Complete Guide to Husqvarna 450 Rancher II Parts Diagram

Maintaining a powerful outdoor tool requires a comprehensive understanding of its internal structure and functionality. Familiarity with each segment ensures not only effective operation but also enhances the longevity of the equipment. Whether you’re a seasoned professional or a weekend warrior, knowing how every piece fits together can significantly improve your experience.

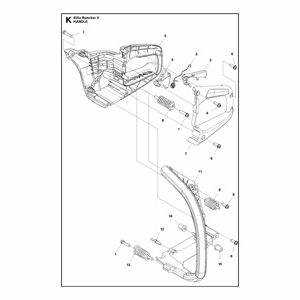

Exploring the intricate relationships between various elements is essential for troubleshooting and repair. This knowledge empowers users to identify potential issues before they escalate, ensuring a smoother workflow. A well-illustrated representation of the assembly can be an invaluable resource, guiding you through each component’s purpose and placement.

In this discussion, we will delve into the visual layout of an exemplary model, breaking down the critical components and their roles. By gaining insight into the configuration of these tools, you’ll be better equipped to handle maintenance tasks with confidence, ensuring your equipment remains in top condition for any outdoor challenge.

Understanding Husqvarna 450 Rancher II

In the world of outdoor equipment, mastering the nuances of your tools is essential for optimal performance and longevity. This particular model exemplifies reliability and efficiency, catering to both amateur users and seasoned professionals. Familiarizing oneself with its structure and components enhances usability and ensures effective maintenance.

This machine is designed for a range of tasks, from light trimming to more demanding cutting jobs. With a powerful engine and ergonomic features, it aims to provide an excellent balance between strength and comfort. Understanding its key elements will empower users to operate it effectively, ensuring they can tackle various projects with confidence.

Maintenance is a critical aspect of owning such a tool. Regular checks and understanding each component’s function can prevent wear and tear, ensuring that your equipment remains in peak condition. Knowing the layout of its internal and external parts facilitates easier troubleshooting and repairs, ultimately extending the lifespan of your device.

Overview of Chainsaw Features

Understanding the essential characteristics of a chainsaw is crucial for both casual users and professionals. These powerful tools are designed for various cutting tasks, making them versatile for different applications. The right combination of features enhances performance, safety, and user comfort.

| Feature | Description |

|---|---|

| Engine Power | Determines the cutting capacity and efficiency, typically measured in cubic centimeters (cc). |

| Bar Length | Affects the cutting depth and overall reach; available in various lengths for different tasks. |

| Weight | Influences maneuverability and user fatigue; lighter models are easier to handle for extended periods. |

| Vibration Reduction | Features designed to minimize vibrations, improving comfort and reducing strain during operation. |

| Safety Features | Includes chain brakes, throttle locks, and hand guards to enhance user safety during cutting tasks. |

| Fuel Efficiency | Indicates how effectively the engine converts fuel into power, impacting operational costs. |

| Easy Start System | Mechanisms that simplify the starting process, ensuring quick and reliable ignition. |

Familiarity with these attributes will aid users in selecting the most suitable model for their specific needs, ensuring a more efficient and enjoyable cutting experience.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations that outline each element’s location and function can significantly enhance the efficiency of any mechanical task. Such resources provide clarity, enabling users to navigate complex assemblies with ease.

Benefits of Visual Resources

- Enhanced Understanding: Clear illustrations help identify components quickly.

- Improved Troubleshooting: Users can easily locate faulty parts, streamlining repairs.

- Time Efficiency: Visual aids reduce the time spent searching for information.

- Accurate Replacements: Knowing specific parts ensures correct replacements, minimizing errors.

Best Practices for Utilizing Visual Guides

- Refer to illustrations before beginning any maintenance work.

- Keep printed or digital copies accessible during repairs.

- Familiarize yourself with the layout to improve confidence and skill.

- Use the visual aid as a checklist to ensure all components are addressed.

