Comprehensive Guide to Ford F350 Front Suspension Parts Diagram

In the realm of automotive engineering, a crucial aspect of vehicle dynamics lies in the intricate network of elements that contribute to stability and handling. This section delves into the various components responsible for maintaining the equilibrium of larger vehicles, enhancing both performance and safety on the road.

Every vehicle is designed with a unique arrangement of these essential elements, each playing a specific role in managing weight distribution and ensuring a smooth ride. By examining the configuration and functionality of these components, enthusiasts and mechanics alike can gain valuable insights into their operation and potential for upgrades or repairs.

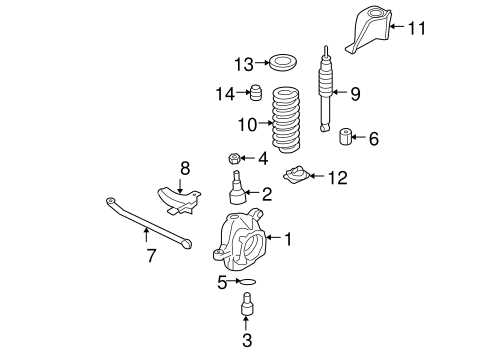

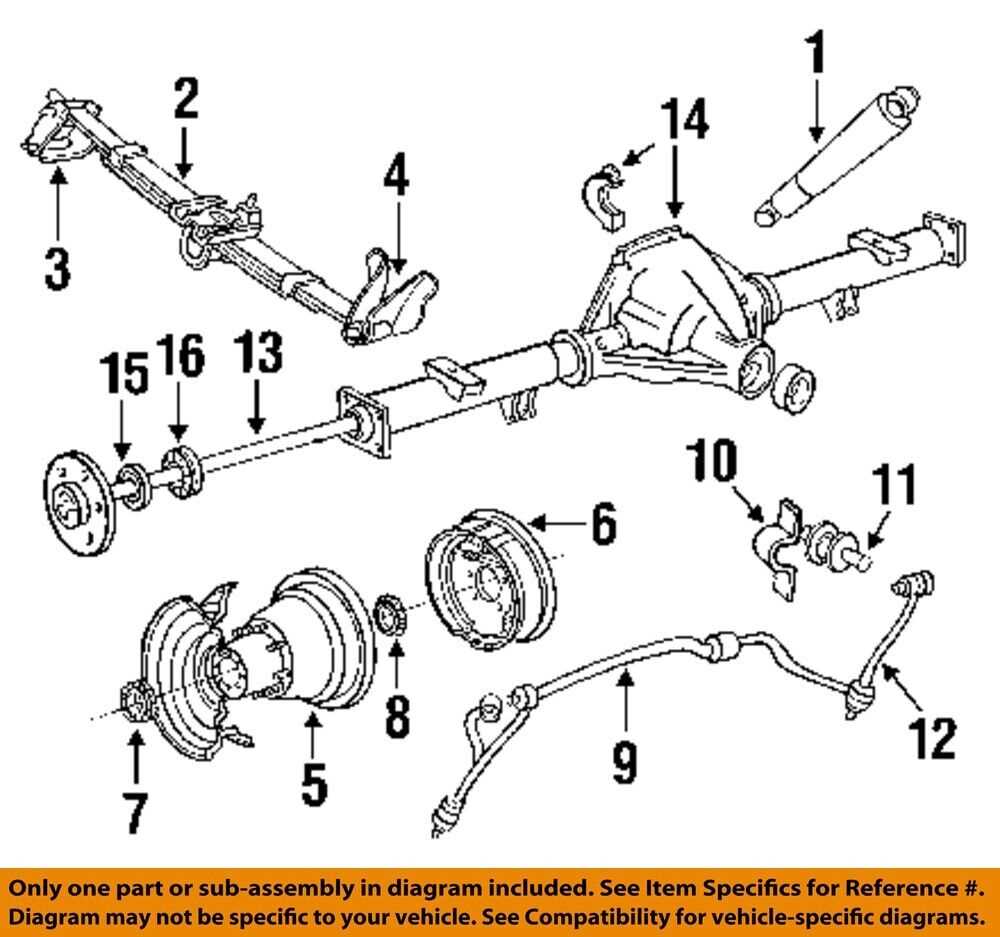

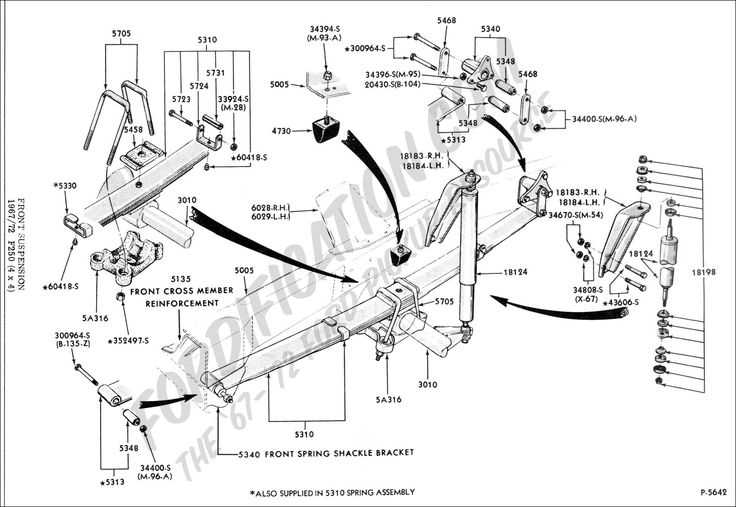

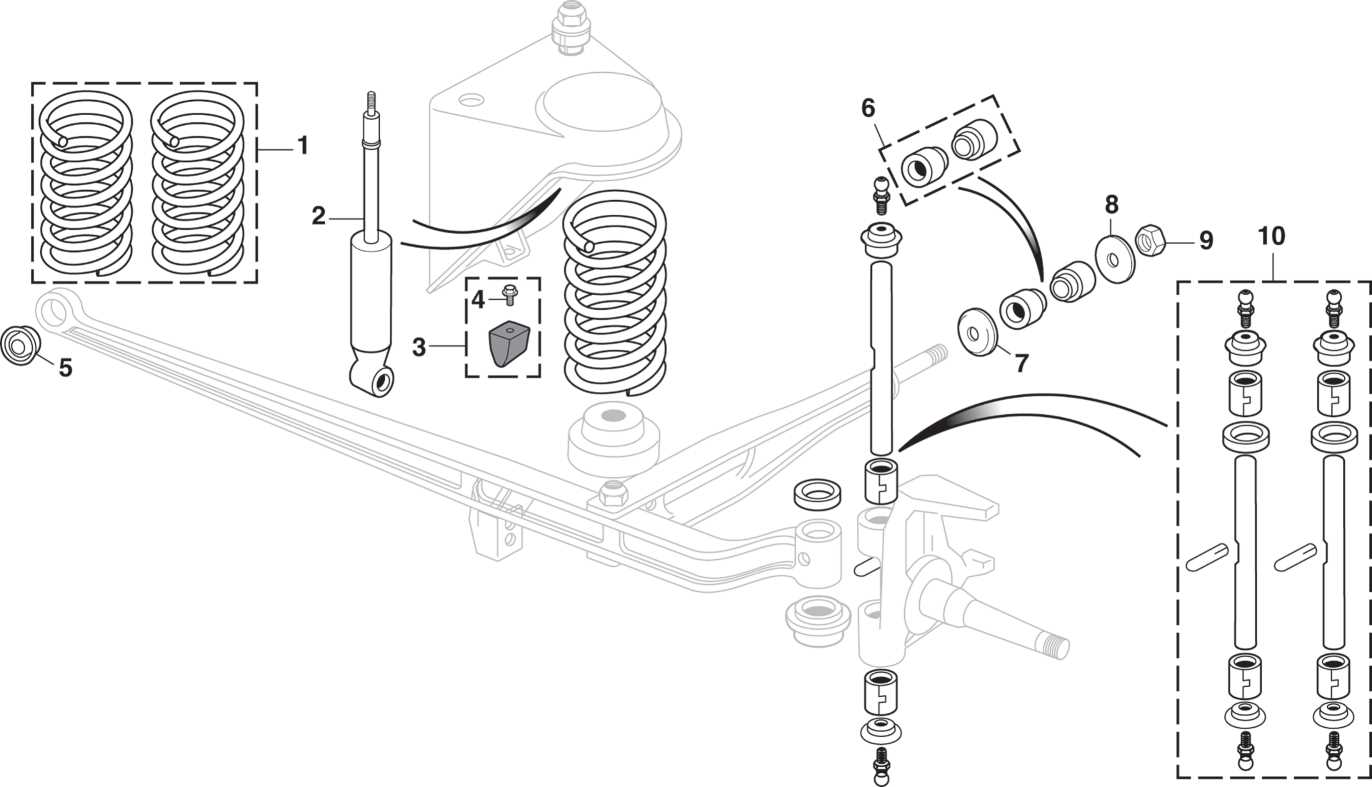

With an emphasis on visual representation, exploring a schematic of these crucial elements can illuminate their interconnectivity and significance. Understanding how each component interacts within the assembly not only aids in troubleshooting but also empowers owners to make informed decisions regarding maintenance and enhancement.

Understanding Ford F350 Front Suspension

The system responsible for providing stability and comfort during travel plays a crucial role in vehicle performance. Its design influences handling, load-bearing capacity, and overall driving experience. A thorough comprehension of this assembly is essential for both maintenance and upgrades.

