Kubota LA211 Parts Diagram for Efficient Maintenance

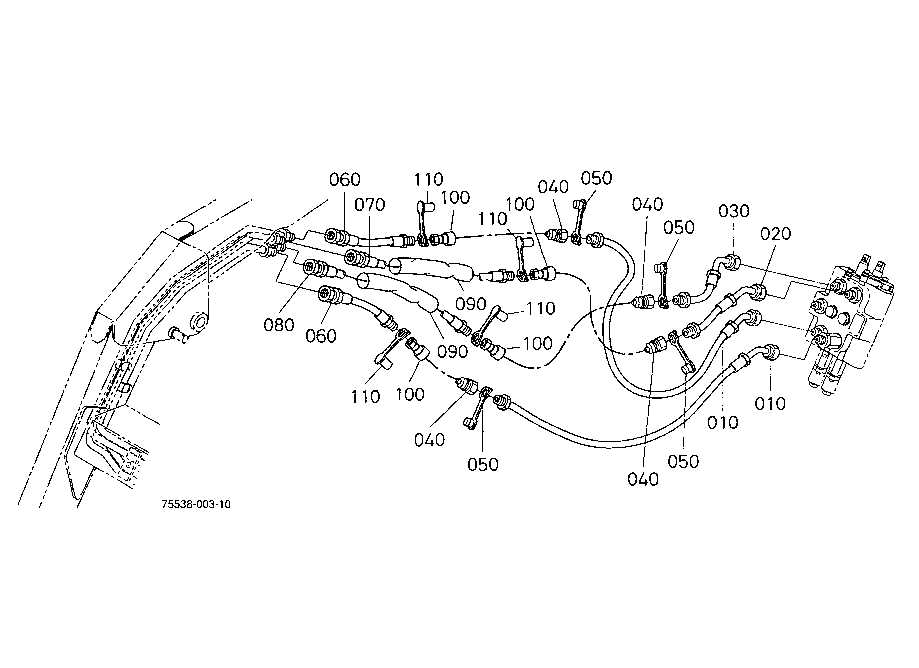

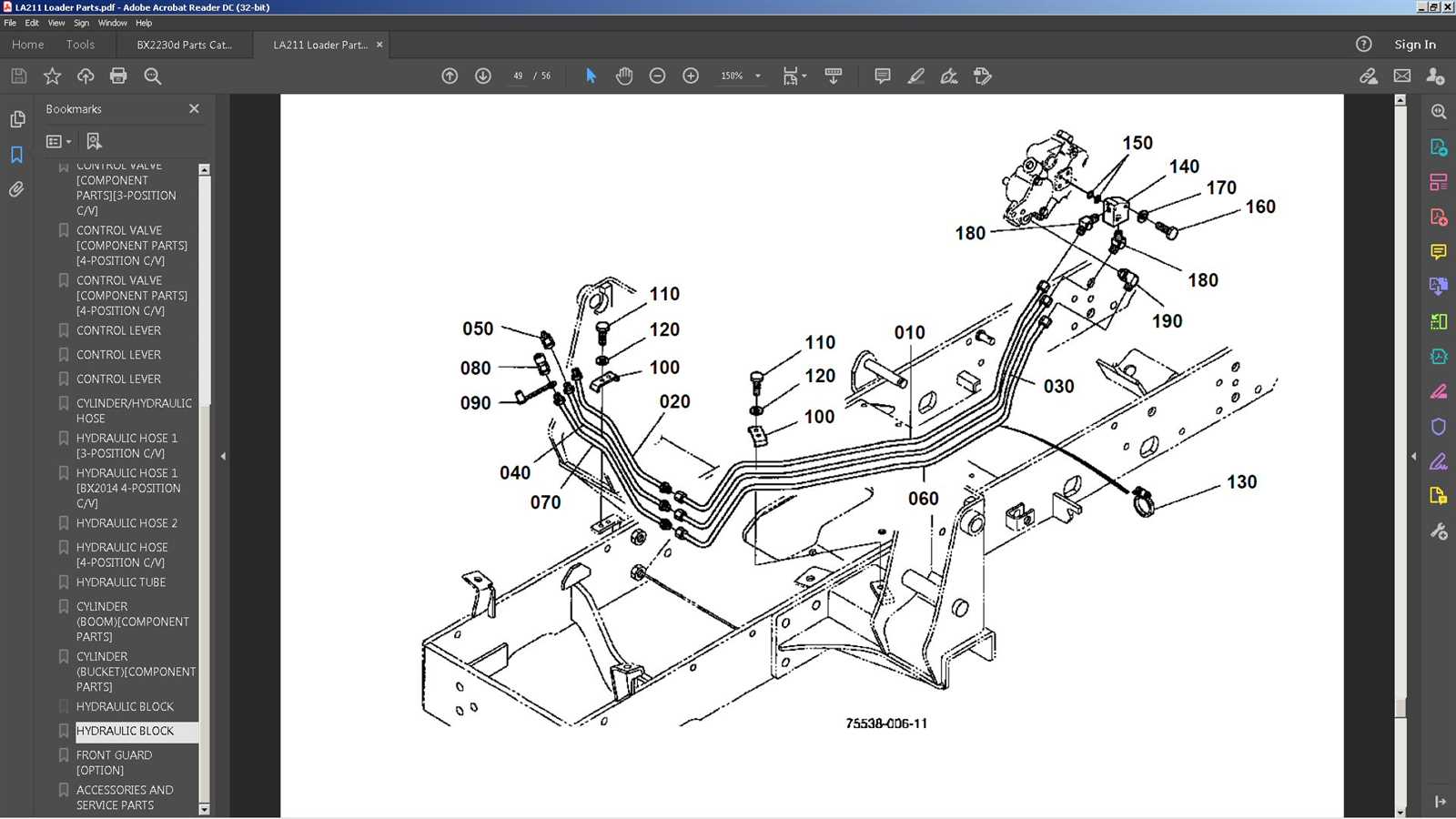

In the realm of machinery maintenance and repair, having a comprehensive understanding of the layout of various components is essential. This knowledge allows operators and technicians to efficiently identify parts, troubleshoot issues, and execute repairs with precision. A well-organized schematic serves as a valuable reference, guiding users through the intricate assembly of the machine.

