Understanding the Parts Diagram of John Deere 826

In the world of agricultural machinery, having a clear understanding of the various components is crucial for effective maintenance and repair. Knowledge of how different parts work together ensures that operators can keep their equipment running smoothly and efficiently. This section delves into the intricate assembly of a specific model, highlighting the relationships between individual elements and their collective function.

Exploring the intricate network of mechanisms that power agricultural machines can be enlightening. Each piece plays a vital role in the overall performance, and recognizing their locations and interactions is essential for troubleshooting issues. By examining these components, users can gain insights into the operational integrity and longevity of their equipment.

Furthermore, this exploration aids in identifying replacement options when necessary. Understanding the layout and connections among various elements can simplify the process of sourcing appropriate alternatives. With a solid grasp of these intricacies, operators can make informed decisions, ultimately enhancing productivity in the field.

This section aims to provide a comprehensive overview of the various components involved in the machine, highlighting their functions and significance. By exploring these elements, users can gain a deeper understanding of how each part contributes to the overall performance and efficiency of the equipment.

Key Components of the Equipment

- Engine Assembly

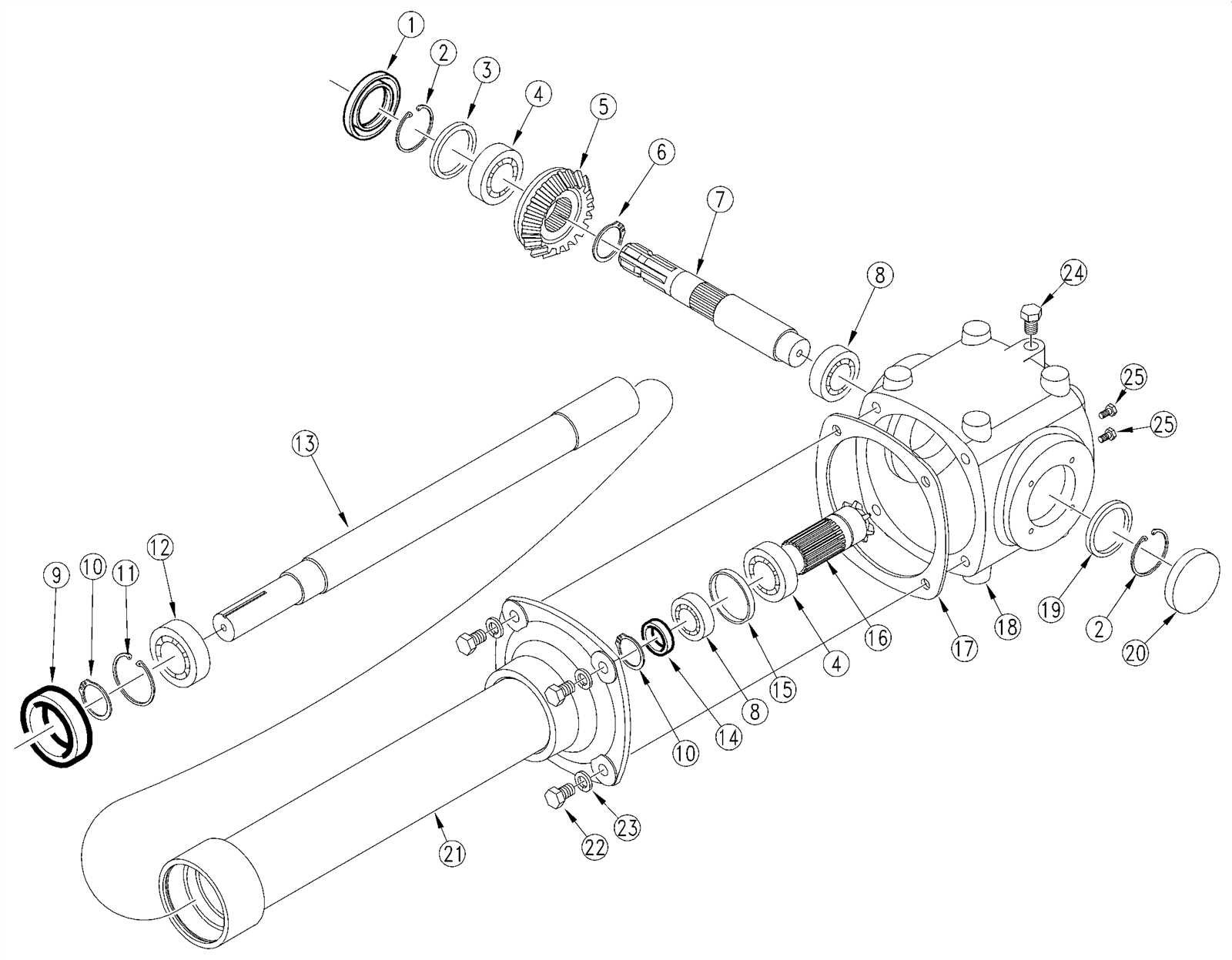

- Transmission System

- Hydraulic Mechanisms

- Electrical System

- Chassis and Frame

Importance of Understanding Each Component

- Enhances Maintenance: Knowing the individual parts allows for better upkeep and servicing.