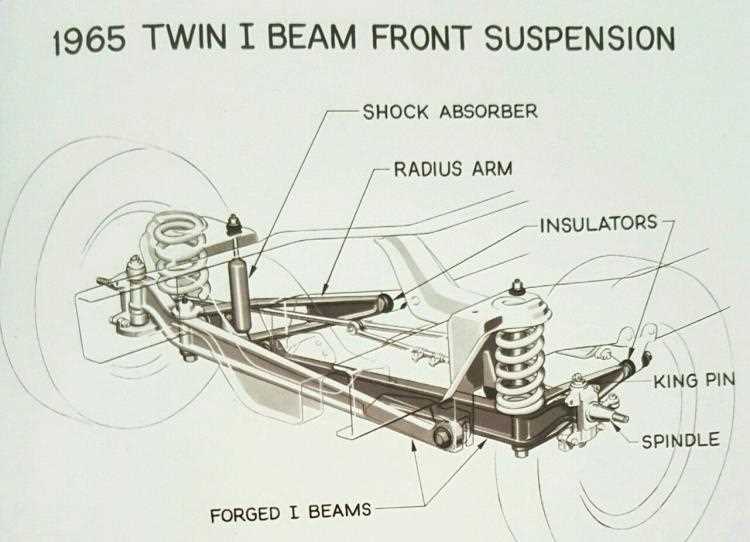

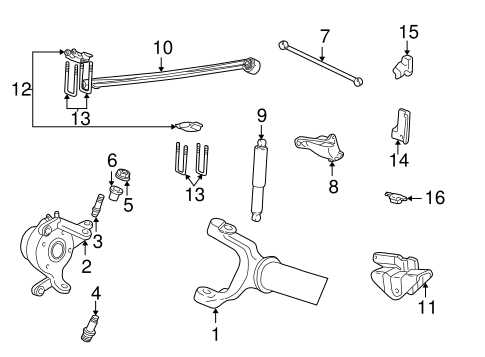

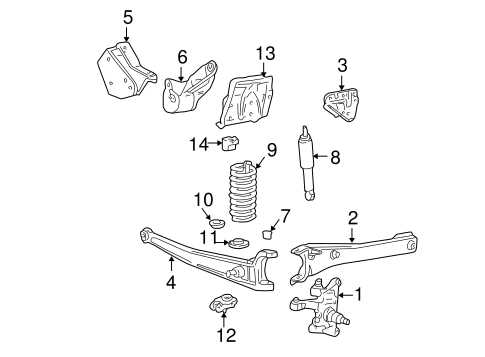

Key components of this arrangement include:

- Shock absorbers

- Control arms

- Springs

- Ball joints

- Steering knuckles

Each element serves a specific function, contributing to the overall efficiency of the system. Regular inspection and timely replacement of worn components can enhance safety and prolong the lifespan of the vehicle.

Understanding the relationships between these components is vital for effective troubleshooting. Here are some important aspects to consider:

- Alignment: Proper alignment ensures even tire wear and responsive steering.

