Comprehensive Guide to Honda Parts Diagram

The intricate world of vehicle assembly often requires a deep dive into the specific arrangements and connections of individual elements. This understanding is essential for anyone looking to maintain, repair, or upgrade their vehicle effectively. A visual representation of these assemblies can provide invaluable insights into how different components interact and function within the larger system.

By exploring the layouts of essential mechanisms, one can gain clarity on the roles and placements of various pieces. This knowledge not only enhances the ability to troubleshoot issues but also empowers enthusiasts and professionals alike to make informed decisions regarding repairs and enhancements. A comprehensive overview of these structures serves as a vital tool in the automotive field.

Furthermore, having access to detailed illustrations can simplify the process of identifying the correct components needed for specific tasks. Whether for routine maintenance or significant modifications, a clear visual guide can bridge the gap between theoretical understanding and practical application, ensuring that every aspect of vehicle care is executed with precision.

Understanding Honda Parts Diagrams

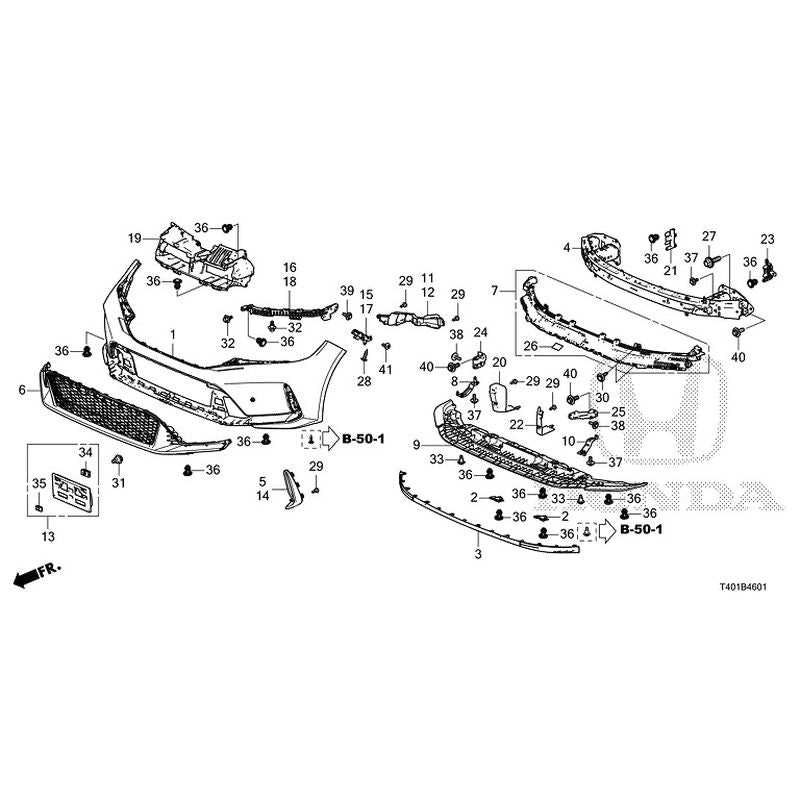

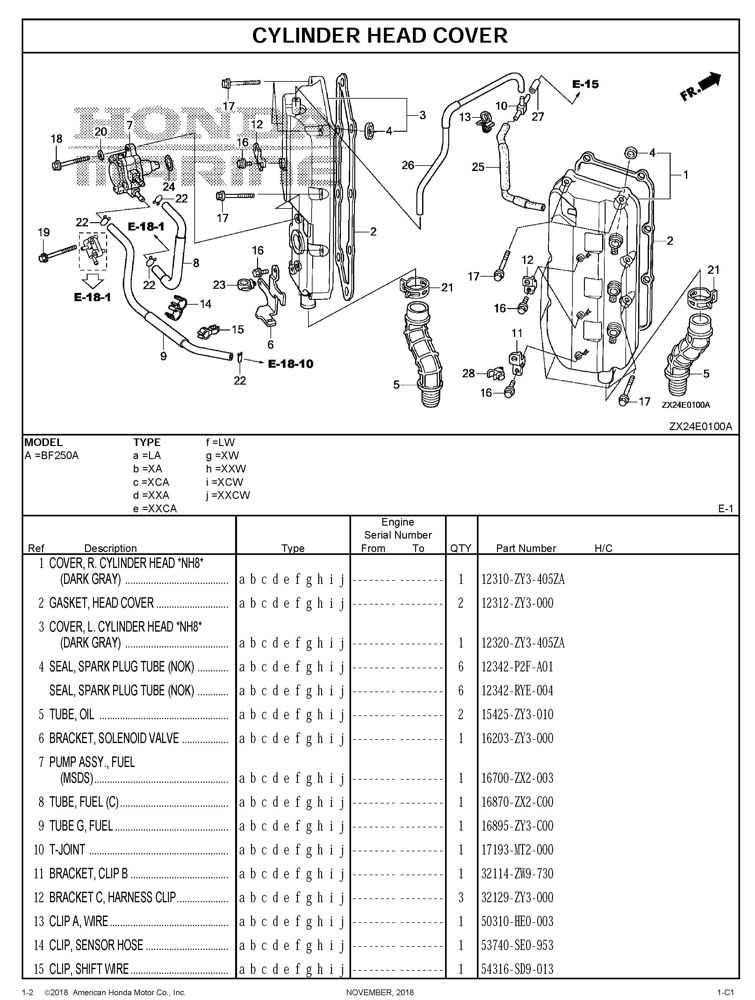

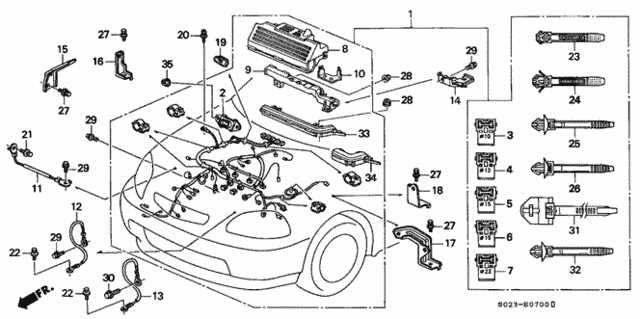

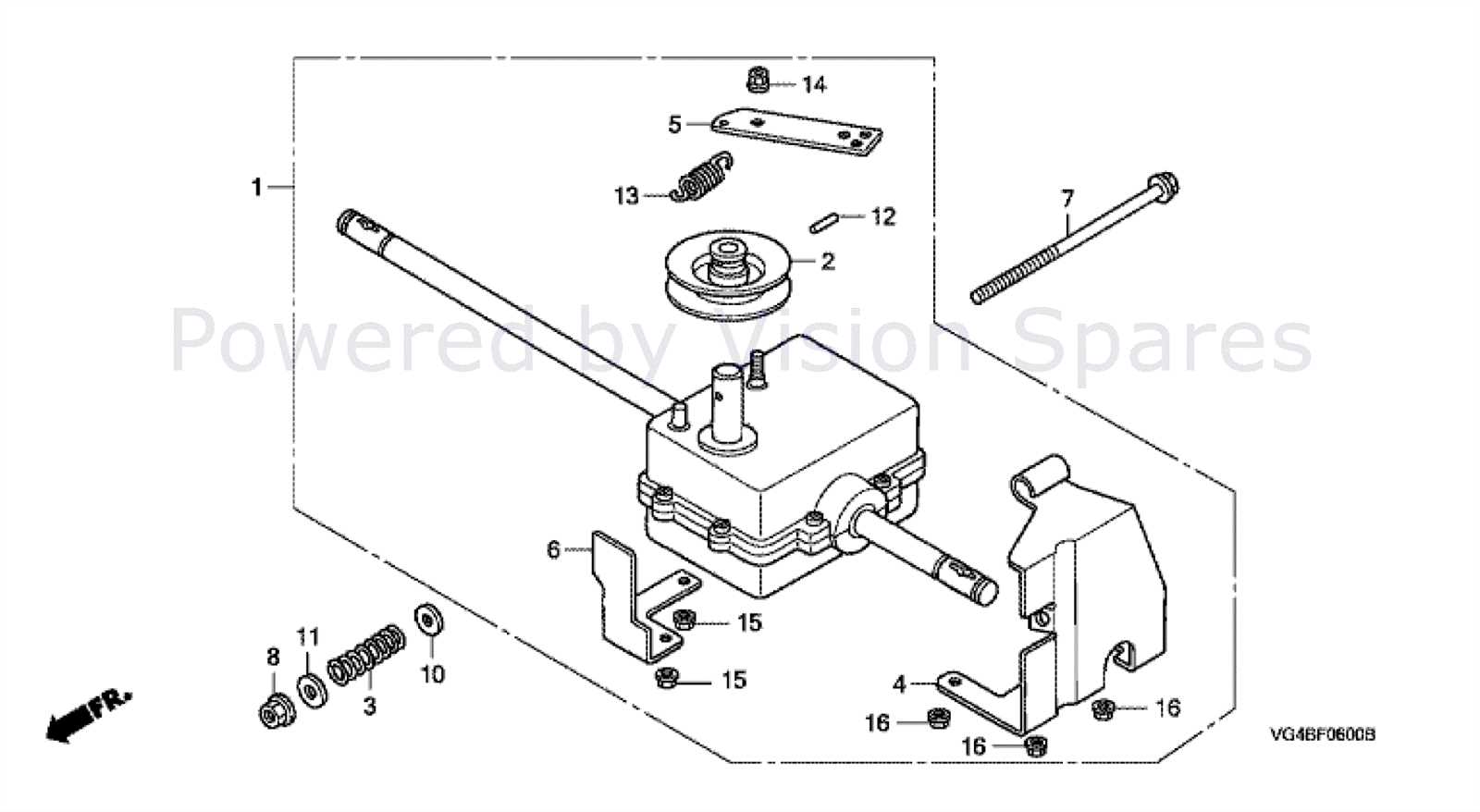

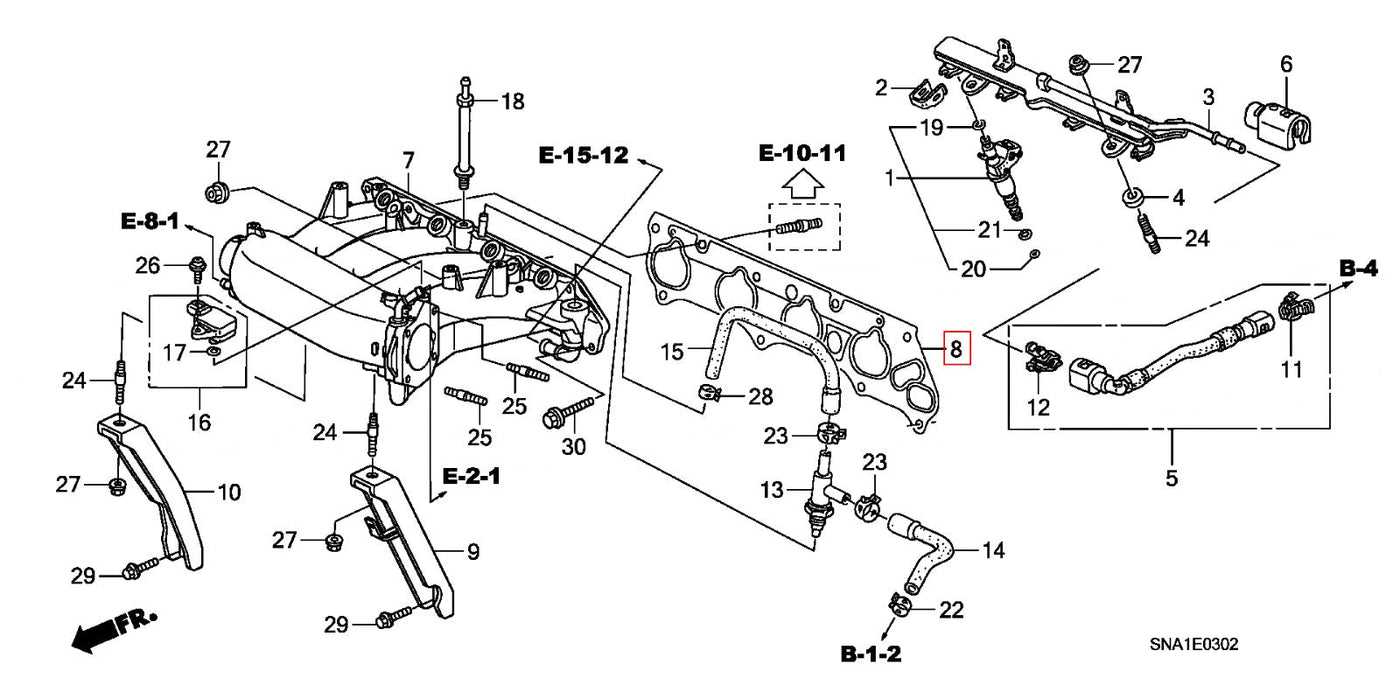

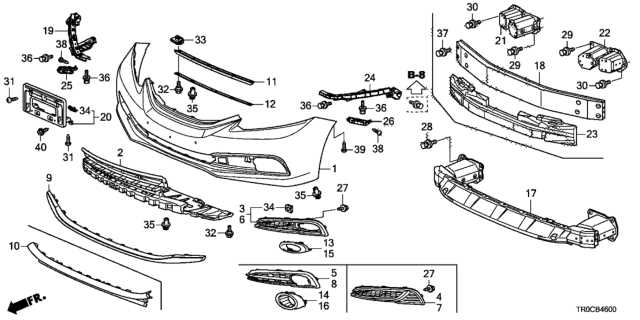

Deciphering technical illustrations is essential for anyone involved in maintenance or repair tasks. These visual representations serve as a comprehensive guide, allowing users to identify components and their respective relationships within a system. Grasping the layout and symbols used in these visuals can significantly enhance the efficiency of troubleshooting and assembly processes.

Each illustration is typically organized into sections, showcasing different assemblies and their respective elements. This structure aids in locating specific items, understanding their functions, and determining compatibility with various models. Familiarity with these resources can empower individuals to make informed decisions, ensuring optimal performance and longevity of the machinery.

