Kubota F3990 Parts Diagram Guide

In the realm of agricultural equipment, comprehending the intricate arrangements of various elements is essential for efficient operation and maintenance. A well-organized visual representation of these components can significantly enhance the user’s ability to identify and manage parts effectively. By exploring such layouts, operators can ensure optimal functionality and longevity of their machinery.

Utilizing a clear illustration that showcases the relationship between different sections allows for better troubleshooting and repair processes. Familiarity with these visual guides empowers users to locate specific items quickly, facilitating prompt maintenance and minimizing downtime. Such insights are invaluable for those dedicated to maximizing their operational efficiency.

Moreover, these representations serve as a crucial resource for anyone involved in the assembly or disassembly of machinery. Whether for repairs, upgrades, or regular upkeep, understanding the configuration of key elements leads to informed decisions and better outcomes. Embracing these visual tools ultimately contributes to a more effective and sustainable approach to agricultural practices.

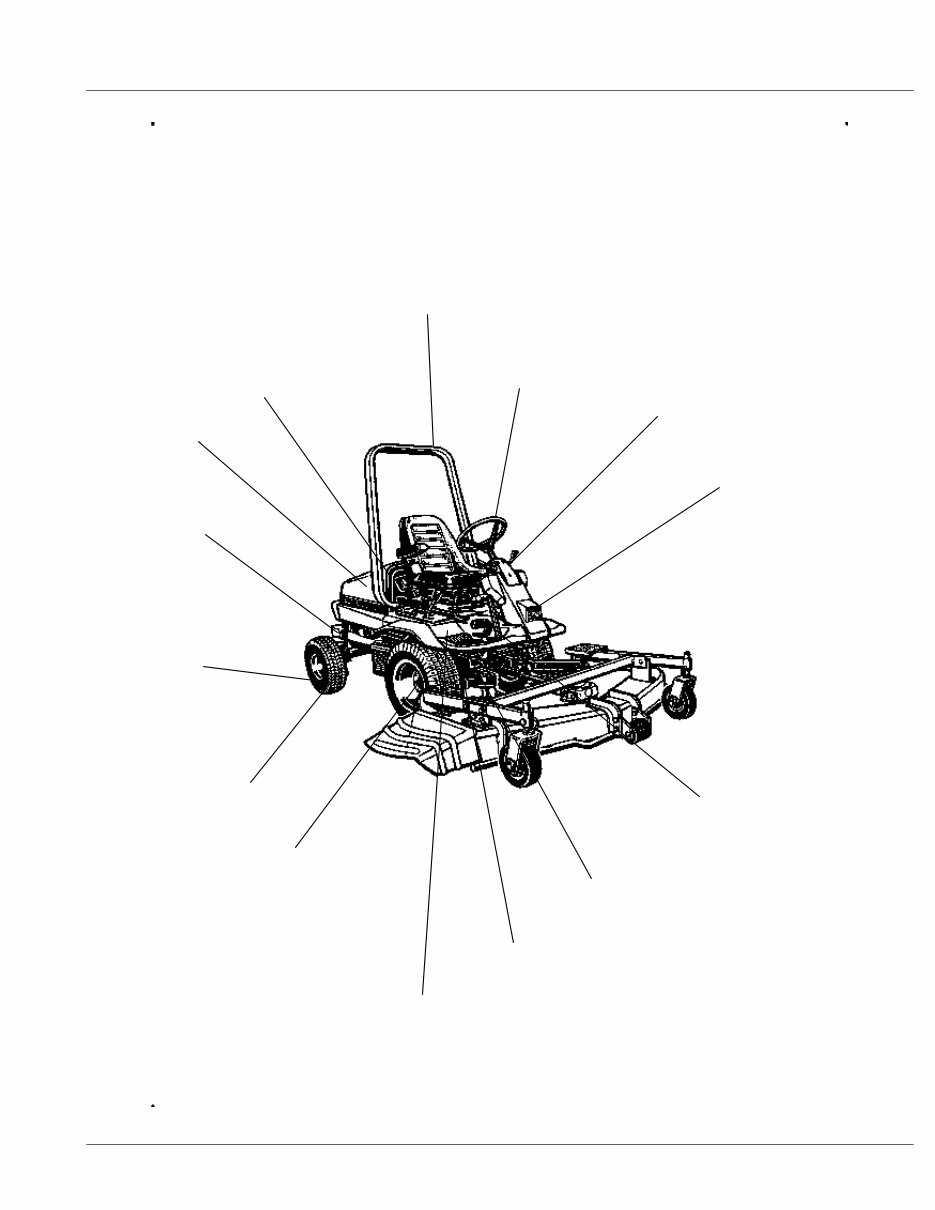

Kubota F3990 Overview

This section provides a comprehensive look at a versatile piece of equipment designed for various agricultural and landscaping tasks. Known for its reliability and efficiency, this model has garnered attention among professionals and enthusiasts alike. Its robust features and user-friendly design make it a preferred choice for those seeking to enhance productivity in their outdoor projects.

Key Features

The machine is equipped with a powerful engine that ensures optimal performance even in demanding conditions. With an advanced transmission system, it offers smooth operation and precise control. Additionally, the compact design facilitates maneuverability in tight spaces, making it suitable for both large and small areas.

Applications

Commonly utilized in farming, gardening, and maintenance tasks, this equipment proves invaluable in a variety of settings. From mowing to tilling, its adaptability allows users to tackle numerous chores effectively. Whether for personal use or commercial purposes, it stands out as a reliable partner in enhancing efficiency and achieving desired results.

Key Features of F3990 Model