- Load Management: The arrangement must handle varying loads without compromising stability.

- Performance Tuning: Upgrades can improve handling and comfort, depending on driving conditions.

By familiarizing oneself with these elements, owners can make informed decisions regarding repairs and enhancements, ensuring optimal functionality and safety on the road.

Key Components of Front Suspension

The arrangement responsible for absorbing shocks and providing stability in a vehicle is crucial for its performance and comfort. Understanding the essential elements that contribute to this system can enhance both safety and driving experience. Each component plays a significant role in ensuring a smooth ride while maintaining control and responsiveness.

Shock Absorbers

These devices are vital for dampening the impact of road irregularities. They work by converting kinetic energy into thermal energy, helping to maintain tire contact with the ground. This enhances vehicle stability and reduces wear on other components.

Control Arms

Control arms serve as the connection between the vehicle’s chassis and the wheels. They allow for vertical movement while keeping the wheels aligned. Their design and material influence the overall handling and ride quality, making them a critical element in this assembly.

Importance of Suspension Systems

The functionality of a vehicle greatly depends on its ability to provide a smooth and stable ride. This crucial aspect not only enhances comfort but also plays a significant role in safety and performance. Effective mechanisms contribute to maintaining proper contact between tires and the road, ensuring optimal handling and control.

A well-designed system serves multiple purposes, from absorbing shocks caused by uneven surfaces to minimizing wear and tear on various components. It also affects the overall driving experience, influencing everything from steering responsiveness to load capacity. Understanding the significance of these systems is vital for any vehicle owner or enthusiast.

| Function | Impact |

|---|---|

| Shock Absorption | Enhances comfort by reducing vibrations |

| Tire Contact | Improves traction and stability |

| Load Distribution | Increases safety by balancing weight |

| Handling | Promotes responsive steering and cornering |

Ultimately, the role of these systems extends beyond mere mechanics; they are integral to the overall driving experience and vehicle longevity. Regular maintenance and understanding their importance can lead to enhanced performance and safety on the road.

Common Issues with Front Suspension

Many vehicle owners encounter challenges related to the system that supports the wheels and provides stability during driving. These concerns can lead to decreased performance and safety. Understanding these issues can help in timely maintenance and repairs, ensuring a smoother ride.

Wear and Tear on Components

Over time, various elements can suffer from fatigue, causing misalignment and reduced efficiency. Ball joints and tie rods are particularly susceptible to wear. Signs of deterioration may include unusual noises or vibrations while driving, indicating the need for inspection.

Improper Alignment

Misalignment can occur due to hitting potholes or curbs, leading to uneven tire wear and compromised handling. Regular check-ups are essential to maintain correct positioning, which enhances both safety and tire longevity. Addressing alignment issues promptly can prevent more severe complications down the road.

Maintenance Tips for Ford F350

Proper upkeep of your vehicle is essential to ensure its longevity and optimal performance. Regular maintenance not only enhances safety but also prevents costly repairs in the future. This section provides practical advice to help you maintain your heavy-duty truck efficiently.

Regular Inspections: Conduct routine checks on vital components, including the braking system, steering mechanisms, and undercarriage. Early detection of wear and tear can save time and money down the line.

Fluid Levels: Keep an eye on the levels of engine oil, transmission fluid, brake fluid, and coolant. Maintaining these fluids at appropriate levels ensures smooth operation and prevents overheating or other complications.

Tire Maintenance: Regularly inspect tires for proper inflation and tread wear. Rotate them every 5,000 to 7,500 miles to promote even wear and extend their lifespan.

Filter Changes: Replace air and oil filters according to the manufacturer’s recommendations. Clean filters improve engine efficiency and prolong its life.

Battery Care: Check the battery terminals for corrosion and ensure connections are tight. A well-maintained battery can prevent unexpected breakdowns.

Professional Servicing: Schedule routine maintenance with a qualified technician. They can provide a comprehensive inspection and address any issues that may arise, ensuring your vehicle remains in peak condition.

How to Diagnose Suspension Problems

Identifying issues within a vehicle’s support system is crucial for maintaining safety and performance. Various symptoms can indicate underlying problems, and recognizing these signs early can prevent further damage. This guide outlines effective methods for assessing the condition of the components that provide stability and comfort during driving.

