Understanding the Frigidaire Gallery Ice Maker Parts Diagram

Maintaining the efficiency of your freezing appliance is essential for ensuring a steady supply of chilled refreshments. Understanding the intricate workings of this household device can greatly enhance its performance and longevity. By familiarizing yourself with the various elements involved, you can troubleshoot issues more effectively and even undertake minor repairs with confidence.

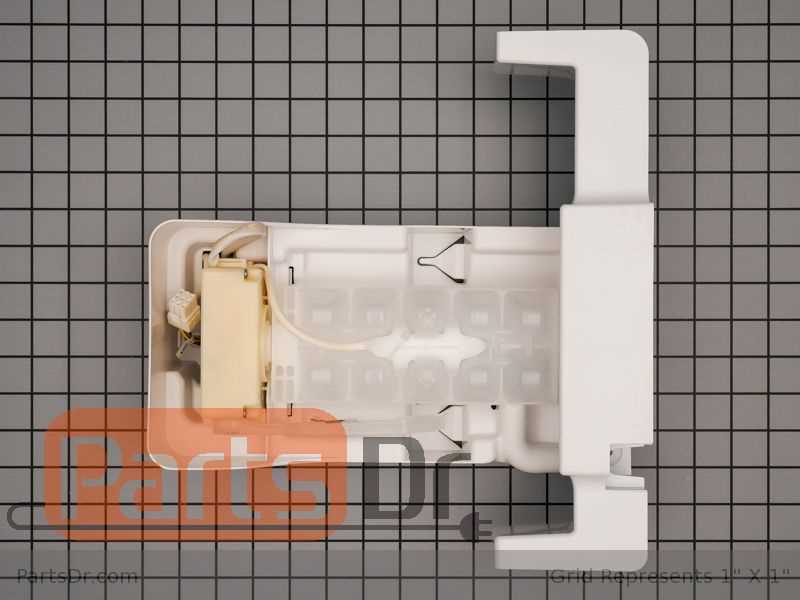

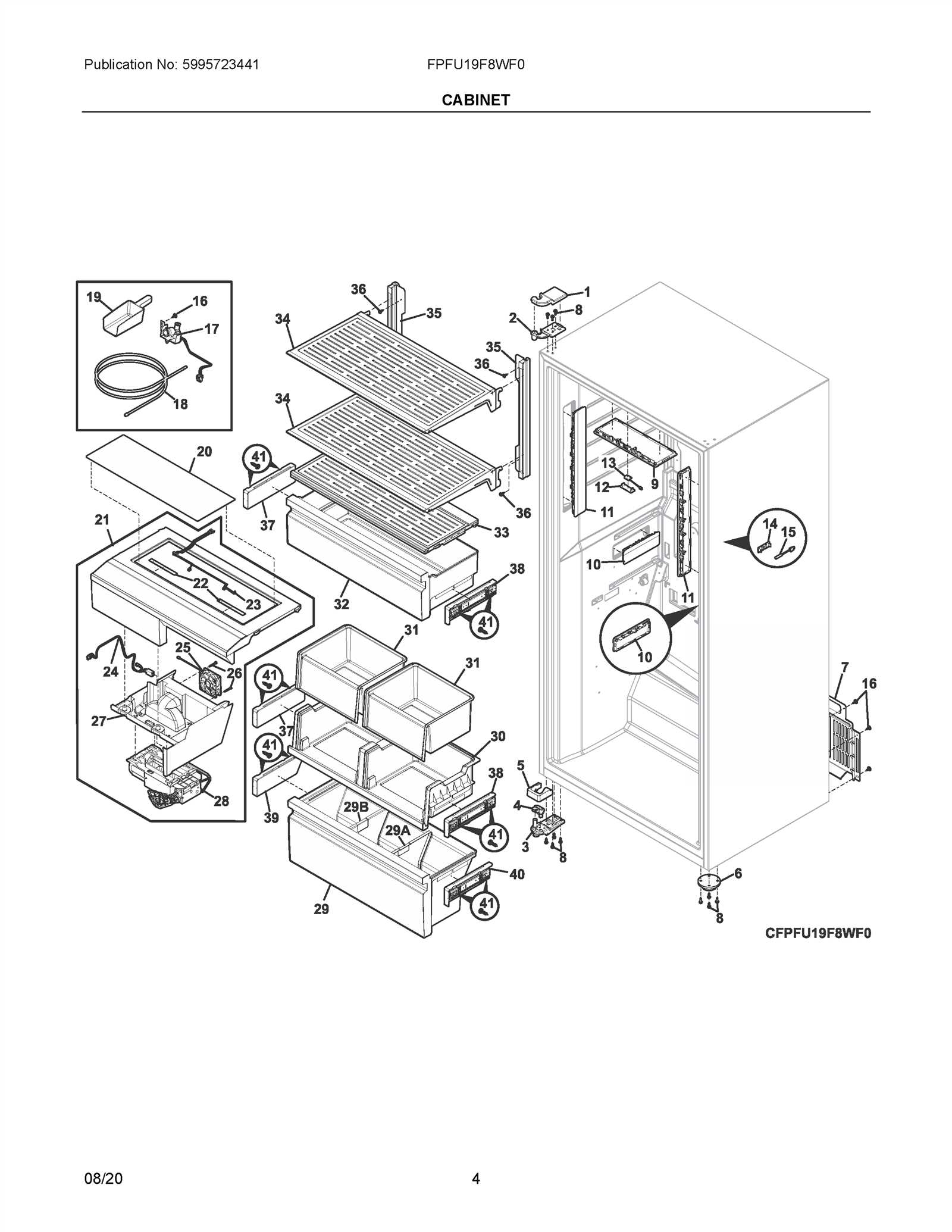

In this section, we will delve into the key components that play a crucial role in the operation of your cooling unit. Whether you are looking to replace a malfunctioning element or simply seeking to understand how everything fits together, having a clear visual representation can be incredibly beneficial. This guide will provide an overview that simplifies the complexities of your appliance, empowering you to tackle maintenance tasks head-on.

Equipped with knowledge about the specific features and functions of each part, you will be better prepared to ensure your unit runs smoothly. With the right information at your fingertips, you’ll find that addressing potential problems becomes a more manageable task. Let’s explore the essential components and their arrangement within your appliance, paving the way for a more efficient and reliable cooling experience.

Understanding Frigidaire Ice Maker Functionality

