Kubota B1750 Parts Diagram for Easy Reference

In the realm of agricultural equipment, having a comprehensive understanding of the various components is essential for effective maintenance and operation. Knowledge of how different elements fit together not only enhances the longevity of machinery but also improves performance in the field. This section will explore the intricacies of component organization within a specific model, enabling operators to navigate repairs and enhancements with confidence.

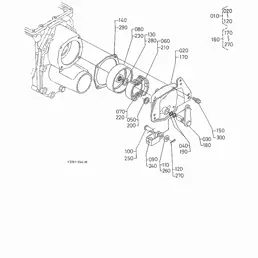

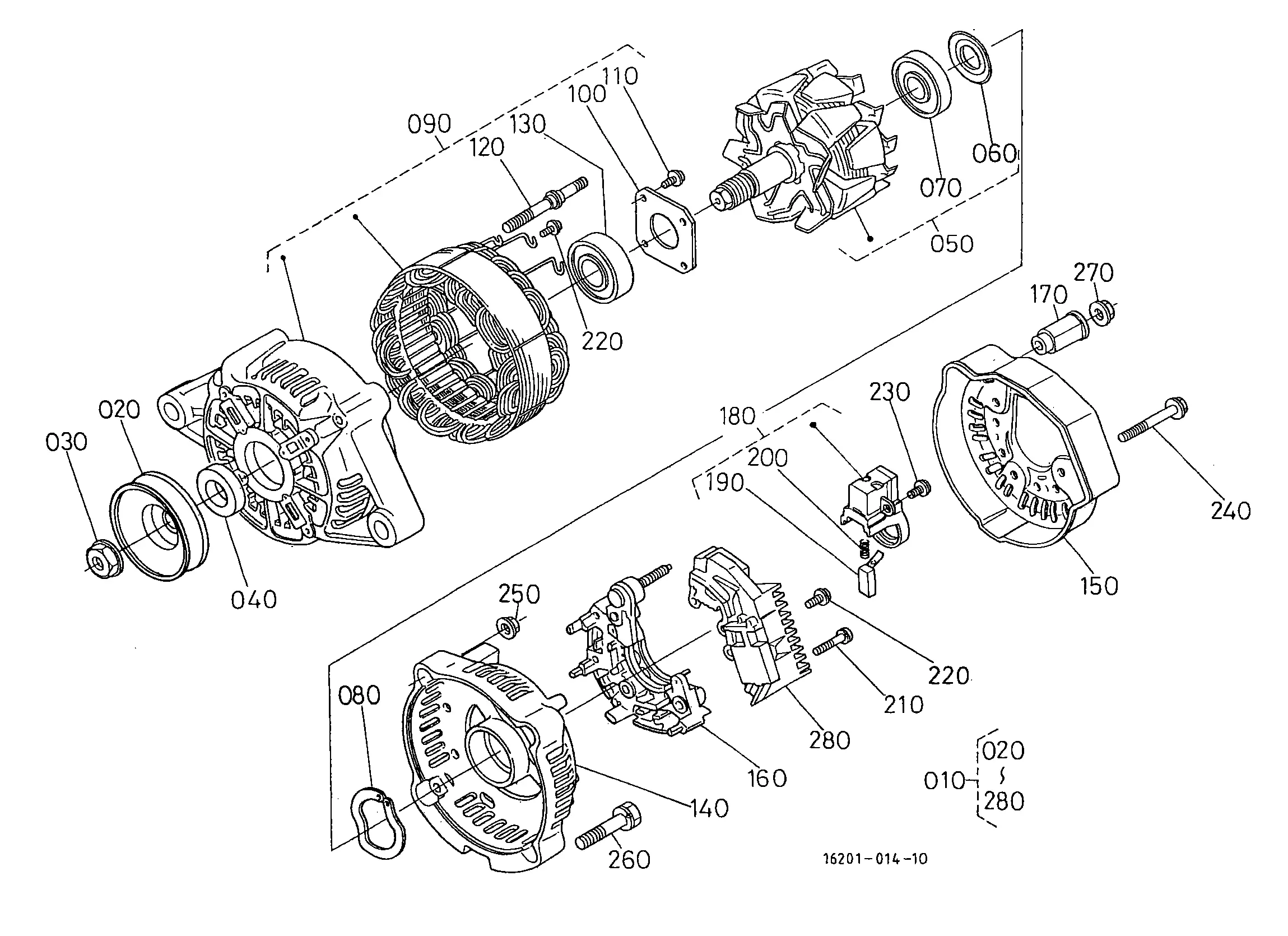

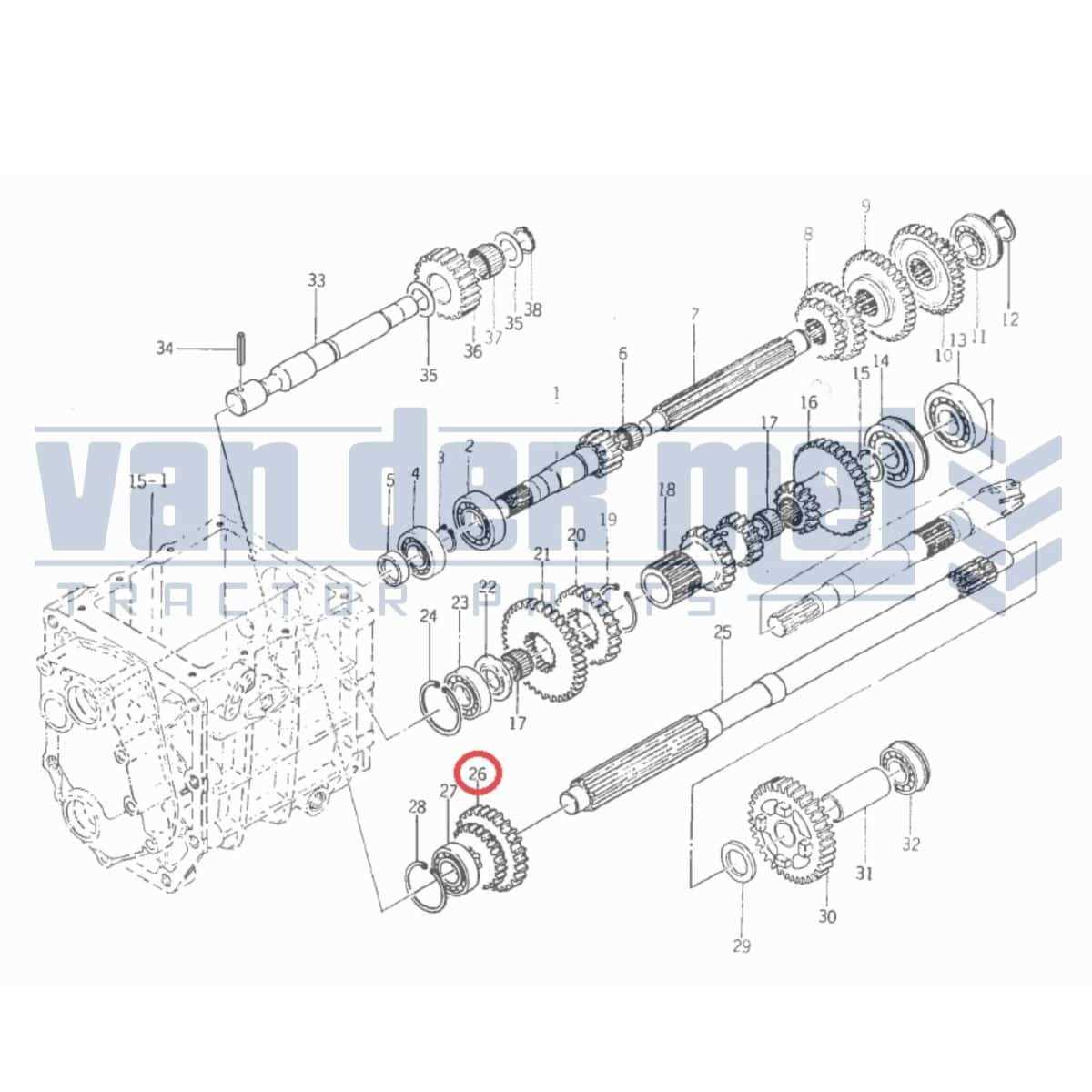

Detailed illustrations serve as invaluable resources for anyone looking to familiarize themselves with the structure and functionality of their machinery. By examining these visuals, users can identify critical parts, assess their condition, and understand their roles within the larger system. The clarity provided by these layouts ensures that both novice and experienced operators can approach maintenance tasks with greater ease and precision.

Furthermore, a well-organized representation of the elements fosters an appreciation for the engineering that goes into creating reliable agricultural tools. As users delve into the specifics of component relationships, they gain insights that extend beyond simple repairs, enriching their overall knowledge of machinery operation. This understanding not only promotes efficient use but also cultivates a deeper connection with the equipment that supports their work.

Kubota B1750 Overview

This section provides a comprehensive look at a compact agricultural machine known for its reliability and versatility. Designed to meet the needs of various farming tasks, it combines power and efficiency, making it a preferred choice for many operators. Its robust build and innovative features enable users to tackle a wide range of activities, from mowing to tilling.

With an array of compatible attachments, this machine can adapt to different requirements, showcasing its multifunctional capabilities. Whether for small-scale operations or larger agricultural endeavors, it stands out as a reliable workhorse, ensuring tasks are completed with precision and speed.

