Understanding the Clarke Super 7R Edger Parts Diagram

In the realm of landscaping and gardening, the efficiency and effectiveness of a precision cutting device are paramount. Such tools are designed to achieve meticulous finishes along edges, ensuring that lawns and gardens maintain their aesthetic appeal. To fully grasp the functionality of these machines, it is essential to delve into their intricate structures and the roles each element plays in overall performance.

Every component, from the cutting mechanism to the power source, contributes to the seamless operation of the equipment. By familiarizing oneself with these individual sections, users can optimize maintenance routines and enhance longevity. Additionally, understanding how each part interacts with others provides insights into troubleshooting and potential upgrades.

This exploration serves not only to inform but also to empower users in their quest for precision in yard care. Armed with knowledge about the internal workings of these tools, operators can ensure their investments yield the best possible results for years to come.

Understanding Clarke Super 7R Edger

Exploring the intricacies of a versatile landscaping tool reveals its essential components and their functions. This machinery is designed for precision in creating clean lines and well-defined edges in outdoor spaces. Understanding how each element contributes to its overall efficiency can enhance both its use and maintenance.

| Component | Description |

|---|---|

| Motor | Powers the device, providing the necessary torque for cutting. |

| Blade | Critical for shaping edges, available in various sizes for different tasks. |

| Handle | Ensures user control and comfort during operation. |

| Wheel | Facilitates mobility and stability while in use. |

Overview of Edger Functionality

This section explores the essential functions of a landscaping tool designed to create clean, precise edges in outdoor spaces. These tools are integral for achieving well-defined borders between lawns and garden beds, enhancing both aesthetic appeal and functionality.

Key Functions

- Defines borders to improve visual appeal.

- Prevents grass and weeds from encroaching into garden areas.

- Facilitates maintenance of landscape by simplifying trimming tasks.

- Enhances the overall design of outdoor spaces.

Benefits of Using the Tool

- Promotes healthier plant growth by minimizing competition.

- Increases efficiency in yard maintenance routines.

- Offers versatility for various landscaping projects.

- Reduces the need for manual labor in edge creation.

