Comprehensive Guide to Honda GXV390 Parts Diagram

In the realm of small engine mechanics, grasping the intricate relationships between various components is essential for optimal performance and maintenance. A thorough examination of the structure and assembly of these machines can significantly enhance both efficiency and longevity. Mechanics and enthusiasts alike benefit from a comprehensive overview that elucidates how each piece fits within the larger system.

The importance of visual aids in understanding engine configurations cannot be overstated. By providing a clear representation of each element and its placement, these tools enable users to quickly identify potential issues and perform necessary repairs. This knowledge empowers individuals to take control of their equipment, fostering a deeper connection with the technology they work with.

Whether for routine maintenance or troubleshooting complex problems, having access to detailed schematics allows users to navigate the intricacies of engine design with confidence. This resource serves as a vital reference, guiding users through the various aspects of engine management while ensuring that every component operates harmoniously within its designated role.

Understanding Honda GXV390 Engine Parts

Grasping the components of an engine is essential for effective maintenance and repair. Each element plays a crucial role in the overall functionality and efficiency of the machine. This section delves into the various elements that constitute a specific engine model, highlighting their significance and interrelationships.

Key Components Overview

Among the primary elements are the cylinder, crankshaft, and valvetrain. The cylinder serves as the chamber where combustion occurs, while the crankshaft converts the linear motion of the pistons into rotational motion. The valvetrain, encompassing valves and associated mechanisms, regulates the flow of air and fuel into the cylinder, as well as the expulsion of exhaust gases.

Importance of Regular Maintenance

Maintaining these components is vital for longevity and optimal performance. Neglect can lead to wear and tear, resulting in decreased efficiency or potential failures. Regular checks and timely replacements of worn parts can significantly extend the life of the engine, ensuring smooth operation and reduced downtime.

Importance of a Parts Diagram

Understanding the assembly and components of machinery is essential for effective maintenance and repair. A visual representation of these elements can greatly enhance one’s ability to identify and source necessary components, ensuring smooth operation and longevity of the equipment. Having a clear reference allows users to navigate complex systems with ease, reducing downtime and improving efficiency.

Facilitating Repairs

When facing a malfunction, a visual guide serves as an invaluable tool. It simplifies the process of locating specific elements that need attention, enabling quicker diagnosis and repair. This not only saves time but also minimizes the risk of misplacing or damaging components during the disassembly process.

Enhancing Understanding

A well-structured visual guide aids in grasping how different parts interact within the system. This knowledge empowers users to make informed decisions regarding upgrades, replacements, or modifications. Ultimately, a comprehensive reference fosters confidence and competence in handling various machinery tasks.

Common Components of GXV390

Understanding the essential elements of a small engine can greatly enhance maintenance and repair efforts. Each component plays a vital role in ensuring efficient operation and longevity, making it crucial for users to be familiar with their functions and interrelationships. This section explores the typical parts found in such engines, highlighting their importance and functionality.

Engine Block and Cylinder

The core of any engine is its block, which houses the cylinder. This structure is designed to withstand high temperatures and pressures, providing a durable environment for combustion. The cylinder facilitates the intake of air and fuel, while also containing the explosion that powers the piston. Proper maintenance of these components ensures optimal performance and prevents premature wear.

Fuel System Components

A well-functioning fuel system is crucial for reliable engine operation. This includes the fuel tank, filter, and carburetor, each of which plays a distinct role. The tank stores the fuel, the filter cleans it, and the carburetor mixes it with air before entering the cylinder. Regular checks and cleaning of these parts can help maintain engine efficiency and prevent starting issues.

Where to Find the Diagram

Locating a visual representation of components for small engines can greatly assist in maintenance and repairs. Understanding the layout and function of each element ensures a smoother workflow and more efficient troubleshooting.

Online Resources

- Manufacturer’s Official Website: Many manufacturers provide detailed illustrations and manuals for their engines.

- Repair Forums: Online communities often share resources, including schematics and user-contributed guides.

- Parts Retailers: Websites specializing in engine components frequently have downloadable manuals or visual aids.

Printed Manuals

- Authorized Dealers: Visit local dealers for printed guides that may include comprehensive diagrams.

- Books and Guides: Look for printed manuals in bookstores or libraries that cover small engine maintenance.

- Online Marketplaces: Consider purchasing used manuals from platforms where individuals sell technical books.

