Complete Guide to Echo HC 150 Parts Diagram

In the realm of outdoor machinery, familiarity with the individual elements that comprise your device is essential for optimal performance and maintenance. Each component plays a critical role, contributing to the overall efficiency and longevity of the equipment. A comprehensive understanding of these parts not only facilitates effective troubleshooting but also empowers users to make informed decisions regarding repairs and upgrades.

For enthusiasts and professionals alike, exploring the intricate layout of various mechanisms can reveal valuable insights into functionality and design. By examining how each element interacts within the system, users can enhance their operational skills and extend the lifespan of their tools. Whether for personal use or professional purposes, knowledge of the underlying structure proves invaluable.

This guide aims to provide a clear visual representation of the various components, allowing readers to easily navigate the complexities of their machinery. By breaking down the anatomy of the device, users can better understand their equipment, ensuring they are well-prepared for any challenges that may arise during operation.

Understanding Echo HC 150 Parts Diagram

When it comes to comprehending the components of a specific tool, having a visual representation can be invaluable. Such illustrations not only enhance the understanding of individual elements but also demonstrate how they interact within the overall mechanism. This knowledge is crucial for effective maintenance and troubleshooting.

Each component plays a vital role, and recognizing their functions allows users to perform repairs efficiently. By analyzing the layout, one can identify potential issues or wear, ultimately leading to better performance and longevity of the device.

Diving deeper into the intricacies of the assembly provides insight into its operation. Familiarity with each section empowers users to tackle challenges with confidence, ensuring optimal functionality and minimizing downtime.

Overview of Echo HC 150 Components

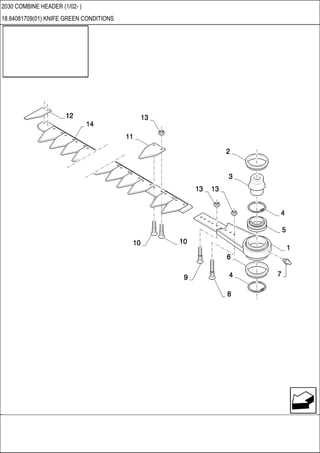

This section provides an insightful look into the various elements that make up a specific cutting tool model designed for efficient garden maintenance. Understanding these components is crucial for users who wish to maximize performance and longevity while ensuring effective operation.

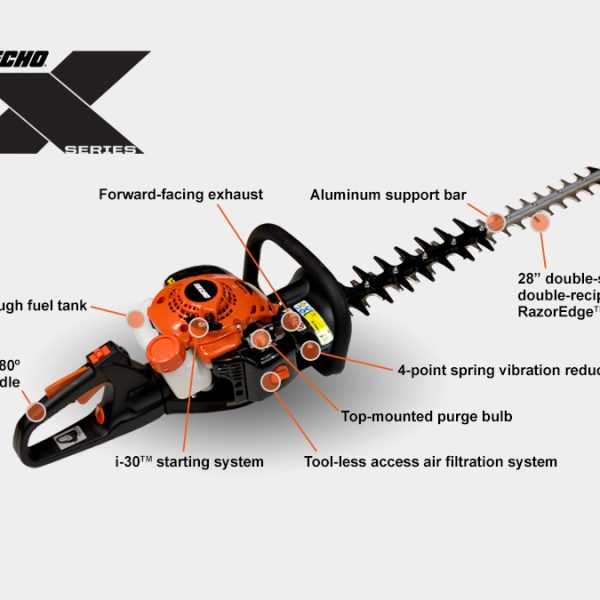

At the core of this tool is a robust engine, which serves as the powerhouse, delivering the necessary energy to facilitate cutting tasks. Blades, specifically designed for optimal precision, are integral for achieving clean and accurate trims. The handle system offers ergonomic support, enhancing user comfort during prolonged use.

Additionally, the fuel tank is vital for maintaining operational readiness, while the starter mechanism ensures quick and efficient ignition. Each of these components works in harmony, contributing to the overall effectiveness and reliability of the device.

Benefits of Using Original Parts

Choosing genuine components for machinery and equipment provides numerous advantages that contribute to optimal performance and longevity. Authentic pieces are specifically designed to meet the exact specifications required, ensuring seamless integration and functionality. This choice enhances reliability and minimizes the risk of malfunctions, ultimately leading to a more efficient operation.

Quality Assurance

Original components undergo rigorous testing and quality control processes, which guarantees their durability and performance. When opting for these pieces, users can be confident in their ability to withstand wear and tear, thereby reducing the need for frequent replacements and repairs. This not only saves time but also enhances the overall user experience.