- Improves Performance: Familiarity with components aids in optimizing functionality and efficiency.

- Facilitates Troubleshooting: Understanding how parts interact can simplify diagnosing issues.

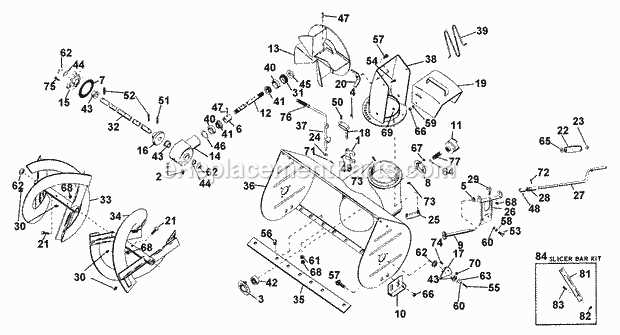

Key Components of the Model

The intricate design of this agricultural machine features several essential elements that contribute to its overall functionality and efficiency. Each component plays a pivotal role, ensuring that the equipment operates smoothly and effectively in various farming conditions.

Among the primary features are the powerful engine and advanced transmission system, which work in unison to provide optimal performance. The robust chassis is designed to withstand rigorous use while supporting the weight of additional attachments. Additionally, the cutting mechanism, featuring durable blades, ensures precise and clean operations during harvesting tasks.

Furthermore, an efficient cooling system is crucial for maintaining optimal temperature levels, preventing overheating during extended periods of use. The user-friendly control panel allows operators to easily manage settings, enhancing usability and safety. Overall, the combination of these key elements establishes a reliable and effective machine for agricultural endeavors.

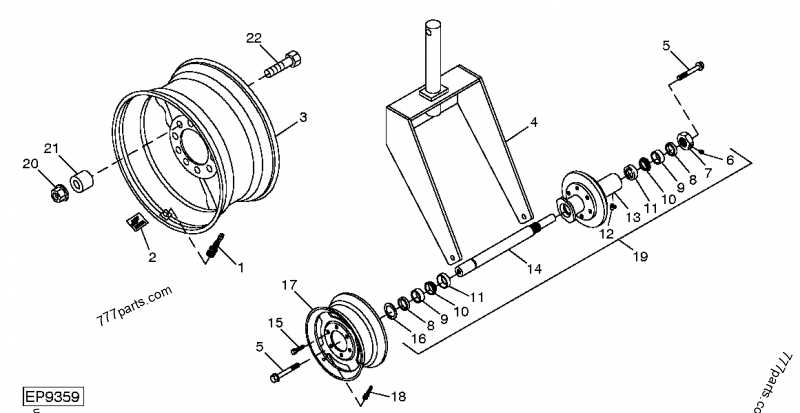

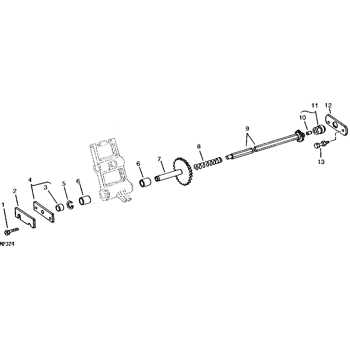

Parts Breakdown for Maintenance

Understanding the various components of machinery is crucial for effective upkeep and performance. A detailed examination of the individual elements allows users to identify potential issues and ensure longevity. Proper knowledge of these elements facilitates timely interventions and helps maintain operational efficiency.