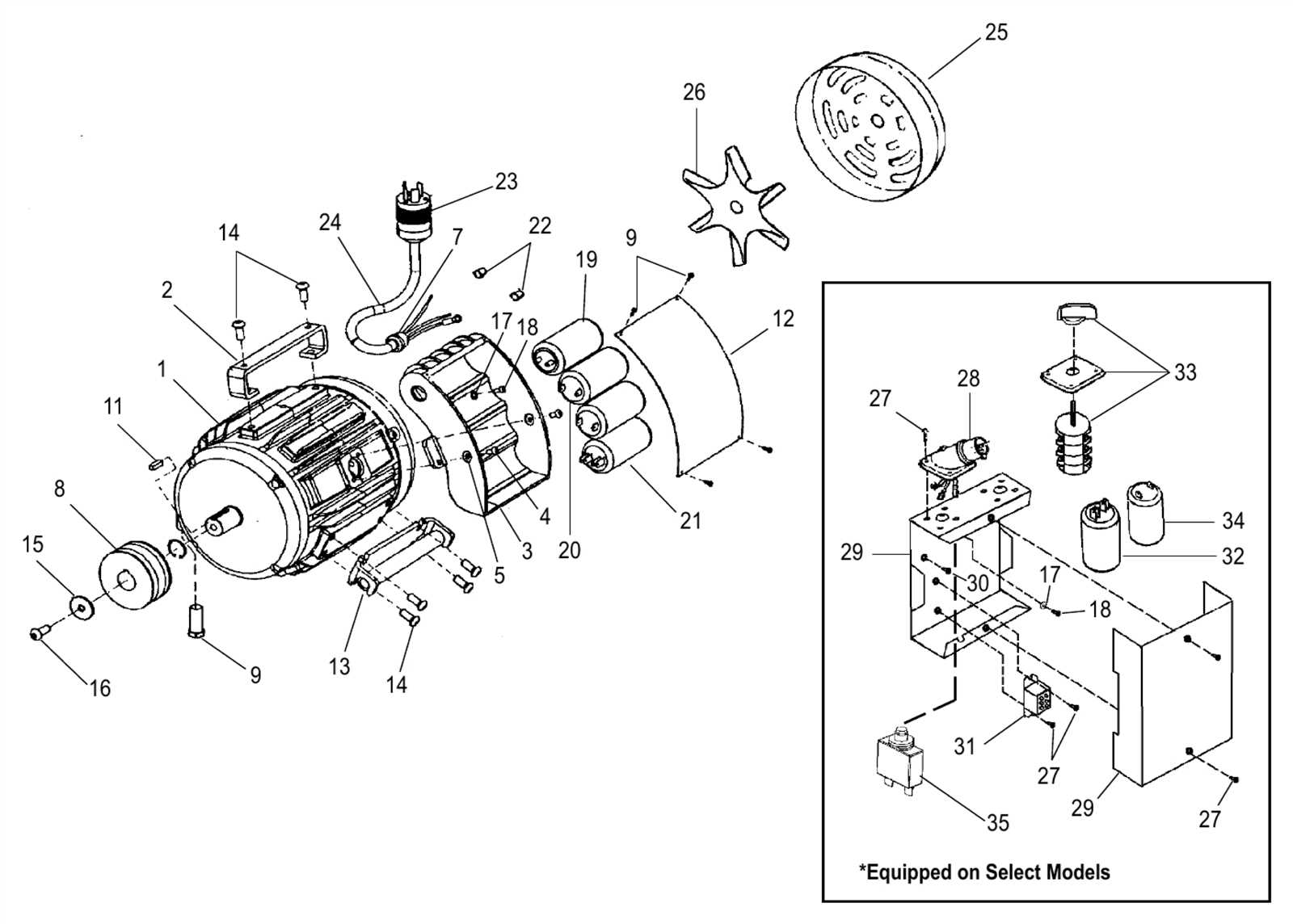

Key Components of Clarke Super 7R

Understanding the essential elements of this machine enhances its efficiency and maintenance. Each component plays a crucial role in its overall functionality, ensuring optimal performance during operations.

| Component | Description |

|---|---|

| Motor | Provides the necessary power for effective operation. |

| Blade Assembly | Ensures precise cutting and trimming capabilities. |

| Handle | Offers control and maneuverability during use. |

| Wheel System | Facilitates smooth movement across various surfaces. |

| Chassis | Provides structural support and stability to the unit. |

Importance of Parts Diagram

A comprehensive visual representation of a machine’s components is crucial for effective maintenance and repair. Such illustrations provide a clear understanding of how each element interacts within the system, aiding technicians and operators in identifying issues and executing necessary adjustments efficiently.

Benefits of Visual Representations

- Enhanced Clarity: Detailed visuals simplify complex assemblies, making it easier to comprehend individual parts.

- Efficient Troubleshooting: Quickly pinpointing problems becomes possible with an organized layout of components.

- Streamlined Repairs: Knowing the exact location and function of each piece expedites the repair process.

Key Considerations

- Accessibility: Ensure that these illustrations are readily available to all users, promoting a proactive approach to maintenance.

- Updates: Regularly revise visual aids to reflect any modifications or improvements in design.

- Training: Use these resources as educational tools for new operators and technicians, enhancing their familiarity with the equipment.

