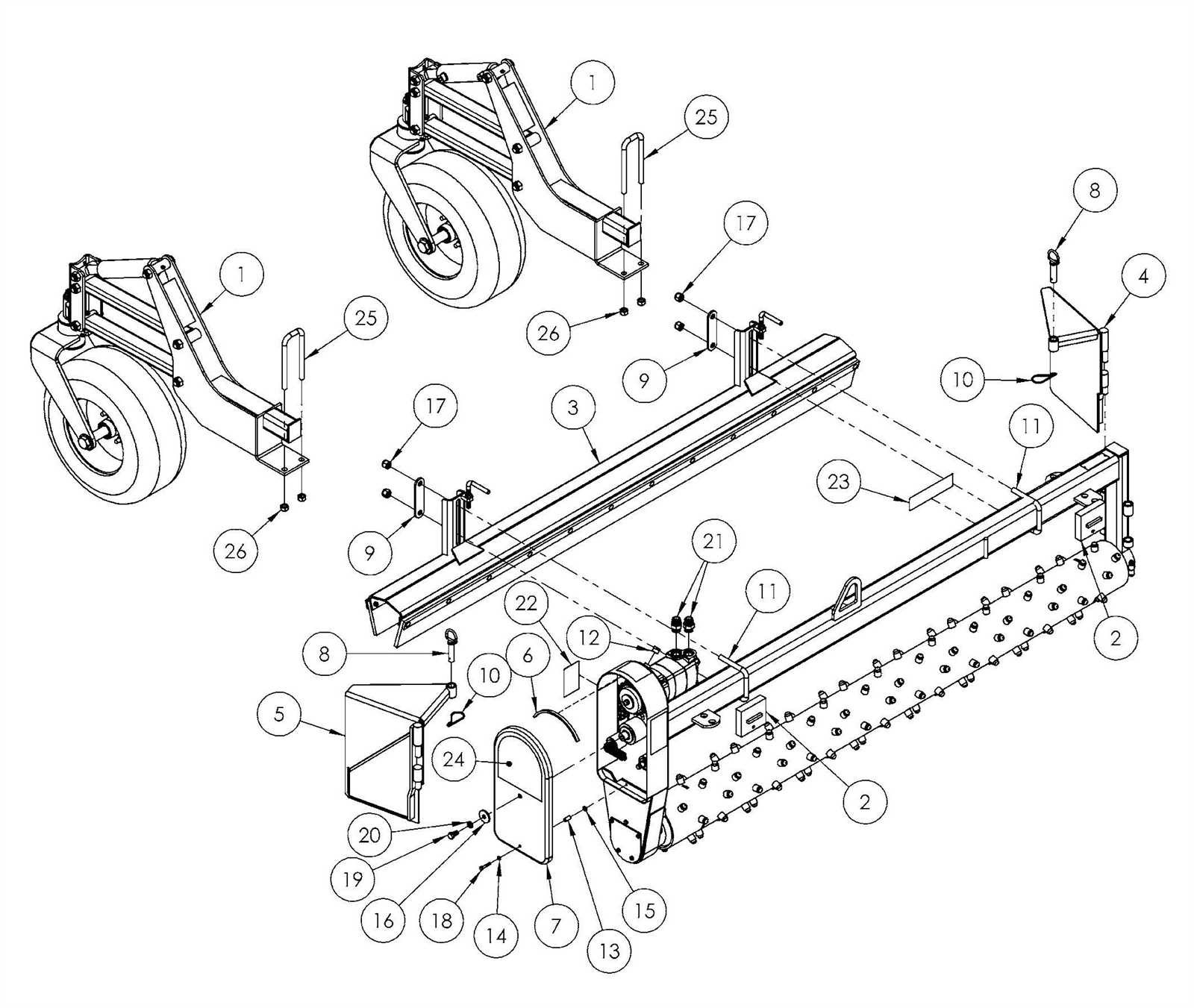

Understanding the Harley Rake Parts Diagram for Optimal Performance

Exploring the intricate elements of a specialized ground-leveling implement reveals the essential features that contribute to its efficiency. Each component plays a pivotal role in the overall functionality, ensuring that the equipment performs optimally in various terrains. By examining these elements, users can gain insight into the operational mechanics that drive effective soil management.

From the cutting edges to the frame, every section of this machinery is meticulously designed for specific tasks. Knowledge of these components not only aids in maintenance but also enhances the user’s ability to troubleshoot issues that may arise during operation. Understanding how each piece interacts with the others is crucial for achieving the desired results in landscaping and construction projects.

