Comprehensive Guide to 3208 Cat Engine Parts Diagram

In the world of heavy machinery, comprehending the intricate arrangement of various components is crucial for optimal performance and maintenance. Each element plays a vital role in ensuring that the entire system operates seamlessly. From the power unit to auxiliary features, a thorough understanding of these constituents can enhance efficiency and longevity.

When delving into the structure of these complex machines, it’s essential to visualize how each segment interacts with one another. The interplay between different sections can often determine the overall functionality. Grasping this interconnectivity not only aids in troubleshooting but also supports informed decisions regarding repairs and upgrades.

For enthusiasts and professionals alike, having access to a clear representation of these elements simplifies the process of learning and applying knowledge. Whether for educational purposes or practical applications, a comprehensive overview serves as a valuable resource for anyone looking to deepen their understanding of heavy machinery.

Understanding the 3208 Cat Engine

This section explores the fundamentals of a well-regarded power unit known for its reliability and efficiency. Its design and functionality make it a preferred choice in various heavy machinery applications, serving diverse industries with robust performance.

Key Features

The unit boasts several remarkable characteristics that enhance its operation. These features include durable construction, impressive torque output, and efficient fuel consumption, contributing to its popularity among operators.

Applications

This power source is utilized in a multitude of settings, ranging from construction sites to agricultural environments. Its versatility ensures that it meets the demands of different tasks effectively.

| Feature | Description |

|---|---|

| Durability | Constructed to withstand harsh conditions. |

| Torque | Delivers high torque for heavy loads. |

| Fuel Efficiency | Optimized for lower fuel consumption. |

Key Components of the Engine

This section explores the fundamental elements that contribute to the overall functionality of a powerful machine. Each component plays a crucial role, working in harmony to ensure optimal performance and reliability.

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and supports other parts. |

| Pistons | Convert combustion energy into mechanical power. |

| Crankshaft | Transforms linear motion of pistons into rotational motion. |

| Camshaft | Controls the timing of valve openings and closings. |

| Fuel Injector | Delivers fuel into the combustion chamber. |

| Intake and Exhaust Valves | Regulate airflow into and out of the combustion chamber. |

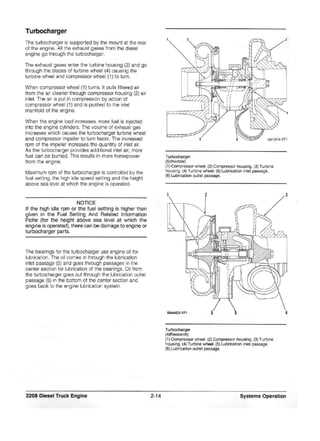

Importance of Engine Diagrams

Visual representations of mechanical systems are essential for understanding complex machinery. They provide clarity and facilitate communication among technicians and engineers, ensuring everyone is on the same page regarding functionality and maintenance.

Enhancing Understanding

- Simplifies intricate designs

- Highlights relationships between components

- Facilitates troubleshooting and repairs

Streamlining Maintenance

- Provides reference for disassembly and assembly

- Ensures accurate replacement of components

- Assists in identifying potential issues before they arise

Common Issues with the 3208 Cat

Many individuals encounter a variety of challenges with this specific machinery model. Understanding these common problems can significantly enhance maintenance and operational efficiency.

- Fuel System Problems: Clogging or leaks can lead to performance issues.

- Overheating: Insufficient cooling can cause excessive temperatures.

- Electrical Failures: Faulty wiring or poor connections may disrupt functionality.

- Oil Leaks: These can arise from worn gaskets or seals, affecting performance.

- Exhaust Issues: Blockages or leaks can hinder efficiency and increase emissions.

Regular inspections and timely repairs can help mitigate these issues and prolong the lifespan of the machinery.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires a proactive approach to care and upkeep. Regular attention to key components can significantly enhance performance and reliability.

Regular Inspections

- Conduct routine checks for wear and tear.

- Monitor fluid levels and quality.

- Inspect for leaks or unusual noises.

Proper Lubrication

- Use the recommended lubricants for optimal function.

- Maintain clean and sufficient lubricant levels.

- Schedule lubrication as per the manufacturer’s guidelines.

How to Read an Engine Diagram

Understanding a schematic representation of a power unit is essential for maintenance and repair tasks. These visual aids provide a structured overview, showcasing the arrangement and interaction of various components. Grasping how to interpret these visuals will enhance your ability to troubleshoot and service effectively.