How to Read the Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations serve as guides, allowing users to identify and locate various elements within a mechanical assembly. Familiarity with the layout and notation used in such visuals can greatly enhance your ability to troubleshoot issues and procure necessary replacements.

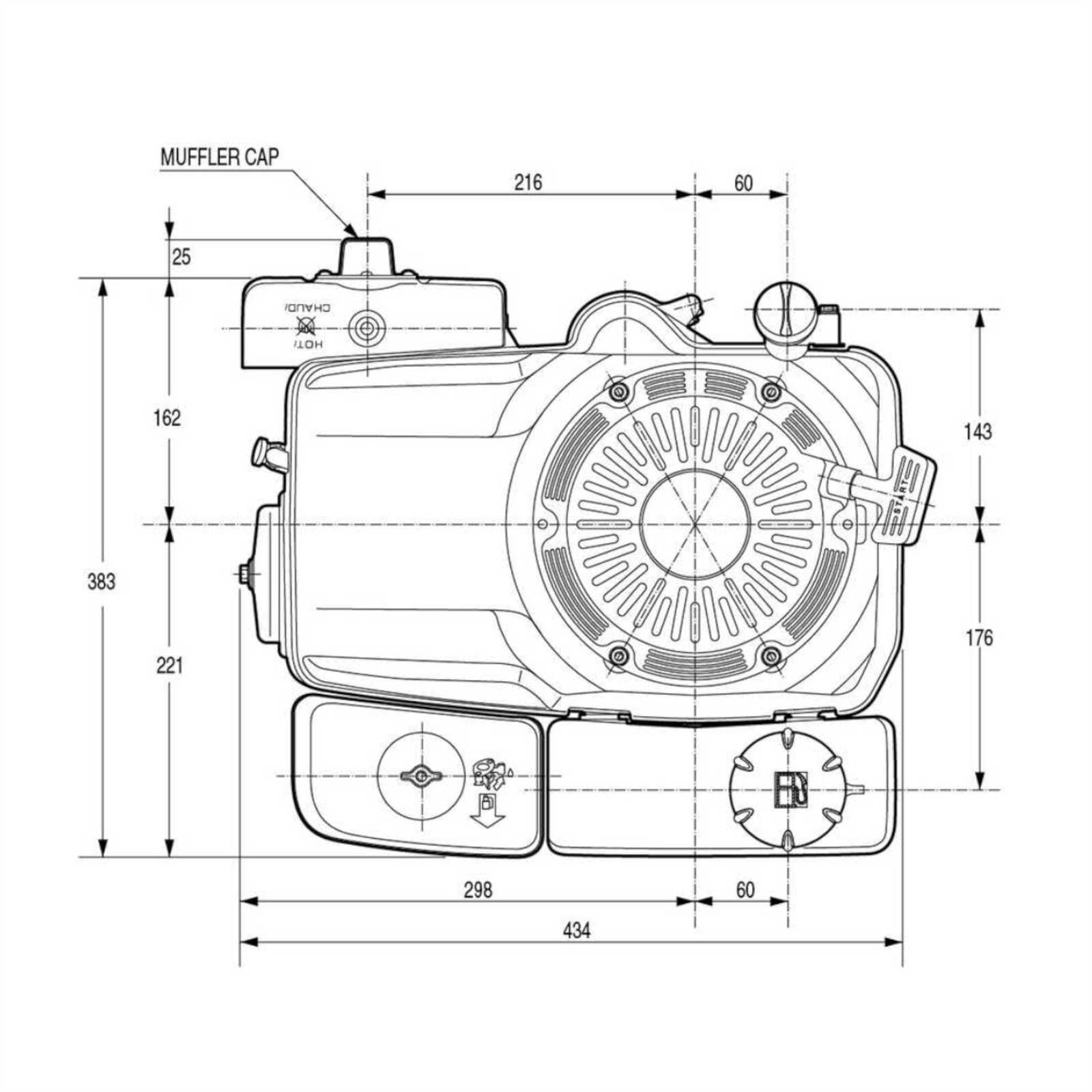

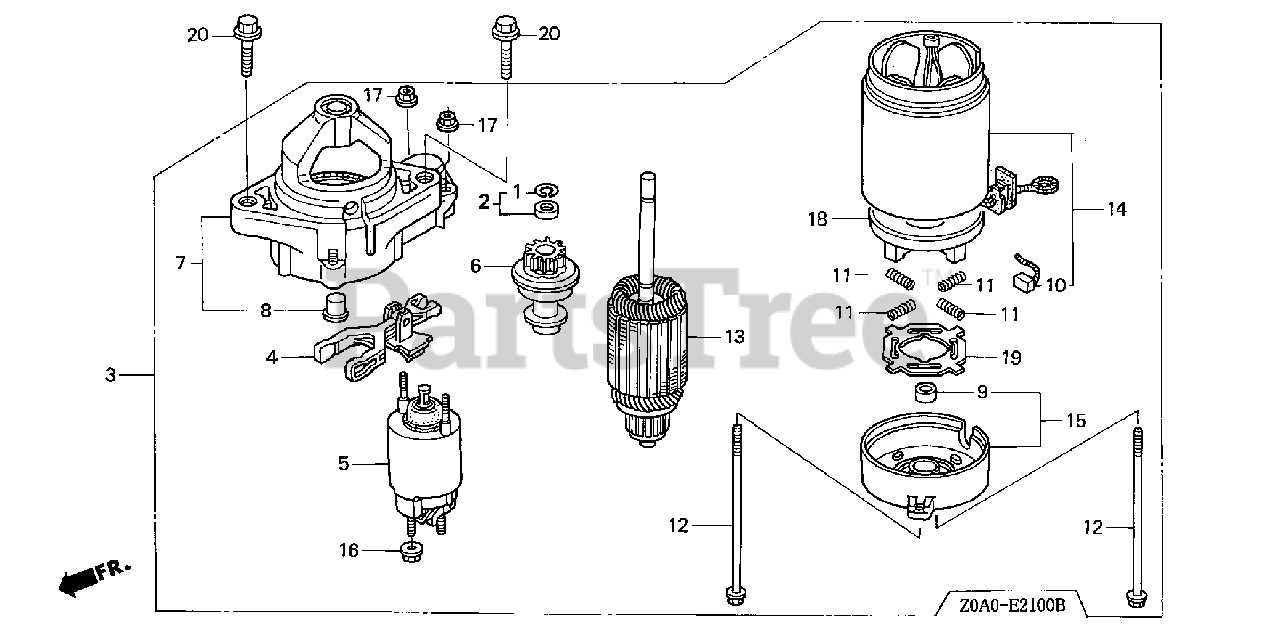

To begin, focus on the numbering system that often accompanies the visual. Each item is typically assigned a unique identifier, facilitating easy reference when ordering replacements. Take note of how parts are grouped; related components may be clustered together, which helps in understanding their function and relationship within the overall system.

Next, pay attention to the legend or key that accompanies the illustration. This guide explains symbols and color codes used, providing clarity on different materials or statuses of the components depicted. Understanding these symbols can save time and prevent confusion when sourcing the right items.

Finally, familiarize yourself with the scale of the representation. While it may not always be to scale, having a sense of size can help in visualizing the actual dimensions of each element. This knowledge is particularly useful when determining compatibility with other components or when planning for repairs.

Maintenance Tips for GXV390 Parts

Proper upkeep of your machinery is essential for ensuring longevity and optimal performance. Regular attention to various components can prevent premature wear and reduce the likelihood of unexpected breakdowns. Below are some key strategies to help you maintain your equipment effectively.

Routine Checks

- Inspect the oil level frequently, ensuring it remains within the recommended range.

- Examine air filters regularly and clean or replace them as needed to maintain airflow efficiency.

- Check fuel lines for cracks or leaks to prevent fuel wastage and ensure safe operation.

Cleaning and Lubrication

- Clean the exterior of the machinery to prevent debris buildup that can affect performance.

- Lubricate moving parts according to the manufacturer’s specifications to minimize friction and wear.

- Remove any rust or corrosion from metal components to prolong their lifespan.

By following these maintenance tips, you can ensure that your equipment runs smoothly and efficiently, reducing the risk of costly repairs and extending its useful life.

Identifying Wear and Tear

Recognizing signs of deterioration is crucial for maintaining the efficiency and longevity of any machinery. Regular inspection allows users to detect subtle changes that may indicate underlying issues. This proactive approach can help prevent more significant problems down the line, ensuring optimal performance and safety.

Common Indicators

One of the most frequent signs of wear includes unusual noises during operation, which may signal misalignment or damaged components. Additionally, visible cracks, fraying, or discoloration in materials can point to fatigue or exposure to harsh conditions. Regularly checking for fluid leaks is also essential, as they can indicate compromised seals or gaskets.

