Comprehensive Guide to Dayton Heater Parts Diagram

When it comes to maintaining warmth in our spaces, a thorough comprehension of the various components involved is essential. These devices consist of numerous elements that work together to ensure efficient operation and comfort. Familiarizing oneself with these parts can greatly enhance the effectiveness of troubleshooting and repairs.

Each individual piece plays a critical role in the overall functionality of the unit. From the ignition system to the airflow mechanisms, understanding how these components interact can lead to better maintenance practices. Whether it’s for residential or commercial settings, knowledge of these essential elements can significantly impact performance and longevity.

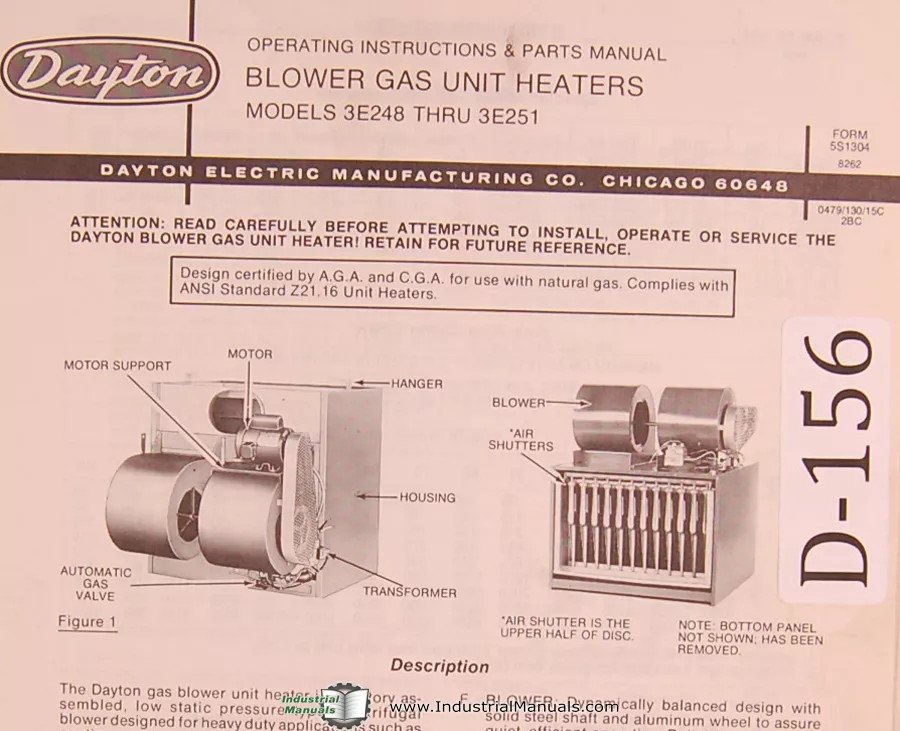

For those seeking to dive deeper into the specifics, visual aids can provide clarity. Illustrated guides serve as valuable resources, enabling users to identify and understand each component’s purpose and position within the assembly. This approach not only simplifies repair tasks but also empowers users to take proactive measures in ensuring their devices operate at peak efficiency.

Understanding Dayton Heater Functionality

This section aims to explore the mechanics behind thermal devices commonly used for providing warmth in various environments. By examining the inner workings, users can gain insights into how these systems operate efficiently and effectively.

Thermal Regulation: At the core of these systems is the principle of heat generation and distribution. Various components work together to ensure that warmth is evenly spread, adapting to changing temperature needs.

Control Mechanisms: Advanced systems often include thermostats and sensors that monitor ambient conditions, allowing for automatic adjustments. This feature enhances energy efficiency while maintaining comfort.

Safety Features: Modern units are equipped with multiple safeguards to prevent overheating and other hazards. These elements ensure reliability and peace of mind for users.

Maintenance Considerations: Regular upkeep is essential for optimal performance. Understanding the function of each component can aid in timely inspections and replacements, extending the lifespan of the unit.

Common Issues with Dayton Heaters

Understanding the typical problems associated with heating devices can help in maintaining their efficiency and longevity. Users often encounter a variety of malfunctions that can hinder performance, leading to discomfort in colder months. Identifying these issues early can facilitate timely repairs and enhance overall functionality.

No Power Supply: One of the most frequent issues is a complete lack of power. This can stem from tripped breakers, blown fuses, or faulty power cords. Checking these components should be the first step in troubleshooting.

Inconsistent Heat Output: Many users report fluctuations in temperature. This could be caused by a malfunctioning thermostat or a buildup of dust and debris within the unit. Regular cleaning and calibration can often resolve this problem.

Unusual Noises: Strange sounds can indicate mechanical problems, such as loose components or worn-out parts. If the device starts to make clanking, buzzing, or grinding noises, it’s crucial to inspect it to prevent further damage.

