Understanding the Generac GP7500E Parts Diagram

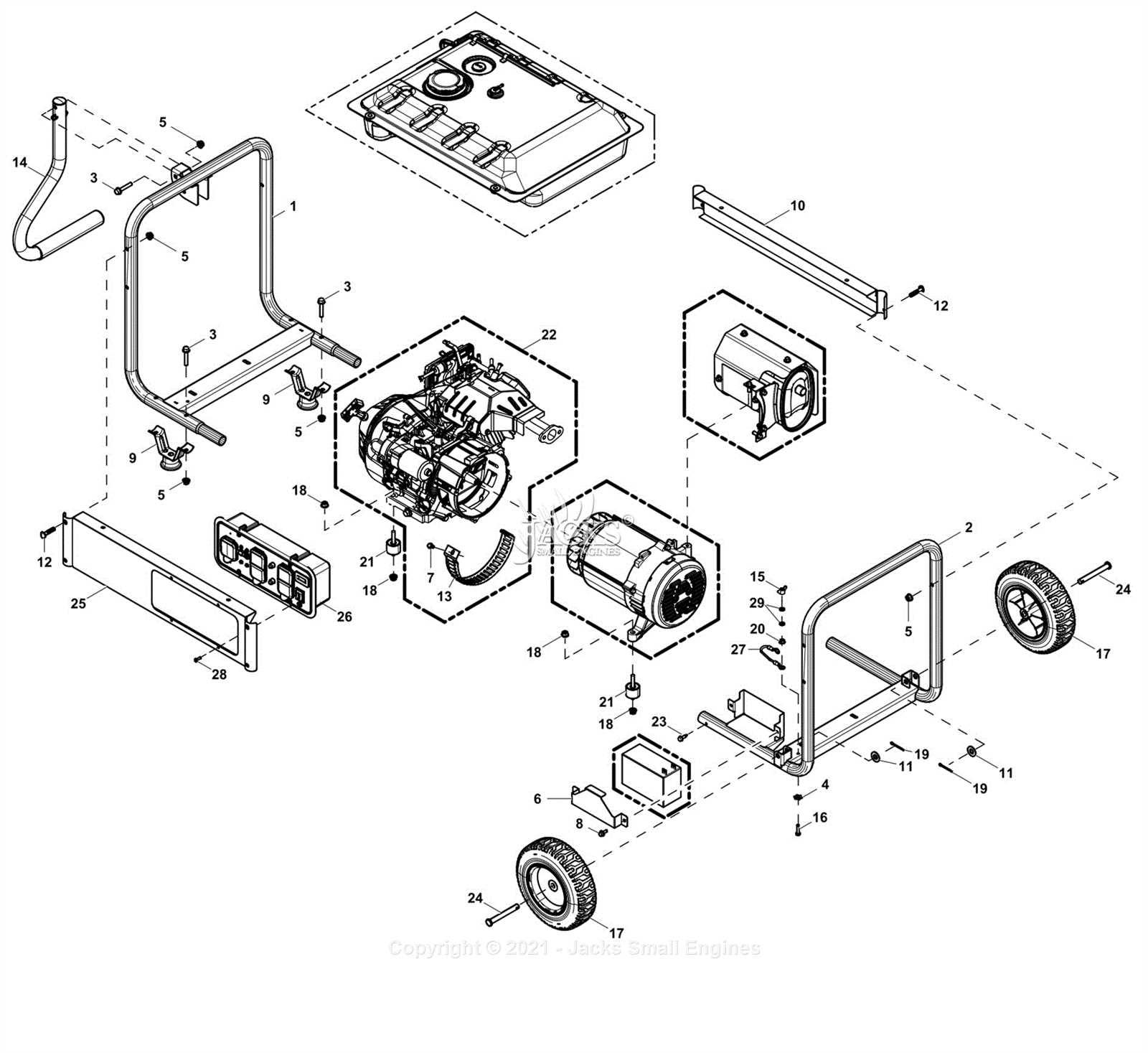

In the realm of portable energy solutions, comprehending the arrangement and functionality of various elements is crucial for effective operation and maintenance. A clear visualization of these components not only aids in troubleshooting but also enhances the overall user experience. Grasping how each part interrelates fosters a deeper appreciation of the device’s mechanics.

Visual guides serve as invaluable resources, allowing users to identify and locate essential sections swiftly. These illustrations provide a roadmap that simplifies the complexities of generator assemblies. With a better understanding of how each element fits together, users can ensure their equipment runs smoothly and efficiently.

Furthermore, familiarizing oneself with the individual components enhances the ability to perform routine inspections and replacements. Recognizing potential wear and tear becomes more manageable, ultimately prolonging the life of the machinery. This proactive approach not only saves time but also reduces the likelihood of unexpected failures.