This model stands out in the market due to its exceptional blend of power, efficiency, and user-friendly design. It caters to a variety of agricultural and landscaping tasks, making it a versatile choice for both professionals and hobbyists.

One of the most notable characteristics is its robust engine, which delivers impressive performance while maintaining low fuel consumption. This balance ensures that users can complete demanding jobs without excessive downtime or operational costs.

The ergonomic design enhances operator comfort, allowing for extended use without fatigue. Intuitive controls are strategically placed to facilitate ease of operation, promoting a seamless experience in various working conditions.

Additionally, the model features a high-quality transmission system that provides smooth shifting and optimal power delivery. This ensures that users can tackle inclines and rough terrain with confidence.

Lastly, its durability is a key aspect, as it is constructed from high-grade materials designed to withstand rigorous use over time. This reliability, combined with the model’s advanced technology, makes it a smart investment for anyone in need of a dependable machine.

Importance of Parts Diagrams

Understanding the intricate components of machinery is essential for effective maintenance and repair. Visual representations that outline each element not only enhance comprehension but also streamline the troubleshooting process. These illustrations serve as vital references, providing clarity in identifying and locating specific pieces within complex systems.

Efficiency in Repairs: Access to detailed visuals allows technicians to quickly pinpoint faulty components, reducing downtime. When workers can easily see how parts fit together, they can perform repairs more swiftly and accurately, ultimately saving time and resources.

Improved Communication: Clear depictions foster better communication among team members. Whether discussing issues with colleagues or conveying information to clients, having a shared visual reference ensures that everyone is on the same page, minimizing misunderstandings.

Educational Value: For those learning about machinery, these representations provide an invaluable educational tool. They facilitate a deeper understanding of how systems operate, allowing newcomers to develop their skills and confidence in handling equipment.

Inventory Management: Visual aids also assist in managing stock by clearly showing the required elements for each model. This helps in maintaining adequate inventory levels and ensuring that replacements can be obtained promptly when needed.