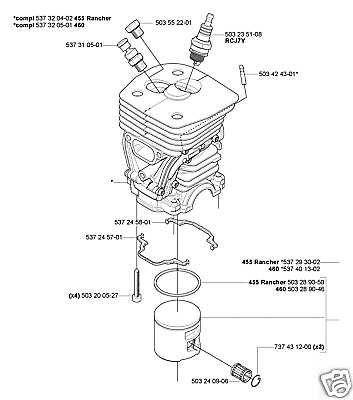

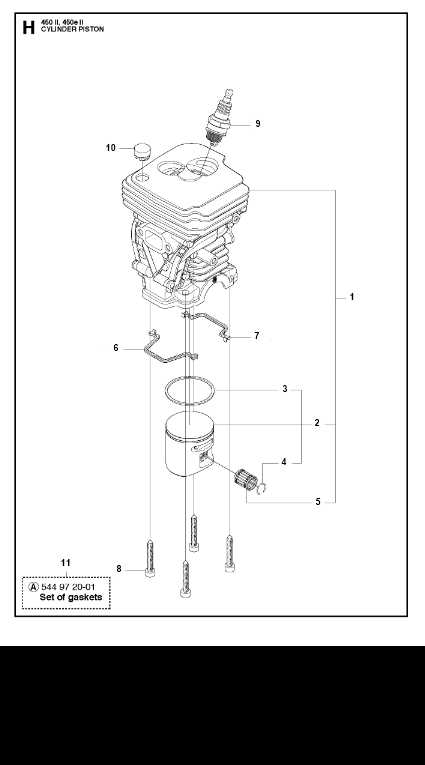

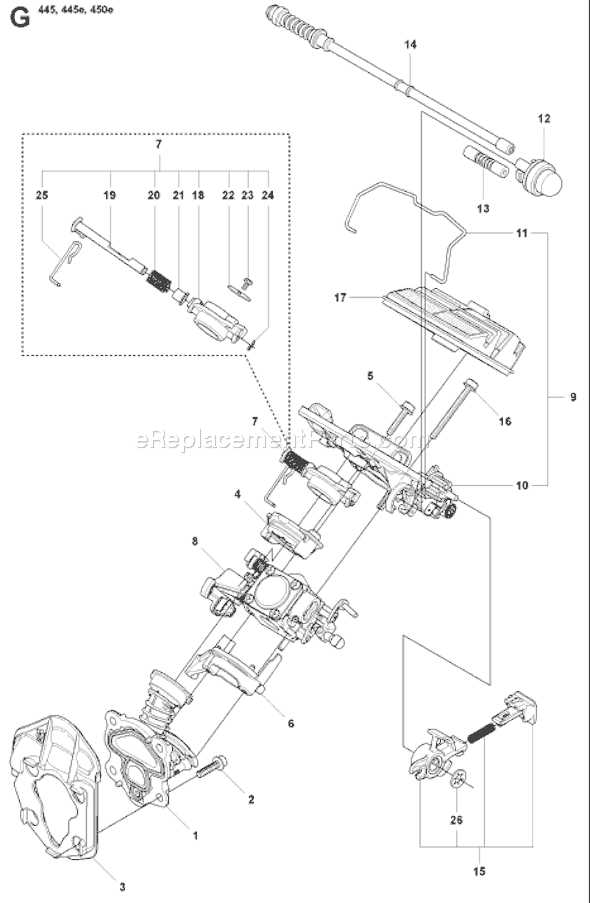

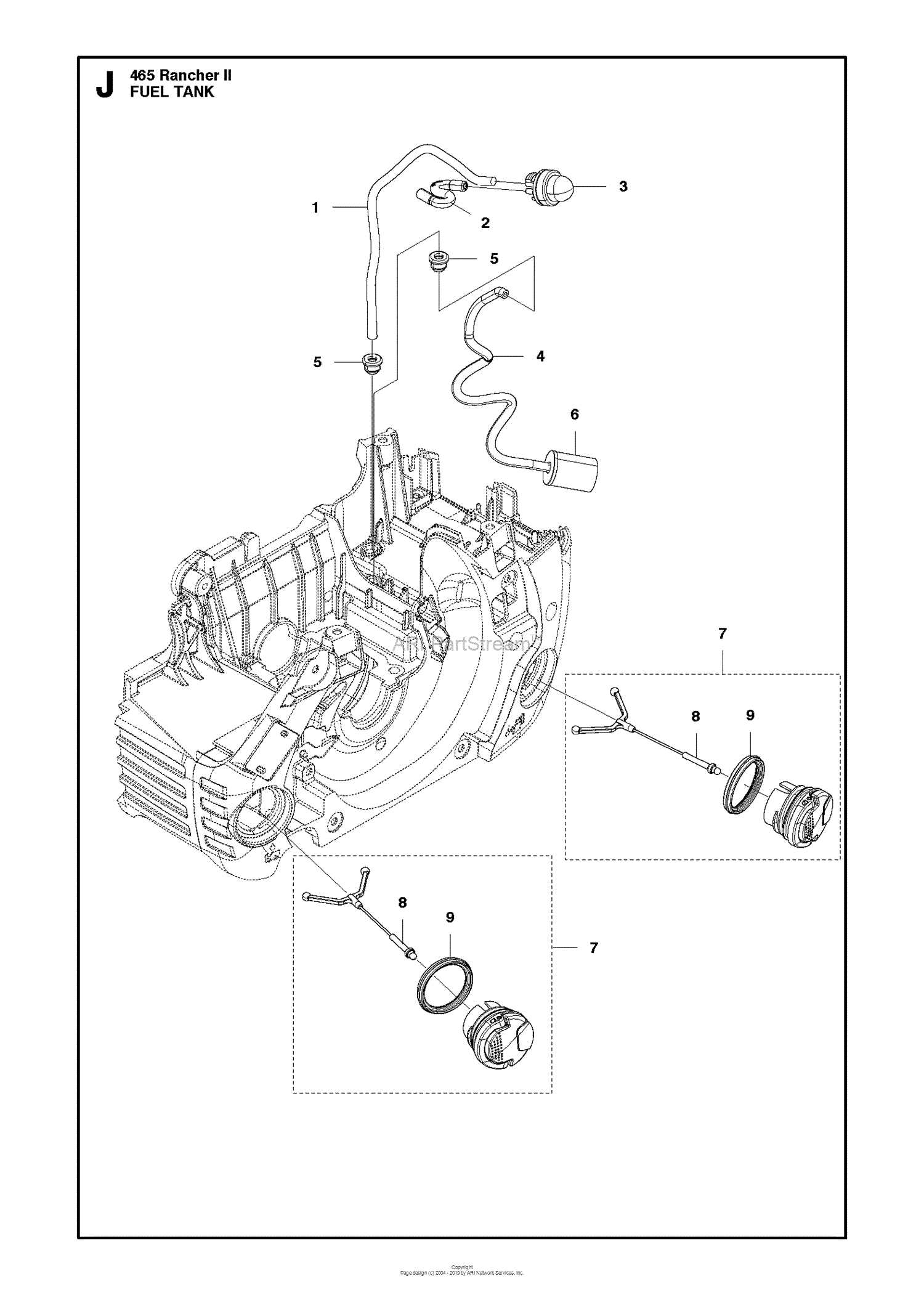

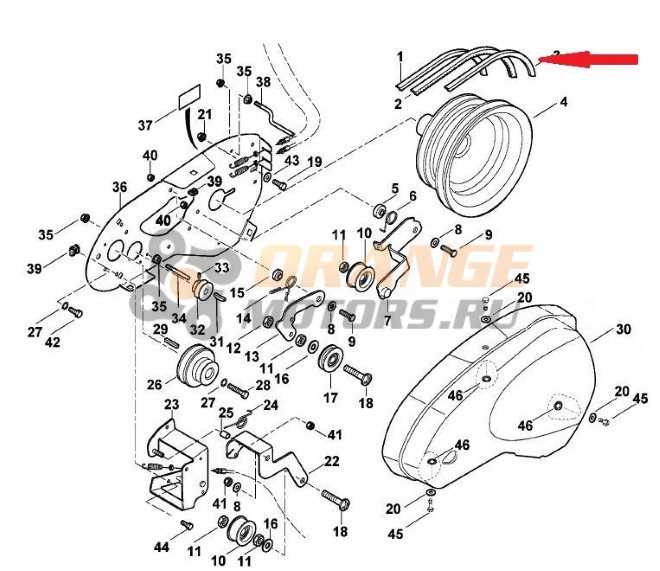