Compatibility and Performance

Utilizing authentic components ensures perfect compatibility with existing systems. This integration results in superior performance, allowing machines to operate at their best. Moreover, original parts often come with manufacturer warranties, providing additional peace of mind and support should any issues arise during usage. Ultimately, investing in genuine components translates to long-term benefits for both productivity and equipment maintenance.

Common Issues with Echo HC 150

When it comes to garden maintenance tools, certain problems frequently arise that can hinder performance and efficiency. Understanding these common challenges can help users address them swiftly and maintain optimal functionality.

- Fuel System Problems:

- Clogs in the fuel filter

- Old or contaminated fuel

- Starting Difficulties:

- Faulty spark plug

- Weak ignition coil

- Cutting Performance Issues:

- Dull blades

- Improper tension on cutting elements

- Vibration Problems:

- Loose components

- Worn-out mounts

Identifying these issues early can significantly enhance the longevity and effectiveness of your equipment.

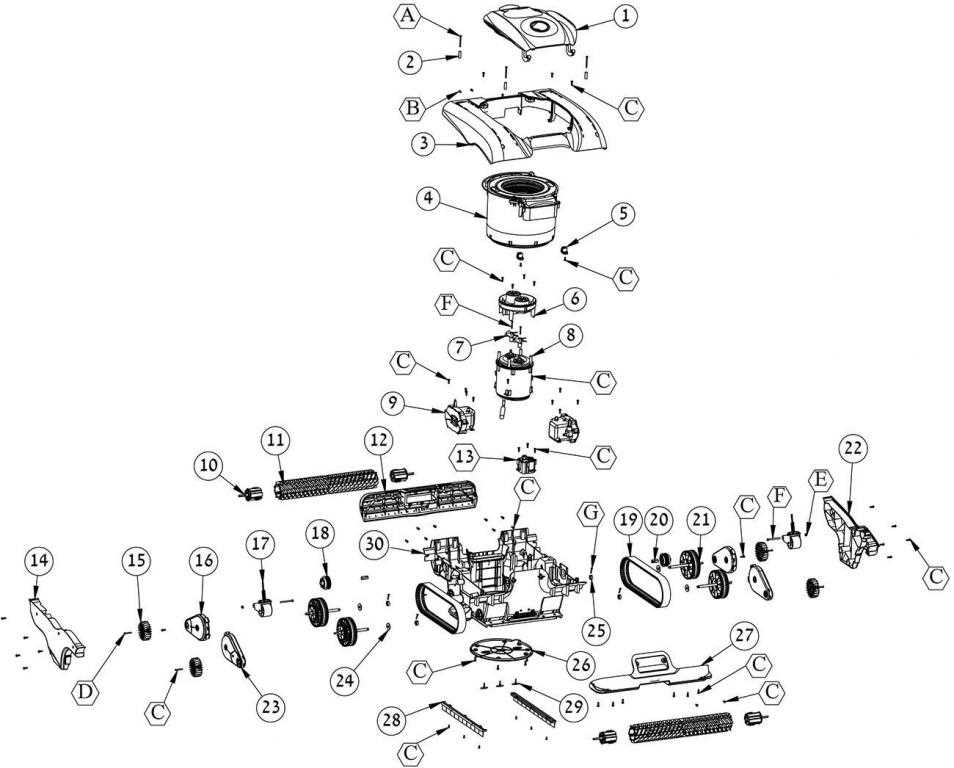

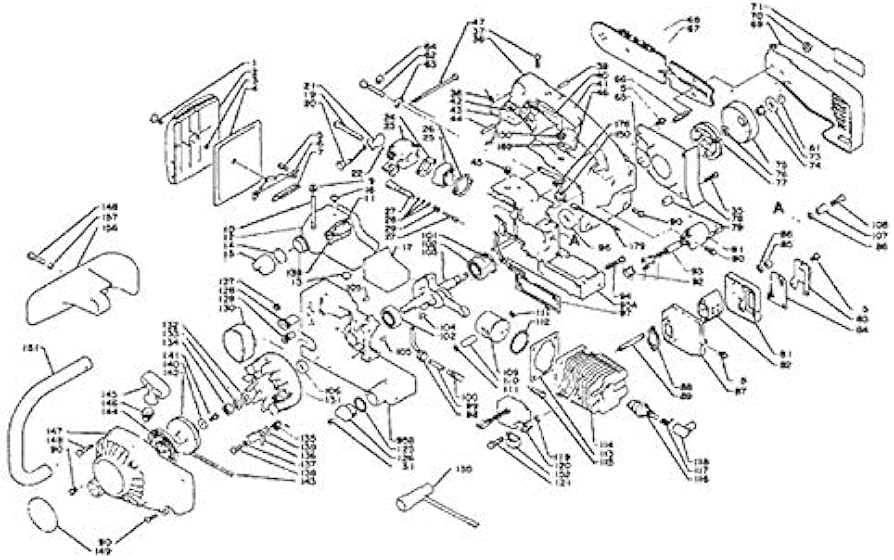

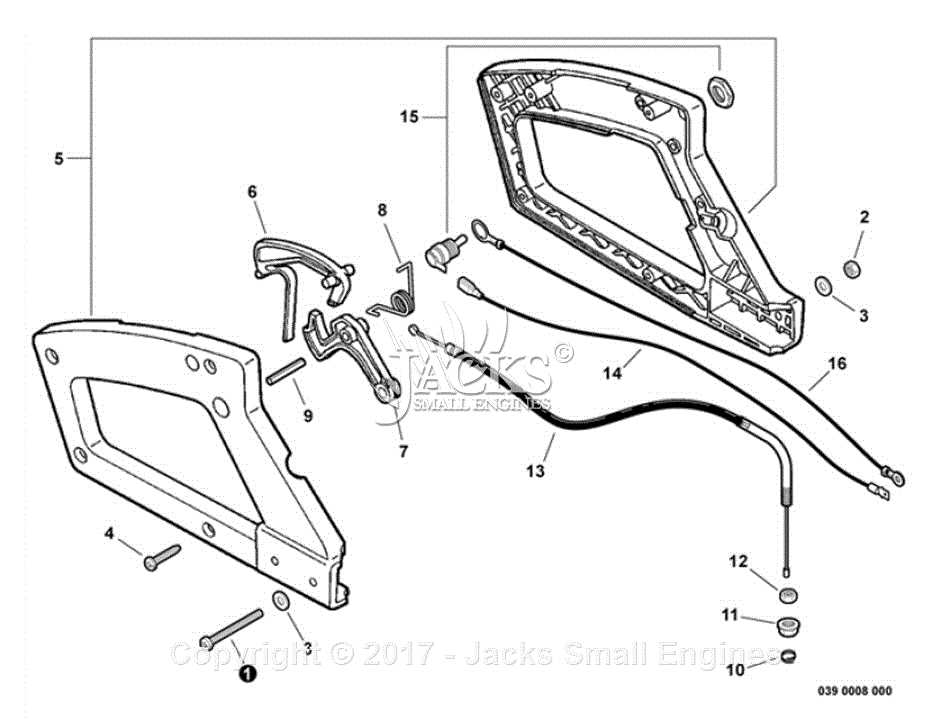

How to Interpret the Diagram

Understanding the visual representation of components is essential for effective maintenance and repair tasks. This illustration provides a detailed overview of the various elements and their interconnections, allowing users to quickly identify and locate specific sections of the equipment. By familiarizing oneself with this visual guide, one can streamline the troubleshooting process and enhance overall operational efficiency.

Begin by observing the layout, noting the arrangement of parts and how they relate to one another. Each section is typically labeled to indicate its function, which aids in quickly pinpointing areas of interest. Pay attention to any symbols or color codes that may indicate different functionalities or types of components. This will help in comprehending the relationships between the various elements and their roles within the entire system.