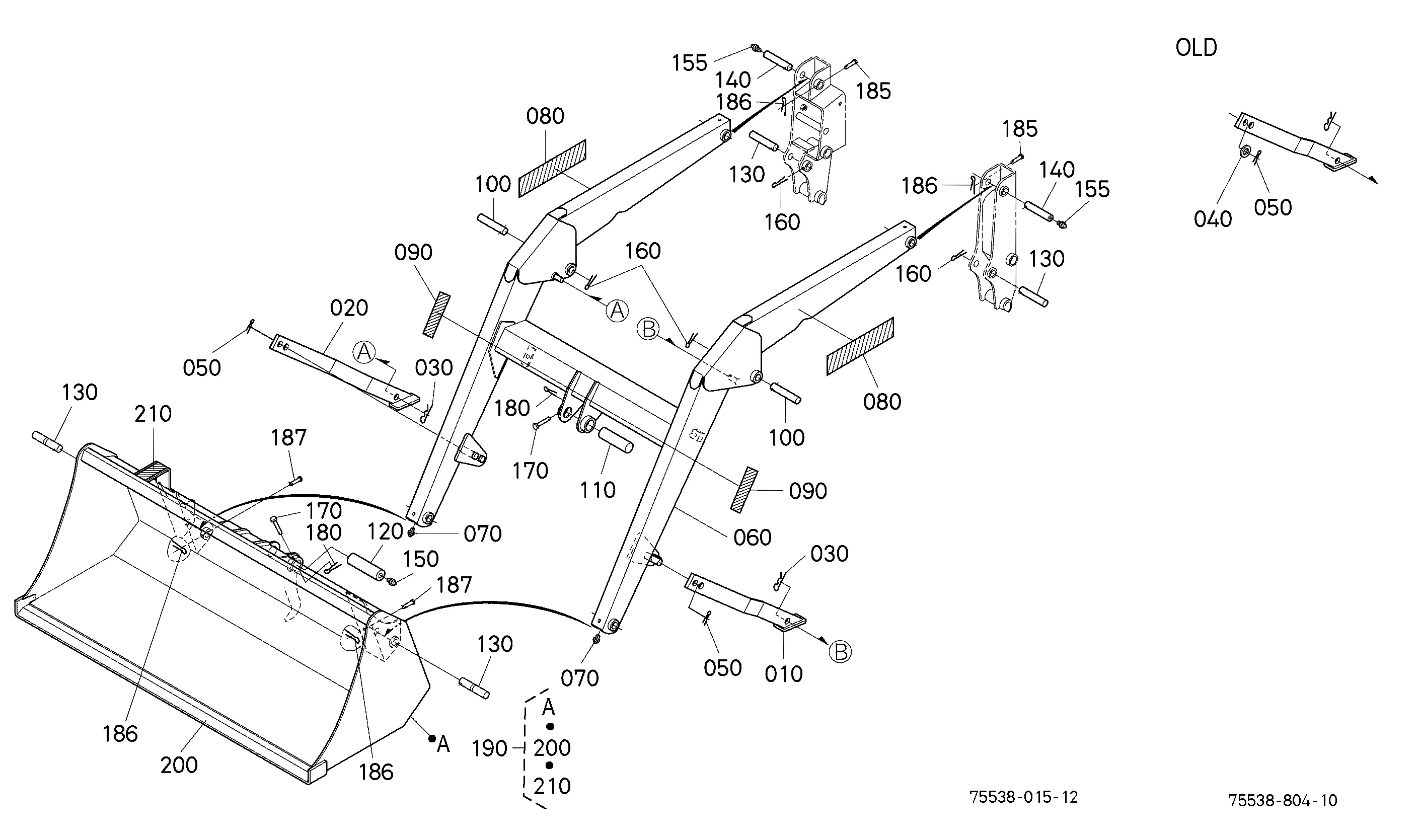

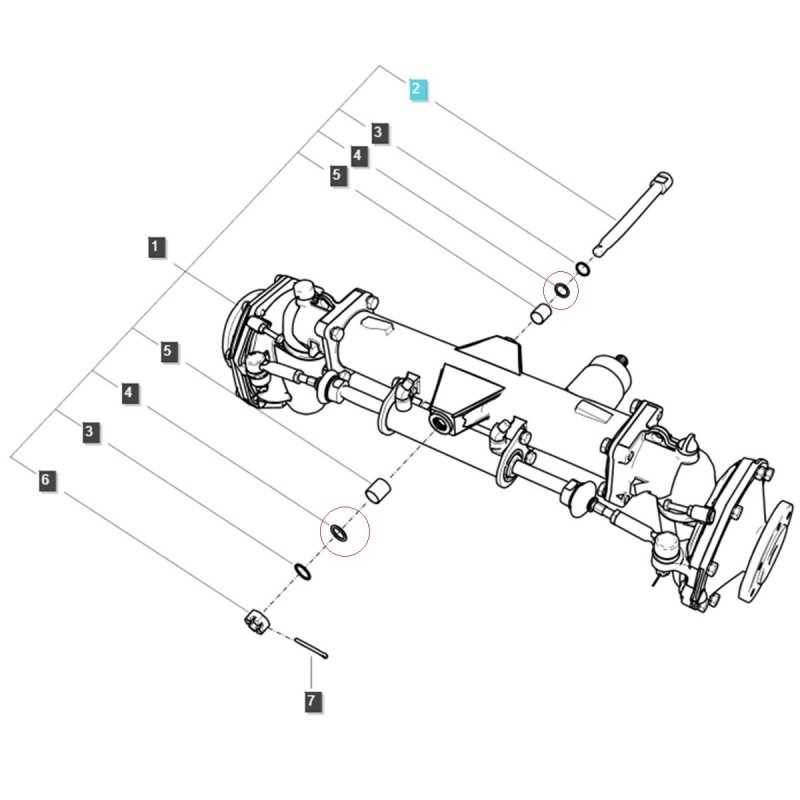

Assembling and disassembling equipment can be daunting, especially for those who are not familiar with its structure. Utilizing visual aids can significantly streamline this process. These illustrations not only highlight the relationship between different elements but also ensure that every piece is correctly positioned during reassembly.

Moreover, understanding the intricacies of a machine’s construction can enhance overall performance and longevity. When users are equipped with the right information, they can anticipate potential problems and address them proactively, leading to improved efficiency and reduced downtime.