In the following sections, we will delve deeper into the individual elements, offering a comprehensive overview that will serve as a valuable resource for both seasoned operators and newcomers. By familiarizing oneself with the intricate layout of this tool, one can significantly improve both performance and longevity.

Understanding Harley Rake Components

Exploring the intricacies of a specific attachment reveals a range of essential elements that contribute to its overall functionality. Each component plays a crucial role in ensuring efficiency and performance, making it important to grasp their individual purposes and interconnections.

Main Elements

The primary elements consist of structural frameworks, blades, and support systems, each designed to enhance usability. The framework provides stability, while the blades are engineered for precise ground manipulation. Support systems ensure durability and adaptability to various terrains.

Understanding how these components work together allows operators to optimize performance during use. Proper maintenance and knowledge of each element can lead to improved outcomes, ultimately achieving the desired results in any landscaping or construction task.

Importance of Rake Parts in Landscaping

In the realm of outdoor design, specific components play a crucial role in achieving optimal results. Understanding the significance of these elements can enhance both the functionality and aesthetics of a landscaped area.

Key reasons for the importance of these components include:

- Soil Preparation: Essential for creating a level and smooth surface, which promotes healthy plant growth.

- Debris Removal: Efficiently clears unwanted materials, ensuring a clean and tidy environment.

- Material Distribution: Aids in evenly spreading mulch, soil, or gravel, contributing to effective drainage and plant health.

Moreover, the quality of these components can greatly influence the overall effectiveness of landscaping tasks. Investing in durable and efficient tools can lead to:

- Time savings in project completion.

- Improved results in landscaping design.

- Enhanced ease of use, reducing physical strain.

Ultimately, the thoughtful selection and maintenance of these crucial elements will significantly impact the success of any outdoor project.

Common Issues with Harley Rake Parts

Equipment used for landscaping and soil preparation often encounters various challenges that can hinder performance and efficiency. Understanding these common problems is essential for ensuring optimal functionality and longevity of the machinery.

One frequent issue involves wear and tear on components, leading to decreased effectiveness in soil leveling and debris removal. This can result from prolonged use or exposure to harsh conditions. Regular inspections and timely replacements are crucial to maintain peak performance.

Another common concern is misalignment of parts, which can cause uneven operation and potential damage. Proper calibration and alignment checks should be a part of routine maintenance to prevent these complications.

Additionally, hydraulic system failures may arise due to leaks or pump malfunctions, impacting the overall operation of the equipment. Ensuring that all hydraulic lines are intact and regularly serviced can mitigate these issues.

Maintenance Tips for Harley Rake Equipment

Proper upkeep of your landscaping machinery is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances functionality but also prevents costly repairs down the line. Here are some key tips to keep your equipment in excellent working condition.

Regular Inspections

- Check for any visible signs of wear or damage before each use.

- Inspect hydraulic lines and connections for leaks or cracks.

- Ensure that all fasteners and bolts are secure.

Lubrication and Cleaning

- Apply appropriate lubricants to moving parts as recommended by the manufacturer.

- Clean the machinery after each use to remove debris and prevent rust.

- Pay special attention to bearings and gears, ensuring they are free from dirt.

By following these maintenance tips, you can enhance the efficiency and lifespan of your equipment, allowing for better performance on the job site.