This section explores the inner workings of an appliance designed to produce frozen cubes for beverages and culinary uses. Gaining insight into its operation helps in troubleshooting issues and maintaining efficiency.

At its core, this appliance consists of several key components that work in harmony to generate frozen water. The main elements include:

- Water Supply System: Provides a continuous flow of water for freezing.

- Freezing Mechanism: Cools the water to create solid cubes.

- Control System: Regulates cycles and ensures proper functioning.

- Harvesting Component: Releases the frozen product for use.

Each of these parts plays a vital role:

- The water supply system fills the mold with liquid.

- The freezing mechanism cools it to below freezing point.

- The control system monitors temperature and timing.

- The harvesting component ejects the cubes into the storage bin.

Understanding these elements provides a solid foundation for maintaining and repairing the appliance effectively.

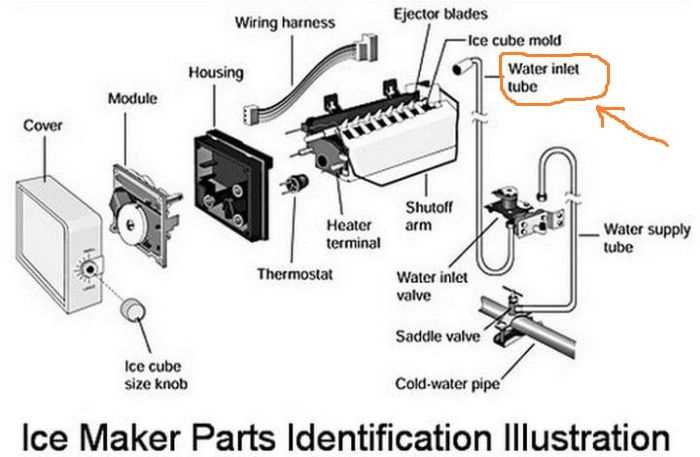

Common Parts in Ice Makers

Understanding the essential components of a freezing unit is crucial for efficient operation and maintenance. Each element plays a significant role in ensuring that the appliance functions smoothly, producing frozen cubes consistently. Below is a breakdown of the most frequently encountered elements found in these devices.