As you analyze the illustration, take time to correlate the labels with the actual components on the equipment. This hands-on approach will solidify your understanding and enable you to identify parts more confidently in future maintenance tasks. Additionally, consider using a highlighter or note-taking method to emphasize critical areas that require particular attention during your inspections.

Finally, practice makes perfect. Regularly referring to the visual guide while working on the equipment will enhance your ability to interpret it effectively. Over time, you will develop a familiarity with the layout and functions, which will ultimately lead to more efficient repairs and an extended lifespan for the equipment.

Key Replacement Parts for Maintenance

Proper upkeep of equipment relies heavily on the timely replacement of essential components. Regularly assessing and addressing worn or damaged elements ensures optimal functionality and longevity. This practice not only enhances performance but also minimizes unexpected breakdowns.

Filters play a crucial role in maintaining efficiency by preventing contaminants from affecting the internal systems. Ensuring they are replaced periodically can drastically improve the overall performance.

Belts are another vital component that require attention. Over time, these can wear down, leading to decreased power transmission and efficiency. Regular inspections and timely replacements are key to sustaining operational standards.

Blades must also be monitored closely. Dull or damaged cutting edges can compromise the effectiveness of the equipment. Sharp blades not only perform better but also enhance safety during operation.

By focusing on these essential elements, users can ensure their machinery remains in peak condition, ultimately leading to better performance and reliability over time.