Regular inspections and replacements of worn-out items are vital for preventing larger malfunctions. Each segment plays a unique role in the overall functionality, and neglecting any can lead to diminished performance. Therefore, familiarizing oneself with the structure and role of each component will greatly enhance maintenance efforts.

Using comprehensive schematics, one can easily locate and replace specific parts as needed. This proactive approach not only reduces downtime but also contributes to a smoother operation. Ultimately, thorough understanding and management of these elements lead to better results and increased reliability.

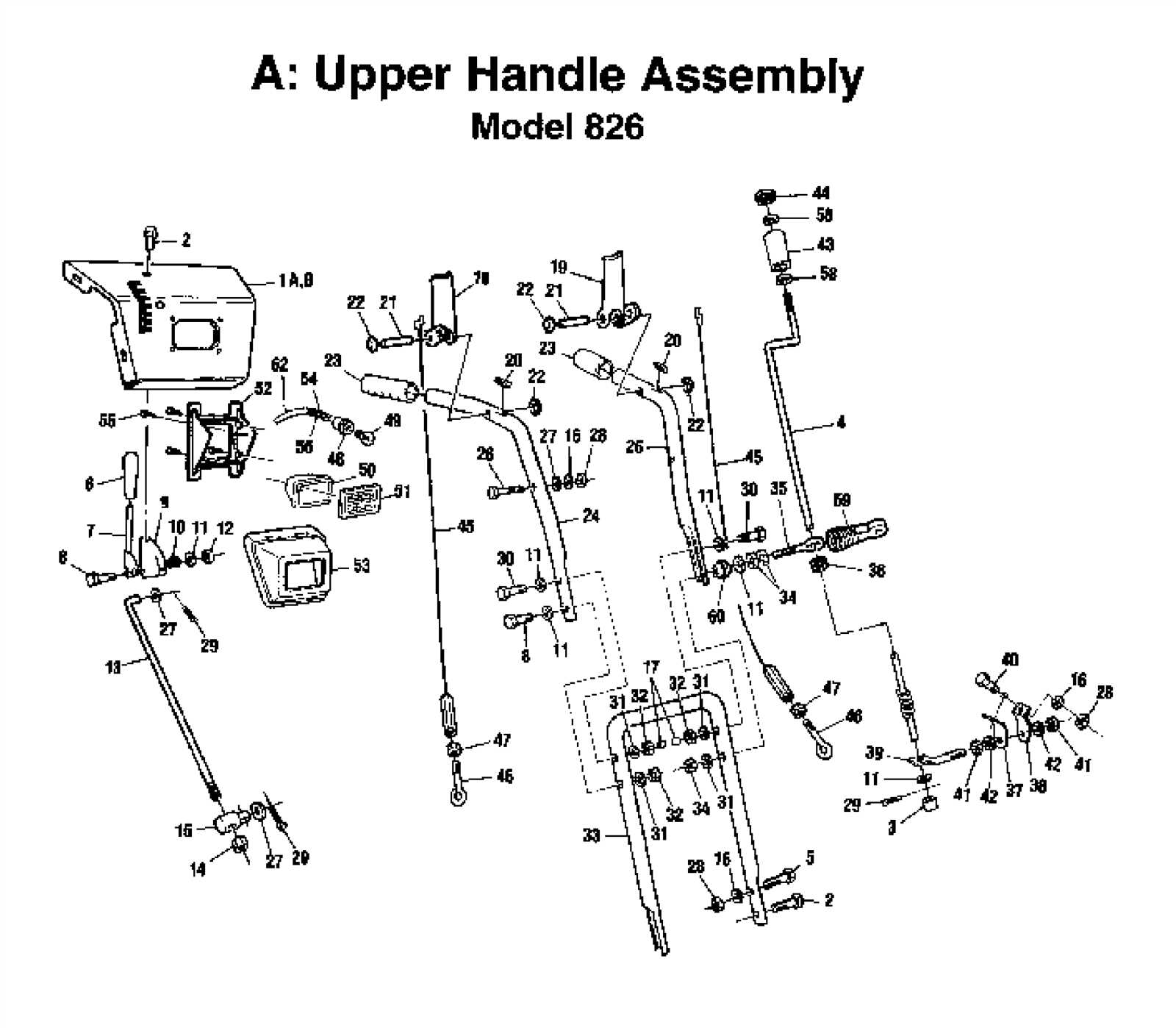

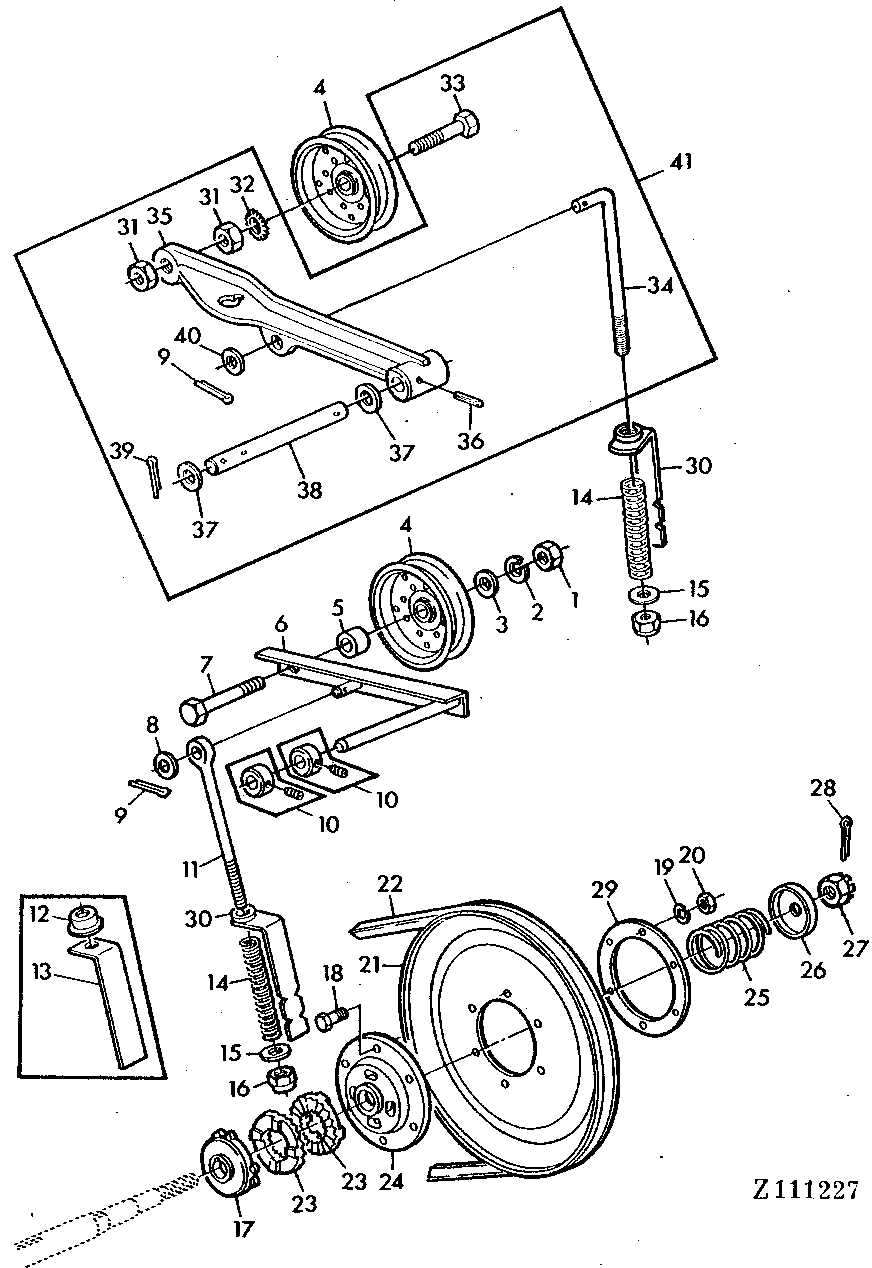

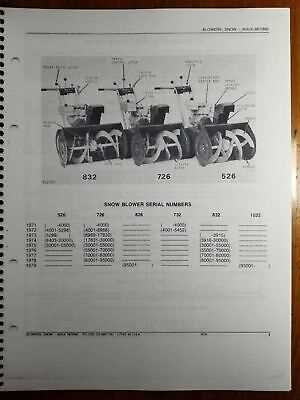

Visual Guide to Parts Diagram

This section serves as a comprehensive reference for understanding the components of your machinery. A well-organized visual representation allows users to identify each element and comprehend their functions within the overall system. This guide is essential for anyone looking to maintain or repair their equipment efficiently.

Understanding the Component Layout

The layout provides clarity on the arrangement of different elements, helping users navigate through the various sections with ease. By familiarizing yourself with the configuration, you can streamline maintenance processes and troubleshoot issues more effectively. Recognizing the specific roles of each part is crucial for optimal operation.

Benefits of Using Visual Aids

Utilizing visual aids enhances learning and retention. Clear illustrations can significantly reduce the time spent on repairs and replacements. Investing in a thorough understanding of the equipment’s structure leads to better performance and longevity. Moreover, visual references can prevent errors and miscommunication during maintenance tasks.

