Comprehensive Parts Diagram for John Deere D110

Maintaining a lawn tractor requires a comprehensive understanding of its essential elements and how they interact. Each component plays a vital role in ensuring optimal performance, making it crucial for owners to familiarize themselves with the various parts. This knowledge not only aids in effective maintenance but also enhances the longevity of the machine.

In this section, we will explore a detailed representation of the key components found within a popular model of garden machinery. By dissecting the intricacies of each element, users can better identify issues and perform necessary repairs or replacements with confidence. A thorough grasp of these mechanisms empowers operators to tackle challenges head-on, ensuring a smoothly running machine throughout the seasons.

Understanding the layout and functionality of these components is essential for any enthusiast or professional alike. This guide serves as a valuable resource, helping you navigate the complexities of your equipment and maximize its capabilities for years to come.

Understanding John Deere D110 Parts

Grasping the components of a specific model is essential for maintenance and efficient operation. Recognizing how each element functions in harmony can enhance the overall performance of your machine. This knowledge empowers users to identify issues quickly and undertake necessary repairs with confidence.

Each component serves a distinct purpose, contributing to the seamless operation of the equipment. Familiarity with these elements not only aids in troubleshooting but also assists in making informed decisions regarding upgrades or replacements. An in-depth understanding allows for better care, extending the lifespan of the machine.

Moreover, having a clear overview of the various sections can simplify the process of acquiring replacements or enhancements. Whether it’s the engine, transmission, or other critical systems, knowing their roles ensures that any modifications align with the desired functionality. Such awareness fosters an environment where efficiency and reliability thrive.