Moreover, these visual aids often include notations that provide additional insights into specifications and installation procedures. This information is invaluable for both amateur enthusiasts and seasoned professionals alike, as it promotes accuracy and reduces the likelihood of errors during repairs. Overall, mastering these illustrations is a key skill for successful equipment maintenance.

Importance of Accurate Parts Identification

Ensuring precise identification of components is crucial in the maintenance and repair of vehicles. Accurate recognition not only enhances the efficiency of the service process but also plays a significant role in preventing potential issues that may arise from using incorrect elements. When technicians can easily identify the right pieces, they can provide better service and ensure the longevity of the vehicle.

Furthermore, the correct identification aids in streamlining inventory management. When components are clearly categorized and easily found, it reduces downtime and accelerates the repair process, leading to higher customer satisfaction. In contrast, errors in identifying necessary components can lead to unnecessary delays, increased costs, and even safety risks.

| Benefits of Accurate Identification | Consequences of Misidentification |

|---|---|

| Increased efficiency in repairs | Extended repair times |

| Improved customer satisfaction | Potential safety hazards |

| Better inventory management | Higher costs due to returns and exchanges |

| Enhanced component longevity | Damage to other vehicle systems |

How to Access Honda Parts Diagrams

Accessing detailed schematics for your vehicle can significantly enhance your understanding of its components and maintenance needs. Whether you’re a DIY enthusiast or simply looking to identify a specific piece, there are several reliable methods to obtain these invaluable resources.

First, consider visiting the official website of the manufacturer. Most automotive companies offer a dedicated section where you can find electronic versions of component illustrations. This approach ensures that the information is accurate and up-to-date.

Another useful option is online forums and communities dedicated to vehicle enthusiasts. These platforms often feature shared resources, including links to high-quality visuals. Engaging with other members can also provide insights and tips on how to interpret these visuals effectively.