Odors: Unpleasant smells emanating from the unit can signal overheating or burning dust. Ensuring proper ventilation and conducting routine cleanings can mitigate these odors and improve air quality.

Malfunctioning Safety Features: Safety mechanisms are designed to prevent accidents, but they can sometimes fail. If the unit shuts off unexpectedly or exhibits warning lights, it’s essential to consult a professional to address these safety concerns.

Identifying Key Components

Understanding the essential elements of a heating system is crucial for effective maintenance and troubleshooting. Each component plays a specific role in ensuring optimal performance and efficiency. Recognizing these parts helps users to diagnose issues and undertake appropriate corrective actions.

Main Elements

- Power Supply: This is the source of energy, often electrical, that powers the entire system.

- Thermostat: A device that regulates the temperature by switching the heating element on or off based on the set temperature.

- Blower Fan: Responsible for circulating warm air throughout the space, enhancing comfort levels.

- Heating Element: The core component that generates heat, which can vary in type depending on the system design.

Auxiliary Components

- Safety Switch: Ensures that the unit operates safely, shutting down in case of malfunctions.

- Filter: Captures dust and debris, maintaining air quality and system efficiency.

- Ductwork: Channels that distribute warm air to different areas, crucial for even heating.

- Control Panel: The interface for users to set and adjust temperature settings and system operations.

Familiarity with these elements not only aids in effective troubleshooting but also enhances the overall understanding of system functionality and maintenance needs.

How to Read Parts Diagrams

Understanding schematics is essential for effective maintenance and repair. These visual representations offer clarity on how components interact and function within a system. By familiarizing yourself with the layout and symbols, you can navigate the complexities with confidence.

Identifying Key Elements

Focus on the main components highlighted in the illustration. Each part is typically labeled, providing crucial information about its role and connection points. Pay attention to the legend, as it explains the symbols used, enhancing your comprehension.

Following the Flow

Trace the connections and pathways illustrated. This will help you visualize how energy or resources move through the system. Understanding this flow is critical for diagnosing issues and determining the ultimate cause of any malfunction.

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan and efficiency of your heating appliance. Regular attention to its components not only ensures reliable performance but also prevents costly repairs down the line. Here are some effective strategies to maintain optimal functionality.

Regular Cleaning

Keeping the unit clean is crucial. Dust and debris can accumulate and hinder performance. Ensure that the exterior and surrounding areas are free from obstructions.

Check and Replace Filters

Filters play a vital role in maintaining air quality and efficiency. Regularly inspect them and replace as necessary to ensure smooth airflow.

| Task | Frequency |

|---|---|

| Clean exterior | Monthly |

| Inspect filters | Every 3 months |

| Professional check-up | Annually |

Replacement Parts: What You Need

When it comes to maintaining your heating equipment, understanding the components that may require substitution is crucial. Regular wear and tear can lead to diminished performance, making it essential to identify the necessary replacements to ensure optimal functionality.

Common components that often need replacing include elements, thermostats, and fans. Each of these items plays a vital role in the overall operation, and selecting the right alternatives can enhance efficiency and longevity.

Before purchasing, it’s important to consult the manufacturer’s specifications to ensure compatibility. Taking the time to identify specific models and technical details will save you both time and money in the long run.

In addition, consider the quality of the replacements. Opting for high-grade materials can significantly affect the performance and durability of your unit. Investing in reliable components will provide peace of mind and improve your system’s reliability.

Safety Features of Dayton Heaters

Ensuring a secure environment is paramount when utilizing any heating device. The integration of advanced protective measures not only enhances performance but also minimizes risks associated with operation. Various safety innovations are designed to provide peace of mind while delivering warmth effectively.

Overheat Protection

One of the most crucial safety mechanisms is overheat protection. This feature automatically shuts off the device when it detects excessive temperatures, preventing potential fires or damage. Such proactive measures are essential for maintaining safe operation in any setting.

Tip-Over Switch

A tip-over switch is another vital component that ensures safety. If the unit is accidentally knocked over, this switch immediately cuts power, reducing the likelihood of accidents or hazardous situations. This feature is especially important in homes with pets or small children, providing an ultimate layer of security.

Wiring and Electrical Connections

Understanding the intricate web of electrical connections is crucial for optimal operation and safety. Proper wiring not only ensures efficient functionality but also minimizes the risk of electrical failures. Each component must be accurately connected to maintain a seamless flow of electricity throughout the system.

Color coding is an essential aspect of electrical installations, providing a quick reference for identifying wires and their respective functions. Common colors include black for hot wires, white for neutral, and green or bare for ground connections. Adhering to these conventions can prevent confusion and enhance safety during maintenance or repairs.

When making connections, quality matters. Utilize durable connectors and ensure that all joints are secure to avoid any potential hazards. It is advisable to inspect the wiring regularly for signs of wear or damage, as even minor issues can lead to significant problems if left unaddressed.