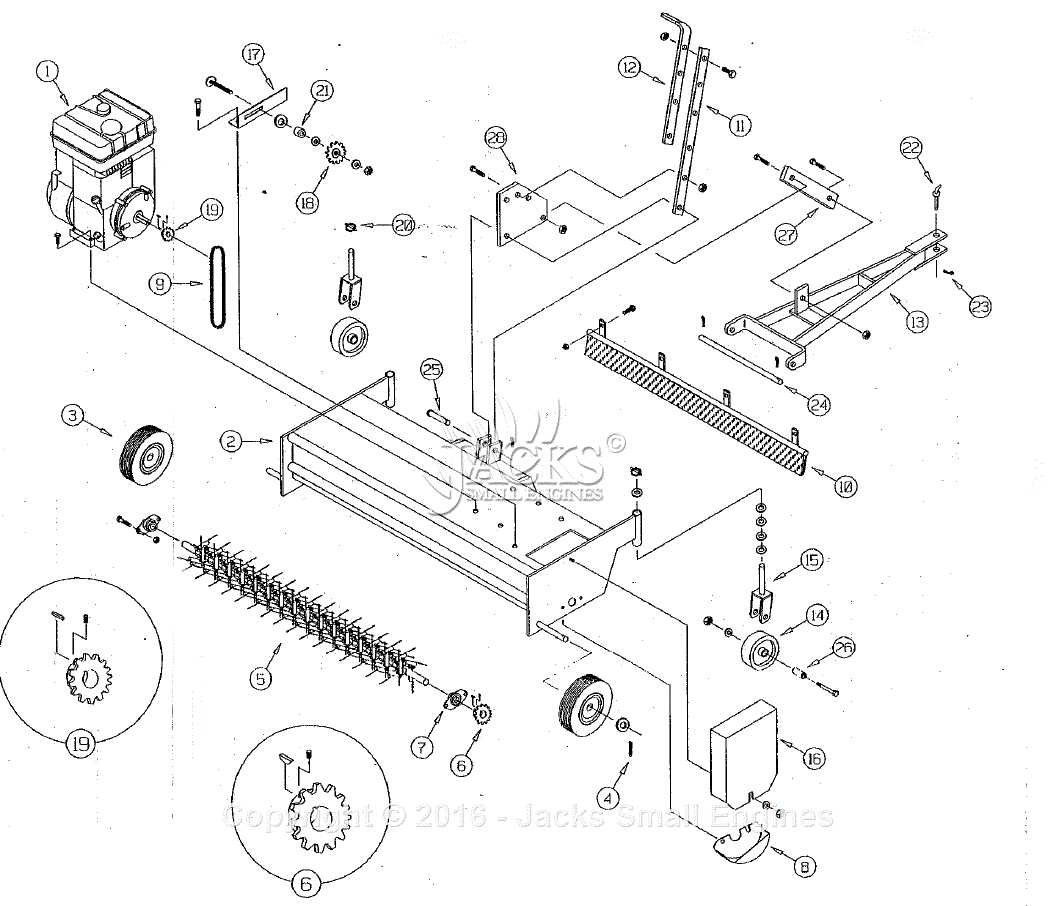

Importance of Parts Diagrams

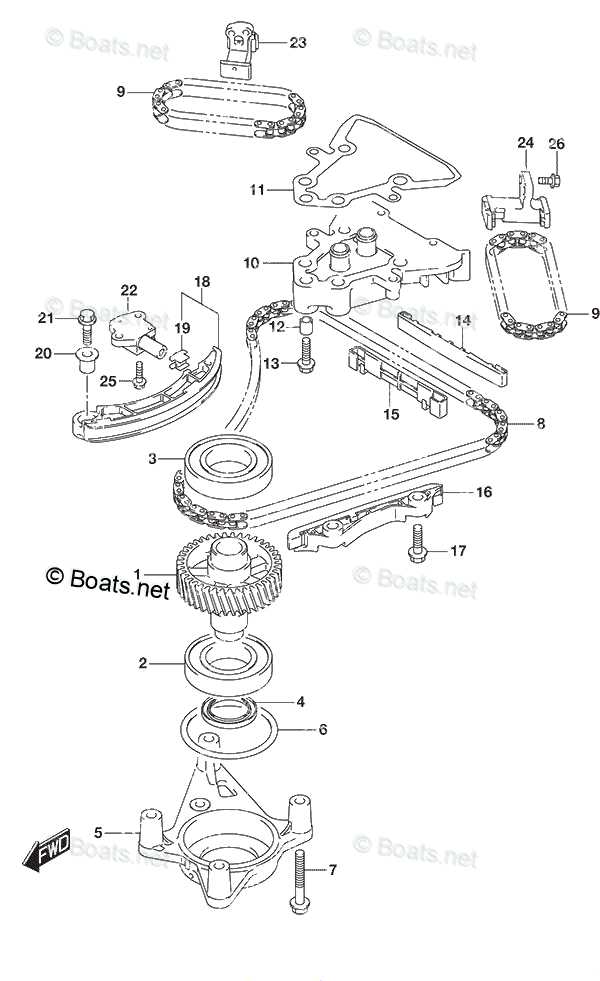

Understanding the intricate assembly of machinery is essential for effective maintenance and repairs. Visual representations play a crucial role in conveying the relationship between various components, allowing users to identify each element’s function and position within the whole system.

Visual aids simplify complex information, making it accessible even to those who may not possess extensive technical knowledge. By providing a clear overview, these illustrations enhance the ability to locate specific elements swiftly, reducing the time spent troubleshooting.

Moreover, familiarity with these visuals fosters a deeper comprehension of how individual pieces interact. This understanding not only aids in efficient repairs but also encourages proactive maintenance practices, ultimately extending the lifespan of the equipment. In summary, having a well-organized visual guide is invaluable for anyone looking to maintain machinery effectively.