Kubota LA211 Overview

This section provides an in-depth look at a compact utility attachment designed for a variety of tasks in agriculture and landscaping. Known for its versatility, this equipment enhances productivity and efficiency, making it a valuable asset for both small and large operations.

The attachment is engineered for compatibility with specific tractors, ensuring seamless integration and optimal performance. Its robust construction allows it to handle diverse challenges, from lifting and moving materials to performing intricate tasks in tight spaces.

Users appreciate the ease of operation and maintenance, contributing to reduced downtime and increased reliability. With a focus on user-friendly features, this equipment is suitable for both seasoned professionals and those new to utility operations.

Overall, this attachment exemplifies a blend of power and precision, making it an essential tool for enhancing workflow in various agricultural and construction applications.

Importance of Parts Diagrams

Understanding the intricate layout of components within machinery is essential for effective maintenance and repair. Visual representations serve as invaluable tools for identifying individual elements and their respective functions, enabling technicians to work more efficiently. When users can easily access these schematics, they enhance their ability to troubleshoot issues and execute repairs with precision.

Moreover, such illustrations facilitate communication between various stakeholders, including technicians, suppliers, and customers. A clear visual guide allows for accurate identification of necessary components, reducing the likelihood of errors during ordering or installation. This not only saves time but also minimizes costs associated with incorrect parts.

Additionally, these visual aids play a significant role in training and education. New technicians can familiarize themselves with the layout and operation of complex machinery more quickly, leading to improved confidence and skill development. Overall, having a detailed visual guide is crucial for ensuring the longevity and optimal performance of equipment.

Common Issues with LA211

Operating machinery can often present a range of challenges that users need to address for optimal performance. Understanding the typical problems that may arise helps in maintaining efficiency and prolonging the lifespan of the equipment. Here, we will explore frequent concerns encountered with this model.

| Issue | Description | Possible Solutions |

|---|---|---|

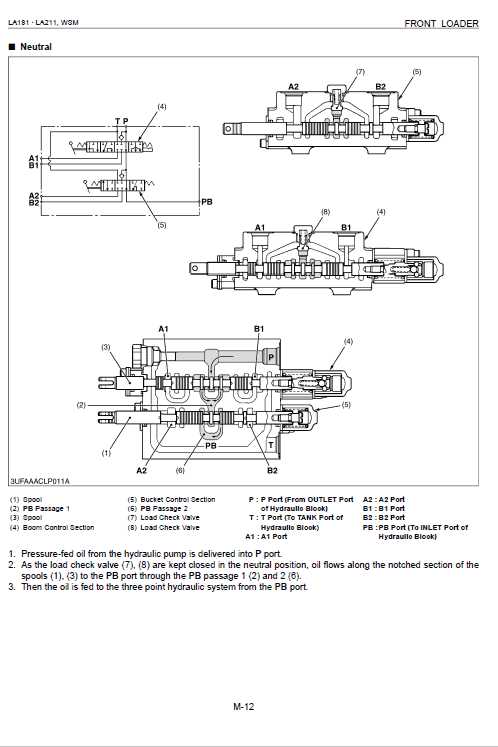

| Hydraulic Problems | Loss of power or responsiveness in hydraulic functions can occur. | Check fluid levels, inspect for leaks, and replace filters as necessary. |

| Engine Overheating | Overheating can lead to significant engine damage if not addressed. | Ensure coolant levels are adequate and radiators are free from debris. |

| Starting Difficulties | Starting issues may arise due to battery or electrical system faults. | Inspect the battery condition, cables, and connections for corrosion. |

| Transmission Issues | Shifting problems may indicate wear or lack of fluid. | Check transmission fluid levels and inspect for leaks or damage. |

Where to Find Parts Diagrams

Locating visual references for components of machinery is essential for effective maintenance and repair. These resources provide detailed illustrations that help users understand the structure and organization of various elements, ensuring that any work carried out is informed and precise.

One of the best places to start is the manufacturer’s official website. Many companies offer downloadable resources that feature comprehensive visuals and specifications. Additionally, authorized dealers often provide catalogs that include annotated images, making it easier to identify specific parts.

Online forums and community groups dedicated to machinery enthusiasts can also be invaluable. Members frequently share manuals and resources, including detailed visuals, that can aid in troubleshooting and repairs. Websites specializing in machinery components often feature interactive tools that allow users to explore the layout of different assemblies.

