Comprehensive Guide to John Deere 894A Hay Rake Parts Diagram

The functionality and efficiency of any farming equipment rely heavily on its individual components. A thorough comprehension of how each element contributes to the overall performance can significantly enhance maintenance practices and operational longevity.

In this section, we will explore a detailed visual representation that breaks down the intricate parts of a specific agricultural tool. By delving into the anatomy of this implement, users can identify potential issues and ensure that their machinery operates at peak performance.

Moreover, understanding these elements not only aids in repairs but also empowers operators to make informed decisions when upgrading or replacing components. With this knowledge, one can achieve the ultimate efficiency in their agricultural endeavors.

Understanding the John Deere 894A Hay Rake

This section delves into the functionality and design of a specific agricultural implement, renowned for its efficiency in managing grass and forage. Its construction is tailored to optimize the collection and arrangement of crop material, enhancing the overall productivity of farming operations.

The machine features an innovative system that allows for adjustable working widths, ensuring versatility across different field conditions. This adaptability is crucial for farmers who need to manage varying crop types and densities, allowing for effective harvest preparation.

Maintenance is essential to keep this implement operating at peak performance. Familiarity with its components and their functions aids in identifying potential issues early, ensuring longevity and reliability during peak seasons. Regular inspections and timely replacements contribute significantly to overall efficiency.

Additionally, understanding the operational mechanics can enhance the user experience. Knowledge of how different settings affect performance enables farmers to make informed adjustments, maximizing their output while minimizing resource wastage.

Key Features of the 894A Model

The 894A model stands out in its category, offering a range of essential attributes that enhance its efficiency and reliability. Designed for optimal performance, it caters to the diverse needs of users, ensuring a seamless experience in various conditions.

Robust Construction: This unit is built with durable materials, providing longevity and resistance to wear, making it suitable for heavy-duty applications.

Advanced Maneuverability: The design allows for easy navigation across different terrains, facilitating effective operation in tight spaces and uneven ground.

Efficient Operation: Equipped with innovative mechanisms, it ensures a consistent performance while reducing energy consumption, promoting eco-friendliness.

User-Friendly Features: The intuitive controls and straightforward maintenance requirements make it accessible for operators of all skill levels, enhancing overall productivity.

In summary, this model combines strength, efficiency, and ease of use, establishing itself as a reliable choice for various agricultural tasks.

Importance of Proper Maintenance

Regular upkeep of agricultural equipment is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to various issues, including reduced efficiency, costly repairs, and even safety hazards. By prioritizing proper care, operators can significantly enhance productivity and reduce downtime.

Benefits of Regular Upkeep

- Increased Efficiency: Well-maintained machinery operates more smoothly and effectively, allowing for faster completion of tasks.

- Cost Savings: Preventive care can prevent major breakdowns, ultimately saving money on repairs and replacements.

- Enhanced Safety: Regular checks help identify potential hazards, reducing the risk of accidents in the field.

- Extended Lifespan: Consistent maintenance practices contribute to a longer operational life for the equipment.

Key Maintenance Practices

- Regularly inspect all components for signs of wear and tear.

- Keep machinery clean to prevent dirt and debris buildup.

- Lubricate moving parts to reduce friction and wear.

- Monitor fluid levels and change fluids as recommended by the manufacturer.

- Follow the manufacturer’s guidelines for seasonal maintenance tasks.

By adhering to a structured maintenance routine, operators can ensure that their equipment remains in peak condition, resulting in efficient operation and reduced risk of unexpected failures.

Common Issues with Hay Rake Parts

In the world of agricultural machinery, certain challenges frequently arise that can affect the efficiency and performance of equipment. Understanding these common problems can help operators maintain their tools effectively and ensure optimal functionality. Various components may experience wear and tear, leading to decreased productivity and increased maintenance needs.