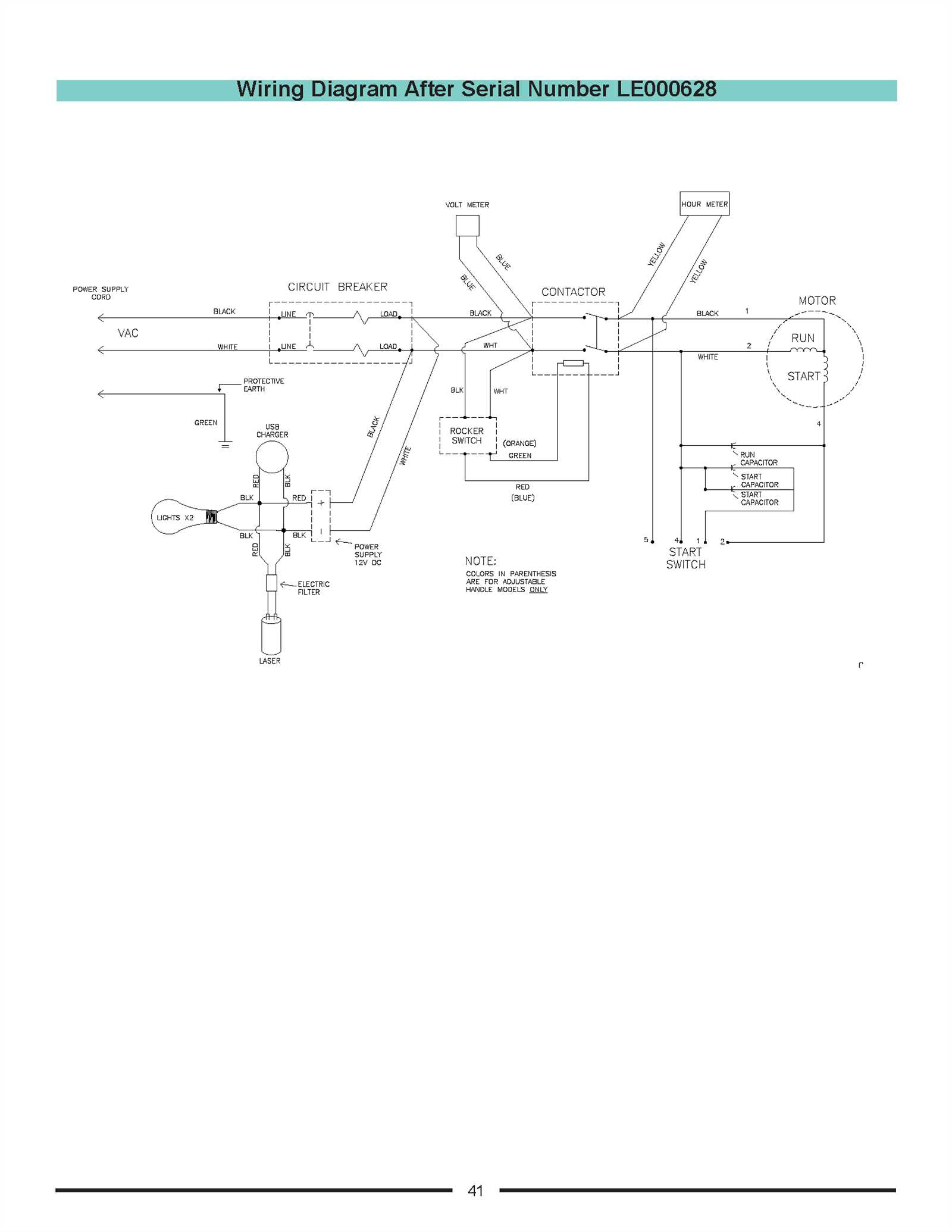

How to Interpret the Diagram

Understanding the visual representation of components is essential for effective maintenance and repairs. This guide will help you navigate the illustration to ensure proper handling of your equipment.

Follow these key steps to interpret the image:

- Familiarize Yourself: Start by getting to know the different symbols and lines used in the illustration.

- Identify Components: Look for labels that indicate each part’s name and function.

- Follow Connections: Trace the lines to see how each element interacts with others.

- Refer to the Legend: Utilize the accompanying legend for clarification on specific symbols.

By following these guidelines, you can confidently delve into your machinery and address any issues effectively.

Common Parts for Replacement

In the realm of outdoor maintenance equipment, certain components are frequently subjected to wear and tear. Understanding which elements are most often replaced can significantly enhance the longevity and performance of the machinery.

Essential Components

- Blades: Critical for achieving clean cuts, these often need sharpening or replacing.

- Belts: Vital for power transmission, they can fray or break over time.

- Filters: Essential for maintaining engine efficiency, they require regular replacement to ensure optimal function.

Maintenance Tips

- Regularly inspect components for signs of damage or wear.

- Keep a stock of common spares for quick replacements.

- Follow the manufacturer’s guidelines for installation and maintenance.

Identifying Worn Components

Recognizing signs of wear in machinery is crucial for maintaining optimal performance and extending equipment lifespan. Understanding which elements are prone to degradation allows for timely interventions and replacements, preventing potential failures during operation. Regular inspection and awareness of common wear indicators can significantly enhance efficiency and reliability.

