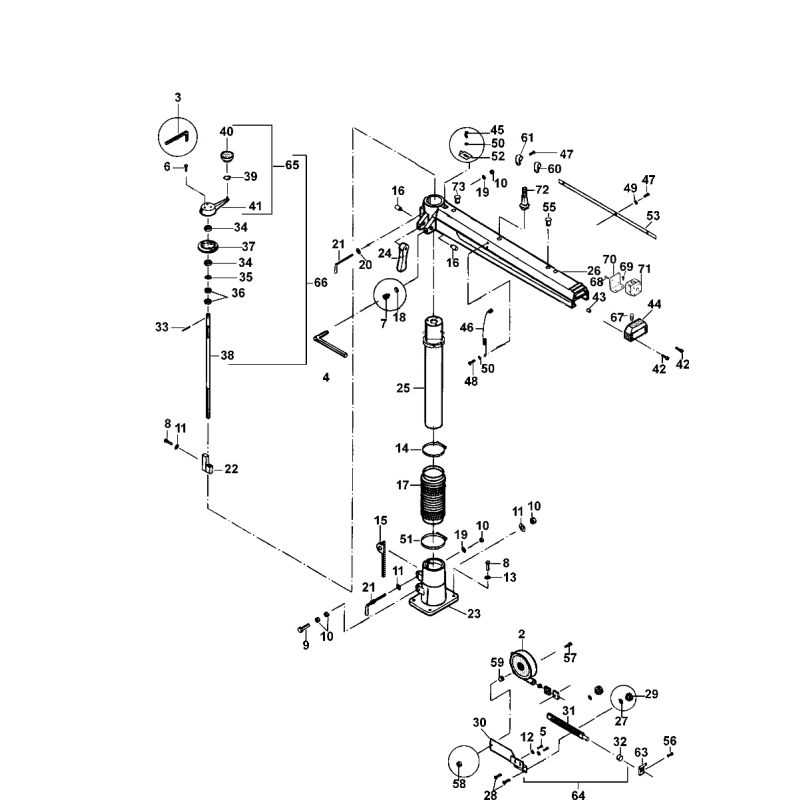

Dewalt DW734 Planer Parts Diagram Explained

When delving into the mechanics of a particular woodworking instrument, it is essential to grasp the intricate details of its construction. A comprehensive overview of the individual elements not only enhances the user experience but also facilitates maintenance and troubleshooting. By familiarizing oneself with the various components, one can ensure optimal performance and longevity of the equipment.

In the realm of woodworking, the assembly of each unit plays a pivotal role in achieving precision and efficiency. Recognizing how these parts interact with one another allows for a deeper appreciation of the craftsmanship involved. From the motor to the feed rollers, each segment contributes to the tool’s overall functionality, making it imperative for users to understand their significance.

This guide aims to provide an insightful exploration into the specific elements of a renowned woodworking device, breaking down its structure for better understanding. Through detailed visual representations and explanations, users will gain the knowledge needed to navigate their tool effectively, ensuring that every project is completed with skill and confidence.

Dewalt Planer DW734 Overview

This section provides a comprehensive look at a popular woodworking tool designed for precision and efficiency. Renowned for its robust construction and user-friendly features, this machine is an essential addition to any craftsman’s workshop. Its ability to deliver smooth, even surfaces makes it a favorite among both professionals and hobbyists.

Key specifications highlight the tool’s capabilities, offering insights into its performance and usability. Below is a summary of its main features and technical details:

| Feature | Description |

|---|---|

| Motor Power | Powerful motor for efficient material removal |

| Cutting Width | Standard width suitable for various projects |

| Depth Adjustment | Easy depth adjustment for customized finishes |

| Dust Port | Integrated dust port for cleaner workspaces |

| Weight | Lightweight design for easy mobility |

This overview emphasizes the tool’s practicality and efficiency, making it an ideal choice for those seeking quality results in their woodworking endeavors.

Key Features of the DW734

This tool stands out in its category due to a combination of innovative design and functionality. Users benefit from its user-friendly features that enhance efficiency and precision, making it an essential addition to any workshop.

Powerful Performance

- High motor capacity ensures consistent cutting power.

- Ability to handle a variety of materials, from softwoods to hardwoods.

- Robust build allows for smooth operation even under heavy loads.

User-Friendly Design

- Easy-to-read depth adjustment scale for quick settings.

- Compact size facilitates portability and storage.

- Integrated dust port helps maintain a clean workspace.

Understanding Parts Functionality

Grasping the functionality of individual components is essential for effective maintenance and optimal performance of any machinery. Each element plays a specific role, contributing to the overall operation and efficiency. By familiarizing oneself with how these parts interact, users can troubleshoot issues more effectively and ensure longevity in performance.