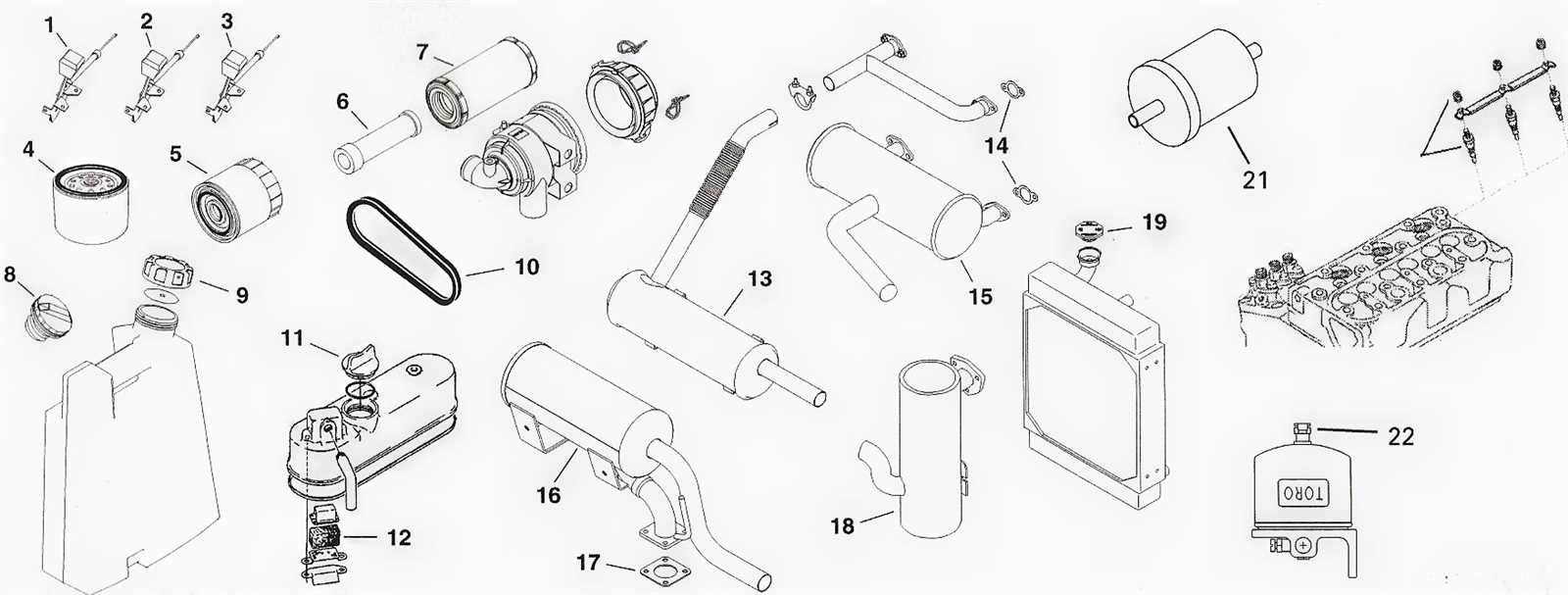

How to Identify Part Numbers

Understanding how to recognize component identifiers is crucial for anyone involved in maintenance or repair. These identifiers serve as essential references, ensuring you select the correct elements for your machinery or equipment. Proper identification not only aids in efficiency but also guarantees compatibility and functionality.

Key Steps for Identification

- Check Manufacturer’s Documentation

- Examine Existing Components

- Utilize Online Resources

- Consult with Professionals

Tips for Accurate Identification

- Look for Serial Numbers: Often found on the component itself.

- Take Note of Shapes and Sizes: Physical dimensions can be indicative of specific items.

- Consider Application Context: Understanding where and how the item is used can narrow down options.

By following these guidelines, you can enhance your ability to pinpoint the exact identifiers needed for your tasks, leading to successful repairs and maintenance.

Best Practices for Rake Assembly

Assembling equipment components requires attention to detail and a systematic approach to ensure optimal performance and longevity. Following best practices during assembly can help avoid common pitfalls and enhance overall functionality.

- Preparation: Gather all necessary tools and components before starting the process. This minimizes interruptions and ensures a smooth workflow.

- Clean Workspace: Maintain a tidy environment to reduce the risk of losing parts and to facilitate easier handling of components.

- Follow Manufacturer Instructions: Always refer to the official guidelines for assembly. This helps in understanding specific requirements and avoiding mistakes.

Proper alignment is crucial in ensuring that all components fit together seamlessly. Pay close attention to each piece and how they interact with one another.

- Check for Compatibility: Verify that all components are suitable for use together to prevent any operational issues.

- Use the Right Tools: Employ the appropriate tools to avoid damage and ensure a secure fit.

- Secure Fastenings: Ensure that all connections are tightened to the manufacturer’s specifications to maintain structural integrity.

Lastly, conduct a thorough inspection after assembly. This final check can catch any overlooked issues and help confirm that everything is in proper working order.

Where to Find Replacement Parts

Locating the necessary components for your equipment can significantly enhance its performance and longevity. Understanding the best sources for acquiring these essentials is crucial for any maintenance or restoration project.

One of the most reliable options is to visit local dealerships that specialize in your brand. These establishments often carry a wide array of components, ensuring compatibility with your specific model. Additionally, knowledgeable staff can provide valuable insights and recommendations.

Online retailers offer another convenient avenue, with numerous websites dedicated to selling various components. Many of these platforms feature user-friendly search tools, making it easy to find exactly what you need. Customer reviews and ratings can also guide you in making informed decisions.

