Comprehensive Guide to John Deere BC1600 Parts Diagram

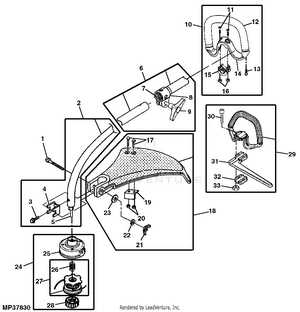

When it comes to maintaining and repairing heavy machinery, having a clear visual representation of the various elements is essential. These schematics provide invaluable insight into the intricate workings of the equipment, allowing for effective troubleshooting and efficient repairs. By examining these illustrations, operators and technicians can identify the relationships between different components, facilitating a deeper understanding of the overall system.

Moreover, familiarity with the layout and functions of each section can significantly enhance the efficiency of maintenance tasks. Whether it’s routine checks or addressing specific issues, knowing how parts interact helps streamline the repair process. This knowledge is vital for ensuring that the machinery operates at optimal performance, ultimately extending its lifespan and reliability.

In this article, we will explore the various aspects of these visual aids, focusing on how they can be utilized to improve maintenance practices. We will delve into the specifics of interpreting the schematics, highlighting the importance of each component and its role within the machinery. Armed with this information, operators can tackle repairs with confidence, ensuring that their equipment remains in top-notch condition.

Understanding the BC1600 Model

This section delves into the features and functionalities of a specific model renowned for its efficiency and durability in various applications. By exploring its design and technical specifications, users can gain insights into how this machine enhances performance and reliability in the field.

Key Features

The highlighted model is equipped with advanced technology that streamlines operations. Its robust construction ensures longevity, making it suitable for demanding environments. Additionally, the integration of innovative components enhances its overall effectiveness, allowing operators to achieve optimal results with ease.

Operational Benefits

Efficiency is a hallmark of this model, which translates to significant time savings and reduced operational costs. The intuitive controls and ergonomic design contribute to user-friendliness, enabling operators to maximize productivity. Understanding these benefits is crucial for those looking to leverage this equipment for various tasks.

Key Features of John Deere BC1600

This powerful machinery is designed to enhance efficiency and performance in various agricultural tasks. Its robust construction and innovative features provide users with reliability and ease of use, making it an essential tool for modern farming.

Durability: Built with high-quality materials, this equipment can withstand tough working conditions, ensuring longevity and reduced maintenance costs.

Versatility: The unit is capable of handling multiple applications, allowing farmers to tackle different jobs without needing additional tools.

Efficiency: Advanced technology integrated into its design maximizes productivity, helping users complete tasks more quickly and effectively.

User-Friendly Interface: The intuitive controls simplify operation, enabling both experienced and novice users to operate the equipment with confidence.

Enhanced Safety Features: Safety mechanisms are in place to protect operators, ensuring a secure working environment during operation.

Overall, this machinery represents an ultimate solution for those seeking reliability and performance in agricultural endeavors.

Importance of Parts Diagrams

Visual representations of component layouts are essential for anyone involved in machinery maintenance and repair. They provide clarity, ensuring that technicians and operators can efficiently identify and understand the various elements that comprise a machine. This understanding is crucial for effective troubleshooting, assembly, and replacement tasks.

Facilitating Maintenance

Clear visual guides significantly enhance the maintenance process. By illustrating the relationships between different components, they allow for quicker diagnosis of issues and streamline the steps needed for repairs. This leads to reduced downtime and increased productivity.

Enhancing Understanding

For individuals learning about machinery, these visual tools serve as an educational resource. They break down complex systems into manageable parts, making it easier for users to grasp how each element functions and interacts with others. This knowledge is invaluable for both novice and experienced users alike.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repairs. These illustrations serve as a guide, showcasing various elements and their relationships within a machine. Familiarizing yourself with these visuals can significantly enhance your ability to identify and replace parts accurately.

1. Familiarize with Symbols: Each representation often includes unique symbols that denote different components. Take time to learn these icons, as they provide essential information about the items depicted.

2. Follow the Flow: Most visual guides are organized logically, typically following the assembly or operational flow of the equipment. Start from one end and work your way through to understand how parts interact with each other.

3. Pay Attention to Labels: Labels and annotations often accompany the visuals, offering critical details such as part numbers, descriptions, and quantities. These notes are invaluable for ordering the correct replacements.

4. Utilize the Legend: Many illustrations include a legend that explains the various symbols and lines used throughout the visual. Refer to this section to clarify any uncertainties you may encounter while interpreting the guide.

5. Cross-Reference with Manuals: For a more comprehensive understanding, cross-reference the visual representation with the corresponding service manual. This can provide deeper insights into the function and maintenance of each component.

By mastering the art of interpreting these visuals, you will enhance your troubleshooting skills and ensure that your equipment remains in optimal condition.

Common Replacement Parts for BC1600

When maintaining agricultural machinery, understanding the essential components that may require regular replacement is crucial for optimal performance. These elements are vital for ensuring longevity and efficiency, allowing operators to achieve their desired results without unnecessary interruptions.

Wear Components

Several wear items are particularly susceptible to degradation over time. Blades and belts are prime examples, as they experience significant stress during operation. Regular inspection and timely replacement of these components can prevent more extensive damage and costly repairs.

Hydraulic Elements

Another category to consider involves hydraulic systems, which are integral to many functions of the machinery. Filters and hoses should be checked frequently, as their integrity directly impacts performance. Replacing these items as needed ensures that the system operates smoothly and efficiently.

Finding OEM Parts for BC1600

Locating original equipment manufacturer components can be crucial for maintaining optimal functionality in your machinery. Ensuring you have the right pieces not only enhances performance but also prolongs the lifespan of your equipment. By focusing on reliable sources, you can streamline the process and ensure compatibility.