Common Issues and Solutions

In the realm of machinery maintenance, identifying and addressing frequent problems is essential for optimal performance. Understanding typical challenges can help users make informed decisions and take corrective measures to ensure their equipment operates smoothly. This section explores some of the most common issues encountered and provides effective solutions for each.

Common Challenges

Various complications may arise during operation, affecting efficiency and functionality. Below are some frequently encountered challenges:

| Issue | Description |

|---|---|

| Engine Difficulties | Problems such as rough idling, starting issues, or stalling can occur due to various factors like fuel quality or ignition system malfunctions. |

| Hydraulic Failures | Weak or unresponsive hydraulic systems often result from leaks, low fluid levels, or air trapped within the system. |

| Electrical Malfunctions | Inconsistent electrical performance can be caused by faulty wiring, blown fuses, or defective components. |

Solutions and Recommendations

To mitigate these challenges, consider the following solutions:

- Regularly inspect and replace filters and fluids to maintain engine health.

- Check hydraulic fluid levels and inspect hoses for any signs of wear or leaks.

- Test electrical connections and replace any damaged wiring or components as needed.

Upgrading Your John Deere 826

Enhancing the performance and functionality of your equipment can significantly improve its efficiency and longevity. Various components can be upgraded to ensure optimal operation and meet specific needs. By focusing on key areas of improvement, you can elevate your machine to a higher standard, enabling it to tackle various tasks more effectively.

Essential Components for Enhancement

When considering upgrades, it’s important to focus on components that will provide the most benefit. Here are a few crucial parts to consider:

| Component | Upgrade Options | Benefits |

|---|---|---|

| Engine | Performance chips, air filters | Increased horsepower, better fuel efficiency |

| Transmission | Higher torque converters | Smoother shifting, improved towing capacity |

| Hydraulic System | Upgraded pumps and hoses | Faster response time, increased lifting capacity |

Installation and Maintenance Tips

Proper installation and maintenance are critical to ensure the longevity of any upgrades. Regularly check the upgraded components for wear and tear, and perform maintenance as needed. Consulting with professionals can provide valuable insights and assistance during the upgrade process, ensuring everything is installed correctly and functions as intended.

Where to Find Replacement Parts

Finding the right components for your machinery can be a daunting task. Fortunately, numerous resources are available to help you locate the necessary items for maintenance or repair. Whether you prefer shopping online or visiting a physical store, there are various options to explore.

Online Retailers

Online platforms offer a convenient way to access a wide range of components. Many websites specialize in machinery supplies and provide detailed catalogs that allow you to search by model or type. Additionally, some platforms offer customer reviews and ratings to help you make informed decisions.

