoot, one should systematically check each component, looking for signs of wear, damage, or corrosion. Maintaining clean connections and ensuring all components are in good condition is essential for optimal performance.

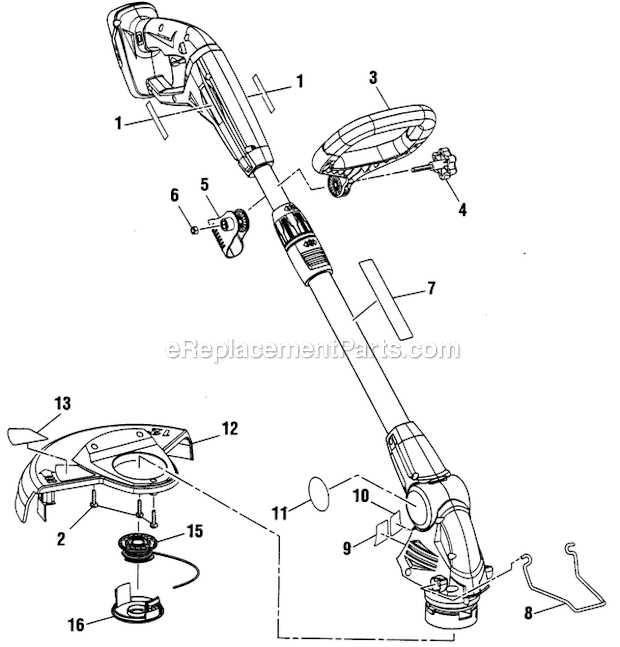

Blade Assembly and Cutting Deck Overview

The blade assembly and cutting deck are essential components of any lawn care equipment, playing a crucial role in achieving a well-manicured lawn. Understanding their structure and function helps users maintain efficiency and extend the lifespan of their machinery. This section provides insights into the various parts involved in these assemblies and their significance in delivering optimal cutting performance.

Components of the Blade Assembly

The blade assembly typically consists of several key elements, including the blades themselves, spindles, and mounting hardware. Blades are designed to create a sharp edge for effective grass cutting, while the spindles support the blades and enable them to rotate smoothly. Proper maintenance of these parts is essential to ensure a clean and precise cut.

Understanding the Cutting Deck

The cutting deck houses the blade assembly and serves as the primary structure for lawn mowing. It is designed to provide a protective enclosure for the blades, enhancing safety during operation. Additionally, the deck’s shape and design influence the grass flow and overall cutting efficiency. Regular inspections and cleaning of the cutting deck can prevent clogs and promote consistent performance.

Transmission and Gearbox Overview

The transmission and gearbox play a crucial role in the efficient operation of machinery, ensuring that power is effectively transmitted from the engine to the wheels or other functional components. This system is responsible for controlling the speed and torque, allowing for optimal performance based on varying operational demands.

Understanding the components and their functions is essential for maintenance and troubleshooting. Each part works in harmony to facilitate smooth transitions between different speed levels and to manage the load effectively.

| Component | Function | Description |

|---|---|---|

| Transmission | Modulates power output | Converts engine power into usable motion, allowing for speed adjustments. |

| Gearbox | Changes gear ratios | Adjusts the torque and speed by shifting gears, enhancing performance efficiency. |

| Clutch | Engages/disengages power flow | Allows the operator to control power transfer between the engine and the transmission. |

| Drive Shafts | Transmits power | Transfers power from the transmission to the wheels or other working parts. |

Fuel System Layout and Key Parts

The fuel system of a lawn tractor is essential for delivering the necessary energy to the engine. It comprises various components that work in harmony to ensure the smooth operation of the machine. Understanding the layout and the key elements involved can significantly enhance maintenance efforts and troubleshooting processes.

Fuel Tank: The reservoir that stores the fuel before it is transported to the engine. It is crucial to keep it clean to avoid contamination.

Fuel Lines: These are the conduits that carry the fuel from the tank to the engine. They must be checked regularly for leaks or blockages that could impede fuel flow.

Fuel Filter: This component cleans the fuel before it reaches the engine, preventing debris from causing damage. Regular replacement is necessary to maintain optimal performance.

Fuel Pump: The device that moves fuel from the tank to the engine. It can be mechanical or electrical, depending on the system design.

Carburetor: This critical component mixes the fuel with air to create a combustible mixture for the engine. Proper adjustment and cleaning of the carburetor are vital for efficient operation.

By familiarizing oneself with these essential components and their functions, users can ensure the fuel system operates efficiently and extends the longevity of the equipment.