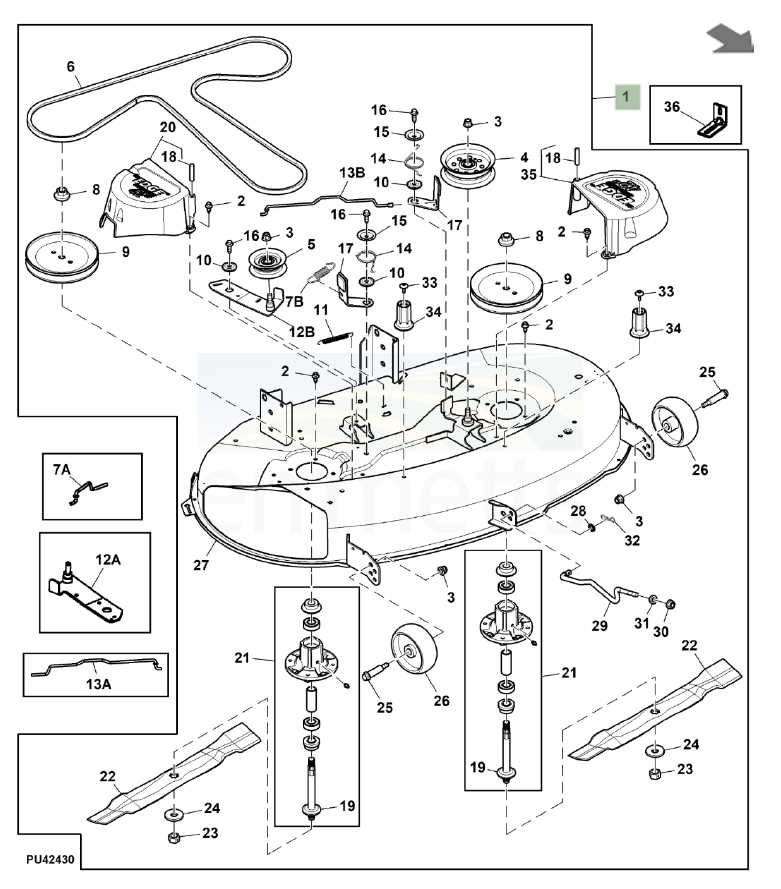

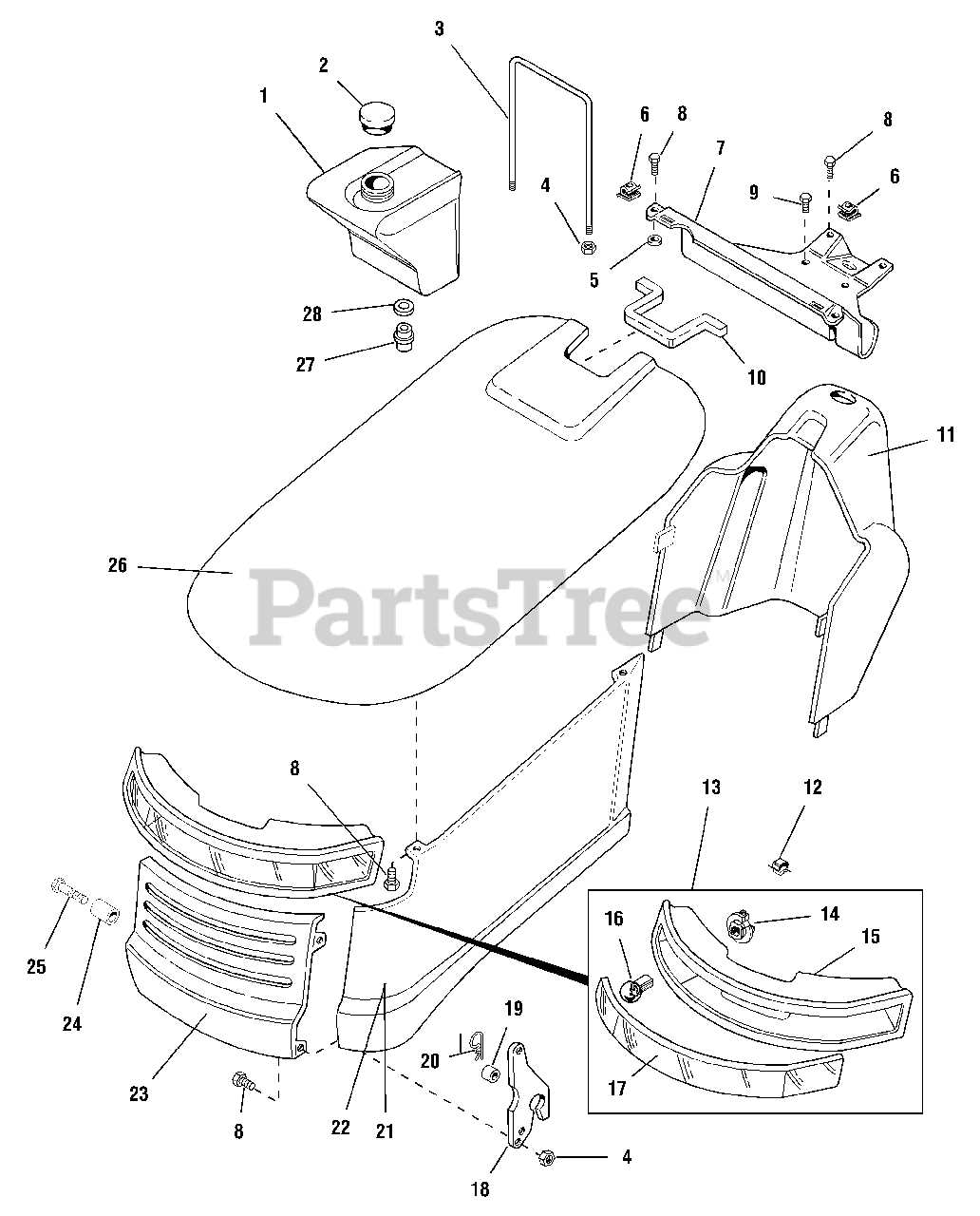

Key Components of the D110

Understanding the essential elements of this lawn care machine is crucial for optimal performance and maintenance. Each part plays a significant role in ensuring efficiency and longevity, contributing to the overall functionality of the equipment.