For those seeking cost-effective solutions, consider exploring second-hand marketplaces or forums dedicated to enthusiasts. Here, you can often find gently used items at a fraction of the cost, alongside opportunities for networking with other users who may have valuable information or resources.

Finally, specialized repair shops can serve as a great resource for sourcing unique or hard-to-find components. These professionals not only sell what you need but also provide expert advice and installation services, ensuring your equipment remains in peak condition.

Comparison of Different Rake Models

When exploring various types of ground preparation tools, it’s essential to recognize the unique features and functionalities each model offers. These implements are designed to meet diverse agricultural needs, and understanding their differences can aid in selecting the most suitable option for specific tasks.

Model A is known for its lightweight construction, making it ideal for small-scale operations and residential use. Its design allows for easy maneuverability, although it may not handle heavy-duty tasks as effectively as other options.

Model B, on the other hand, boasts a robust build that enhances durability and performance in larger agricultural settings. Its powerful design can tackle more demanding projects, though it may sacrifice some ease of handling compared to lighter versions.

Additionally, Model C offers advanced features, such as adjustable settings, which provide versatility for varying soil conditions. This model is perfect for those looking to optimize their workflow by adapting to different tasks quickly.

Ultimately, the choice between these models should be guided by specific requirements, including the scale of work and the type of terrain being addressed. By delving into these comparisons, users can make informed decisions that enhance efficiency and productivity.

Safety Precautions During Use

Ensuring a secure working environment is essential when operating any equipment. Following specific guidelines can prevent accidents and promote safe practices. Always prioritize personal safety and the safety of those around you.

General Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Inspect the machinery before each use to ensure it is in good working condition.

- Keep the work area clear of obstacles and debris to prevent tripping hazards.

Operational Precautions

- Read and understand the operating manual thoroughly before use.

- Never exceed the manufacturer’s recommended capacity and usage limits.

- Stay alert and avoid distractions while operating the machinery.

Innovative Upgrades for Rake Efficiency

Enhancing the performance of soil cultivation tools can significantly improve productivity and reduce labor intensity. By integrating advanced features and technologies, users can maximize the effectiveness of their equipment. This section explores various upgrades that can lead to improved functionality and efficiency.

- Durable Materials: Utilizing high-strength alloys or composite materials can enhance durability and reduce wear over time.

- Adjustable Width: Implementing mechanisms for width adjustment allows for versatile usage across different landscapes.

- Ergonomic Design: Redesigning handles and grips to fit the natural contours of the hand can decrease fatigue during prolonged use.

- Enhanced Tine Configurations: Experimenting with tine shapes and arrangements can optimize soil engagement and material collection.

- Integrated Technology: Adding sensors to monitor performance and efficiency in real-time can lead to smarter, data-driven decisions.

By focusing on these enhancements, users can ensure that their equipment is not only more effective but also tailored to their specific needs, ultimately resulting in better outcomes in various applications.

Resources for Harley Rake Owners

For enthusiasts of powerful land-leveling machinery, having access to reliable materials and support is essential for optimal performance and maintenance. A variety of resources are available to ensure that operators can make the most out of their equipment, enhance its longevity, and tackle any challenges that may arise.

Online Forums and Communities: Engaging with fellow owners through dedicated online platforms can provide invaluable insights. Members often share experiences, tips, and troubleshooting advice, creating a rich repository of knowledge.

Manufacturer’s Manuals: Comprehensive guides from the manufacturer offer detailed information about operation, maintenance, and safety protocols. These documents are crucial for understanding the functionality and care of the machine.

Local Dealerships: Authorized dealers can be a reliable source of components and expert advice. They often have trained staff who can assist with specific queries and recommend appropriate upgrades.

Instructional Videos: Visual learning through tutorials and maintenance videos can significantly help in grasping complex tasks. Platforms like YouTube host numerous channels dedicated to equipment handling and repair.

Workshops and Training Sessions: Participating in hands-on workshops can enhance your skills and knowledge about the machinery. These events often feature expert instructors who provide personalized guidance.

Maintenance Checklists: Keeping a checklist for regular upkeep can streamline maintenance routines. These lists help in tracking essential tasks and ensuring that all aspects of the machinery are in optimal condition.

Utilizing these resources effectively can empower operators, leading to improved efficiency and satisfaction in their work. Staying informed and connected within the community fosters a deeper understanding and appreciation of this powerful equipment.