| Component | Function |

|---|---|

| Water Inlet Valve | Regulates water flow into the freezing chamber. |

| Evaporator | Freezes the water to form cubes through a refrigerant cycle. |

| Ice Cube Tray | Holds water while it freezes into solid form. |

| Heating Element | Helps release cubes from the tray by slightly warming it. |

| Control Module | Manages the entire operation and timing of the freezing process. |

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as valuable guides, providing insight into how various elements fit together and function within a larger system. By familiarizing yourself with the symbols and layout used in these depictions, you can enhance your troubleshooting skills.

First, identify the key components marked within the illustration. Each part is typically labeled, which allows for quick reference. Familiarize yourself with common terminologies associated with these items, as this will aid in deciphering their functions and interconnections.

Second, pay attention to the orientation and arrangement of the components. Understanding their placement can provide context about their roles in the overall assembly. Note any connections shown, as they indicate how different parts interact and support each other’s functions.

Lastly, always cross-reference the illustration with the accompanying documentation. This ensures a comprehensive understanding of the components and can reveal any nuances that may not be immediately apparent in the visual alone.

Identifying Ice Maker Components

Understanding the essential elements of a cooling appliance can significantly enhance its efficiency and maintenance. Each component plays a pivotal role in ensuring optimal functionality, and recognizing them is crucial for troubleshooting and repairs.

Key Components: The primary sections include the water supply system, the freezing chamber, and the dispensing mechanism. Each part contributes uniquely to the overall operation.

Water Supply: This area is responsible for channeling liquid into the freezing compartment, where it transforms into solid form.

Freezing Chamber: This section is where the transformation occurs, featuring various mechanisms to create and store frozen shapes.

Dispensing Mechanism: Once the freezing process is complete, this component ensures easy access to the frozen product for users.

Common Issues with Ice Makers

Many households experience challenges with their cooling devices, leading to frustration and inconvenience. Understanding these frequent problems can help in troubleshooting and maintaining optimal performance.

Low Production of Frozen Cubes

A prevalent issue is the insufficient generation of frozen units. This may arise from factors such as improper water supply, clogged filters, or temperature inconsistencies. Regular checks and maintenance can mitigate these problems.

Unusual Noises and Malfunctions

Another common concern involves strange sounds or complete failure of the equipment. This can be attributed to loose components, worn-out motors, or blocked mechanisms. Identifying the source of the noise is crucial for effective repairs and ensuring longevity.

Replacement Parts for Frigidaire Models

When it comes to maintaining essential appliances, ensuring you have access to quality components is crucial. Understanding the various elements that may require substitution helps in prolonging the lifespan of your device. This section outlines key components commonly needed for efficient operation and reliable performance.

Condenser Coils: These vital elements play a significant role in heat exchange. Regular cleaning and timely replacement can enhance energy efficiency and cooling performance.

Water Filters: Clean water is essential for optimal functionality. Regularly changing filters not only improves the quality of the output but also safeguards internal mechanisms from damage.

Thermostats: Accurate temperature control is essential for maintaining the right conditions. A malfunctioning thermostat can lead to inefficient operation and spoilage of stored items.

Fan Motors: These components are crucial for airflow. If your appliance is not cooling properly, a faulty fan motor could be the culprit, necessitating prompt replacement.

Seals and Gaskets: These ensure energy efficiency by preventing temperature loss. Over time, wear and tear can lead to leaks, which may require new seals to maintain effectiveness.

By staying informed about these essential components, you can make better decisions regarding maintenance and repairs, ensuring your appliance operates smoothly for years to come.

Maintenance Tips for Ice Makers

Ensuring the longevity and efficiency of your freezing appliance requires regular attention and care. Implementing a routine maintenance schedule can prevent common issues and enhance performance, leading to optimal output and reliability.

- Regular Cleaning: Clean the interior and exterior frequently to remove any buildup. Use a mild detergent and warm water.

- Check Water Supply: Inspect the water line for any kinks or leaks. Ensure the connection is secure to maintain consistent flow.

- Replace Filters: Change filters as recommended to ensure clean water supply, improving the quality of the frozen product.