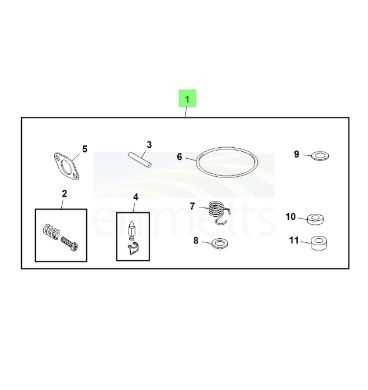

Engine and Power System

The engine serves as the heart of the machine, providing the necessary power for all operations. It is important to recognize the various components that work together to generate energy and drive the mower effectively.

| Component | Function |

|---|---|

| Air Filter | Ensures clean air intake for optimal combustion. |

| Fuel Pump | Delivers fuel from the tank to the engine. |

| Battery | Powers the electrical system and starts the engine. |

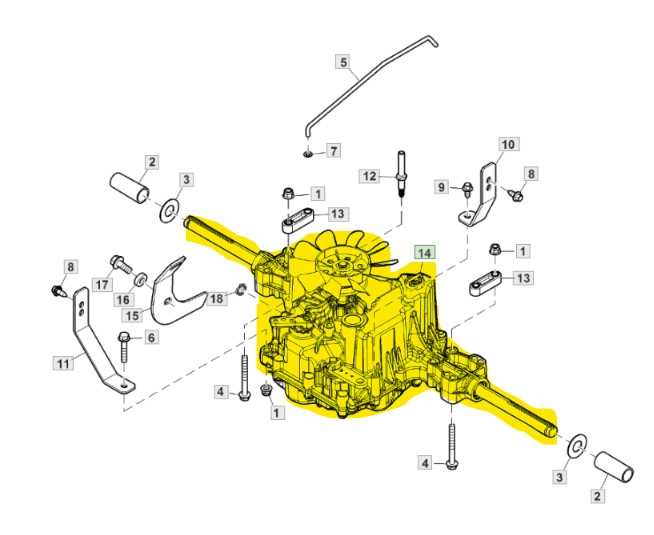

Transmission and Drive Mechanism

The transmission system is vital for controlling speed and direction. Understanding its components allows for better handling and maneuverability of the machine.

| Component | Function |

|---|---|

| Transmission Belt | Transfers power from the engine to the wheels. |

| Drive Axle | Connects the wheels, enabling movement. |

| Gear System | Adjusts speed and torque for different terrains. |

How to Access Parts Diagrams

Understanding how to locate technical illustrations for equipment components is essential for effective maintenance and repair. These visuals provide a detailed overview of various parts, allowing users to identify and source the necessary elements for their machinery. By utilizing available resources, you can ensure your equipment remains in optimal condition.

Online Resources: Many manufacturers offer comprehensive online platforms where you can find these illustrations. Start by visiting the official website and navigating to the support or resources section. You may need to enter specific model information to access the relevant materials.

User Manuals: Printed or digital manuals often include detailed visuals. Check the documentation that came with your equipment or search for downloadable versions online. These guides not only feature illustrations but also provide valuable assembly instructions and maintenance tips.

Community Forums: Engaging with fellow users on dedicated forums can be incredibly helpful. Many enthusiasts and professionals share links to useful resources, including technical visuals. Participating in discussions may also lead you to unique insights about repairs and upgrades.

Local Dealers: Authorized dealers can be an excellent source for obtaining these visuals. They typically have access to the most current information and can assist in finding the right parts for your specific model. Don’t hesitate to reach out for assistance.

Identifying Common Replacement Parts

Understanding essential components for machinery maintenance is crucial for ensuring optimal performance and longevity. Recognizing which elements frequently require substitution can aid in efficient upkeep and minimize downtime. By familiarizing yourself with the most common items that may wear out over time, you can better prepare for repairs and enhance the functionality of your equipment.

Key components that often need to be replaced include belts, blades, and filters. Belts play a vital role in transferring power, while blades are essential for cutting efficiency. Additionally, filters help maintain engine cleanliness and performance. Regular inspection of these items can prevent potential issues before they escalate.

Moreover, components such as spark plugs and batteries are critical for starting and operating machinery effectively. Keeping a close eye on their condition and replacing them as necessary will ensure reliable functionality. Familiarizing yourself with these elements allows for timely interventions and smoother operations.

Maintenance Tips for D110 Owners

Regular upkeep is essential for optimal performance and longevity of your equipment. Implementing a structured maintenance routine not only enhances efficiency but also helps in identifying potential issues before they escalate.

- Check fluid levels frequently, including oil and coolant, to ensure smooth operation.

- Inspect belts and hoses for wear or damage, replacing them as needed.