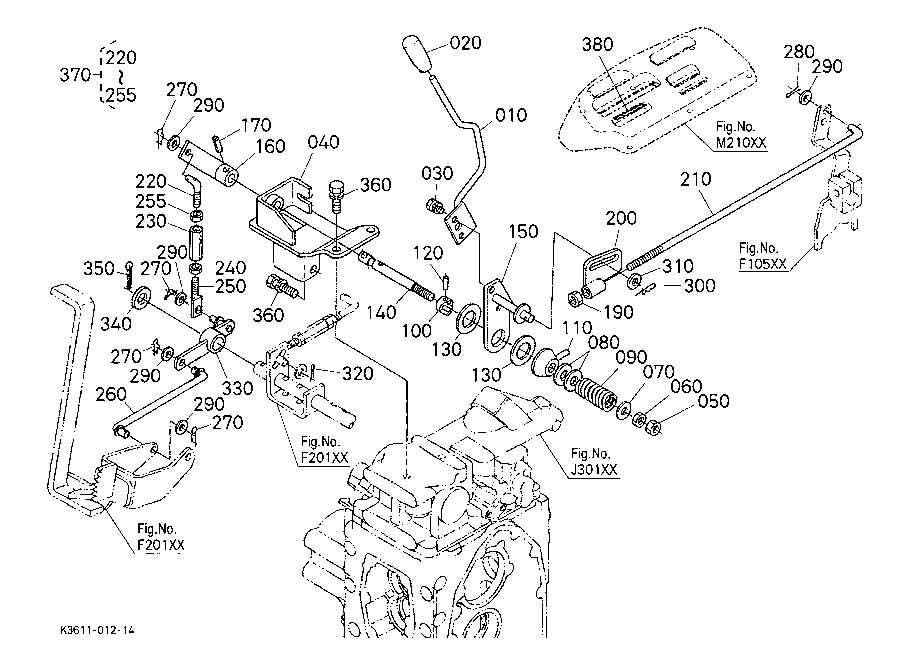

Understanding Kubota F3990 Components

When operating complex machinery, a solid grasp of its individual elements is crucial for optimal performance and maintenance. Each component plays a distinct role, contributing to the overall efficiency and functionality of the equipment. Recognizing how these parts interconnect and interact can enhance troubleshooting and repair efforts.

Key Elements of the Machinery

Familiarity with the primary components can lead to better operational understanding. Here are some essential parts:

- Engine Assembly

- Transmission System

- Hydraulic Components

- Steering Mechanism

- Electrical System

Importance of Each Component

Each element contributes uniquely to the machine’s overall functionality:

- Engine Assembly: Powers the unit, providing the necessary force for operation.

- Transmission System: Facilitates speed and torque adjustments, essential for various tasks.

- Hydraulic Components: Enable lifting and movement, crucial for handling heavy loads.

- Steering Mechanism: Allows for precise maneuvering, enhancing control and safety.

- Electrical System: Powers lights, ignition, and other electronic features, ensuring smooth operation.

Understanding these components not only aids in maintenance but also empowers users to maximize their equipment’s capabilities.

Where to Find Parts Diagrams

Locating detailed schematics for machinery components can be crucial for maintenance and repairs. Various resources are available to assist owners and technicians in accessing these invaluable visuals, ensuring efficient service and accurate replacements.

One of the most reliable sources is the official manufacturer’s website, which often provides comprehensive resources, including manuals and illustrations. Additionally, authorized dealers and service centers frequently have access to updated catalogs that showcase the necessary components.

Online forums and community groups dedicated to specific machinery can also be a treasure trove of information. Enthusiasts and professionals share their insights and often upload diagrams that can aid in troubleshooting and repairs.

For those looking for a more comprehensive approach, specialized websites dedicated to equipment maintenance may offer searchable databases. These platforms can house a wide array of resources, from technical documents to user-contributed schematics, making it easier to find exactly what you need.

Lastly, consider reaching out to local repair shops or technicians. Many have accumulated extensive knowledge and may provide access to their own resources, ensuring you find the right visual aids for your equipment needs.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations provide a detailed overview of the various elements within a machine, showcasing their arrangement and interconnections. Mastering the interpretation of these visuals can streamline the process of identifying and sourcing the necessary items.