- Monitor Temperature: Keep an eye on the ambient temperature around the unit. It should be in a well-ventilated area to prevent overheating.

- Inspect Components: Regularly check all operational components for wear and tear, replacing any that show signs of damage.

By following these practices, you can help maintain optimal functionality and extend the lifespan of your appliance, ensuring it continues to serve your needs effectively.

Tools Needed for Repairs

Having the right equipment is crucial for successful maintenance and troubleshooting of your appliance. Proper tools not only make the process smoother but also enhance safety and efficiency. Below is a list of essential instruments that will assist you in your repair endeavors.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is essential for loosening and tightening screws.

- Wrenches: Adjustable and socket wrenches will help you tackle various nuts and bolts.

- Pliers: Needle-nose and standard pliers are useful for gripping and bending components.

- Multimeter: This tool is vital for checking electrical connections and diagnosing issues.

- Utility Knife: A sharp utility knife can assist in cutting through any packaging or insulation material.

- Flashlight: A reliable light source is necessary for illuminating dark areas within the appliance.

- Measuring Tape: Accurate measurements can help ensure components fit properly during reassembly.

Equipping yourself with these tools will facilitate a more effective and efficient repair process, ultimately extending the life of your appliance.

DIY Troubleshooting Techniques

When appliances encounter issues, understanding basic troubleshooting techniques can empower homeowners to identify and resolve problems without the need for professional help. By exploring simple methods, you can often diagnose issues efficiently, saving time and money.

Common Issues and Solutions

| Issue | Potential Causes | Solutions |

|---|---|---|

| Not Producing Enough Frozen Items | Clogged lines, low water supply, or malfunctioning components | Check water line for blockages, ensure proper water supply, inspect internal parts |

| Unusual Noises | Loose components, ice buildup, or motor issues | Tighten any loose parts, clear any obstructions, listen for motor sounds |

| Water Leaking | Damaged seals, blocked drainage, or improper installation | Inspect seals for wear, ensure drainage path is clear, review installation steps |

Step-by-Step Troubleshooting

Begin your troubleshooting process by examining the appliance’s user manual for specific guidance. Then, follow these general steps:

1. Disconnect the unit from power to ensure safety.

2. Conduct a visual inspection for any obvious signs of wear or damage.

3. Test individual components systematically to isolate the issue.

4. Reconnect power and observe the appliance’s operation after each change.

Where to Find Genuine Parts

Finding authentic components for your appliances can be crucial for maintaining their efficiency and longevity. Relying on original elements ensures that your equipment operates as intended, preventing potential issues caused by inferior substitutes.

One of the best resources for sourcing high-quality components is the manufacturer’s official website. They often provide detailed catalogs of available items, ensuring that you can easily identify what you need. Additionally, authorized retailers frequently offer genuine replacements, making it simple to purchase reliable options.

Another excellent avenue is specialty appliance shops, which often stock a variety of original elements. Staff members in these stores are typically knowledgeable and can assist you in selecting the right part for your specific model.

For those who prefer online shopping, reputable e-commerce platforms also feature sections dedicated to original components. Always verify the seller’s credentials and check customer reviews to ensure you are purchasing from a trustworthy source.

Lastly, consider joining online forums or communities focused on home appliances. Fellow enthusiasts often share recommendations for where to find authentic elements and may even provide tips on installation.

Enhancing Ice Maker Performance

Optimizing the functionality of your refrigeration unit is essential for achieving consistent and high-quality output. Several factors can influence efficiency, from regular maintenance to understanding the underlying components that contribute to overall operation. Focusing on these elements can lead to improved results and extended lifespan.

Regular Maintenance

Consistent upkeep is crucial for ensuring effective operation. This includes cleaning and checking for any wear and tear that could affect performance. Regular inspections can prevent minor issues from escalating into significant problems.

Understanding Components

A thorough knowledge of individual components and their roles can significantly enhance functionality. Each element plays a critical part in the overall process, and recognizing how they interact allows for better troubleshooting and maintenance.

| Component | Function |

|---|---|

| Water Supply | Delivers necessary liquid for freezing |

| Freezer Thermostat | Regulates temperature for optimal freezing |

| Evaporator Coil | Facilitates the freezing process |

| Fan | Distributes cold air evenly |