Lastly, don’t overlook the potential of third-party websites specializing in automotive resources. Many of these sites host a comprehensive collection of schematics, complete with part numbers and descriptions. Just ensure that the source is reputable to avoid outdated or incorrect information.

Navigating the Diagram Interface Effectively

Understanding how to maneuver through the visual representation of components can significantly enhance your experience and efficiency. This section aims to equip you with the necessary skills to interpret and utilize these illustrations to their fullest potential. By familiarizing yourself with the layout and functionality, you can quickly locate and identify essential elements.

Utilizing the Zoom and Pan Features

One of the most beneficial aspects of the interface is the ability to zoom in and out. This feature allows you to focus on specific sections while retaining an overview of the entire layout. Pan tools enable you to shift your view seamlessly, ensuring you can explore all areas without losing context. Mastering these functions can save you time and prevent frustration.

Leveraging Search Functions

Many interfaces come equipped with a search capability that streamlines the process of finding particular items. By inputting relevant keywords or part numbers, you can swiftly pinpoint what you need. Employing filters can further refine your search, allowing for a more targeted approach. Utilizing these tools effectively will enhance your navigation and overall efficiency.

Common Symbols Used in Diagrams

When exploring technical illustrations, understanding the various icons and notations is crucial for effective interpretation. These visual cues serve as a universal language, allowing users to navigate complex information easily. Familiarity with these symbols enhances comprehension and ensures proper execution of tasks.

Rectangles often indicate components or sections within a system, while ovals typically represent starting or ending points. Arrows are essential for illustrating the direction of flow or movement, guiding the viewer’s understanding of how different elements interact.

Dashed lines may signify optional features or alternative paths, while solid lines denote definitive connections. Additionally, diamonds are frequently used to indicate decision points, prompting further action based on specific conditions.

By recognizing and interpreting these common symbols, users can navigate illustrations more effectively, leading to improved performance and maintenance outcomes.

Step-by-Step Guide to Reading Diagrams

Understanding technical illustrations can significantly enhance your ability to work with various mechanical systems. These visual aids provide essential information about components, their arrangement, and how they interact with each other. This guide will help you navigate these illustrations effectively.

1. Familiarize Yourself with Symbols

The first step is to become acquainted with the common symbols used in technical illustrations. Each symbol represents a specific component or function. Take time to study the legend or key that often accompanies the illustration. Recognizing these symbols will make it easier to interpret the information presented.

2. Analyze the Layout

Once you are comfortable with the symbols, focus on the overall layout. Look for the flow of the components and how they are interconnected. Pay attention to any annotations or numbers that indicate assembly order or part specifications. This step will provide context for how everything fits together, making it easier to understand the complete picture.

Tip: Take notes as you analyze the illustration. This can help reinforce your understanding and serve as a reference for future tasks.

Finding OEM Parts Using Diagrams

Identifying authentic components for your vehicle can often be a challenging task, especially when aiming for quality and compatibility. Utilizing visual guides can significantly simplify this process. These resources provide a clear representation of various elements, making it easier to locate the exact items needed for repairs or upgrades.

When exploring these visual aids, it’s essential to familiarize yourself with the specific areas and functions of each component. This understanding allows you to efficiently navigate through the illustrations, pinpointing the precise pieces that require replacement. Additionally, these references often include part numbers, which can expedite your search when contacting suppliers or online retailers.

Moreover, leveraging these resources can help you distinguish between original and aftermarket offerings. By ensuring you select genuine components, you can enhance the performance and longevity of your vehicle. Thoroughly examining these guides not only aids in the selection process but also fosters a deeper knowledge of your vehicle’s construction and mechanics.

Benefits of Using Diagrams for Repairs

Visual representations play a crucial role in the maintenance and repair process, providing clarity and precision that textual instructions often lack. By offering a graphical overview, these illustrations help users understand the intricate relationships between components, making it easier to identify issues and implement solutions effectively.

Enhanced Understanding

Utilizing visual guides significantly improves comprehension. They allow technicians to quickly locate parts and understand their functions within the larger system. This reduces the time spent deciphering written instructions and minimizes the risk of errors during the repair process.

