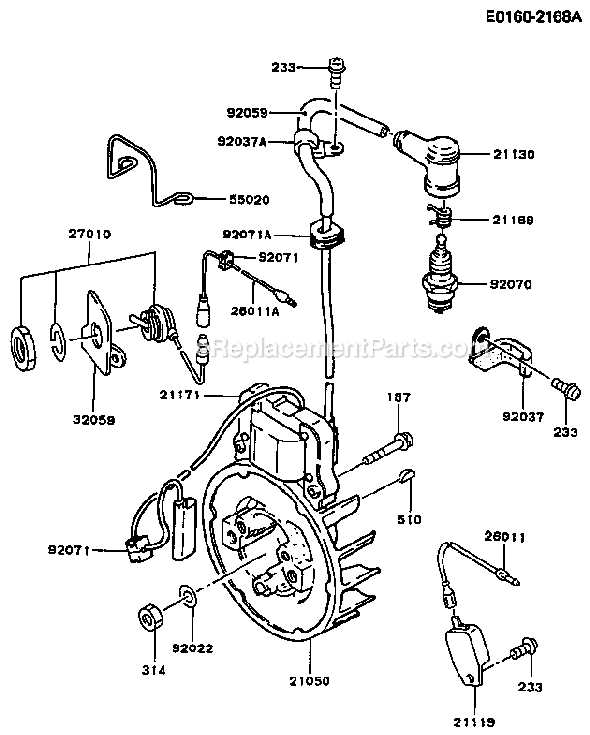

Kawasaki Parts Diagrams for Easy Maintenance and Repair

In the realm of machinery, visual representations serve as essential tools for understanding the intricate relationships between various elements. These illustrations provide a clear insight into the structure and functionality of different assemblies, facilitating maintenance and repair tasks.

By examining detailed visuals, enthusiasts and professionals alike can grasp the layout and interconnections of key components. Such resources enhance comprehension, allowing users to navigate complex systems with confidence and precision.

Moreover, these graphical aids simplify the identification of specific items, making it easier to source replacements or enhancements. Whether for routine upkeep or specialized modifications, having access to accurate visual guides is invaluable for anyone engaged in mechanical endeavors.

Kawasaki Parts Diagrams Overview

This section delves into the visual representations that showcase the various components of specific motorcycle models. These illustrations serve as essential tools for enthusiasts and mechanics alike, providing clarity on assembly and maintenance procedures. By understanding these visuals, users can effectively identify individual pieces and their placements, ensuring accurate repairs and enhancements.

Importance of Visual References

Utilizing these visual guides is crucial for anyone involved in motorcycle upkeep. They not only facilitate a smoother repair process but also help in recognizing potential wear or damage in different elements. The clarity offered by these images significantly reduces the likelihood of errors during reassembly, promoting a safer riding experience.

Finding and Using Illustrations

Accessing these visual aids is straightforward, with numerous resources available online. Many platforms provide comprehensive collections organized by model and year, making it easy to locate the needed information. Additionally, understanding how to interpret these illustrations empowers users to make informed decisions regarding upgrades and replacements, ultimately enhancing the overall performance of their vehicles.

Importance of Parts Diagrams

Understanding the intricacies of machinery and vehicles is essential for maintenance and repair. Visual representations of components play a crucial role in facilitating this comprehension. They provide clarity, enabling users to identify and manage various elements effectively. With these illustrations, the complexity of assembly and disassembly is significantly reduced, making the process more efficient and less daunting.

Enhancing Communication

Visual aids are invaluable tools for both professionals and enthusiasts. They serve as a common language among technicians, ensuring everyone is on the same page regarding specific elements. By breaking down complex systems into understandable sections, these representations foster better collaboration and information sharing.

Streamlining Repair Processes

Having access to detailed visuals can drastically shorten repair times. Users can quickly locate necessary items, reducing the risk of errors during the process. Furthermore, when individuals can easily identify the required components, it simplifies the ordering process, leading to a more efficient workflow.

In conclusion, visual representations are essential for anyone involved in the maintenance of machinery. They not only enhance understanding but also improve efficiency and communication in repair tasks.

How to Access Kawasaki Diagrams

Finding detailed illustrations of components for various vehicles is essential for maintenance and repairs. Understanding how to locate these resources can significantly enhance your ability to work on your machine effectively. Whether you’re a seasoned mechanic or a novice enthusiast, knowing the best methods to access these valuable resources can save time and reduce frustration.