Common symptoms of deterioration include unusual noises, vibrations, and reduced effectiveness in operation. For instance, if you notice a decrease in cutting precision or an increase in effort required to perform tasks, it may indicate that certain parts are no longer functioning at their best. Additionally, visible signs such as cracks, fraying, or discoloration can also be key indicators of wear.

Monitoring components closely and keeping an eye on their performance can lead to early detection of issues. Employing a routine maintenance schedule that includes checking for wear and tear ensures that machinery remains in top condition and minimizes the risk of unexpected breakdowns. By understanding the typical lifespan of various components, operators can plan for replacements before wear leads to more significant problems.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your equipment. By following a few key practices, you can enhance performance and extend the lifespan significantly.

Routine Cleaning

- Remove debris after each use to prevent buildup.

- Use a soft brush or cloth to clean surfaces and components.

- Check and clear any air vents to maintain airflow.

Periodic Inspections

- Examine all moving parts for wear and tear.

- Ensure all bolts and screws are tightened appropriately.

- Lubricate parts as recommended to reduce friction.

Tools Needed for Repairs

Having the right equipment is essential for effectively addressing maintenance tasks. This section outlines the necessary instruments that will facilitate the repair process, ensuring efficiency and accuracy.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws. |

| Wrench | To adjust nuts and bolts securely. |

| Pliers | For gripping and manipulating small components. |

| Replacement Blades | To ensure sharpness and precision in cuts. |

| Safety Gear | To protect yourself during repair tasks. |

Where to Purchase Replacement Parts

When it comes to maintaining your equipment, sourcing the right components is essential for optimal performance. Finding quality replacements can significantly enhance the lifespan and efficiency of your tools. Fortunately, there are several reliable avenues to explore when seeking these essential items.

Authorized Dealers

One of the best options for obtaining quality replacements is to visit authorized distributors. These retailers often carry a comprehensive range of components specifically designed for your equipment. Purchasing from these sources ensures that you receive genuine items, which can help avoid compatibility issues and ensure reliability.

Online Marketplaces

Another convenient option is to browse online platforms that specialize in hardware and machinery components. Many websites provide detailed catalogs and customer reviews, making it easier to compare prices and find exactly what you need. Always check the seller’s reputation and return policy to ensure a smooth transaction.

Benefits of Using Genuine Parts

When it comes to maintaining and repairing equipment, opting for authentic components offers significant advantages. These original elements are specifically designed to work seamlessly with the machinery, ensuring optimal performance and longevity.

Enhanced Performance

Using genuine components guarantees that each piece fits perfectly and functions as intended. This leads to improved efficiency and reliability, reducing the likelihood of unexpected breakdowns. Authentic parts are crafted to meet the exact specifications required for superior operation.

Long-term Savings

While it may be tempting to choose cheaper alternatives, the initial savings can be deceptive. Genuine components often lead to reduced maintenance costs and extend the lifespan of the equipment. Investing in original pieces ultimately translates to lower replacement frequencies and fewer repairs over time.

Comparing Aftermarket Options

When it comes to enhancing lawn maintenance tools, evaluating alternative components can significantly impact performance and longevity. Many users seek cost-effective solutions that provide similar or improved functionality compared to original items. This section delves into the advantages and potential drawbacks of various aftermarket choices.

Advantages of Aftermarket Components

Aftermarket alternatives often offer a broader range of options, allowing users to customize their equipment to better meet specific needs. Additionally, these items can frequently be found at lower prices, making them attractive for budget-conscious consumers.

Potential Drawbacks

While aftermarket parts may present appealing benefits, it’s essential to consider quality and compatibility. Some products may not meet the same standards as original items, potentially leading to performance issues or reduced durability.

| Factor | Aftermarket | Original |

|---|---|---|

| Cost | Generally lower | Higher price point |

| Variety | More options available | Limited selection |

| Quality | Variable quality | Consistent quality |

| Compatibility | May vary | Designed for perfect fit |

FAQs About Clarke Edger Parts

This section aims to address common inquiries regarding components of a particular flooring machine. Understanding these elements is crucial for maintenance and optimal performance.

What are the common issues with these components?

Frequent challenges include wear and tear, improper alignment, and lack of lubrication. Regular inspection can prevent major failures.

How can I identify the correct replacement items?

Refer to the manufacturer’s manual for specifications, and consult with a professional if uncertain. Accurate identification ensures compatibility and functionality.