Frequent Malfunctions

Several key issues can arise during operation, often stemming from regular use and environmental factors. Identifying these malfunctions early can save time and resources.

| Issue | Description | Potential Solution |

|---|---|---|

| Wear and Tear | Components may deteriorate over time, leading to reduced efficiency. | Regular inspection and timely replacement of worn parts. |

| Misalignment | Improper alignment can cause uneven performance and stress on the machinery. | Check and adjust alignment settings periodically. |

| Clogging | Debris buildup can obstruct operation and lead to mechanical failure. | Regular cleaning and maintenance of all components. |

Preventive Measures

Taking proactive steps can significantly reduce the occurrence of these issues. Routine maintenance and careful operation are essential to prolonging the lifespan of machinery. Operators should establish a consistent schedule for inspections and repairs to mitigate potential problems before they escalate.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing issues with agricultural machinery. By following a systematic method, you can effectively diagnose and resolve common problems that may arise during operation. This guide aims to assist you in performing repairs efficiently, ensuring your equipment remains in optimal condition.

Preparation and Assessment

Before starting any repair, it is essential to gather the necessary tools and materials. Conduct a thorough inspection of the equipment to identify any visible damage or wear. Make a list of components that require attention, which will streamline the repair process and ensure nothing is overlooked.

Step-by-Step Repair Process

Begin by disassembling the relevant parts according to your assessment. Carefully document each step and keep track of all screws and fasteners to avoid losing them. Once the components are removed, clean each part to remove dirt and debris. This will help you identify any further damage and ensure proper functioning once reassembled.

Next, replace any worn or damaged pieces with suitable alternatives, ensuring compatibility with your model. When reassembling, refer to your documentation to reattach everything in the correct order. Finally, conduct a thorough test of the machinery to confirm that repairs were successful and everything operates smoothly.

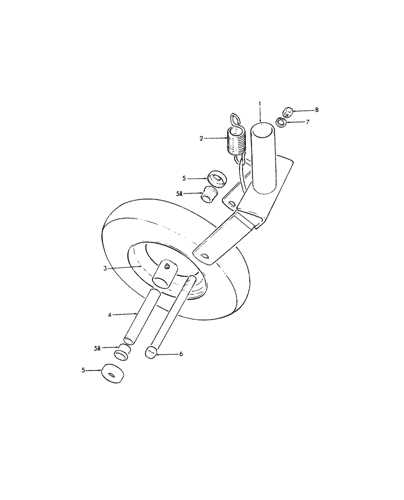

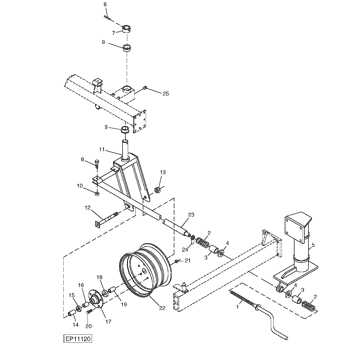

Parts Diagram Overview

This section provides a comprehensive look at the various components that make up the equipment in question. Understanding the layout and functions of these elements is crucial for effective maintenance and repair, ensuring optimal performance and longevity.

Component Identification

Each part plays a vital role in the overall functionality. Familiarity with these components allows users to quickly identify issues and address them promptly. A clear understanding enhances operational efficiency and reduces downtime.

Benefits of Familiarization

Gaining insight into the structure aids in troubleshooting and enhances repair strategies. This knowledge empowers users to make informed decisions, ultimately leading to improved equipment management and a smoother working experience.

Where to Find Replacement Parts

Locating suitable components for agricultural machinery can be a straightforward process if you know where to look. Various sources offer a range of options, from official suppliers to online marketplaces. Each option comes with its own benefits, ensuring that you can find what you need for efficient repairs or upgrades.

| Source | Description | Advantages |

|---|---|---|

| Manufacturer’s Website | Official online platform offering original components. | Guaranteed quality and compatibility. |

| Local Dealers | Nearby agricultural equipment suppliers. | Personalized service and immediate availability. |

| Online Marketplaces | Websites where various sellers offer components. | Wide selection and competitive pricing. |

| Salvage Yards | Facilities specializing in used equipment and parts. | Cost-effective options for budget-conscious buyers. |

By exploring these avenues, you can efficiently find the necessary components to keep your machinery in top working condition, ensuring longevity and optimal performance.