Understanding the Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They serve as invaluable tools for both technicians and enthusiasts, facilitating a clearer understanding of how each element fits within the larger system. These illustrations simplify the process of identifying individual pieces, ensuring that users can efficiently locate and replace parts when necessary.

Having access to these schematics enhances the ability to troubleshoot issues effectively. They provide insights into assembly and disassembly procedures, allowing for a more systematic approach to repairs. By visualizing the arrangement of components, users can minimize errors and save time, ultimately leading to more efficient project completion.

Moreover, these visual guides help maintain an accurate inventory of necessary elements. They enable users to easily identify what is needed for specific tasks, preventing delays caused by missing items. This organizational aspect contributes to a smoother workflow and better resource management in any repair or maintenance scenario.

In summary, the role of component illustrations cannot be overstated. They enhance understanding, streamline repairs, and aid in effective management of resources, making them essential for anyone involved in machinery upkeep.

Key Components of Kubota B1750

Understanding the essential elements of this compact machine is crucial for effective maintenance and operation. Each part plays a significant role in ensuring optimal performance and reliability. Below are the primary components that contribute to its functionality.

- Engine: The heart of the machine, providing the necessary power for all operations.

- Transmission: Responsible for transferring power from the engine to the wheels, allowing for smooth movement.

- Hydraulic System: Enables various attachments and implements to function efficiently, providing versatility in tasks.

- Chassis: The framework that supports all components and maintains structural integrity during use.

- Electrical System: Powers lights, gauges, and other electronic features essential for operation.

- Cooling System: Prevents overheating by regulating engine temperature, ensuring longevity and performance.

Familiarity with these critical components allows for better upkeep and troubleshooting, ultimately enhancing the lifespan of the machine.

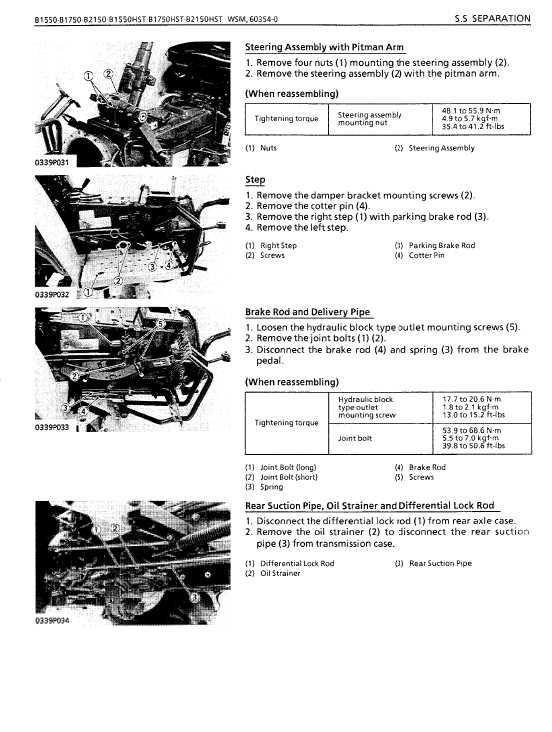

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to maintain and repair machinery. These illustrations provide a detailed view of various elements, their arrangement, and how they interact within a system. Knowing how to interpret these visuals allows you to identify parts and their functions more effectively.

Key Elements to Look For

- Labels: Each component usually has a label or number that corresponds to a list of parts. This helps in identifying specific items.

- Legend: Most visuals include a legend explaining symbols or colors used, which can clarify the function or type of each element.

- Connections: Pay attention to how components are linked. Understanding these connections can reveal assembly and disassembly processes.

Steps for Effective Reading

- Start by examining the legend to understand the symbols used.

- Identify the main components and their labels.

- Trace the connections between parts to grasp their relationships.

- Refer to the accompanying list for detailed descriptions or specifications.

By following these steps and focusing on key elements, you can navigate visual representations with confidence, making repairs and maintenance tasks easier and more efficient.

Common Issues with B1750 Parts

When dealing with machinery components, various challenges may arise that can affect performance and efficiency. Identifying these issues early can save time and resources in maintenance and repair. Understanding the common problems associated with these elements can help operators take proactive measures to ensure longevity and reliability.

Wear and Tear

One prevalent issue is the natural degradation of components due to regular use. Over time, parts can become less effective, leading to reduced functionality. Regular inspections can help detect wear, allowing for timely replacements to maintain optimal performance.

Compatibility Concerns

Another challenge involves compatibility between different components. Using mismatched elements can lead to operational inefficiencies and even damage. Ensuring that all parts fit well and function together harmoniously is essential for smooth operation and preventing future complications.