Common Symptoms to Look For

There are several key indicators that may suggest malfunctioning elements within the vehicle’s support system:

| Symptom | Possible Cause |

|---|---|

| Uneven tire wear | Misalignment or worn components |

| Excessive bouncing | Worn dampers or shock absorbers |

| Pulling to one side | Imbalance in the structure or alignment issues |

| Noisy rides | Loose or damaged fixtures |

Inspection Techniques

Regularly inspecting the vehicle can help catch issues early. Here are some effective techniques:

- Visual Examination: Check for visible wear and damage on components.

- Physical Testing: Perform bounce tests to assess damping efficiency.

- Alignment Check: Use alignment tools to ensure proper positioning of the wheels.

By paying attention to these symptoms and employing thorough inspection methods, vehicle owners can effectively identify and address problems, ensuring a safer and smoother driving experience.

Upgrading Suspension Parts Effectively

Enhancing the components that support a vehicle’s stability and handling can significantly improve performance and comfort. This process often involves selecting high-quality alternatives that offer better durability, responsiveness, and adaptability to different driving conditions. By investing in superior elements, drivers can experience a smoother ride and greater control.

Choosing Quality Over Cost

When it comes to upgrading, prioritizing quality is essential. While it may be tempting to opt for the cheapest options, lower-quality materials can lead to premature wear and subpar performance. Researching reputable brands and reading reviews can help in making informed decisions that ensure longevity and efficiency.

Consulting Experts

Engaging with professionals who specialize in vehicle enhancements can provide valuable insights. These experts can recommend suitable upgrades based on specific needs, driving styles, and vehicle types. Their knowledge helps to navigate the myriad of options available, ensuring that the enhancements are both effective and compatible with the existing system.

Comparison of Aftermarket vs. OEM Parts

When it comes to vehicle components, consumers often face the choice between original equipment manufacturer options and alternatives from third-party suppliers. Each category has its own advantages and drawbacks, which can significantly influence the decision-making process for vehicle owners. Understanding these differences is essential for making informed purchases that align with personal needs and budget constraints.

OEM options are typically designed to match the exact specifications of the original parts installed during manufacturing. This ensures compatibility and reliability, as these components are crafted by the same producers that supply the automaker. However, they can often come at a higher price point, reflecting the brand value and assurance of quality.

On the other hand, aftermarket alternatives offer a wide range of choices, often at more competitive prices. These parts can be made by various manufacturers and may provide features or enhancements not found in original components. While some aftermarket options can match or even exceed the quality of OEM parts, others may vary significantly in terms of durability and performance.

In conclusion, the selection between OEM and aftermarket alternatives should consider factors such as budget, quality expectations, and specific vehicle requirements. Each choice presents unique benefits that can cater to different priorities, making it crucial to weigh these aspects before finalizing a decision.

Installation Process of Suspension Components

The procedure for installing critical elements of the vehicle’s support system is essential for ensuring optimal performance and safety. Each component plays a significant role in maintaining stability and control while driving. This guide outlines the necessary steps to successfully replace or upgrade these components, ensuring a smooth and reliable ride.

Preparation Steps

Before beginning the installation, it’s crucial to gather all necessary tools and replacement components. Ensure the vehicle is parked on a flat surface and securely lifted using jack stands. Additionally, it’s advisable to consult the service manual for specific instructions related to the vehicle model. Having a clean workspace will facilitate a more efficient process.

Installation Procedure

Start by removing the old components carefully, paying attention to how they are connected. This can involve detaching bolts, clips, or other fasteners. Once removed, inspect the new elements for any damage. Install the new components by reversing the removal process. Ensure that all connections are tight and secure to prevent any future issues. Finally, perform a thorough check of all systems before lowering the vehicle back to the ground.

Tip: Always follow manufacturer specifications for torque settings and alignment procedures to maintain vehicle integrity.

Completing this process with diligence will greatly enhance driving comfort and handling. Regular maintenance and timely replacements of these elements are vital for the longevity of the vehicle.