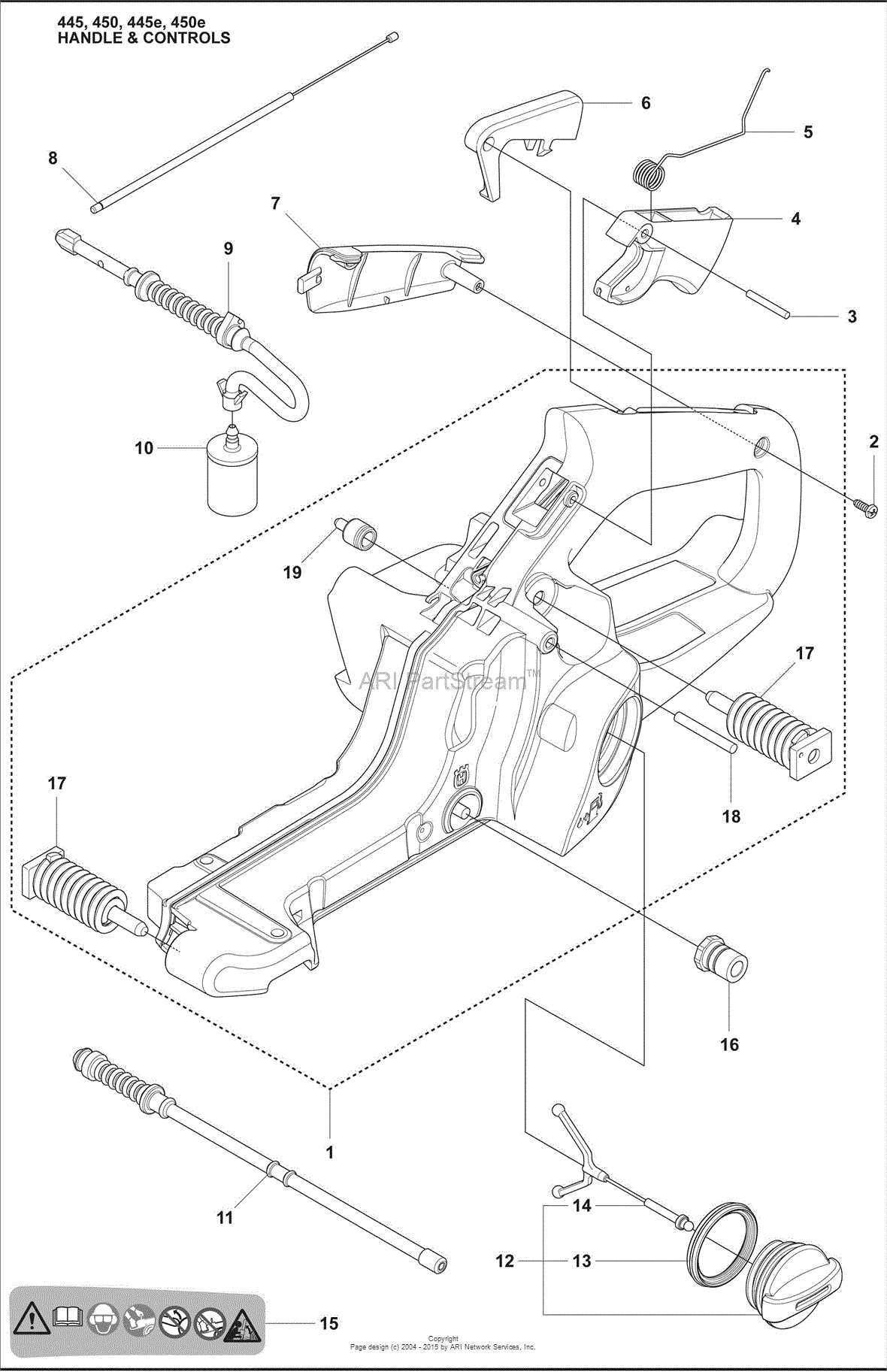

Identifying Key Components

Understanding the main elements of a chainsaw is essential for effective maintenance and troubleshooting. Recognizing these vital parts helps users ensure their equipment operates efficiently and safely. Each component plays a specific role, contributing to the overall performance and durability of the tool.