Key Elements of a Schematic

To decode a visual representation, it is vital to familiarize yourself with its fundamental elements:

- Symbols: Each component is represented by a unique symbol. Recognizing these symbols is crucial for understanding the relationships between parts.

- Labels: Components are often labeled with alphanumeric codes. These identifiers can be cross-referenced with parts lists for clarity.

- Connections: Lines indicate connections between parts, showing how they interact and the flow of fluids or energy.

Steps to Interpret the Visual Aid

- Start with the Legend: Begin by reviewing the legend or key, which explains the symbols and labels used in the schematic.

- Identify Major Components: Look for main assemblies or systems, such as the cooling or fuel system, to understand the overall structure.

- Follow Flow Directions: Pay attention to arrows or flow lines, as they indicate the direction of movement or energy transfer.

- Reference Additional Materials: Utilize service manuals or parts catalogs to gain deeper insights into each component’s function and specifications.

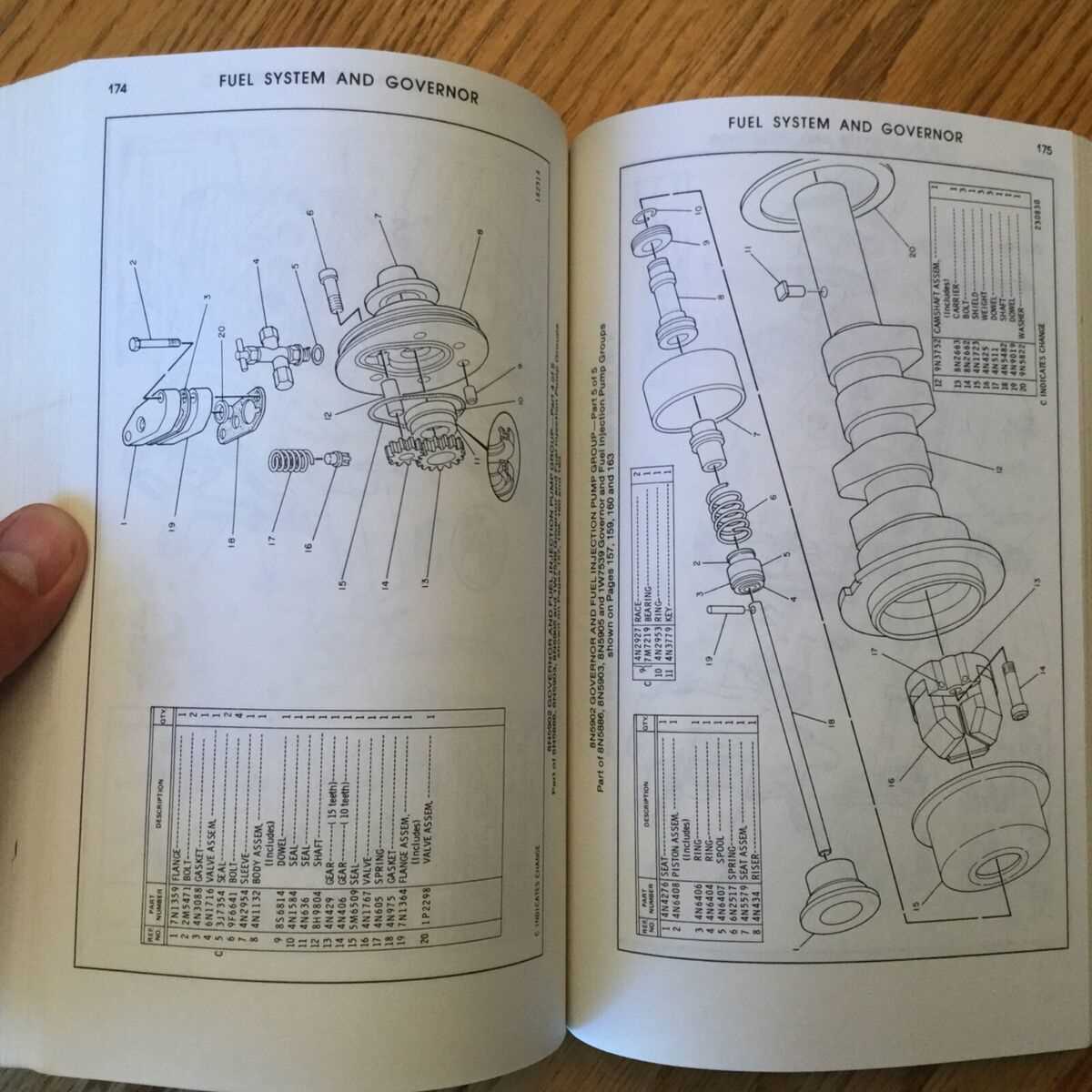

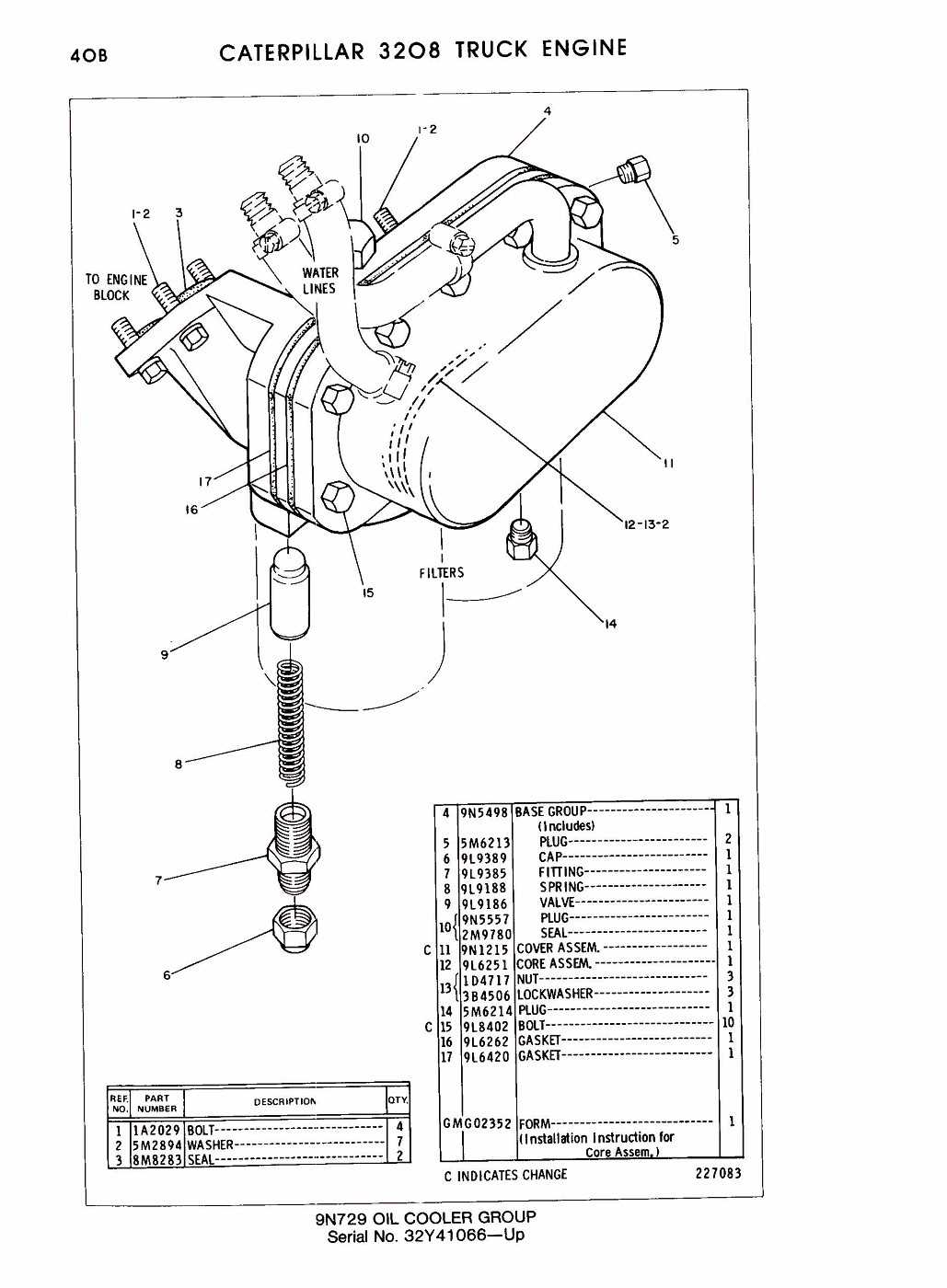

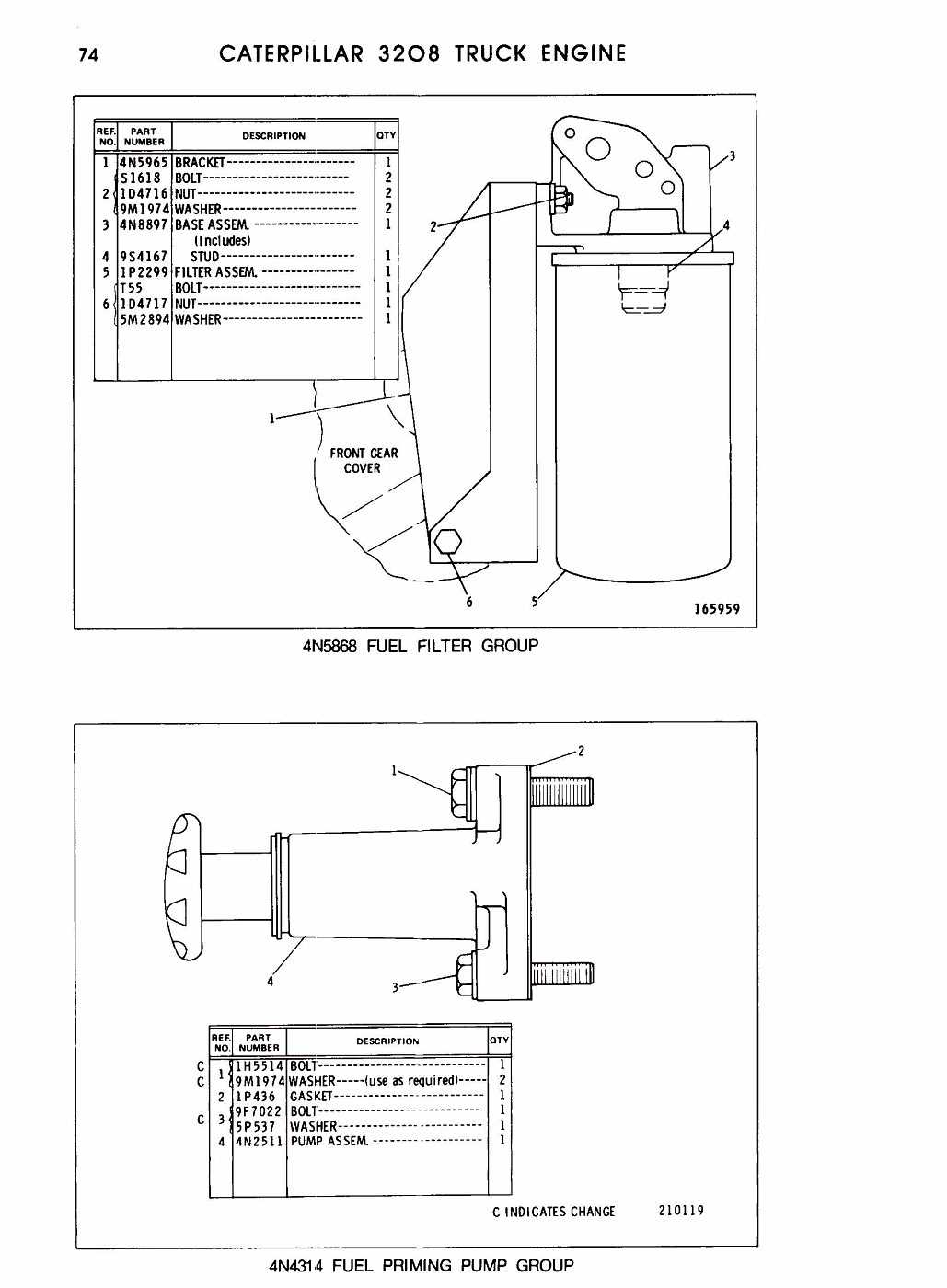

Parts Replacement Guide for 3208

This guide aims to assist you in effectively replacing components within your machinery system. Ensuring proper functionality and longevity requires understanding the various elements and their interactions. A well-planned replacement process not only enhances performance but also minimizes downtime.

Essential Components to Monitor

- Fuel System

- Cooling Mechanism

- Lubrication System

- Electrical Systems

Replacement Process Steps

- Identify the component that requires attention.

- Gather necessary tools and replacement items.

- Follow safety protocols to ensure a secure working environment.