Preventative Measures

To minimize wear, routine maintenance is vital. Keeping parts clean and lubricated reduces friction and prevents premature failure. Following the manufacturer’s guidelines for service intervals and using quality replacement components can significantly extend the life of the equipment. Implementing these practices ensures reliability and enhances overall performance.

Replacing Faulty Components Safely

When it comes to ensuring the longevity and efficiency of your machinery, addressing defective parts is crucial. Understanding the process of replacement not only enhances performance but also safeguards against potential hazards. Adopting a systematic approach can lead to a successful repair while minimizing risks.

Preparation and Safety Measures

Before starting any replacement task, it’s vital to gather the necessary tools and components. Always wear appropriate personal protective equipment, such as gloves and safety glasses, to shield yourself from injuries. Additionally, make sure the device is powered off and disconnected from any power source to prevent accidental activation during the process.

Step-by-Step Replacement Process

Begin by carefully examining the faulty element to identify any specific issues. Follow the manufacturer’s guidelines for removal and installation, ensuring you take note of how each component fits together. If applicable, document the configuration with photographs or notes. Once the replacement is made, test the functionality to confirm everything operates smoothly. Regular maintenance can further enhance performance and prevent future issues.

Tools Needed for Repairs

Having the right tools is essential for effective maintenance and repair tasks. A well-equipped toolkit can significantly simplify the process and enhance efficiency, ensuring that every job is completed with precision. Below is a list of essential instruments that are commonly required for various repair tasks.

- Wrenches: Various sizes are needed for loosening and tightening nuts and bolts.

- Screwdrivers: Both flathead and Phillips types are crucial for different types of screws.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Socket Set: Ideal for removing and installing bolts in tight spaces.

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications.

- Cleaning Supplies: Brushes and cloths for removing dirt and debris from components.

- Safety Gear: Gloves and goggles to protect against injuries during repairs.

Additionally, having a sturdy workbench and good lighting can greatly improve the overall repair experience. Proper organization of tools and components will also facilitate a smoother workflow.

Cost of Replacement Parts

When it comes to maintaining outdoor equipment, understanding the expenses associated with necessary components is crucial. Various factors influence the financial investment required for substitutes, including quality, availability, and sourcing options.

Factors Affecting Cost

- Quality: Premium components often come at a higher price due to enhanced durability and performance.

- Availability: Rare or specialized items may demand a premium due to limited supply.

- Sourcing: Purchasing directly from manufacturers versus third-party retailers can lead to significant price variations.

Average Price Range

Generally, the costs for various replacements can vary widely:

- Basic components: $10 – $50

- Intermediate parts: $50 – $150

- High-end or specialized items: $150 – $300

Investing wisely in replacements can lead to improved functionality and extended lifespan of your machinery.

Comparing GXV390 with Similar Models

This section aims to analyze and compare a specific engine model with its counterparts in the market. By examining key features, performance metrics, and design aspects, we can identify strengths and weaknesses that influence choice among consumers and professionals alike.

One notable competitor is a well-known engine with similar displacement and power output. It offers comparable torque characteristics, but its fuel efficiency may vary, impacting operational costs. Additionally, the overall build quality and durability are often highlighted by users, making it a worthy contender.

Another alternative features advanced technology that enhances performance under load. Users appreciate its reliability, especially in challenging conditions. However, it may come at a higher price point, which can be a decisive factor for budget-conscious buyers.

Lastly, a third model presents an excellent balance between cost and functionality. While it may not have the highest power ratings, its ease of maintenance and availability of replacement components are significant advantages. This makes it appealing for those seeking a dependable option without breaking the bank.

Resources for Further Learning

Exploring the intricacies of small engine technology can significantly enhance your understanding and ability to troubleshoot various machinery. There are numerous resources available that cater to enthusiasts and professionals alike, providing insights into maintenance, repair techniques, and operational efficiencies.

Online Forums and Communities

Engaging with online communities dedicated to engine mechanics can be invaluable. Websites like Reddit and specialized forums allow users to share experiences, ask questions, and access a wealth of knowledge from fellow enthusiasts. These platforms often host discussions about common issues, innovative solutions, and the latest advancements in engine technology.

Instructional Videos and Tutorials

Video content can be a powerful tool for visual learners. Platforms such as YouTube feature numerous channels focused on engine maintenance and repair. These videos often provide step-by-step guides, demonstrating various procedures in detail, making it easier to grasp complex concepts and techniques.