Engine: The powerhouse of the machine, responsible for converting fuel into mechanical energy. A well-maintained engine enhances performance and longevity.

Bar: The long, flat metal piece that guides the chain during operation. Its length and width impact cutting capabilities and precision.

Chain: The loop of sharp links that rotates around the bar. Its sharpness and tension are critical for effective cutting.

Handle: Provides grip and control while operating the device. Ergonomic design is crucial for user comfort and safety.

Safety Features: Elements such as chain brakes and anti-vibration systems that help prevent accidents and reduce user fatigue. Understanding these features is important for safe operation.

Familiarity with these key parts enables users to perform regular inspections and maintenance, ensuring optimal performance and prolonging the lifespan of their equipment.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your outdoor power equipment requires regular care and attention. Implementing a consistent maintenance routine not only extends the life of your machine but also enhances its efficiency and safety. Here are some essential practices to consider for effective upkeep.

Regular Cleaning

Keeping the exterior and interior of your equipment clean is crucial. Debris, dirt, and sap can accumulate and hinder performance. After each use, wipe down surfaces and remove any buildup from components. Periodically, disassemble accessible parts for a thorough cleaning to prevent any blockages or wear.

Inspection and Lubrication

Routine inspections help identify potential issues before they escalate. Check for signs of wear or damage, especially on the chain, bar, and other moving parts. Regular lubrication of these components is vital to reduce friction and enhance functionality. Use the appropriate oils and follow the manufacturer’s recommendations to ensure optimal results.

Common Replacement Parts Explained

When maintaining outdoor equipment, understanding the components that may require periodic replacement is crucial. Regular wear and tear can affect performance, making it important to recognize which elements need attention. Below are some of the most frequently replaced components in such machinery.

1. Chains and Bars

These components are essential for cutting and can suffer from damage due to extensive use. Recognizing the signs of wear will help in timely replacements.

- Chains: Look for dullness or broken links.

- Bars: Check for bending or excessive wear on the grooves.