1. Familiarize Yourself with Symbols

Every illustration uses specific symbols and notations to represent different elements. Take the time to learn what each symbol signifies, as this knowledge will help you decode the information presented more efficiently.

2. Identify Key Sections

Most visuals are divided into sections that correspond to particular assemblies or systems. Start by recognizing these segments to understand how various components work together, making it easier to locate specific items.

3. Use the Legend

Many illustrations include a legend or key that explains the symbols and colors used. Refer to this guide as you analyze the visual to ensure accurate interpretation of the information.

4. Cross-Reference with Manuals

Having access to user manuals or service guides can provide additional context. Cross-referencing the visual with textual descriptions enhances your comprehension of the layout and functionality of each element.

5. Practice and Experience

Like any skill, becoming proficient in reading these visuals takes practice. Regularly reviewing different illustrations will improve your ability to quickly and accurately understand complex systems.

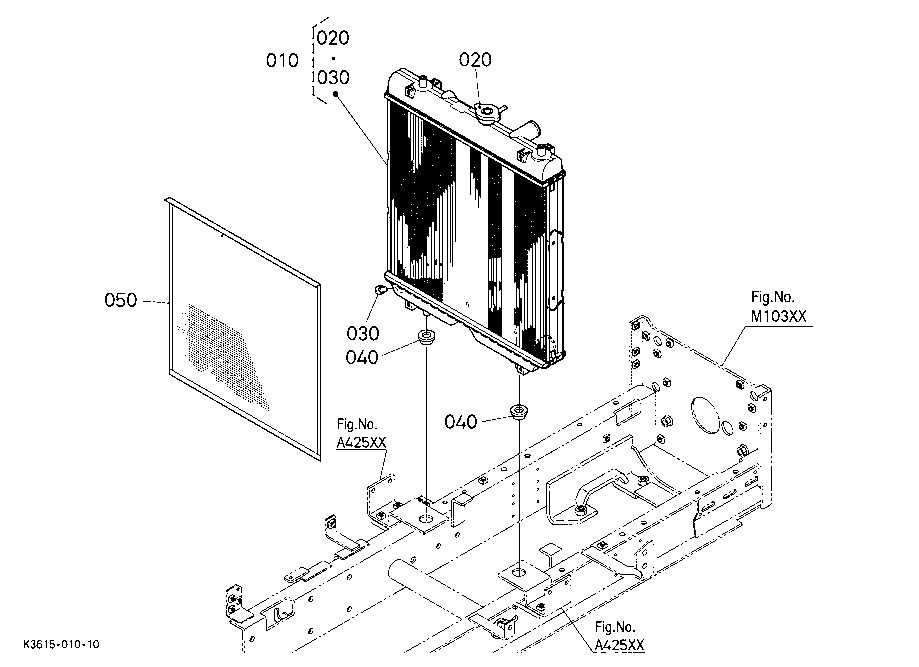

Common Issues and Solutions

When operating heavy machinery, users often encounter a range of common challenges that can affect performance and efficiency. Identifying these issues early and implementing effective solutions is crucial for maintaining optimal functionality and prolonging the lifespan of the equipment.

Overheating: One frequent problem is overheating, which can lead to significant engine damage. This can often be resolved by regularly checking coolant levels and ensuring that the radiator is clean. Additionally, monitoring the engine’s operating temperature can help catch potential issues before they escalate.

Starting Difficulties: Another common issue is trouble starting the engine. This may be caused by a weak battery or faulty starter. Regularly testing the battery and ensuring connections are secure can mitigate this problem. In colder climates, using the correct type of engine oil can also improve starting performance.

Fluid Leaks: Leaks are a prevalent concern and can arise from various seals and hoses. Routine inspections can help detect these leaks early. Replacing worn or damaged seals and ensuring all fittings are tight can help prevent fluid loss and maintain efficiency.