Streamlined Workflow

When working with visual aids, the workflow becomes more efficient. Mechanics can reference these guides on-the-fly, allowing for quicker decisions and actions. This not only speeds up repairs but also enhances productivity, leading to faster turnaround times and greater customer satisfaction.

Comparing Aftermarket vs. OEM Parts

When it comes to vehicle components, the choice between original equipment manufacturer options and alternative solutions often sparks debate among enthusiasts and everyday users alike. Each category offers distinct advantages and disadvantages that can significantly impact performance, reliability, and cost. Understanding these differences can aid in making informed decisions for maintenance and repairs.

| Criteria | OEM Options | Aftermarket Alternatives |

|---|---|---|

| Quality | Generally higher, made to specific manufacturer standards. | Varies widely; some may match or exceed OEM, others may not. |

| Price | Typically more expensive due to brand and quality assurance. | Often more affordable, providing budget-friendly choices. |

| Availability | Limited to authorized dealers and specific retailers. | Widely available from various sources, including online retailers. |

| Warranty | Usually comes with a manufacturer warranty, offering peace of mind. | May vary; some products come with warranties, others do not. |

| Fitment | Designed to fit perfectly without modifications. | Fit may require adjustments; not all options guarantee perfect compatibility. |

Tips for Maintaining Your Honda Vehicle

Keeping your vehicle in optimal condition requires regular attention and care. A few essential practices can help ensure longevity and performance, enhancing your driving experience.

- Regular Oil Changes: Change the oil and filter according to the manufacturer’s recommendations to ensure engine health.

- Tire Maintenance: Check tire pressure monthly and rotate tires every 5,000 to 7,500 miles for even wear.

- Brake Checks: Inspect brake pads and fluid regularly to maintain safety and performance.

In addition to these basics, consider the following tips:

- Fluid Levels: Regularly check and top off fluids such as coolant, transmission fluid, and brake fluid.

- Battery Care: Clean battery terminals and check for corrosion. Test the battery’s health annually.

- Air Filters: Replace air filters every 15,000 to 30,000 miles to maintain optimal airflow and engine efficiency.

By following these guidelines, you can help ensure your vehicle remains reliable and efficient for years to come.

Understanding Warranty Implications

When acquiring components for your vehicle, it’s essential to grasp how warranties are affected by your choices. Many consumers overlook the fine print, which can have significant repercussions on coverage and liability.

Key Considerations

- Original vs. Aftermarket: Determine if using aftermarket components voids your warranty.

- Installation: Professional installation may be required to maintain warranty validity.

- Documentation: Keep all receipts and installation records for warranty claims.

Potential Risks

- Loss of Coverage: Unauthorized modifications can lead to denied claims.

- Safety Concerns: Non-certified components might not meet safety standards.

- Resale Value: Warranty status can impact the future value of your vehicle.

Resources for Further Learning

Expanding your knowledge in automotive maintenance and repair is essential for both enthusiasts and professionals. There are numerous avenues available that provide valuable information and insights, catering to various levels of expertise. Engaging with these resources can enhance your understanding and skills, allowing for more informed decisions when working on vehicles.

Online Forums and Communities: Participating in discussion platforms can connect you with fellow enthusiasts and experts. These communities often share tips, experiences, and troubleshooting advice that can prove invaluable.

Manufacturer Manuals: Accessing official manuals can provide in-depth information about specific components and systems. These documents often include detailed illustrations and maintenance guidelines that are crucial for effective servicing.

Video Tutorials: Many online channels offer step-by-step guides on repairs and installations. These visual aids can help demystify complex processes and provide practical insights that written resources may lack.

Workshops and Seminars: Attending hands-on sessions or lectures can significantly enhance your understanding. These events often feature experts who share their knowledge and answer questions, fostering a deeper grasp of automotive systems.

Books and Magazines: Reading literature focused on automotive technology can provide a solid theoretical foundation. Both textbooks and industry publications often cover advancements and best practices in the field.

By leveraging these diverse resources, you can build a comprehensive understanding of vehicle systems, making your learning experience both effective and enjoyable.