Understanding the Generac GP7500E

This section provides a comprehensive overview of a robust portable power solution designed for versatility and reliability. Understanding its components and functionality is essential for effective usage and maintenance. This device is engineered to meet diverse power needs, making it suitable for various applications, from home backup during outages to outdoor activities.

Key Features

Equipped with a powerful engine and various outputs, this generator is built to deliver dependable electricity. It boasts several features that enhance performance and user experience:

| Feature | Description |

|---|---|

| Engine Power | High-performance engine ensuring consistent power delivery. |

| Fuel Type | Operates on gasoline, providing flexibility and ease of refueling. |

| Portability | Wheeled design for easy transportation across various terrains. |

| Runtime | Extended runtime allowing for prolonged usage without frequent refueling. |

Maintenance Tips

Regular upkeep is vital to ensure longevity and efficiency. Routine checks of oil levels, air filters, and spark plugs can prevent potential issues. Proper storage practices, especially during off-seasons, will also contribute to optimal performance when needed.

Importance of Parts Diagrams

Understanding the intricate details of machinery and equipment is crucial for effective maintenance and repair. Visual representations play a vital role in simplifying complex assemblies, making it easier for users to identify components and their functions.

- Enhancing Clarity: Visual aids eliminate ambiguity, allowing users to see how different elements fit together.

- Streamlining Repairs: Accessing a visual reference expedites the troubleshooting process, saving time and effort.

- Facilitating Ordering: Clear depictions assist in identifying and sourcing specific items when replacements are necessary.

In addition to aiding in repairs, these illustrations can serve as valuable educational tools, helping new users familiarize themselves with the equipment. This knowledge fosters confidence and proficiency, ultimately leading to more effective operations.

- Reducing Errors: Accurate visual guides minimize the risk of mistakes during assembly or disassembly.

- Improving Safety: Knowing the layout of components can prevent accidents and ensure safe handling of machinery.

In conclusion, comprehensive visual references are essential for anyone involved in the upkeep or operation of machinery, ensuring a smoother and more efficient experience.

Key Components of the GP7500E

This section explores the essential elements that contribute to the efficient operation of the portable power generator. Understanding these key components is crucial for both maintenance and troubleshooting, ensuring reliability during usage.

Power Generation Unit

The heart of any generator is its power generation unit. This component transforms mechanical energy into electrical energy, providing the necessary output for various applications. Typically featuring a robust engine, it ensures sustained performance even under demanding conditions.

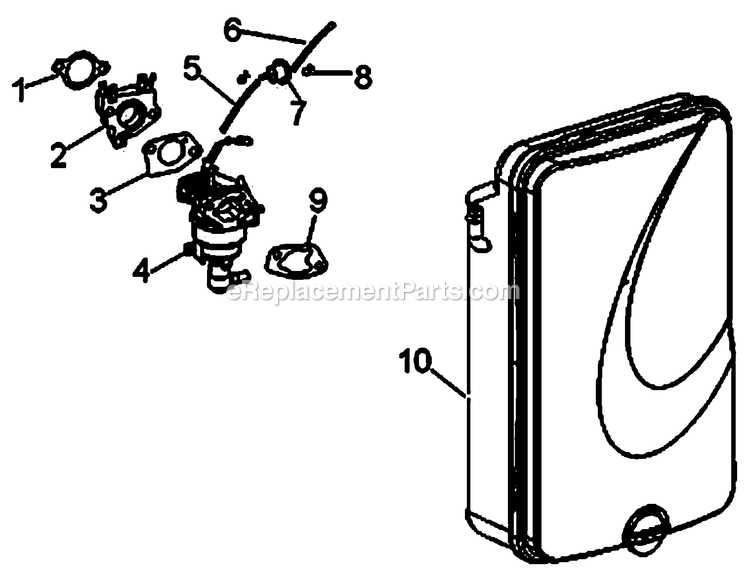

Fuel System

A reliable fuel system is vital for optimal performance. This includes the fuel tank, lines, and filters, all of which work together to supply the engine with the necessary fuel. Regular checks on this system can prevent common issues such as blockages and leaks, maintaining efficiency over time.

Regular maintenance of these critical parts will enhance the longevity and performance of the device, making it an indispensable tool for power needs.

How to Read a Parts Diagram

Understanding a schematic representation of components can significantly enhance your ability to identify, locate, and replace essential elements of your equipment. These visual guides provide a comprehensive view, making it easier to follow the assembly and disassembly processes.

To effectively interpret such illustrations, consider the following steps:

- Familiarize Yourself with Symbols: Recognize the common symbols used to represent different parts. Each element is usually depicted with a unique graphic, making identification straightforward.

- Study the Layout: Observe how components are arranged. The organization often indicates the sequence of assembly or the relationship between various parts.

- Reference the Legend: Most diagrams include a legend or key that explains each symbol. This resource is invaluable for accurate interpretation.