Core components typically include mechanisms that facilitate the feeding of material, the cutting apparatus, and safety features that protect the user during operation. Understanding how these pieces work together allows for better preparation and handling of various tasks, ensuring that each operation runs smoothly and safely.

Additionally, recognizing the signs of wear or malfunction in specific components can aid in timely interventions, preventing further damage and maintaining productivity. Knowledge of the system’s structure not only enhances user confidence but also promotes a proactive approach to equipment care and efficiency.

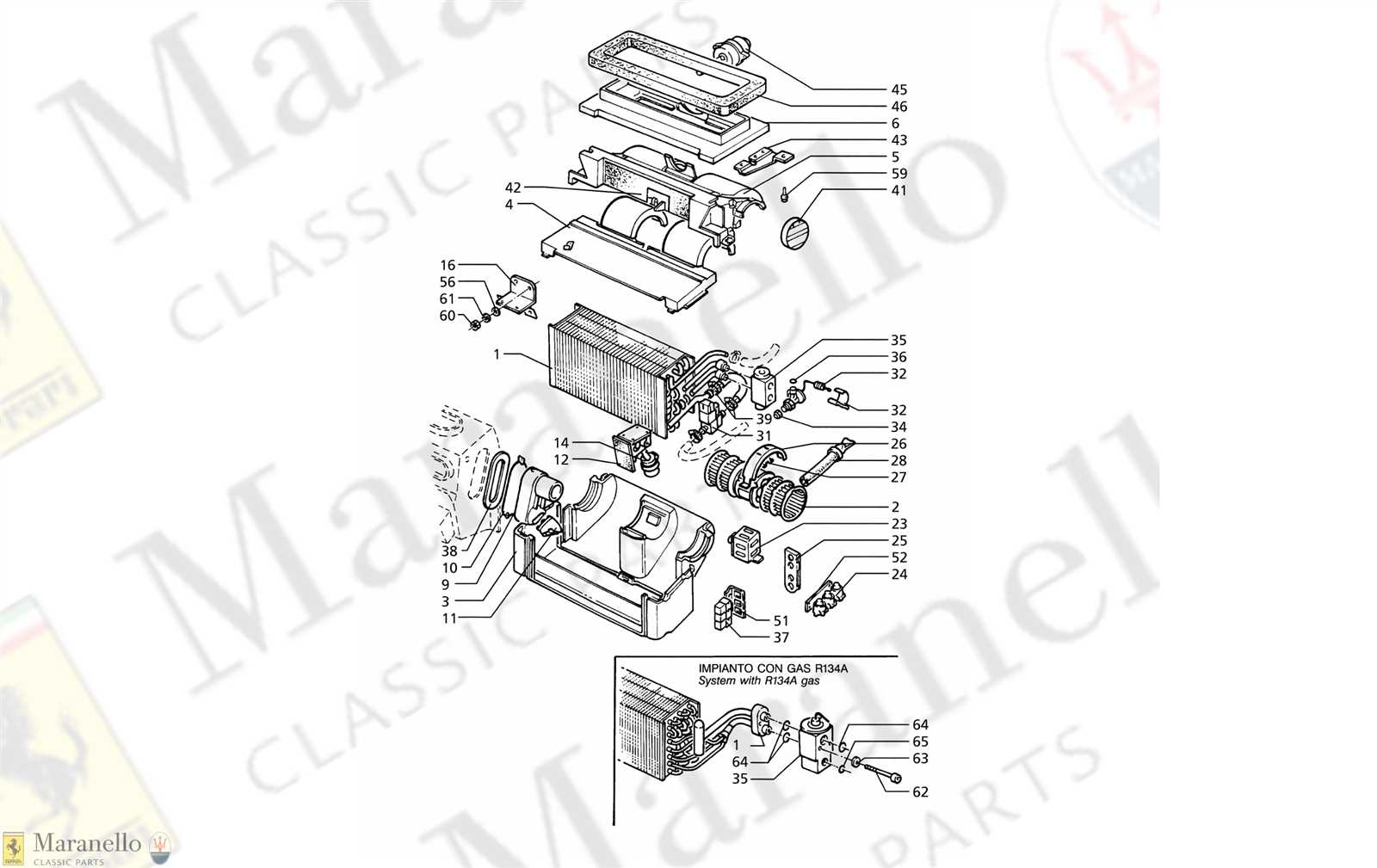

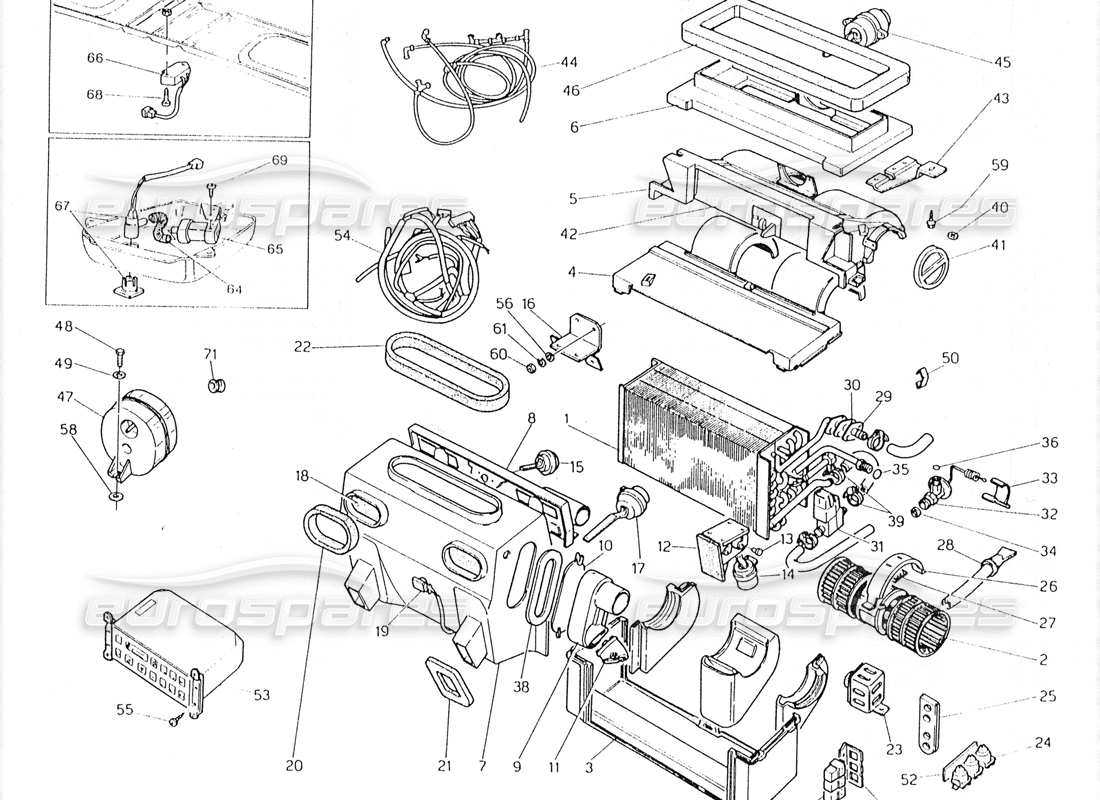

Importance of a Parts Diagram

A schematic representation of components is essential for anyone working with machinery or tools. It provides a clear visual guide that enhances understanding and facilitates maintenance or repairs. By illustrating each element and its connections, such a representation becomes a vital resource for both novice and experienced users alike.

Enhanced Understanding

Having a visual reference helps users quickly identify and comprehend the function of various components. This clarity can significantly reduce the time spent troubleshooting issues, as one can easily locate the necessary parts and understand their roles within the system.

Efficient Repairs and Maintenance

When it comes to servicing equipment, a visual reference streamlines the process. Technicians can efficiently determine what needs to be replaced or repaired, ensuring that tasks are completed swiftly and accurately. This not only saves time but also minimizes the risk of errors, leading to more effective upkeep of the machinery.

In summary, a well-structured visual representation of components serves as an indispensable tool that enhances comprehension and facilitates efficient repair and maintenance, ultimately contributing to the longevity and performance of equipment.

Common Issues with the DW734