Additionally, understanding the overall electrical load is vital. Each component draws a specific amount of current, and exceeding the system’s capacity can lead to overheating and possible failure. Familiarity with the system’s specifications and adhering to recommended guidelines will promote longevity and efficiency.

In summary, thorough knowledge of wiring and electrical connections is fundamental for maintaining a safe and effective system. Attention to detail in connections and regular inspections can ensure smooth operation and prevent potential hazards.

Choosing the Right Parts Supplier

Selecting a suitable vendor for components is crucial for ensuring quality and reliability in any project. The right supplier can significantly impact performance, longevity, and overall satisfaction. It’s essential to assess various aspects, such as product variety, pricing, customer service, and delivery times.

When exploring options, consider the vendor’s reputation within the industry. Reviews and testimonials can provide insights into their reliability and the quality of their offerings. Additionally, ensuring that the supplier has a comprehensive inventory can save time and effort in sourcing necessary items.

Evaluating the support services provided by the supplier is equally important. Effective communication and assistance in addressing issues or queries can enhance the purchasing experience. Opting for a supplier that prioritizes customer care fosters a productive partnership.

Finally, look for a vendor that aligns with your specific needs, whether it’s budget constraints or specialized requirements. Making an informed choice will ultimately lead to successful outcomes and satisfaction with your project.

Steps for Disassembling Your Heater

Disassembling your unit requires careful planning and attention to detail. Following a systematic approach will ensure you can safely access internal components while minimizing the risk of damage. Below are essential steps to guide you through the process.

Preparation

Before beginning, make sure to gather the necessary tools, including screwdrivers, pliers, and a multimeter. Safety first: disconnect the power source and allow the appliance to cool down completely. This will prevent any accidents and ensure a smooth disassembly.

Step-by-Step Disassembly

Start by removing the outer casing. Typically, this involves unscrewing a few screws located at the back or sides. Once the casing is off, carefully detach any wiring harnesses, noting their original positions for reassembly later. Next, remove the internal components such as fans or heating elements by loosening screws or clips. Handle each piece gently to avoid causing any damage. Finally, organize the components as you take them apart, making the reassembly process much easier.

Troubleshooting Heating Problems

When facing issues with your warming system, it’s essential to identify and address the root causes efficiently. Understanding common malfunction signs can guide you in diagnosing problems, ensuring your environment remains comfortable. Regular checks and informed assessments can save time and resources while enhancing the overall functionality of the unit.

Common Issues and Solutions

Several factors can lead to inadequate performance, such as inconsistent temperatures or unusual noises. Start by examining the power supply and connections. If the unit fails to activate, a blown fuse or tripped circuit breaker may be the culprit. Additionally, inspect the airflow; obstructions or dirty filters can significantly affect efficiency.

Advanced Diagnostics

If basic troubleshooting doesn’t resolve the issue, delve into more intricate components. Sensors, thermostats, and control boards often require testing for proper operation. Ensure all connections are secure and free of corrosion. In cases of persistent trouble, consulting a professional can provide the ultimate resolution to restore optimal function.

Enhancing Efficiency in Heating Systems

Improving performance in thermal systems is crucial for achieving optimal comfort while minimizing energy consumption. Various strategies can be employed to ensure that these systems operate at their best, ultimately leading to reduced utility costs and a smaller environmental footprint.

Key Strategies for Improvement

One effective approach is regular maintenance, which helps to identify potential issues before they escalate. Routine checks on components ensure that everything operates smoothly. Additionally, upgrading outdated elements can lead to significant efficiency gains. Consider the following measures:

| Action | Benefit |

|---|---|

| Regular Maintenance | Prevents breakdowns and optimizes performance |

| Upgrade Components | Enhances efficiency and reduces energy usage |

| Install Smart Thermostats | Allows for better control and scheduling |

| Improve Insulation | Reduces heat loss and increases overall efficiency |

Adopting Innovative Technologies

Integrating advanced technologies can further enhance system performance. Smart controls and monitoring systems allow users to track usage patterns and make informed adjustments. By utilizing modern solutions, the overall effectiveness of thermal systems can be maximized, providing greater comfort and efficiency.

Upgrading Old Models: What to Know

Modernizing outdated equipment can significantly enhance efficiency and performance. Understanding the components involved is essential for a successful transition. This section explores key considerations and best practices when undertaking such improvements.

Assessing Current Performance

Before initiating upgrades, evaluate the current functionality and identify specific limitations. Look for signs of wear and tear, energy inefficiency, or outdated technology. This assessment will guide you in selecting the most appropriate enhancements.

Choosing Compatible Upgrades

When selecting new components, ensure compatibility with existing systems. Research the latest advancements and seek out parts that optimize performance while maintaining operational integrity. Investing in quality components will yield the ultimate benefits in longevity and efficiency.