Lastly, consider reaching out to local repair shops or service centers. They typically have access to professional-grade manuals and can offer guidance or copies of necessary resources. Whether through digital platforms or printed materials, finding accurate illustrations is crucial for maintaining the efficiency and longevity of your equipment.

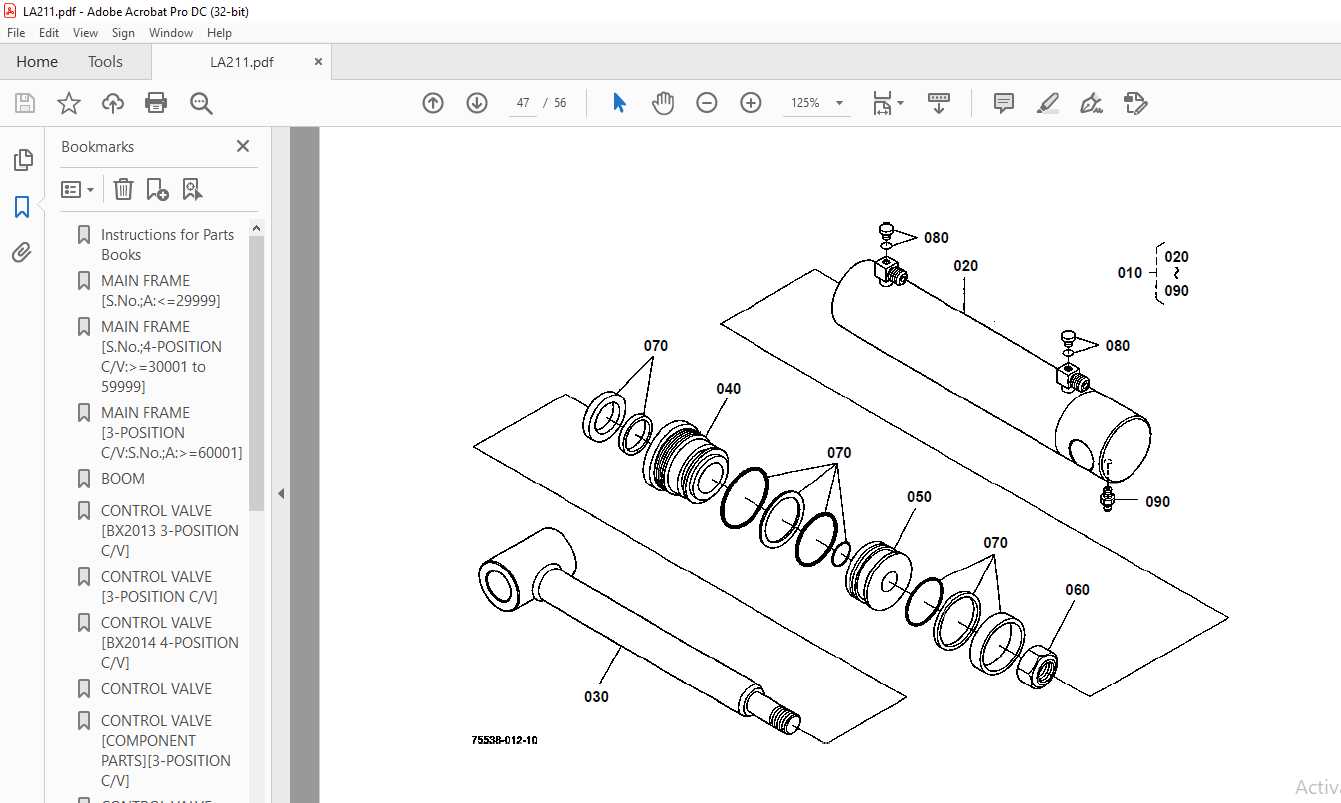

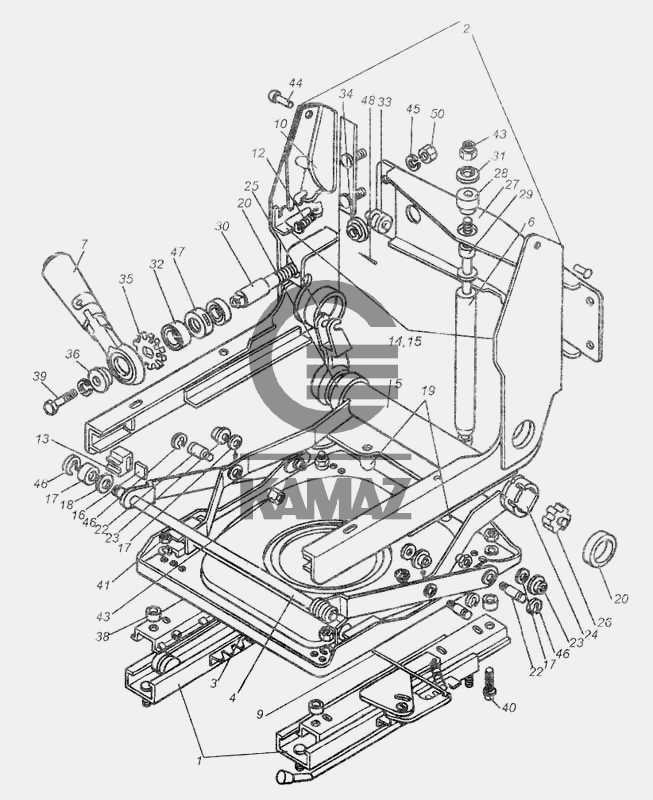

Identifying Components in Diagrams

Understanding the various elements within technical illustrations is crucial for effective maintenance and repair. These representations serve as visual aids, allowing users to quickly locate and identify essential parts of a machine or system. By familiarizing oneself with the common symbols and layout conventions, one can navigate these visuals with greater confidence and efficiency.

Common Symbols and Notations

Each illustration typically employs a set of standardized icons that correspond to specific components. Recognizing these symbols can greatly enhance one’s ability to interpret the information presented. For instance, a circle may indicate a connector, while a square could represent a control unit. Familiarity with these icons allows for quicker reference and reduces the likelihood of errors during assembly or disassembly.

Interpreting the Layout

The arrangement of elements within the illustration also provides valuable context. Components are often organized logically, reflecting their physical relationships within the system. Pay attention to the flow of operations or connections depicted, as this can offer insights into how the machine functions as a whole. Understanding this spatial organization aids in troubleshooting and ensures that all necessary parts are accounted for during repairs.

In summary, grasping the visual language used in technical illustrations not only facilitates more efficient maintenance but also empowers users to engage with machinery more confidently.

Maintenance Tips for LA211