- Clean air filters regularly to maintain engine efficiency and prevent debris buildup.

- Sharpen blades to achieve a clean cut and reduce strain on the engine.

- Examine tires for proper inflation and tread wear to ensure stability and performance.

By following these guidelines, owners can enhance the reliability and effectiveness of their machinery.

Where to Find Genuine Parts

Locating authentic components for your machinery is essential for optimal performance and longevity. Relying on reputable sources ensures you receive high-quality items that meet the specific requirements of your equipment.

Authorized Dealers are often the best starting point, as they typically carry a comprehensive selection of original items. Engaging with these vendors not only guarantees authenticity but also provides expert advice.

Online Retailers also present a convenient option. Websites specializing in equipment components often feature detailed catalogs, allowing for easy comparison and selection. Be sure to verify their reputation and return policies.

Local Repair Shops can be invaluable resources as well. These establishments often have access to original suppliers and may provide insights based on hands-on experience with your specific model.

Additionally, manufacturer websites can serve as a direct source for ordering components. They often provide detailed information on the required specifications, ensuring you choose the right items for your needs.

DIY Repairs: Tools You Need

When tackling home maintenance projects, having the right tools at your disposal can make all the difference. A well-equipped toolbox not only simplifies the repair process but also enhances efficiency and safety. Below is a comprehensive list of essential tools for anyone looking to handle minor repairs with confidence.

- Wrenches: A variety of sizes ensures you can tighten or loosen bolts and nuts effectively.

- Screwdrivers: Both flat-head and Phillips screwdrivers are crucial for assembling or disassembling components.

- Socket Set: Ideal for reaching fasteners in tight spaces, a complete set will cover most applications.

- Pliers: Useful for gripping, twisting, and cutting wire or other materials.

- Hammer: Essential for driving nails or fitting parts together.

In addition to the basics, consider the following specialized tools:

- Torque Wrench: Ensures that nuts and bolts are tightened to the manufacturer’s specifications.

- Multimeter: Useful for diagnosing electrical issues by measuring voltage, current, and resistance.

- Jack and Jack Stands: Necessary for safely lifting and supporting heavier equipment during repairs.

- Cutting Tools: Such as utility knives or snips, for trimming materials or cables.

- Measuring Tools: A tape measure and level help ensure accurate fits and alignments.

By assembling these essential tools, you’ll be well-prepared to tackle various repair tasks efficiently and safely, leading to successful DIY projects.

Common Issues with the D110

Every machine has its quirks, and this model is no exception. Users often encounter several frequent challenges that can affect performance and efficiency.

Starting Problems: A common issue involves difficulties in ignition. This may stem from a weak battery or faulty connections that need inspection.

Overheating: Machines can overheat due to blocked air vents or low coolant levels, which can lead to serious damage if not addressed promptly.

Uneven Cutting: If the blades are dull or misaligned, the resulting cut can be uneven, necessitating regular maintenance to ensure optimal performance.

Transmission Issues: Users may report slipping gears or slow response times, often indicating the need for fluid changes or component adjustments.

Electrical Failures: Problems with lights or other electrical components can occur, often requiring troubleshooting of wiring or fuses to restore functionality.

Addressing these common concerns can significantly enhance the lifespan and efficiency of the equipment, ensuring it operates at its best.

Upgrading Your John Deere Mower

Enhancing your mowing machine can significantly improve its performance and efficiency. By integrating advanced components or accessories, you can transform your equipment into a more powerful tool for maintaining your lawn.

Key Upgrades to Consider

Several modifications can elevate your mowing experience, from increasing cutting precision to boosting overall durability. Below are some popular enhancements:

| Upgrade | Benefits |

|---|---|

| High-Performance Blades | Improved cutting efficiency and cleaner cuts. |

| Engine Enhancements | Increased power and fuel efficiency. |

| Suspension System | Better handling and comfort during operation. |

Maintaining Upgrades

Regular maintenance is essential to keep these enhancements functioning optimally. Following the manufacturer’s guidelines will ensure longevity and reliability of the upgraded components.

Resources for Parts and Service

Accessing reliable resources for components and maintenance is crucial for keeping machinery in optimal condition. Whether you are looking for specific items or need guidance on upkeep, there are various avenues to explore that ensure efficiency and longevity.

Online Platforms

Numerous websites offer extensive catalogs for various machinery components, often including detailed specifications and user reviews. Engaging with these platforms can help identify compatible alternatives and enhance the decision-making process.

Local Dealerships

Visiting local dealerships provides an opportunity to consult experts who can offer tailored advice and support. They often have a selection of original equipment and can assist with installation and troubleshooting, ensuring that your equipment operates at its best.