1999 Ford F350 Front End Components Overview

The effective operation of any robust vehicle relies significantly on its structural elements. In this section, we will explore the various components that contribute to the stability and functionality of a vehicle’s frontal structure. Each element plays a crucial role in ensuring optimal performance and safety, making it essential to understand their interrelations and specific functions.

Whether you are a seasoned mechanic or a vehicle enthusiast, grasping the intricacies of these components can greatly enhance your repair and maintenance skills. From suspension mechanisms to steering linkages, every aspect is vital for the vehicle’s overall handling and maneuverability. Knowledge of these components will empower you to make informed decisions when troubleshooting or upgrading your vehicle.

In the following segments, we will delve deeper into the various components, offering insights into their configurations and functions. This understanding will not only assist in effective repairs but also contribute to enhancing the overall lifespan and reliability of the vehicle.

tags: Overview of Front End Components”>

tags: Overview of Front End Components”>

This section aims to provide a comprehensive overview of the critical components located at the vehicle’s forefront. Understanding these elements is essential for anyone looking to maintain or repair their vehicle effectively. The interplay between these components ensures the vehicle operates smoothly, contributing to safety and performance on the road.

Key Elements of the Vehicle’s Forepart

The foremost section of any vehicle includes various elements, each playing a unique role. From the suspension to the steering mechanism, these components work in unison to provide stability and control. A thorough grasp of these components helps in diagnosing issues and planning maintenance schedules.

Functionality and Maintenance Considerations

Regular inspections and maintenance of these vital elements can prevent costly repairs and enhance the longevity of the vehicle. Identifying signs of wear or damage early can save time and resources in the long run. It is advisable to refer to a detailed schematic for an accurate understanding of how these components interact.

Common Issues with Front End Components

Maintaining optimal performance of vehicle assemblies is essential for ensuring safe and smooth operation. Various challenges can arise with these crucial components, impacting handling and stability. Understanding these common concerns can help drivers identify and address problems early.

Below are some frequent issues associated with these assemblies, along with their potential causes:

| Issue | Description | Possible Causes |

|---|---|---|

| Uneven Tire Wear | Irregular wear patterns on tires indicating alignment problems. | Misalignment, worn suspension elements. |

| Steering Play | Excessive movement in the steering wheel before response from the wheels. | Worn steering components, loose connections. |

| Vibration During Driving | Shaking felt through the steering wheel or seat while in motion. | Imbalanced tires, damaged suspension components. |

| Clunking Noises | Sound indicating potential damage or looseness in the assembly. | Worn out bushings, loose bolts. |

| Difficulty in Steering | Resistance felt when turning the steering wheel. | Low power steering fluid, failing pump. |

Regular inspections and timely maintenance can help mitigate these issues, enhancing vehicle longevity and performance.

