Parts Diagram for John Deere Z540M

In the realm of outdoor machinery, comprehending the arrangement of various elements is crucial for effective maintenance and repair. A thorough grasp of how components interact within a system can enhance operational efficiency and prolong the lifespan of the equipment.

Each assembly comprises numerous parts that contribute to its overall functionality. By familiarizing oneself with the structure and relationships between these components, operators can identify potential issues more easily and undertake necessary adjustments or replacements.

Visual aids can significantly enhance this understanding, providing clear insights into where each piece fits within the larger mechanism. Recognizing the significance of each element enables users to perform tasks with greater confidence and precision.

John Deere Z540M Parts Overview

This section provides a comprehensive look at the various components essential for maintaining and enhancing the performance of a specific model of riding mower. Understanding the different elements can significantly aid in ensuring optimal functionality and longevity.

Key Components

- Engine Assembly

- Transmission Unit

- Blade System

- Deck Structure

- Wheel Assemblies

Maintenance Items

- Oil Filters

- Air Filters

- Fuel Filters

- Belts and Cables

- Blades and Spindles

Having a solid understanding of these components and maintenance items can help users make informed decisions regarding repairs and upgrades, ultimately leading to improved performance and reliability.

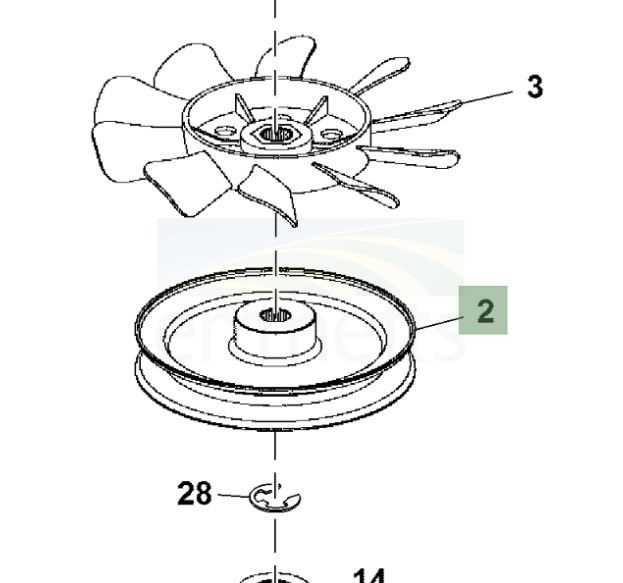

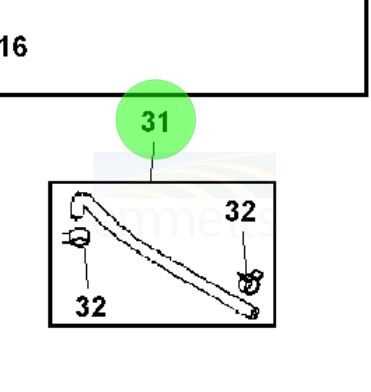

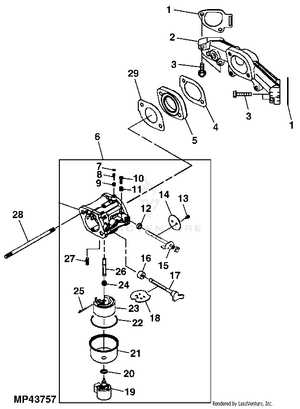

Understanding the Parts Diagram

Interpreting the assembly illustration is crucial for maintaining and repairing machinery efficiently. This visual representation serves as a guide, showcasing the various components and their interconnections. By familiarizing oneself with this layout, users can enhance their understanding of how each element contributes to the overall functionality of the equipment.

Key Components Explained

The illustration typically highlights essential elements that play a significant role in the machine’s operation. Recognizing these components can facilitate troubleshooting and repairs. For instance, important assemblies are often labeled, indicating their respective functions and locations. This clarity helps users pinpoint issues quickly and accurately.

Importance of Familiarity

Being knowledgeable about the assembly visualization fosters better maintenance practices. It allows operators to identify wear and tear or malfunctions early, leading to timely interventions. Moreover, this understanding empowers users to communicate effectively with service technicians, ensuring that repairs are conducted smoothly and efficiently.