Tools Needed for Suspension Repair

When undertaking the task of restoring the undercarriage system, having the right equipment is crucial for a successful outcome. Proper tools not only enhance efficiency but also ensure safety during the repair process. Understanding which instruments to use can make the job easier and more manageable, whether you’re a seasoned mechanic or a DIY enthusiast.

First and foremost, a set of high-quality hand tools is essential. Wrenches, sockets, and ratchets are fundamental for loosening and tightening various components. A torque wrench is particularly important for ensuring that fasteners are secured to the manufacturer’s specifications, preventing future issues.

A hydraulic jack and jack stands are vital for safely lifting the vehicle, allowing access to the undercarriage without compromising safety. Additionally, a pry bar can help in removing stubborn parts that may be rusted or stuck in place. A spring compressor may also be necessary if coil springs are part of the assembly you are working on, as it helps to safely manage the tension.

Lastly, a diagnostic tool can be useful for identifying any underlying issues that may not be immediately visible. Keeping a well-organized toolbox will not only save time but also ensure you have everything at your fingertips when you need it the most.

Signs of Worn Suspension Parts

Understanding the indicators of degraded support components is essential for maintaining vehicle safety and comfort. Recognizing these signs early can prevent further damage and enhance the overall driving experience.

Common symptoms of worn support elements include:

- Unusual Noises: Clunking, creaking, or rattling sounds when driving over bumps or turning may signal deterioration.

- Uneven Tire Wear: Noticeable patterns on tires, such as bald spots or excessive wear on one side, can indicate misalignment caused by faulty components.

- Reduced Handling: A feeling of looseness or vagueness in steering, especially during cornering, often points to compromised support mechanisms.

- Vibration: Excessive shaking in the steering wheel or throughout the vehicle while driving can suggest worn elements that require attention.

- Increased Stopping Distance: Difficulty in halting the vehicle promptly may be related to failing support systems that affect braking efficiency.

Regular inspections and addressing these signs promptly can ensure a safer and more enjoyable driving experience.

Enhancing Ride Quality in F350

Improving the comfort and stability of a heavy-duty vehicle involves a thoughtful approach to its foundational system. By focusing on key elements that influence the smoothness of the ride, owners can experience significant upgrades in both handling and overall driving pleasure.

Adjusting the system components plays a crucial role in achieving optimal performance. Ensuring that the elements responsible for absorbing shocks and providing support are in excellent condition can greatly enhance the driving experience. Regular inspections and timely replacements of worn-out items will contribute to a more pleasant ride.

Upgrading to higher-quality alternatives is another effective strategy. Investing in advanced technology solutions, such as air or coil upgrades, can provide better adaptability to various terrains. These enhancements not only improve comfort but also maintain the vehicle’s stability during heavy loads or rough conditions.

Additionally, tuning the alignment is essential for maximizing efficiency. Proper alignment reduces uneven tire wear and improves handling, making every journey more enjoyable. It is advisable to seek professional assistance to ensure precision in this process.

Lastly, considering tire selection can have a profound impact on ride quality. Choosing the right tires, specifically designed for the intended use, helps in absorbing road imperfections and enhances grip. This careful selection leads to improved control and an overall better driving experience.

Understanding Suspension Geometry Basics

Comprehending the foundational concepts of vehicle dynamics is essential for grasping how different components interact to ensure stability and control. The arrangement of elements plays a crucial role in determining ride quality and handling characteristics, affecting overall performance. By examining these relationships, one can gain insight into how vehicles respond to various driving conditions.

Key Components of Geometry

Each vehicle’s framework includes several key elements that dictate its movement. The positioning and alignment of these components can influence how weight is distributed, how the wheels align with the road, and how effectively the vehicle navigates turns.

| Component | Function |

|---|---|

| Control Arms | Allow vertical movement while maintaining wheel alignment. |

| Ball Joints | Facilitate movement between the control arms and the wheel assembly. |

| Sway Bar | Reduces body roll during cornering by connecting opposite wheels. |

| Struts/Shocks | Dampen oscillations and maintain contact with the surface. |

Importance of Proper Alignment

Maintaining accurate alignment is vital for optimal performance. Misalignment can lead to uneven tire wear, reduced handling capabilities, and compromised safety. Regular checks and adjustments help ensure that all components function harmoniously, providing a smoother and more controlled driving experience.