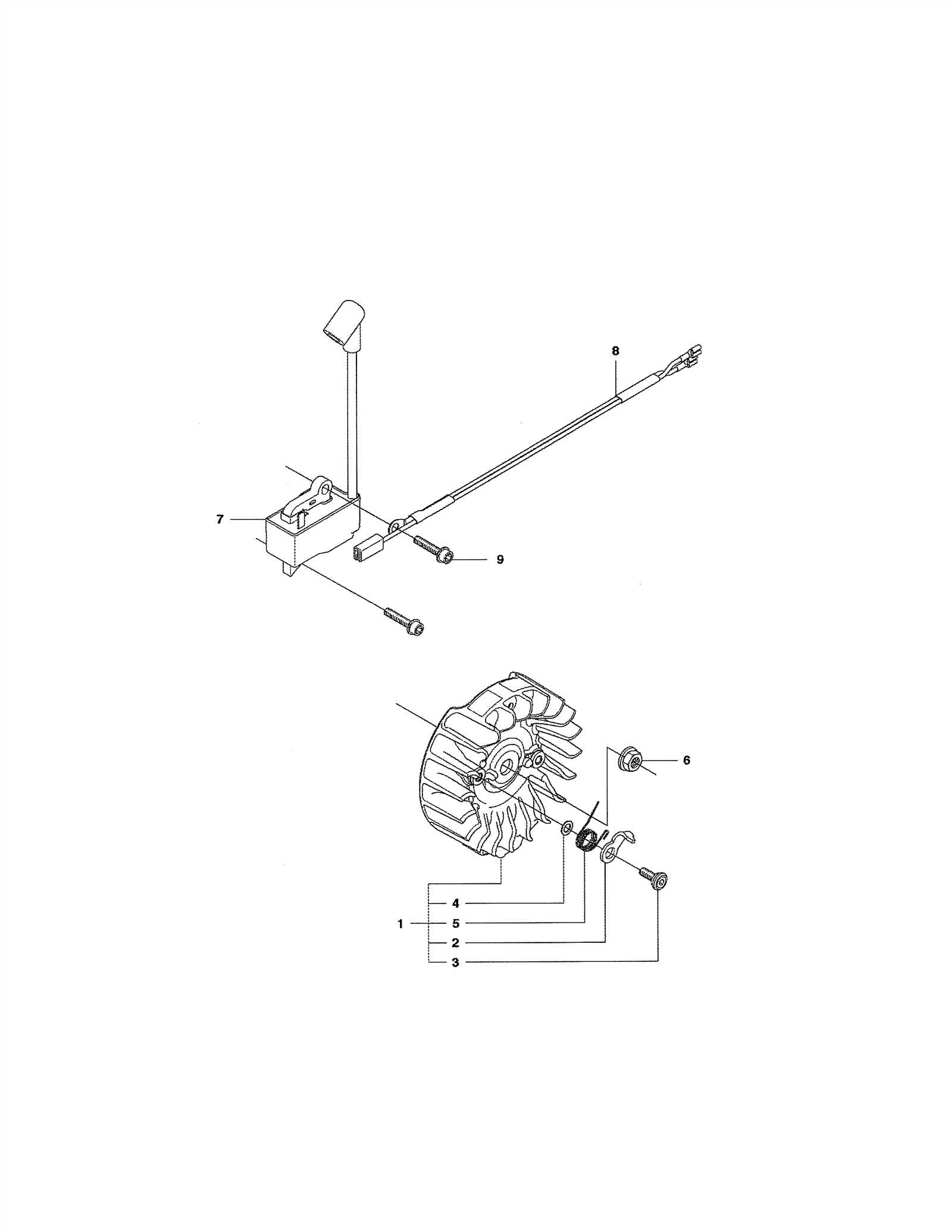

2. Filters and Spark Plugs

Keeping the engine running smoothly is vital, and these components play a significant role in performance.

- Air Filters: Clogged filters can reduce airflow, affecting efficiency.

- Fuel Filters: Replace if you notice reduced power or fuel flow.

- Spark Plugs: Worn plugs can lead to poor ignition and decreased performance.

How to Use the Diagram Effectively

Understanding visual representations of equipment components is crucial for effective maintenance and repairs. These illustrations provide a clear overview of each element, allowing users to identify, locate, and comprehend the function of various sections. Mastering the use of such graphics can significantly enhance the repair process and reduce the likelihood of errors.

To maximize the utility of these visuals, start by familiarizing yourself with the layout. Each section is typically labeled, making it easier to correlate with the physical unit. Use the legend or accompanying notes, if available, to understand the symbols and notations that indicate different parts and their relationships.

When preparing for a repair or maintenance task, cross-reference the visual with the equipment itself. This hands-on approach allows you to match the components and ensures that you are addressing the correct issues. Taking notes on which parts require attention can help streamline your workflow and keep the process organized.

Additionally, consider documenting your findings as you work through repairs. Photographing the assembly can provide a valuable reference for reassembly, ensuring that everything returns to its proper place. Over time, this practice will enhance your familiarity with the components, making future tasks more efficient.

Lastly, don’t hesitate to consult forums or instructional videos that elaborate on using these visuals. Engaging with a community of users can provide insights and tips that might not be immediately obvious, further empowering you to tackle any challenges that arise during your maintenance efforts.

Where to Find Authentic Parts

Finding genuine components for your outdoor power equipment is crucial for ensuring optimal performance and longevity. Utilizing authentic pieces not only guarantees compatibility but also enhances the reliability of your machine. Here are some reliable sources to consider when searching for high-quality replacements.

Authorized Dealers

One of the best ways to ensure you are purchasing legitimate components is through authorized dealers. These vendors are directly affiliated with the manufacturer and offer a range of original items that meet quality standards.

Online Retailers

Numerous online platforms specialize in providing authentic replacement items. When shopping online, it’s essential to verify the seller’s reputation and look for customer reviews to avoid counterfeit products.

| Source Type | Description | Advantages |

|---|---|---|

| Authorized Dealers | Official distributors of equipment | Guaranteed authenticity, expert advice |

| Online Retailers | Websites specializing in replacement items | Convenience, wide selection |

| Manufacturer’s Website | Direct online sales from the maker | Latest models, exclusive items |

| Local Repair Shops | Service centers with genuine stock | Expert installation, local support |

Benefits of OEM vs. Aftermarket Parts

When maintaining outdoor equipment, the choice between original components and those from third-party manufacturers is crucial. Each option presents distinct advantages that can impact performance, reliability, and overall satisfaction.