Key Components of the Z540M

The essential elements of this lawn care machine play a vital role in its overall performance and efficiency. Understanding these components helps users maintain and operate the equipment effectively, ensuring longevity and optimal functionality.

Engine and Transmission

The power unit is crucial for delivering the necessary force to cut through grass effortlessly. Coupled with a robust transmission system, it enables smooth operation and maneuverability across various terrains.

Cutting Deck and Blades

The cutting mechanism, featuring sharp blades, is designed to provide a clean and precise cut. The deck’s design allows for effective grass handling, contributing to a well-manicured lawn.

Common Replacement Parts Explained

When maintaining and repairing outdoor equipment, understanding the various components that may require replacement is crucial. This section provides insights into some frequently needed elements that ensure your machinery operates efficiently.

Key Components to Consider

Several vital components are often subject to wear and tear. Below is a list of these critical elements:

- Blades: Essential for achieving a clean cut, blades need regular sharpening or replacement to maintain performance.

- Batteries: Powering electric systems, batteries should be checked for longevity and replaced when they no longer hold a charge.

- Belts: These components connect various mechanical parts and can wear out over time, affecting functionality.

- Filters: Air and oil filters help keep the engine clean and should be replaced periodically to ensure proper operation.

Choosing the Right Replacements

Selecting appropriate replacements is vital for optimal performance. Here are some tips:

- Consult the user manual for specific recommendations on suitable replacements.

- Opt for high-quality parts to ensure durability and efficiency.

- Consider purchasing components from authorized dealers to guarantee compatibility.

Maintenance Tips for Z540M Parts

Regular upkeep is essential for ensuring the longevity and efficiency of your machinery. By following a few key practices, you can enhance performance and minimize wear and tear on components. Implementing these strategies will help maintain the overall functionality of your equipment.

Regular Inspections

Conduct frequent examinations to identify any signs of wear or damage. Look for loose connections, frayed cables, or any irregularities that could hinder operation. Timely detection allows for prompt repairs, preventing minor issues from escalating into major problems.

Proper Lubrication

Maintaining adequate lubrication is crucial for reducing friction and preventing overheating. Ensure that all moving elements are properly greased according to the manufacturer’s recommendations. Regularly check oil levels and replace fluids as necessary to keep components running smoothly.

Identifying Part Numbers Accurately

Accurate identification of component numbers is essential for ensuring that replacements fit and function as intended. This process helps in maintaining equipment efficiency and prolonging its lifespan. A systematic approach can significantly ease the task of finding the right identifiers.

Firstly, consult the official manual or online resources provided by the manufacturer. These documents typically contain comprehensive listings of components, including their unique identifiers. Secondly, utilize reliable online databases or tools that specialize in cataloging these identifiers. Many platforms offer search functionalities that can help pinpoint specific items based on descriptions or categories.

Moreover, engaging with community forums or user groups can provide valuable insights. Experienced users often share tips and can clarify any uncertainties regarding specific identifiers. Lastly, maintaining a personal inventory of previous orders can serve as a handy reference for future needs.

How to Access the Parts Diagram

Finding the appropriate visual representation of components for your equipment is essential for efficient maintenance and repair. This guide will assist you in navigating the resources available to obtain the necessary illustrations for your specific model.

First, ensure you visit the manufacturer’s official website or authorized service centers. These platforms often host a wealth of information, including downloadable resources and interactive tools that provide detailed views of various assemblies. You may also consider utilizing online forums or user communities where experienced individuals share valuable insights and links to reliable resources.

Additionally, consult the user manual that came with your machinery. Many manuals include references or QR codes that link to digital versions of component illustrations. If you prefer printed materials, consider reaching out to local dealers who can provide catalogs or hard copies.

By following these steps, you can easily locate the visual references needed to assist with your maintenance tasks effectively.

Finding OEM vs. Aftermarket Parts

When it comes to sourcing components for your machinery, understanding the difference between original equipment manufacturer (OEM) and aftermarket options is crucial. Each type offers distinct advantages and disadvantages that can significantly impact performance, longevity, and cost.

OEM components are manufactured by the original creator of the equipment, ensuring a perfect fit and adherence to factory specifications. These parts are often viewed as reliable and are recommended for maintaining warranty coverage. However, they tend to come with a higher price tag.