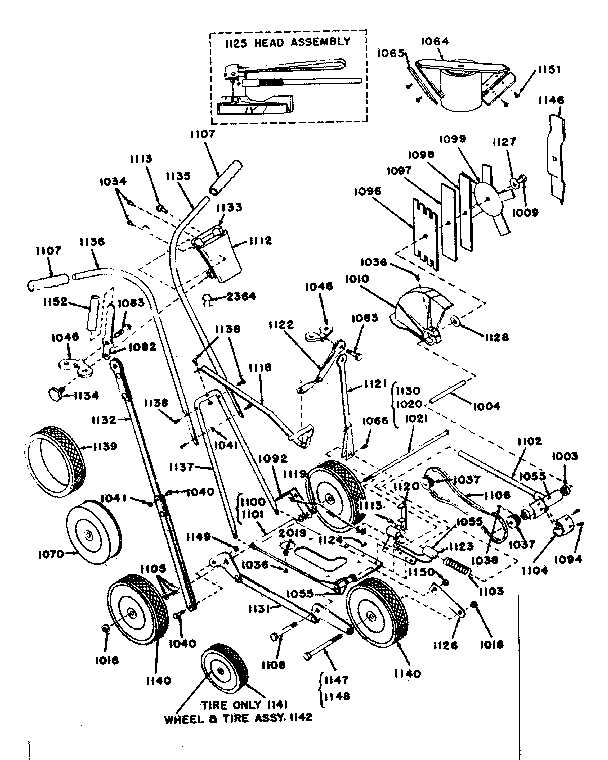

Suspension and Wheel Attachments

The connection between the chassis and the ground is critical for any outdoor machinery, influencing both performance and comfort. Properly designed suspension systems and wheel fittings ensure stability, traction, and effective handling on various terrains. Understanding these components helps in maintaining optimal functionality and extending the lifespan of the equipment.

Suspension systems typically consist of several key elements that work together to absorb shocks and vibrations. These components may include springs, dampers, and control arms, each playing a specific role in managing the vehicle’s dynamics. The wheel attachments, on the other hand, secure the wheels to the axles and allow for efficient power transfer while ensuring proper alignment.

| Component | Description | Function |

|---|---|---|

| Spring | A mechanical device that absorbs shock | Reduces impact from rough terrain |

| Dampers | Devices that control the oscillation of the springs | Enhances stability and ride comfort |

| Control Arms | Linkages connecting the chassis to the wheel assembly | Maintains wheel alignment during movement |

| Wheel Hub | Central part of the wheel assembly | Facilitates rotation and houses bearings |

| Axle | Rod or shaft that rotates the wheels | Transmits power from the engine to the wheels |

Brake System Components and Functionality

The braking system of any vehicle plays a crucial role in ensuring safety and control during operation. This system is composed of various components that work in unison to reduce speed or bring the vehicle to a complete stop. Understanding these elements and their functions is essential for maintaining effective braking performance.

Main Components of the Brake System

At the heart of the braking mechanism are several key components. These include the brake pedal, master cylinder, brake lines, and the brake calipers. The brake pedal is the driver’s interface, allowing them to initiate braking. When pressed, it activates the master cylinder, which generates hydraulic pressure through the brake lines to the calipers. The calipers then clamp down on the brake rotors, creating the necessary friction to slow down the vehicle.

Functionality of Each Component

Each part of the braking system contributes to its overall effectiveness. The master cylinder converts the force from the pedal into hydraulic pressure, ensuring that the calipers engage properly. The brake lines are vital as they transport this pressure efficiently. The calipers’ ability to apply sufficient force against the rotors is what ultimately dictates how quickly a vehicle can stop. Regular inspection and maintenance of these components are essential for optimal performance and safety.

Explaining the Exhaust System Design

The exhaust system plays a crucial role in the overall performance and efficiency of any engine. It is designed to safely channel exhaust gases away from the engine, ensuring optimal operation and reducing harmful emissions. A well-engineered exhaust layout can significantly enhance the engine’s power output while also contributing to a quieter operation.

Key Components of the Exhaust System

Several essential elements work together within the exhaust system. The manifold collects exhaust gases from the engine cylinders and directs them into the exhaust pipe. Following this, the catalytic converter plays a vital role in converting harmful pollutants into less harmful emissions before they exit the system. Finally, the muffler reduces noise produced during the exhaust process, ensuring a smoother and more pleasant sound.

Design Considerations

When designing an effective exhaust system, engineers must consider various factors, including pipe diameter, material, and length. These elements can affect the back pressure experienced by the engine, impacting performance and fuel efficiency. An optimal balance between these components ensures that the system operates efficiently, maximizing engine output while minimizing environmental impact.

Maintenance Tips for Key Parts

Regular upkeep of essential components is vital for the longevity and efficiency of your equipment. Proper maintenance not only enhances performance but also prevents unexpected breakdowns. Here are some useful tips to ensure that the critical elements of your machinery remain in optimal condition.

Cleaning and Inspection

Keeping key components clean is crucial. Accumulation of dirt and debris can lead to malfunction or reduced efficiency. Regularly inspect areas for wear and tear, and ensure that all moving parts are free from obstructions. Use a soft brush or compressed air to remove dust, and be sure to check for any signs of corrosion.

Lubrication Practices

Proper lubrication is essential for smooth operation. Use the recommended lubricants for specific components to reduce friction and wear. Ensure that you apply grease or oil at the right intervals to maintain optimal performance. Pay attention to the manufacturer’s guidelines regarding lubrication frequency and quantity.