Original components are designed specifically for the equipment they support. This precision often leads to enhanced performance and longevity. Here are some key benefits of choosing original components:

- Quality Assurance: Manufactured to strict standards, ensuring compatibility and durability.

- Warranty Protection: Often comes with a warranty, offering peace of mind against defects.

- Optimized Performance: Tailored for the specific machine, contributing to optimal functioning.

On the other hand, third-party components can also offer several appealing advantages:

- Cost Savings: Generally more affordable, making them accessible for budget-conscious users.

- Variety: A wider range of options can cater to specific needs or preferences.

- Availability: Often easier to find, especially for older or less common models.

Ultimately, the decision between original and third-party components should consider the specific needs of the equipment and the user’s priorities, balancing factors such as cost, reliability, and performance expectations.

Assembly Instructions for New Owners

Setting up your new equipment can be an exciting yet challenging experience. Proper assembly is crucial for optimal performance and safety. This guide provides clear steps to help you navigate the process smoothly and ensure that all components are correctly fitted.

Step 1: Unpacking

Carefully remove all parts from the packaging. Check for any visible damage and ensure that all components listed in the manual are included. Lay everything out systematically to make assembly easier.

Step 2: Referencing the Manual

Always keep the user manual handy. It contains essential diagrams and descriptions that will assist you in understanding how each piece fits together. Familiarize yourself with the names and functions of each part to avoid confusion.

Step 3: Assembling Components

Start with the main body and attach any additional sections as directed in the manual. Use the appropriate tools specified, ensuring that all screws and fittings are tightened securely but not over-tightened, as this can cause damage.

Step 4: Safety Checks

Once assembly is complete, conduct a thorough inspection. Make sure all connections are secure and that there are no loose parts. Double-check that safety features are correctly installed and functioning.

Step 5: Initial Start-Up

Before the first use, consult the manual for any pre-start checks. Follow the guidelines for starting the equipment, and take note of any unusual sounds or movements during initial operation.

By following these instructions, new owners can ensure a successful assembly process, paving the way for efficient and safe use of their equipment.

Safety Precautions While Operating

Ensuring safety during operation is crucial for both the user and those nearby. Familiarizing oneself with essential guidelines and adhering to best practices can significantly reduce the risk of accidents and injuries. Awareness and preparation are key components for a safe experience when handling machinery.

Personal Protective Equipment

Before engaging with any equipment, it is vital to equip yourself with the proper personal protective gear. This includes:

- Safety goggles: Protect your eyes from debris and dust.

- Gloves: Ensure a firm grip while safeguarding your hands.

- Ear protection: Prevent hearing damage from loud noise.

- Sturdy footwear: Wear boots that provide ankle support and slip resistance.

Operational Awareness

Maintaining vigilance while using machinery is essential. Always ensure the work area is clear of hazards, and avoid distractions. Before starting, check that all components are functioning correctly. It is also wise to inform others in the vicinity of your activities to prevent unexpected interruptions. Remember to read the manual thoroughly to understand the specific operational protocols.

Troubleshooting Common Issues

When using a power tool, encountering problems is not uncommon. Understanding the typical challenges and their solutions can significantly enhance the user experience and prolong the life of the equipment. This section outlines frequent issues users may face and provides practical steps for resolution.

Engine Performance Problems

- Hard Starting:

- Check the fuel level and ensure it’s fresh.

- Inspect the spark plug for wear or damage.

- Examine the air filter for blockages.

- Stalling:

- Ensure the fuel mixture is correct.

- Inspect the carburetor for clogs.

- Check for proper choke operation.

Cutting Issues

- Ineffective Cutting:

- Sharpen or replace the cutting chain.

- Check the tension of the chain.

- Inspect the guide bar for wear.

- Chain Derailment:

- Ensure the chain is properly tensioned.

- Check for any damage to the chain or bar.

- Regularly clean and lubricate the components.