On the other hand, aftermarket alternatives are produced by third-party companies and can provide a more economical solution. While these parts may vary in quality, many reputable manufacturers offer products that match or exceed OEM standards. It’s essential to evaluate the specific needs of your equipment and consider the potential trade-offs when choosing between these options.

Assembly Instructions for Key Parts

Proper assembly of essential components is crucial for optimal performance and longevity of your equipment. Following these guidelines will help ensure that all elements are correctly installed and function effectively.

Before beginning the assembly process, gather all necessary tools and components. Make sure you have a clean workspace to avoid losing any small parts.

- Step 1: Start by placing the main frame on a flat surface. Ensure that all mounting points are accessible.

- Step 2: Align the primary components, such as the engine and transmission, with the designated slots on the frame.

- Step 3: Secure the engine using the provided fasteners. Make sure each bolt is tightened according to the manufacturer’s specifications.

- Step 4: Connect any necessary cables and hoses, ensuring there are no kinks or bends that could cause issues later.

- Step 5: Install the wheels and tires, making sure to balance them properly for smooth operation.

- Step 6: Finally, conduct a thorough inspection of all connections and fasteners before powering on the equipment.

By adhering to these instructions, you can ensure that the assembly process is efficient and successful, resulting in reliable operation of your machine.

Troubleshooting Common Issues

When operating a lawn maintenance machine, encountering certain challenges is not uncommon. Identifying and resolving these issues promptly can ensure the longevity and efficiency of the equipment. This section will outline typical problems and their potential solutions to maintain optimal performance.

Engine Won’t Start: One frequent issue users face is the inability to start the engine. This could result from a drained battery, faulty ignition switch, or issues with the fuel supply. Check the battery connections and ensure the fuel tank is filled with the appropriate gasoline grade.

Uneven Cutting: Another common concern is uneven cutting. This can occur due to dull blades, incorrect cutting height, or unlevel mower deck. Regularly inspect and sharpen the blades, and adjust the cutting height as needed to achieve an even lawn appearance.

Overheating: Machines can overheat during operation, leading to performance issues. This may be caused by a dirty air filter, blocked cooling fins, or low oil levels. Cleaning the air filter and ensuring the cooling system is unobstructed can help mitigate overheating.

Unresponsive Controls: If the controls become unresponsive, it could indicate a malfunction in the control system or hydraulic components. Inspect the wiring and hydraulic fluid levels to ensure everything is functioning correctly. If problems persist, consulting a professional may be necessary.

By addressing these common issues effectively, users can enjoy a seamless experience while maintaining their outdoor spaces.

Safety Precautions for Parts Replacement

When undertaking the task of substituting components in machinery, it is crucial to prioritize safety. Proper precautions can prevent accidents and ensure efficient operation. Always familiarize yourself with the equipment and its specific requirements before proceeding with any replacements.

Preparation Steps

Before beginning the replacement process, consider the following preparatory measures:

- Ensure the machinery is turned off and disconnected from any power source.

- Gather the necessary tools and components needed for the replacement.

- Read the manufacturer’s instructions for guidelines on safe practices.

Personal Protective Equipment

Wearing appropriate protective gear is essential when working with machinery. The following items are recommended:

| Equipment | Purpose |

|---|---|

| Safety glasses | To protect eyes from debris and harmful substances. |

| Gloves | To prevent injuries from sharp edges and chemical exposure. |

| Steel-toed boots | To shield feet from heavy objects and provide grip. |

| Hearing protection | To minimize noise exposure during operation. |

By adhering to these safety measures, individuals can help ensure a safer working environment while effectively managing component replacement.

Where to Purchase Replacement Parts

Finding reliable sources for acquiring new components can greatly enhance the performance and longevity of your equipment. Whether you are looking for original or aftermarket options, knowing where to shop is essential for maintaining operational efficiency.

Authorized Dealers

Authorized distributors often provide genuine components that guarantee compatibility and quality. These locations typically offer:

- Expert advice from knowledgeable staff

- Access to the latest inventory

- Warranty and return policies for peace of mind

Online Retailers

Online platforms are increasingly popular for purchasing components. These websites can provide:

- A wide selection of both original and aftermarket options

- Competitive pricing and frequent discounts

- User reviews and ratings to guide your choices