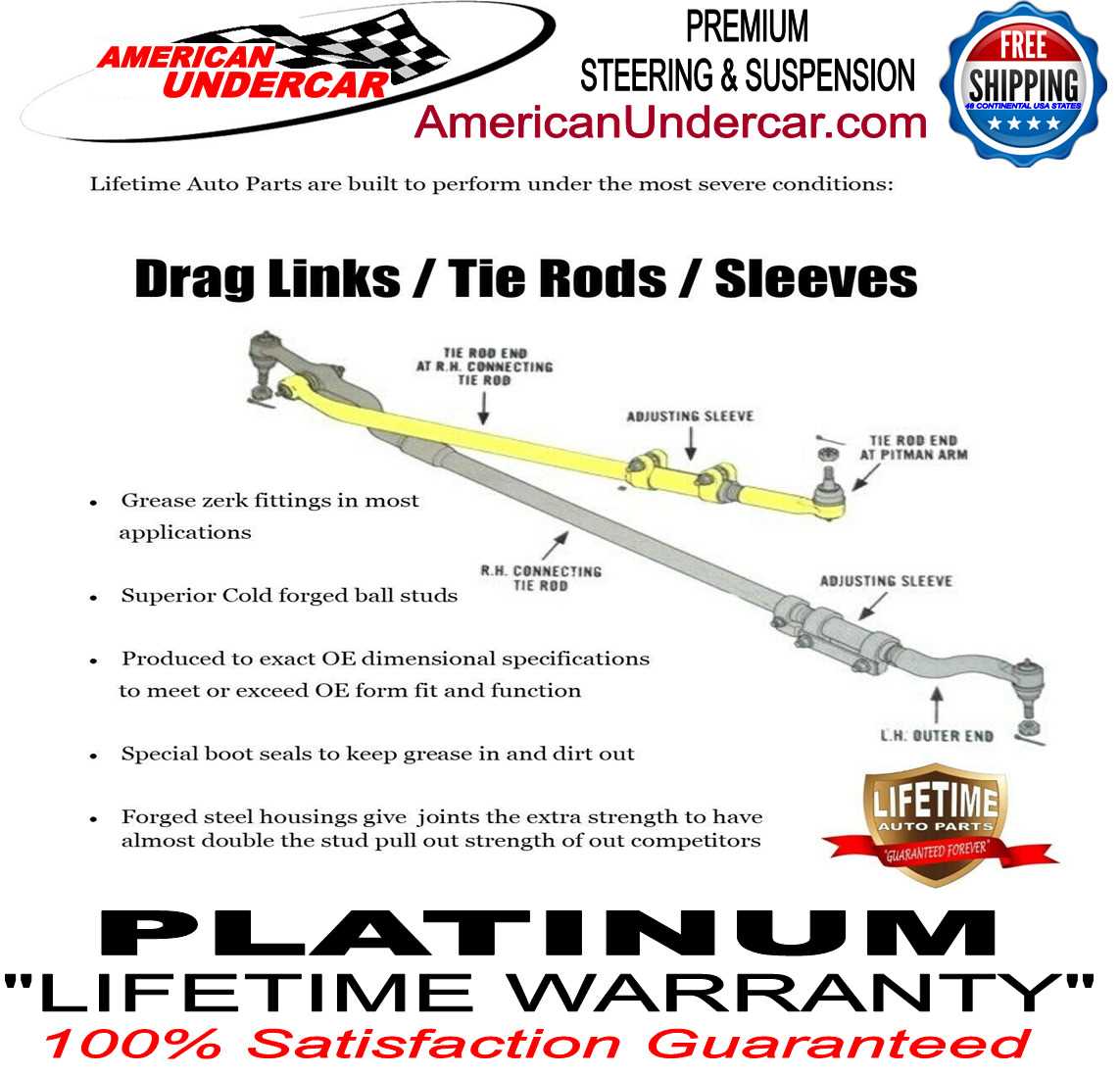

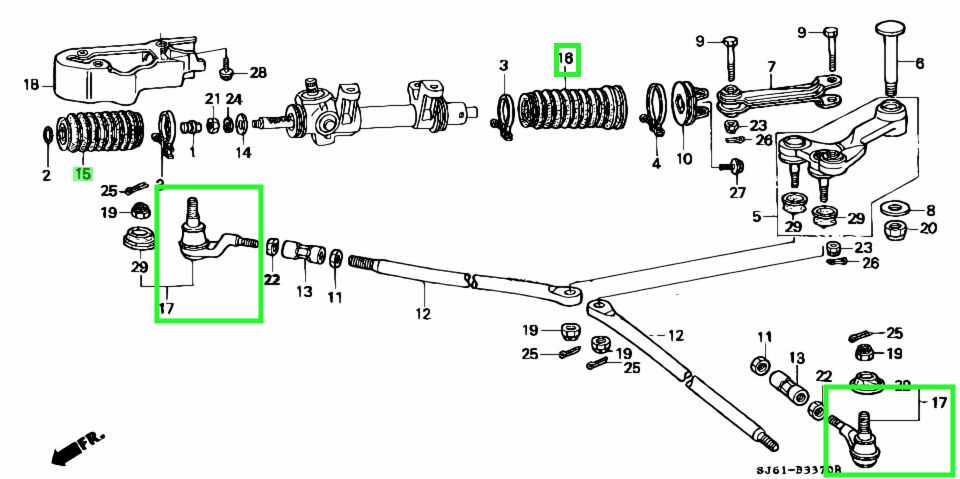

Understanding the Steering System

The steering mechanism is a crucial component of any vehicle, allowing the driver to control the direction and stability during operation. A well-functioning system ensures smooth maneuvering and enhances safety on the road.

This assembly comprises several key elements that work together to translate the driver’s input into vehicle movement. Understanding these components can aid in maintenance and troubleshooting.

- Steering Wheel: The interface between the driver and the steering system, allowing for input on direction.

- Steering Column: Connects the steering wheel to the steering mechanism, housing essential electrical components.

- Gearbox: Converts the rotational motion of the steering wheel into linear movement to turn the wheels.