Tools Needed for Repairs

When undertaking maintenance or fixing equipment, having the right instruments is essential for achieving optimal results. Proper tools not only simplify the repair process but also ensure safety and efficiency. Whether you are a seasoned technician or a DIY enthusiast, being equipped with the necessary gear can make a significant difference in your repair experience.

Essential Hand Tools

Basic hand tools are the backbone of any repair kit. Items such as screwdrivers, wrenches, and pliers are indispensable for handling various tasks. Additionally, having a reliable set of socket wrenches can greatly facilitate access to hard-to-reach bolts and screws. Don’t forget to include measuring tools to ensure precise adjustments and alignments.

Power Tools and Accessories

In more complex situations, power tools can greatly enhance your efficiency. Drills, saws, and impact wrenches are valuable assets that can save time and effort. Ensure you have the appropriate bits and attachments for each power tool, as they are crucial for tackling specific types of repairs. Always prioritize safety gear, such as goggles and gloves, when using these tools to protect yourself during the process.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your equipment efficiently. By following a structured method, you can address common issues and ensure optimal performance.

- Identify the Problem:

Begin by diagnosing the specific issue. Listen for unusual sounds or observe any irregular behavior.

- Gather Tools and Materials:

Collect the necessary tools such as wrenches, screwdrivers, and replacement components.

- Disassemble the Unit:

Carefully take apart the machine, keeping track of all screws and parts. Organize them to simplify reassembly.

- Inspect Components:

Examine each part for wear, damage, or blockages. Note any components that need replacing.

- Replace Damaged Parts:

Install new components as necessary. Ensure they fit securely and are compatible with your model.

- Reassemble the Equipment:

Put the unit back together carefully, following the order in which you disassembled it.

- Test the Functionality:

Once reassembled, test the equipment to ensure it operates smoothly and effectively.

- Maintain Regularly:

Establish a maintenance routine to prevent future issues and prolong the life of your device.

Where to Purchase Replacement Parts

Finding the right components for your equipment can significantly enhance its performance and longevity. Understanding the best sources for these items ensures that you maintain efficiency without compromising quality.

Online Retailers

- Specialized e-commerce platforms offer a wide range of options.

- Manufacturer websites often have direct sales or links to authorized sellers.

- Marketplaces can provide both new and used items at various price points.

Local Stores

- Visit hardware shops for immediate availability and personalized assistance.

- Check with local repair centers for recommendations on quality suppliers.

- Garden centers may carry specific equipment essentials for outdoor tools.

Comparing Echo HC 150 with Similar Models

This section delves into a comparative analysis of a specific trimmer and its counterparts within the same category. By examining various features, performance metrics, and user experiences, we can gain insights into how well this model stands against its peers in the market.

Performance and Efficiency

When evaluating these machines, one of the key aspects is their cutting efficiency. The model in question is designed to provide a powerful performance, making it ideal for tackling dense foliage. In contrast, some competitors may offer lower power outputs, affecting their overall efficiency in challenging conditions. Users often highlight the swift operation of this particular model, especially when faced with extensive yard work.

Design and Usability

Another crucial factor is the ergonomic design that contributes to user comfort during prolonged use. This model features a balanced weight distribution and intuitive controls, making it accessible for both novices and seasoned landscapers. Conversely, some alternatives might lack these thoughtful design elements, leading to fatigue or difficulties in handling. The focus on user experience has made this model a preferred choice among many landscaping enthusiasts.

Tips for Prolonging Equipment Lifespan

Maintaining the longevity of your machinery requires consistent care and attention. By following a few essential practices, you can ensure that your equipment operates efficiently and remains reliable for years to come.

Regular Maintenance

Routine checks are vital. Schedule periodic inspections to identify potential issues before they escalate. Keeping components clean and lubricated minimizes wear and tear, enhancing overall performance.

Proper Usage

Using equipment as intended is crucial. Avoid overloading or operating beyond recommended limits, as this can lead to premature damage. Educating users about correct handling techniques fosters a culture of care that ultimately benefits the machinery.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components, their functions, and the maintenance involved. Understanding these elements can enhance the efficiency and longevity of your equipment.

What should I consider when selecting components?

When choosing components, it’s important to evaluate compatibility with your machine, quality standards, and the manufacturer’s recommendations. Additionally, consider factors such as durability, warranty, and customer reviews to ensure reliable performance.

How can I ensure proper maintenance of my equipment?

Regular inspections and cleaning are vital for maintaining optimal performance. Follow the manufacturer’s guidelines for servicing and replacing worn or damaged items. Keeping a maintenance log can also help track when components need attention, preventing unexpected failures.