- Identify Connections: Pay attention to lines or arrows that indicate how parts connect or interact. Understanding these relationships is crucial for proper installation or replacement.

- Cross-Check with the Manual: Use the accompanying documentation for detailed information about each component. This can help clarify any uncertainties you may encounter.

By mastering these techniques, you will enhance your proficiency in navigating and utilizing visual representations, ultimately leading to more efficient maintenance and repair tasks.

Common Issues with Portable Power Units

In the realm of portable electrical generators, various recurrent challenges can arise, impacting their functionality and reliability. These issues span a spectrum from routine maintenance concerns to more intricate mechanical faults.

Fuel System Problems

One prevalent area of concern involves difficulties within the fuel system. This encompasses issues such as fuel leaks, clogged fuel filters, and carburetor malfunctions. These problems can hinder the generator’s ability to start or maintain consistent power output, often necessitating meticulous inspection and cleaning.

Electrical Component Failures

Another significant category of issues revolves around electrical components. This includes problems with the ignition system, voltage regulators, and wiring connections. Electrical failures can lead to erratic performance or complete operational shutdowns, requiring systematic troubleshooting and, at times, replacement of faulty parts.

| Issue | Symptoms | Solutions |

|---|---|---|

| Fuel System | Difficulty starting, inconsistent power output | Inspect fuel lines, clean carburetor, replace filters |

| Electrical Components | Ignition failures, voltage irregularities | Check wiring, test ignition system, replace faulty components |

Identifying Replacement Parts Easily

When it comes to maintaining equipment, recognizing the correct components for replacement can significantly enhance performance and longevity. Knowing how to identify these elements streamlines repairs and minimizes downtime.

To simplify the identification process, consider the following strategies:

- Consult the Manual: The owner’s manual is a valuable resource, providing specific details about each component, including part numbers and descriptions.

- Online Resources: Various websites offer detailed catalogs and guides, making it easier to locate the necessary components.

- Visual References: Utilize clear images or diagrams available online to understand the layout and functions of different elements.

- Ask Professionals: If in doubt, consult with technicians or customer support for expert guidance in identifying the correct items.

By employing these methods, you can efficiently pinpoint the required components and ensure your equipment remains in top condition.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your equipment requires regular care and attention. By following a few essential maintenance practices, you can significantly extend the lifespan and efficiency of your device, keeping it in optimal condition for years to come.

- Regular Inspection: Routinely check the unit for any signs of wear or damage. Look for loose connections, leaks, or unusual noises that may indicate potential issues.

- Clean Filters: Keep air and fuel filters clean to ensure efficient operation. Replace them as recommended by the manufacturer to maintain performance.

- Change Oil: Regular oil changes are crucial. Use high-quality oil and replace it according to the maintenance schedule to protect internal components.

- Fuel Management: Use fresh fuel and store it properly. Consider adding a fuel stabilizer if the equipment will not be used for an extended period.

- Battery Care: Check the battery regularly. Clean terminals and ensure proper connections to avoid starting issues.

By adhering to these practices, you can enhance the reliability and durability of your equipment, ensuring it remains a dependable resource when needed most.

Where to Find Authentic Parts

Locating genuine components for your equipment is crucial for optimal performance and longevity. Various sources provide assurance of quality and reliability, making it essential to know where to search.

| Source | Description |

|---|---|

| Manufacturer’s Website | The official site often has a dedicated section for genuine items, ensuring authenticity. |

| Authorized Dealers | Certified retailers offer original items and often provide expert advice. |

| Online Marketplaces | Reputable platforms can be useful, but verify seller ratings and product descriptions. |

| Local Repair Shops | Local professionals may stock genuine items and can assist with installation. |

Benefits of Using Original Components

Utilizing authentic parts in machinery ensures optimal performance and longevity. These components are designed specifically for compatibility, enhancing the overall functionality and reliability of the equipment.

Quality Assurance

Original components undergo rigorous testing, guaranteeing a level of quality that aftermarket alternatives may not provide. This results in:

- Increased durability

- Reduced risk of failure

- Consistent performance

Warranty Protection

Choosing genuine parts often helps maintain warranty coverage. This can lead to:

- Financial savings on repairs

- Peace of mind regarding maintenance

- Support from the manufacturer

Step-by-Step Repair Process

This section outlines a comprehensive guide for restoring functionality to your equipment. By following these systematic steps, you can efficiently address common issues and ensure optimal performance.

Assessment and Preparation

Begin by evaluating the device to identify any visible signs of wear or damage. Gather the necessary tools and replacement components before starting the repair. Safety first: always disconnect the power supply to prevent accidents.

Disassembly and Repair

Carefully disassemble the unit, taking note of the arrangement of parts for easy reassembly. Replace any faulty components and clean any dirt or debris that may hinder performance. Attention to detail during this phase is crucial for a successful repair.