Local Dealers

Visiting local dealers can be beneficial as they often have knowledgeable staff who can assist you in identifying the right components for your equipment. They may also offer additional services, such as installation or maintenance advice, enhancing your overall experience.

| Source Type | Advantages | Considerations |

|---|---|---|

| Online Retailers | Convenience, wide selection, customer reviews | Shipping times, potential for incorrect orders |

| Local Dealers | Personalized service, immediate availability | Limited stock, possibly higher prices |

Assembly Instructions and Tips

Proper assembly is crucial for ensuring the optimal performance of your machinery. Following a systematic approach can help prevent mistakes and reduce the risk of malfunctions. This section provides guidelines and helpful suggestions to facilitate a seamless assembly process.

Begin by gathering all necessary components and tools. Ensure that your workspace is clean and organized to avoid misplacing parts. It is beneficial to refer to an assembly guide or schematic, as it can provide visual assistance during the process.

When assembling, take your time to align each piece correctly. Misalignment can lead to complications in functionality. Additionally, use appropriate fasteners and ensure they are tightened to the recommended specifications to maintain structural integrity.

Consider assembling in stages, which allows you to troubleshoot issues more easily as they arise. If you encounter resistance when fitting components together, double-check that no parts are obstructing the connection.

Finally, after the assembly is complete, conduct a thorough inspection to confirm that everything is in place and functioning as intended. Performing this final check can save time and resources in the long run.

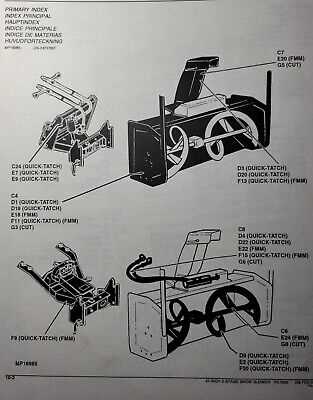

Compatibility with Other Models

Understanding the interchangeability of components across various equipment can enhance maintenance efficiency and reduce costs. This section focuses on how certain machinery can share parts and features, making it easier for users to find compatible options when repairs or upgrades are necessary.

Many models share similarities in design and functionality, which often allows for the use of the same components. This compatibility can be particularly beneficial for those looking to replace specific parts without being limited to a single brand or model. Cross-referencing specifications ensures that users can maximize the lifespan of their machinery while optimizing performance.

It’s crucial to consult compatibility charts and part numbers to determine which models can effectively utilize shared components. Doing so not only aids in making informed decisions but also promotes sustainability by extending the life of existing equipment. Utilizing compatible parts from various models can lead to significant cost savings and improved operational efficiency.

Importance of Genuine Parts

The utilization of authentic components in machinery is crucial for optimal performance and longevity. Genuine items are designed specifically for particular equipment, ensuring compatibility and reliability. Their quality is often superior, as they meet the original manufacturer’s standards.

When using original components, users can avoid common issues associated with inferior alternatives, such as premature wear and malfunction. Investing in high-quality replacements not only enhances the overall functionality but also contributes to the safety and efficiency of operations. In the long run, this choice can lead to reduced maintenance costs and increased productivity.

Furthermore, authentic components typically come with warranties that provide added peace of mind. This assurance allows users to operate their machinery confidently, knowing that they are supported by the manufacturer’s guarantee. Choosing genuine items is a smart decision that pays off over time.

Resources for DIY Repairs

When tackling maintenance tasks on your outdoor machinery, having access to the right resources can significantly enhance your repair experience. Whether you’re a novice or an experienced enthusiast, various materials can guide you through troubleshooting and fixing your equipment effectively.

Online Forums: Engaging with online communities dedicated to machinery repairs can provide invaluable insights. Users often share their experiences, solutions, and even step-by-step guides for specific issues, making it easier to understand complex repairs.

Manufacturer Manuals: Official manuals are a must-have for any DIYer. These documents typically include essential information on assembly, disassembly, and maintenance, helping you identify the components and their functions.

Video Tutorials: Platforms like YouTube host countless video tutorials that demonstrate various repair techniques. Visual guidance can be particularly helpful for those who learn better through observation, offering a clear view of the necessary steps involved.

Local Workshops: Participating in workshops or classes at local hardware stores or community centers can offer hands-on experience. These sessions often cover fundamental repair skills and provide opportunities to learn from professionals.

By utilizing these resources, you can empower yourself to handle repairs with confidence and efficiency, ensuring your machinery remains in optimal condition.