Online Resources

Many manufacturers provide online databases where users can easily search for technical visuals and specifications. Start by visiting official websites or reputable forums dedicated to vehicle maintenance. Utilizing the search feature with the model and year of your machine can yield quick results. Some platforms may require registration, but they often provide extensive libraries of resources.

Service Manuals and Books

In addition to digital platforms, consider investing in printed service manuals. These comprehensive books often include not only illustrations but also detailed instructions for disassembly and assembly. Check with local retailers or online marketplaces for available editions. Many enthusiasts also share scanned versions in community groups, so it may be worthwhile to reach out to fellow owners for recommendations.

By utilizing these methods, you can effectively access the necessary illustrations and enhance your repair skills.

Understanding Diagram Symbols

In any technical illustration, the use of symbols plays a crucial role in conveying information efficiently. These visual representations serve as a universal language, allowing users to interpret complex components and their interrelations with ease. Familiarity with these icons is essential for accurate comprehension and effective communication within the field.

Key symbols often include various shapes and lines, each denoting specific functions or characteristics. For instance, circles may represent connection points, while arrows indicate direction or flow. Understanding these conventions helps users to navigate the illustrations more effectively and identify essential elements quickly.

Moreover, color coding can provide additional context, highlighting different categories or statuses of components. Recognizing these nuances enhances the ability to troubleshoot and maintain systems efficiently. By mastering the interpretation of these symbols, individuals can significantly improve their technical literacy and problem-solving skills.

Common Parts for Popular Models

Understanding the essential components that make up popular motorcycle models can greatly enhance your maintenance and repair efforts. Whether you are an enthusiast looking to upgrade or a casual rider in need of replacements, familiarity with these elements can ensure your machine performs at its best. Below are some frequently needed items across well-known models.

| Component | Description | Common Models |

|---|---|---|

| Brake Pads | Crucial for effective stopping power and safety. | Ninja 300, Z900 |

| Air Filter | Ensures optimal engine performance by filtering out impurities. | KLR650, Vulcan S |

| Chain and Sprocket Set | Key for transferring power from the engine to the wheels. | Ninja 650, Z125 Pro |

| Headlight Assembly | Provides visibility and safety during night rides. | Ninja ZX-6R, Versys 650 |

| Battery | Essential for starting the engine and powering electrical systems. | Ninja H2, Z900RS |

Benefits of Using Diagrams

Utilizing visual representations in technical documentation significantly enhances understanding and efficiency. These illustrations serve as a roadmap, simplifying complex information and making it more accessible to users of all skill levels.

Enhanced Clarity

Visual aids break down intricate concepts into manageable parts, allowing users to:

- Quickly identify components and their functions

- Easily navigate through assembly or maintenance processes

- Minimize confusion caused by lengthy textual descriptions

Improved Efficiency

Incorporating visuals can streamline workflows and save time. Benefits include:

- Faster troubleshooting by providing clear guidance

- Reduced errors during installation or repairs

- Increased confidence in handling tasks independently

Comparing OEM and Aftermarket Parts

When it comes to vehicle maintenance and repair, enthusiasts often face a crucial decision: whether to opt for original equipment manufacturer components or to explore alternatives from third-party suppliers. Each option presents unique benefits and potential drawbacks, which can significantly influence performance, durability, and overall value.

Advantages of OEM Components

- Precision Fit: Designed specifically for your vehicle model, ensuring compatibility and optimal performance.

- Quality Assurance: Typically subjected to rigorous testing standards set by the manufacturer, offering reliability.

- Warranty Coverage: Often accompanied by a warranty, providing peace of mind in case of defects.

Benefits of Aftermarket Alternatives

- Cost Savings: Generally more affordable, making them an attractive option for budget-conscious consumers.

- Diverse Selection: A wider variety of choices available, including performance upgrades and specialized designs.

- Accessibility: More readily available from various retailers, both online and in physical stores.

In conclusion, the choice between original and alternative components hinges on individual priorities such as budget, performance requirements, and personal preferences. Evaluating these factors can lead to a more informed decision that aligns with your specific needs.

Troubleshooting with Diagrams

Effective problem-solving in mechanical systems often hinges on visual representations that illustrate the relationships between components. These graphical tools enable users to identify issues swiftly and accurately, streamlining the repair process.

When faced with a malfunction, following a systematic approach can significantly enhance the likelihood of a successful resolution. Consider these steps:

- Identify the symptom: Recognize the specific issue your machine is exhibiting.

- Refer to visual aids: Utilize illustrations to locate the relevant components involved in the problem.

- Analyze connections: Examine how various elements interact and where potential failures may have occurred.