Many users encounter specific challenges when using this popular woodworking tool. Understanding these common problems can help in maintaining optimal performance and prolonging its lifespan.

- Uneven Cutting: One frequent complaint is the inconsistency in the thickness of the material being processed. This can be caused by dull blades or improper feed rates.

- Excessive Noise: Unusual sounds during operation may indicate loose components or worn-out parts, necessitating a thorough inspection.

- Material Snagging: Users may notice that boards occasionally get caught, which can lead to snipe or tearing. This often results from misalignment or feeding issues.

- Power Issues: Intermittent power loss can disrupt workflow. This could stem from electrical connections or motor problems.

- Dust Collection Failures: Inefficient dust management can hinder visibility and affect the quality of the workspace. Clogged hoses or improper connections are common culprits.

Addressing these issues promptly can enhance performance and improve the overall user experience with the machine.

How to Identify Replacement Parts

When it comes to maintaining your equipment, knowing how to accurately identify components that need to be replaced is essential. This process ensures that your tool functions optimally and extends its lifespan. Understanding the specific elements required can save time and money while enhancing performance.

To effectively determine the necessary components, consider the following steps:

| Step | Description |

|---|---|

| 1 | Consult the user manual for your device, which often includes a list of components and their specifications. |

| 2 | Examine the equipment for any visible identifiers, such as model numbers or serial numbers, that can assist in locating the correct pieces. |

| 3 | Utilize online resources or manufacturer websites to find diagrams and lists of components that correspond to your model. |

| 4 | Contact customer support or forums dedicated to your equipment for expert advice and recommendations on replacements. |

By following these guidelines, you can ensure that you obtain the right components for effective repairs and maintenance.