Where to Find Replacement Parts

Locating suitable components for machinery can be a daunting task, but with the right approach, it becomes manageable. Various resources are available for those seeking to maintain or restore their equipment. Understanding where to look can save both time and money while ensuring that the quality of the parts meets the necessary standards.

Online Retailers

The internet is a treasure trove of options. Numerous websites specialize in offering a wide range of components for various types of machinery. When searching online, it’s essential to use reliable platforms that provide detailed descriptions and customer reviews. This will help ensure that the items you purchase are compatible and of high quality. Look for vendors that offer a return policy, which can provide peace of mind when making your selection.

Local Dealerships and Shops

In addition to online options, visiting local dealerships or specialized shops can be beneficial. These establishments often carry a selection of components and can provide expert advice on what is needed. Moreover, speaking directly with knowledgeable staff allows for questions to be answered promptly, ensuring that you get exactly what you require. Building a relationship with local suppliers can also lead to better service and potential discounts on future purchases.

Benefits of Using Original Parts

Opting for authentic components in machinery maintenance offers numerous advantages that contribute to enhanced performance and longevity. Utilizing these genuine items ensures compatibility and reliability, which can significantly reduce the risk of malfunctions.

- Quality Assurance: Original items are manufactured to meet stringent quality standards, ensuring durability and effective operation.

- Compatibility: Genuine components are designed to fit seamlessly with the equipment, minimizing the chances of installation issues or operational failures.

- Performance Optimization: Using authentic products can enhance the overall functionality, leading to improved efficiency and productivity.

- Warranty Protection: Many manufacturers provide warranty coverage for their machinery when original components are used, offering peace of mind to users.

- Long-Term Cost Savings: While the initial investment may be higher, using genuine items can reduce long-term maintenance costs by preventing premature wear and breakdowns.

In conclusion, investing in authentic components is a wise choice for anyone looking to maintain their machinery effectively. The benefits extend beyond immediate performance, impacting long-term reliability and efficiency.

Maintenance Tips for Longevity

Regular upkeep is essential for extending the life of any machinery. By adhering to a consistent maintenance routine, users can ensure optimal performance and reduce the likelihood of unexpected failures. This approach not only enhances efficiency but also contributes to the overall reliability of the equipment.

Routine Inspections

Conducting frequent checks on vital components can prevent minor issues from escalating into significant problems. Inspect fluid levels, belts, and filters regularly to ensure they are in good condition. Addressing wear and tear promptly will help maintain peak functionality.

Proper Cleaning and Storage

Keeping machinery clean is crucial for preventing rust and buildup that can hinder performance. After each use, remove dirt and debris, and store the equipment in a dry, sheltered location. This practice will protect against environmental damage and extend the lifespan of the unit.

Comparison with Other Kubota Models

When evaluating the features and specifications of various agricultural machinery, it’s essential to understand how different models stack up against each other. Each version brings its unique strengths and capabilities, tailored to meet specific user needs. This comparison highlights key differences and similarities among various offerings from the same manufacturer, allowing potential buyers to make informed decisions based on their requirements.

Performance and Efficiency

The performance metrics of different models can vary significantly, influencing their suitability for various tasks. Some machines may excel in power output, while others focus on fuel efficiency or compactness. Assessing these factors is crucial for users aiming to maximize productivity on the field.

Specifications Overview

| Model | Engine Power (HP) | Weight (lbs) | Fuel Tank Capacity (gal) |

|---|---|---|---|

| Model A | 25 | 1,800 | 6.5 |

| Model B | 30 | 2,000 | 8.0 |

| Model C | 20 | 1,600 | 5.5 |

This overview serves as a foundation for understanding how various models can serve different purposes, helping users identify which equipment aligns best with their operational goals.

DIY Repairs: What You Should Know

When it comes to maintaining your machinery, understanding the intricacies of its components can significantly enhance your repair skills. Engaging in do-it-yourself maintenance not only saves you money but also empowers you to keep your equipment running smoothly. Familiarity with the various elements involved can make troubleshooting and fixing issues much more manageable.

Before diving into repairs, ensure you have the right tools and a clear understanding of the assembly. Consulting detailed schematics can help you visualize how parts interact and identify potential problems. It’s essential to prioritize safety by wearing appropriate protective gear and working in a well-ventilated space. Moreover, having a methodical approach to disassembling and reassembling components can prevent confusion and mishaps.

Documentation is vital; keeping a record of your repairs and any parts replaced will assist you in future maintenance efforts. Additionally, consider reaching out to online forums or local repair communities for guidance and tips from experienced enthusiasts. They can provide valuable insights that may save you time and effort during your projects.

Lastly, don’t hesitate to seek professional help if a repair seems too complex or if you encounter unexpected challenges. Knowing your limits is crucial in ensuring the longevity and reliability of your equipment.