Understanding Authenticity

When searching for genuine components, it’s vital to recognize the difference between authentic and aftermarket options. OEM items are specifically designed for your model, guaranteeing a perfect fit and reliable performance. Researching reputable suppliers is essential to avoid counterfeit alternatives.

Where to Look

Online marketplaces, specialized retailers, and manufacturer websites are excellent starting points for your search. Many platforms offer comprehensive catalogs that include detailed specifications, helping you make informed decisions. Additionally, consulting with local dealers can provide insights into availability and recommendations for trusted vendors.

Tools Needed for Maintenance

Proper upkeep of machinery is crucial for ensuring longevity and optimal performance. To achieve this, having the right set of tools is essential. These instruments not only facilitate routine checks and repairs but also help in identifying issues before they escalate. Below is a list of indispensable tools that can aid in effective maintenance.

Essential Tools

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening and loosening bolts and nuts. |

| Screwdrivers | Necessary for assembling and disassembling components. |

| Socket Set | Facilitates easier access to fasteners in tight spaces. |

| Oil Can | For lubrication of moving parts to reduce friction. |

| Cleaning Supplies | Used for removing dirt and debris from surfaces. |

Additional Considerations

In addition to the basic tools, certain specialized instruments may be required depending on the type of machinery and the specific tasks at hand. Investing in high-quality tools can yield better results and make maintenance tasks more efficient.

Repair Techniques for BC1600

Maintaining and restoring machinery requires a solid understanding of various methods and practices that enhance performance and longevity. Employing the right techniques can significantly improve efficiency and reduce downtime.

Essential Repair Methods

- Regular Inspection: Conduct thorough evaluations to identify wear and tear.

- Component Replacement: Swap out damaged or worn parts to ensure optimal functionality.

- Lubrication: Apply appropriate oils and greases to reduce friction and enhance operation.

- Calibration: Adjust settings for precision and accuracy in performance.

Advanced Techniques

- Welding Repairs: Utilize welding for structural integrity on compromised components.

- Hydraulic System Maintenance: Regularly check and service hydraulic systems to prevent leaks.

- Electrical Troubleshooting: Address electrical issues systematically to restore functionality.

Maintenance Schedule for John Deere

Establishing a consistent upkeep routine is crucial for the longevity and efficiency of agricultural machinery. Regular maintenance not only ensures optimal performance but also prevents unexpected breakdowns that can disrupt operations.

Daily Inspections

Performing daily checks is essential. Focus on fluid levels, tire pressure, and general cleanliness. Address any visible issues promptly to avoid larger complications.

Seasonal Maintenance Tasks

As the seasons change, so should your maintenance practices. Conduct thorough inspections before planting and harvest seasons, including checking belts, filters, and lubrication points. Regular servicing will ultimately enhance productivity and extend the lifespan of your equipment.

Identifying Parts by Serial Number

Recognizing components through their unique identification numbers is crucial for efficient maintenance and repair. This method streamlines the process of locating specific elements, ensuring that users can obtain the correct replacements without confusion. By utilizing these identifiers, one can avoid potential errors that might arise from using generic or incompatible items.

Benefits of Using Serial Numbers

Employing identification numbers provides several advantages. It enhances accuracy, minimizes downtime, and guarantees compatibility. Furthermore, having access to precise information about each item allows for better planning during repairs and replacements.

How to Locate the Serial Number

The identification number is typically found in specific locations on the machinery. Common areas include the frame, near the engine, or on a dedicated plate. Knowing where to look can significantly speed up the identification process.

| Location | Description |

|---|---|

| Frame | Often stamped or labeled directly on the chassis. |

| Engine | Usually located on a metal plate affixed to the engine block. |

| Control Panel | May include the number on a sticker or engraved section. |

Where to Buy Replacement Parts

Finding quality components for your machinery is essential for maintaining optimal performance and longevity. Various sources offer the necessary items, ranging from online retailers to local suppliers, ensuring you have access to what you need for repairs and maintenance.

Online Retailers

The internet provides a vast selection of shops specializing in machinery components. Websites dedicated to agricultural equipment often have detailed catalogs, making it easier to find specific items. Look for reputable vendors with customer reviews to ensure reliability.

Local Dealerships

Your nearest dealership can be a valuable resource for obtaining authentic components. They typically carry a range of items and can offer expert advice on compatibility and installation. Establishing a relationship with local suppliers may also lead to better deals and personalized service.

Comparing BC1600 with Other Models

When evaluating the efficiency and capabilities of various agricultural equipment, it is essential to assess how specific models stand against their counterparts. This comparison can reveal unique advantages and limitations, guiding users in making informed decisions.

In this section, we will explore key differences and similarities, focusing on several critical aspects:

- Performance: Different models may offer varying power outputs and operational speeds.

- Durability: Construction materials and design can influence longevity and maintenance needs.

- Features: Advanced functionalities such as automation and ease of use can differentiate options.

- Cost-effectiveness: Initial investment versus long-term savings is a significant consideration.

Understanding these factors helps users delve into their specific requirements and find the ultimate equipment suited to their needs.

Tips for Efficient Repairs

Maintaining machinery requires a systematic approach to ensure optimal functionality and longevity. Effective repairs not only save time but also minimize costs, allowing for smooth operation in the long run.

Preparation is Key

- Gather all necessary tools before starting.

- Review any available manuals for guidance.

- Identify the specific components that need attention.

Stay Organized

- Label parts and fasteners as you remove them.

- Use containers to keep small items together.

- Document your process for future reference.