- Isolate the problem: Focus on one component at a time to narrow down the source of the malfunction.

- Implement repairs: Based on your findings, proceed with necessary adjustments or replacements.

Incorporating these visual tools into your diagnostic routine can provide clarity and efficiency, ultimately saving time and resources during maintenance efforts.

Common issues that can be diagnosed using these visual resources include:

- Electrical failures

- Fluid leaks

- Mechanical wear and tear

- Improper assembly

By leveraging these resources, you can ensure that your troubleshooting process is thorough and informed, leading to more effective solutions and a longer lifespan for your equipment.

Ordering Parts Using Diagrams

When maintaining or restoring vehicles, understanding how to navigate assembly visuals is crucial. These illustrations provide clarity on component layouts, helping enthusiasts identify and acquire the necessary items effectively. Utilizing these resources streamlines the ordering process and ensures that the right elements are selected for repairs or upgrades.

Understanding the Visuals

Before placing an order, it’s essential to familiarize yourself with the visuals that depict each component’s positioning and connections. This knowledge allows for precise identification of the required elements, reducing the chances of errors. Pay attention to the labels and numbers associated with each part, as they will guide you in finding the correct replacements.

Placing Your Order

Once you’ve identified the necessary components, the next step is to proceed with the ordering process. Make sure to note the part numbers, as these are vital for accurate transactions. Whether you choose to order online or visit a local retailer, having this information at hand will facilitate a smooth experience. Always double-check the specifications to ensure compatibility with your vehicle’s model.

Diagram Resources and Tools

This section highlights valuable resources and tools for those seeking detailed visuals and information on components and assemblies. Accessing accurate and clear illustrations is essential for maintenance and repairs, ensuring efficiency and effectiveness in any project.

Here are some key resources to consider:

- Online Databases: Various websites offer extensive libraries of schematics that can be easily searched by model and year.

- User Manuals: Many manufacturers provide downloadable manuals that include exploded views and part numbers.

- Community Forums: Engaging with fellow enthusiasts can yield personal experiences, tips, and shared resources.

In addition to these resources, the following tools can enhance your experience:

- CAD Software: Programs like AutoCAD can help create custom layouts and diagrams tailored to specific needs.

- Mobile Applications: Several apps allow users to access technical information on-the-go, including visuals and troubleshooting guides.

- 3D Modeling Tools: These tools offer interactive views of components, aiding in understanding complex assemblies.

Utilizing these resources and tools can significantly streamline the process of understanding and managing various components, ultimately leading to more successful outcomes in projects.

Maintenance Tips from Schematics

Explore essential insights directly from detailed schematics to ensure optimal performance and longevity of your equipment. Delve into visual representations that provide a comprehensive view of component interactions and functionality. By leveraging these graphical depictions, you gain a clearer understanding of the inner workings, facilitating efficient troubleshooting and maintenance strategies.

Identify key components effortlessly and discern their roles within the larger system. Each diagram offers a roadmap to navigate potential issues, guiding precise actions to maintain peak operational conditions. Enhance your technical prowess by decoding intricate connections and dependencies illustrated in these diagrams.

Utilize these visual aids as a proactive tool for preemptive maintenance, anticipating wear and optimizing part replacement schedules. Empower yourself with the knowledge embedded in these diagrams to execute preventive measures and extend the lifespan of your equipment.

By integrating insights derived from these schematics, you foster a proactive approach to maintenance, mitigating risks and ensuring sustained performance. Harness the power of visual representation to elevate your maintenance practices beyond routine tasks, aligning actions with the intricate details encapsulated in each schematic.

Staying Updated with New Models

Keeping abreast of the latest releases in the motorcycle industry is essential for enthusiasts and professionals alike. With the constant evolution of technology and design, understanding new additions can enhance performance, maintenance, and overall riding experience.

Why Staying Informed Matters

- Enhanced Performance: New models often feature improved engineering, leading to better handling and efficiency.

- Maintenance Insights: Awareness of the latest innovations can simplify maintenance tasks, as newer components may have different requirements.

- Resale Value: Knowing the current trends can help in making informed decisions about upgrades or reselling your vehicle.

How to Stay Updated

- Follow Industry News: Subscribe to reputable motorcycle magazines and websites for the latest updates.

- Join Online Communities: Engage with forums and social media groups where enthusiasts share experiences and information.

- Attend Trade Shows: Participate in expos and events to see new models firsthand and speak with manufacturers.

- Utilize Manufacturer Resources: Regularly check official websites for announcements and detailed specifications of new releases.