Where to Find Parts Diagrams

Locating detailed illustrations of component layouts can greatly aid in repairs and maintenance. These resources provide a visual reference that simplifies the identification and ordering of necessary items for various tools. Whether you’re a seasoned professional or a DIY enthusiast, having access to these schematics is essential for efficient troubleshooting and restoration.

Manufacturer Websites

The official websites of tool manufacturers often host a wealth of information, including exploded views and detailed listings of individual components. By navigating to the support or resources section, users can typically find downloadable files or interactive tools to assist in identifying specific pieces related to their equipment.

Online Retailers and Forums

Many online retailers provide comprehensive parts lists alongside product descriptions. Additionally, community forums can be invaluable, as users frequently share links to diagrams and personal experiences regarding repairs. Engaging with these platforms can enhance your understanding and provide alternative solutions to common issues.

Tips for Maintaining Your Planer

Regular upkeep is essential for ensuring the longevity and performance of your woodworking tool. By following a few straightforward practices, you can enhance its efficiency and reduce the likelihood of malfunctions. Here are some practical suggestions to keep your equipment in top condition.

1. Keep It Clean: After each use, make sure to remove any wood shavings or dust from the surfaces. A clean workspace not only promotes safety but also prevents buildup that can affect performance.

2. Check the Blades: Dull blades can lead to poor results and increased strain on the motor. Inspect the cutting edges regularly and sharpen or replace them as needed to maintain optimal cutting efficiency.

3. Lubricate Moving Parts: Apply appropriate lubricants to all moving components to reduce friction and wear. This will help maintain smooth operation and extend the lifespan of the machinery.

4. Monitor Alignment: Ensure that all parts are properly aligned to avoid unnecessary stress and uneven cuts. Regularly check for misalignments and make adjustments when necessary.

5. Store Properly: When not in use, store your equipment in a dry and safe place. Protect it from moisture and extreme temperatures to prevent rust and degradation.

6. Follow the Manual: Always refer to the user manual for specific maintenance guidelines. Adhering to the manufacturer’s recommendations can help you avoid common pitfalls and ensure reliable performance.

By incorporating these maintenance tips into your routine, you can enjoy consistent results and prolong the life of your woodworking tool.

Tools Needed for Repairs

When it comes to maintaining and fixing equipment, having the right tools on hand is essential. Proper tools not only streamline the repair process but also ensure that the job is done efficiently and safely. This section outlines the necessary implements that can aid in the disassembly, troubleshooting, and reassembly of machinery.

Essential Hand Tools

Basic hand tools such as screwdrivers, wrenches, and pliers are fundamental for any repair task. A good set of screwdrivers, including both flathead and Phillips, will allow you to tackle various screws with ease. Wrenches, both adjustable and fixed, are crucial for loosening and tightening nuts and bolts, while pliers can assist in gripping and pulling components apart.

Power Tools and Accessories

In addition to hand tools, power tools can greatly enhance your efficiency. A reliable drill can help in quickly removing screws and making precise holes, while a sander may be necessary for smoothing surfaces after repairs. Always ensure that you have the appropriate bits and accessories that match the specifications of your equipment to achieve optimal results.

Safety Precautions When Repairing

When engaging in maintenance or repair work on machinery, prioritizing safety is essential to prevent accidents and ensure a smooth process. Proper precautions not only protect the individual performing the tasks but also safeguard the equipment itself. Understanding the necessary safety measures can significantly reduce the risk of injury and enhance the overall repair experience.

Essential Safety Guidelines

Before starting any repair work, it is crucial to follow specific guidelines to ensure a safe environment. Here are some fundamental practices to consider:

| Safety Measure | Description |

|---|---|

| Wear Protective Gear | Always use safety glasses, gloves, and ear protection to shield yourself from debris and noise. |

| Disconnect Power Supply | Ensure that the equipment is unplugged or disconnected from any power source before starting repairs. |

| Work in a Well-Lit Area | A well-illuminated workspace helps in spotting potential hazards and makes the repair process easier. |

| Keep the Area Clean | Maintain a tidy work environment to avoid tripping hazards and ensure easy access to tools. |

Handling Tools Safely

The tools used during repairs are vital to the task, but they can also pose risks if not handled properly. Follow these tips for safe tool usage:

| Tool Safety Tip | Explanation |

|---|---|

| Inspect Tools Regularly | Check tools for wear and tear to prevent malfunctions during use. |

| Use the Right Tool for the Job | Using appropriate tools reduces the likelihood of accidents and improves efficiency. |

| Store Tools Properly | Keep tools organized and in designated areas to prevent accidents and loss. |