- Linkage: Transfers motion from the gearbox to the wheels, ensuring precise control.

- Rack and Pinion: A common design that enhances steering response and reduces effort needed for turning.

Regular inspections and maintenance of these elements can prevent issues that might compromise steering performance. It is advisable to consult a professional mechanic for any concerns or irregularities observed in the system.

Brake System Specifications

The braking mechanism of a heavy-duty vehicle is crucial for ensuring safety and control during operation. This system is designed to effectively slow down or halt the vehicle while providing reliable performance under various conditions. Understanding the specifications of the braking assembly helps in maintaining optimal functionality and addressing potential issues.

Components of the Brake Assembly

- Brake Rotors

- Brake Pads

- Calipers

- Brake Lines

- Master Cylinder

Key Specifications

- Rotor Diameter: Typically ranges from 14 to 16 inches, depending on the vehicle’s weight capacity.

- Pad Material: Common materials include semi-metallic, ceramic, and organic compounds, each offering different performance characteristics.

- Brake Fluid Type: DOT 3 or DOT 4 fluids are usually recommended for optimal performance.

- Maximum Operating Pressure: The system generally operates between 1,000 to 1,500 psi.

Regular inspection and maintenance of these components are essential for ensuring the braking system functions effectively and safely. Following the manufacturer’s guidelines for replacement and adjustments can enhance the lifespan of the braking assembly.

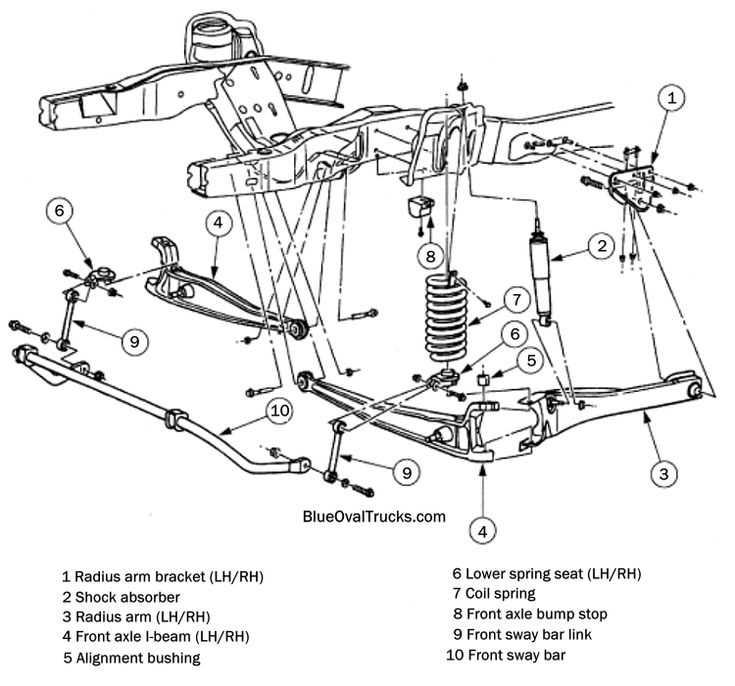

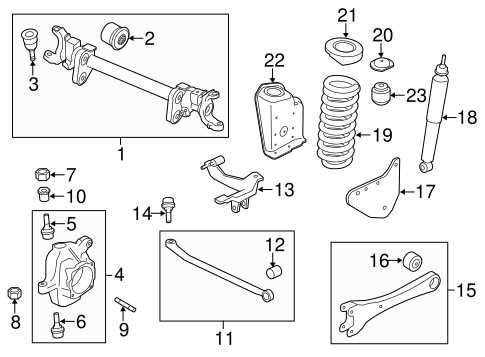

Suspension Components Explained

The suspension system plays a crucial role in ensuring a smooth ride and maintaining vehicle stability. It comprises various elements that work together to absorb shocks, support the weight of the vehicle, and enhance handling characteristics. Understanding these components can help in identifying issues and improving overall performance.

Shock Absorbers are vital for controlling the impact of bumps and irregularities on the road. They prevent excessive bouncing and help keep the tires in contact with the surface, contributing to better traction and handling.

Coil Springs provide the necessary support for the vehicle’s weight while allowing for vertical movement. These springs compress and expand, helping to maintain a stable ride by absorbing energy from road imperfections.

Control Arms connect the vehicle’s frame to the wheels, allowing for controlled movement during suspension travel. They play a significant role in wheel alignment and overall handling, ensuring that the wheels maintain proper contact with the road.