- Remove the old component carefully, noting any connections or fittings.

- Install the new component, ensuring all connections are secure.

- Test the system to confirm proper operation.

Regular maintenance and timely replacements are crucial for optimal functionality. Stay proactive to avoid potential issues and extend the lifespan of your machinery.

Benefits of OEM vs Aftermarket Parts

When it comes to sourcing components for machinery, the choice between original equipment manufacturer (OEM) and alternative suppliers can significantly impact performance and longevity. Understanding the pros and cons of each option helps in making informed decisions that align with maintenance goals and budget constraints.

Advantages of OEM Components

- Quality Assurance: OEM components are produced to meet strict manufacturer specifications, ensuring high quality and reliability.

- Warranty Protection: Most OEM parts come with a warranty that covers defects and performance issues, providing peace of mind.

- Perfect Fit: These components are designed specifically for particular models, ensuring seamless compatibility and functionality.

Benefits of Aftermarket Options

- Cost-Effectiveness: Aftermarket components often come at a lower price point, making them an attractive option for budget-conscious users.

- Variety and Innovation: Many aftermarket suppliers offer a wider range of products, including enhanced versions that may improve performance.

- Availability: Aftermarket components can be easier to source, especially for older models or discontinued lines.

Ultimately, the decision between OEM and alternative components hinges on specific needs, performance expectations, and financial considerations. Assessing these factors carefully can lead to optimal outcomes in equipment maintenance and longevity.

Tools Needed for Repairs

When it comes to performing maintenance and fixing machinery, having the right tools is essential for achieving optimal results. Proper equipment not only facilitates the repair process but also ensures safety and efficiency. Below is a list of essential tools to consider for your next project.

- Wrenches: A variety of sizes to tackle different fasteners.

- Screwdrivers: Both flathead and Phillips for various screws.

- Pliers: For gripping, twisting, and cutting wire or small parts.

- Torque wrench: To ensure proper tightening of bolts.

- Socket set: For quick and easy access to fasteners in tight spaces.

- Jack and jack stands: Necessary for safely lifting and securing the equipment.

In addition to the basics, specialized tools may be required depending on the specific task at hand. Below are some additional items that can enhance your repair experience:

- Multimeter: For electrical diagnostics.

- Fluid extractor: To remove old fluids without mess.

- Shop manual: Offers detailed information on procedures and specifications.

Having these tools on hand will prepare you for a range of maintenance and repair activities, ensuring that you can effectively address any issues that arise.

Connecting Systems in the 3208 Cat

The integration of various components is crucial for the optimal performance of any mechanical assembly. Understanding how these systems interact can significantly enhance efficiency and reliability. Each subsystem plays a vital role in the overall functionality, requiring precise coordination to achieve desired outcomes.

Subsystem Interaction

Different systems within the assembly must communicate effectively to ensure smooth operation. For instance, the linkage between the power delivery and cooling mechanisms is essential for maintaining operational temperatures while maximizing output. Regular maintenance of these connections can prevent potential failures and prolong lifespan.

Importance of Maintenance

Regular upkeep is not just beneficial but necessary for sustaining performance. Inspections and adjustments of the connecting elements can reveal wear and tear before they lead to significant issues. Investing in proactive maintenance not only enhances functionality but also minimizes downtime and repair costs.

Resources for Further Learning

To deepen your understanding of mechanical components and their functions, a variety of materials and tools are available for exploration. These resources can enhance your knowledge and provide practical insights into the intricacies of machinery.

- Online Courses:

- Platforms like Coursera and Udemy offer specialized courses on machinery maintenance and diagnostics.

- Look for certifications that focus on heavy equipment and mechanical engineering.

- Books and Manuals:

- Technical manuals provide detailed information about specifications and troubleshooting techniques.

- Textbooks on mechanical engineering can offer foundational knowledge and advanced concepts.

- Forums and Online Communities:

- Join forums where professionals discuss common issues and solutions.

- Engage with communities on platforms like Reddit for shared experiences and advice.

- Video Tutorials:

- YouTube channels dedicated to machinery repairs can visually guide you through processes.

- Look for expert demonstrations that cover both basic and advanced topics.

- Workshops and Seminars:

- Attend local workshops to gain hands-on experience with experts.

- Seek out seminars that cover the latest technologies and best practices in the field.

Utilizing these resources will enable you to expand your expertise and stay updated on industry advancements, ultimately enhancing your proficiency in the field.