Poor Performance: If the machinery exhibits a decline in power or responsiveness, it may indicate issues with fuel delivery or air intake. Cleaning or replacing air filters and ensuring fuel lines are clear can often restore performance levels. Regular maintenance checks are essential to keep these components in good condition.

By addressing these common issues proactively, operators can enhance the reliability and effectiveness of their equipment, ensuring smoother operations and reducing downtime.

Maintenance Tips for F3990

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. Implementing a consistent maintenance routine not only enhances efficiency but also helps prevent costly repairs in the future. Here are some valuable tips to keep your machine in top shape.

1. Routine Inspections: Conduct regular checks on various components, including the engine, hydraulics, and electrical systems. Look for signs of wear or damage, and address any issues promptly to avoid more significant problems later.

2. Fluid Levels: Ensure all fluids, such as oil, coolant, and hydraulic fluid, are at proper levels. Regularly change oil and filters according to the manufacturer’s recommendations to maintain engine health and performance.

3. Cleaning: Keep the exterior and engine compartment clean. Dirt and debris can lead to overheating and reduced efficiency. Use a gentle pressure wash, avoiding direct blasts on sensitive components.

4. Tire Maintenance: Check tire pressure frequently and inspect for uneven wear. Properly inflated tires improve traction and fuel efficiency, enhancing overall performance.

5. Belts and Hoses: Inspect belts and hoses for cracks, fraying, or leaks. Replace any worn components to prevent breakdowns and ensure smooth operation.

6. Seasonal Checks: Before seasonal changes, perform a thorough inspection. This includes checking battery health and ensuring that all systems are ready for the upcoming workload.

By adhering to these maintenance practices, you can extend the lifespan of your equipment and ensure reliable operation throughout its service life.

Ordering Replacement Parts Effectively

Ensuring the longevity and efficiency of your machinery requires timely and accurate ordering of components when replacements are needed. A systematic approach can streamline this process, saving both time and resources. Here are some strategies to enhance your ordering experience.

- Identify the Correct Component: Before placing an order, ensure that you have the correct specifications. This may include part numbers, descriptions, or compatibility details.

- Consult the Manual: Refer to the user guide or maintenance manual for insights on required components. This can prevent misordering and reduce downtime.

- Use Trusted Suppliers: Choose reputable vendors known for quality and reliability. Look for reviews or recommendations from other users.

Once you have identified the necessary component, follow these steps to complete your order efficiently:

- Gather Information: Compile all relevant details, including part numbers, quantities, and shipping information.

- Check Availability: Verify the stock status with your chosen supplier to ensure that your order can be fulfilled promptly.

- Place Your Order: Utilize online platforms or direct contact methods to submit your request, confirming all details before finalizing.

- Track Your Order: Monitor the progress of your shipment to anticipate its arrival and schedule any necessary installation.

By following these guidelines, you can enhance your procurement process, ensuring your equipment remains operational with minimal interruption.

Upgrading Your Kubota F3990

Enhancing your machinery can significantly improve performance and efficiency. By selecting the right upgrades, you can boost functionality, increase durability, and tailor your equipment to better meet your specific needs.

Here are some effective ways to enhance your machine:

- Engine Performance: Consider tuning your engine for improved horsepower and torque. Upgrading components like the air intake and exhaust system can lead to better fuel efficiency.

- Transmission Improvements: Evaluate your current transmission system. Upgrading to a more advanced gearbox can provide smoother shifts and better power delivery.

- Hydraulic System Enhancements: Upgrading hydraulic components can improve lift capacity and response time, making tasks easier and faster.

When selecting upgrades, it’s essential to consider compatibility with your existing setup. Consulting the manufacturer’s specifications can provide guidance on suitable enhancements.

Regular maintenance should accompany any upgrades to ensure longevity and optimal performance. Keep an eye on wear and tear, and replace any worn parts promptly.

With thoughtful upgrades, your equipment can operate at peak performance, allowing you to tackle tasks more efficiently and effectively.