Sway Bars (or anti-roll bars) help reduce body roll during cornering, improving stability and control. By connecting opposite wheels, they distribute weight more evenly, enhancing grip and responsiveness.

Each component within the suspension assembly is designed to work in harmony, contributing to the vehicle’s performance, comfort, and safety. Regular maintenance and inspection of these elements are essential for optimal functionality and longevity.

Replacing Worn Out Parts

Maintaining vehicle performance is crucial, and replacing deteriorated components is a key aspect of this process. Over time, various elements of your vehicle can wear down, impacting handling and safety. Addressing these issues promptly can enhance both functionality and driving experience.

Identifying Worn Components

Before starting the replacement process, it’s important to recognize the signs of wear. Common indicators include:

- Unusual noises while driving, such as clunking or grinding.

- Excessive vibration in the steering wheel.

- Uneven tire wear or alignment issues.

- Fluid leaks beneath the vehicle.

Replacement Process

Once worn components are identified, follow these general steps for replacement:

- Gather necessary tools and replacement parts.

- Lift the vehicle securely using jack stands.

- Remove the damaged component carefully.

- Install the new part, ensuring it is properly secured.

- Lower the vehicle and perform a test drive to ensure everything functions correctly.

Regular maintenance and timely replacement of worn components will not only improve vehicle performance but also prolong its lifespan.

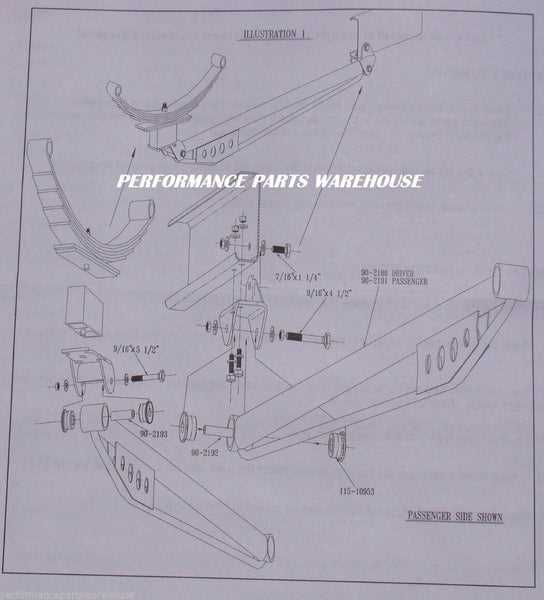

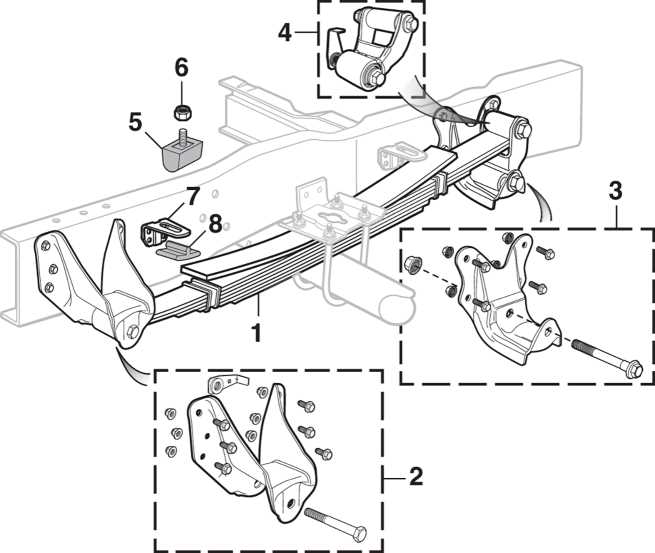

Assembly of Front End Components

Assembling the components at the front section of a vehicle is a crucial process that requires attention to detail and precision. Each element plays a vital role in the overall functionality and performance of the automobile. Proper installation ensures safety, stability, and durability over time.

To effectively carry out the assembly process, follow these key steps:

- Preparation:

- Gather all necessary tools and components.

- Ensure the workspace is clean and organized.

- Alignment:

- Begin with aligning the main structure components for accurate fitting.

- Use a measuring tool to confirm the positions are correct.

- Attachment:

- Securely fasten each component using appropriate bolts and fasteners.

- Double-check the tightness of connections to prevent loosening over time.

- Final Inspection:

- Inspect the assembled components for any signs of misalignment or instability.

- Conduct a test to ensure proper operation of the assembled section.