Tips for Effective Hay Raking

Achieving optimal results in the collection of dried forage requires careful attention to various techniques and practices. Understanding the right timing, equipment adjustments, and environmental conditions can significantly enhance efficiency and quality in the process.

Timing and Conditions

It’s crucial to monitor weather patterns and soil moisture levels. Ideal conditions for collection are during dry, sunny days to prevent spoilage and ensure better texture. Timing your operations early in the morning or late in the afternoon can also help maintain optimal forage quality.

Equipment Maintenance

Regular maintenance of your machinery is essential for peak performance. Inspecting components for wear, ensuring proper tension, and making necessary adjustments can lead to smoother operations. Keeping your tools clean and lubricated will also prolong their lifespan and enhance productivity.

Upgrading Your Hay Rake Components

Enhancing the efficiency of your agricultural implement can lead to significant improvements in productivity and overall performance. By investing in quality enhancements, you can ensure that your equipment operates at its best, minimizing downtime and maximizing output.

Assessing Current Components

Before making any upgrades, it’s essential to evaluate the current state of your implement’s components. Identify areas that require attention, whether it’s wear and tear, outdated technology, or compatibility with new attachments. This assessment will help you determine the most effective upgrades to implement.

Selecting Upgrades

When choosing enhancements, consider factors such as durability, efficiency, and ease of installation. Upgrading to high-quality materials can reduce maintenance needs and extend the lifespan of your equipment. Additionally, innovative features may offer improved functionality, making your operations smoother and more efficient.

Comparing Models: 894A vs. Others

This section explores the nuances between various agricultural implements, focusing on a specific model and its competitors. By examining features, performance, and user feedback, we aim to provide insights into their relative strengths and weaknesses.

Performance Metrics: Different models offer varying levels of efficiency and output. While one may excel in speed, another might provide superior durability or ease of use, impacting overall productivity.

User Experience: Feedback from operators often highlights the practical aspects of using each implement. Comfort, maintenance, and adaptability to different terrains can significantly influence a user’s preference.

Design Innovations: The evolution of these tools often leads to enhanced features that improve functionality. Innovations such as adjustable settings or advanced material use can set a model apart in a crowded market.

Conclusion: Understanding the distinctions between these agricultural devices can aid in making informed choices, ensuring that the selected implement aligns with specific operational needs and preferences.

Operator Safety and Best Practices

Ensuring the well-being of operators while using agricultural machinery is paramount. Understanding the potential hazards and implementing effective strategies can significantly reduce the risk of accidents and injuries.

Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear. Familiarize yourself with the equipment’s manual to grasp its features and safety protocols. Before operating, conduct a thorough inspection to identify any worn or damaged components.

Maintain a clean workspace and ensure that the area around the machinery is free from obstacles. This practice not only enhances safety but also improves efficiency during operation. Additionally, be mindful of your surroundings, particularly when working in close proximity to others or in variable weather conditions.

Follow all operational guidelines, including speed limits and load capacities, to prevent mechanical failures. Regularly attend safety training sessions to stay updated on best practices and emerging safety technologies in the field. By prioritizing these safety measures, operators can create a safer working environment and maximize productivity.

Customer Reviews and Feedback

This section highlights the experiences and opinions of users who have interacted with various components and machinery used in agricultural settings. Gathering feedback is essential to understand the quality, functionality, and overall satisfaction of the equipment in question. Customers often share valuable insights that can assist potential buyers in making informed decisions.

Overall Satisfaction

Many users express their satisfaction with the reliability and performance of the machinery. Here are some common themes observed in the feedback:

| Feedback Aspect | Positive Comments | Negative Comments |

|---|---|---|

| Durability | Sturdy construction, withstands heavy use | Some parts may require early replacement |

| Ease of Use | User-friendly design, easy to operate | Initial setup can be complex |

| Maintenance | Low maintenance needs, easy to clean | Occasional difficulties in finding specific components |

Recommendations from Users

Customers often provide suggestions for improvements based on their experiences. Some recommend enhanced customer support for troubleshooting, while others emphasize the importance of comprehensive manuals. These insights can be crucial for manufacturers aiming to improve their offerings and address user concerns effectively.