Following these steps will lead to a successful assembly of the components at the front of the vehicle, enhancing its performance and longevity.

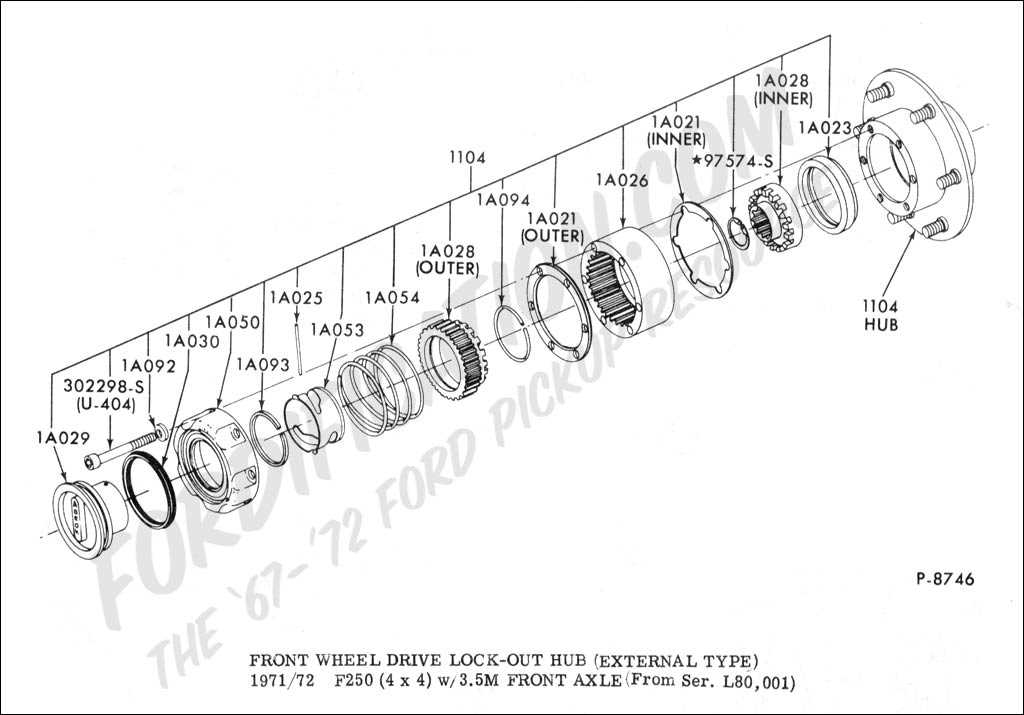

Diagram Interpretation Tips

Understanding the layout of a technical illustration can be crucial for efficient maintenance or repair tasks. By carefully examining each symbol and notation, you can gain valuable insights into the assembly’s structure, ensuring that every component is correctly identified and handled.

Start by familiarizing yourself with the legend or key provided, as it often contains essential details about the icons and labels used. This step will help you quickly recognize different elements in the illustration, making it easier to follow the connections and relationships between them.

It’s also beneficial to break down the image into smaller sections, focusing on one area at a time. This method allows for a clearer understanding of individual components and how they interact with surrounding elements. Analyzing these connections systematically can lead to a more accurate and effective approach to any troubleshooting or replacement task.

Tools Needed for Repairs

When preparing for a repair task on your vehicle, it’s essential to gather all necessary equipment to ensure a smooth and efficient process. The right set of tools can make a significant difference in handling various adjustments and replacements, minimizing the risk of delays or complications.

Basic Hand Tools

For most automotive tasks, a collection of standard hand tools is indispensable. These tools are commonly used for loosening, tightening, and adjusting various components. Investing in quality hand tools can greatly enhance the precision of your work and reduce the likelihood of damage to parts.

| Tool | Purpose |

|---|---|

| Socket Wrench Set | Ideal for fastening and removing nuts and bolts of different sizes. |

| Screwdrivers | Useful for tasks requiring both Phillips and flat-head applications. |

| Pliers | Essential for gripping, bending, or cutting wires and small components. |

Specialized Equipment

Certain repairs may call for more specific tools designed to handle unique automotive challenges. These specialized items ensure that intricate tasks can be completed safely and efficiently, especially when dealing with precision adjustments or stubborn components.

| Tool | Application |

|---|---|

| Torque Wrench | Ensures that fasteners are tightened to the correct specifications. |

| Ball Joint Separator | Facilitates the removal of ball joints without damaging other components. |