Proper upkeep is essential for ensuring the longevity and efficiency of your equipment. Regular attention to maintenance tasks can prevent costly repairs and enhance performance. Following a systematic approach will keep your machine running smoothly and reliably over time.

Begin by routinely checking fluid levels, including oil and coolant, to ensure they are at optimal levels. Regular oil changes are crucial for maintaining engine health. Additionally, inspect air filters frequently; clean or replace them as needed to promote proper airflow and engine performance.

Pay close attention to the condition of belts and hoses. Look for signs of wear or fraying, and replace any damaged components promptly. Tire pressure and tread depth should also be monitored to guarantee safe and efficient operation.

Lastly, consult the manufacturer’s guidelines for specific service intervals and recommendations. Keeping a maintenance log can help track completed tasks and upcoming needs, ensuring that your machine remains in top condition for years to come.

Ordering Replacement Parts

Acquiring necessary components for machinery maintenance is a crucial step in ensuring optimal performance and longevity. Whether it’s for repairs or upgrades, knowing how to efficiently source these items can save time and resources.

Here are some steps to consider when looking for suitable replacements:

- Identify the Component: Ensure you know exactly which item needs replacement. Consult the user manual or online resources for specifications.

- Research Suppliers: Look for reputable vendors who specialize in machinery components. Consider both online and local options.

- Compare Prices: Check multiple sources to find the best deals. Prices can vary significantly, so thorough comparison is beneficial.

- Check Availability: Confirm that the item is in stock before making a decision. Some suppliers may offer backorder options.

- Review Return Policies: Understand the terms in case the component does not meet expectations or is incompatible.

Utilizing these strategies will help ensure you procure the correct components efficiently and effectively, minimizing downtime and enhancing operational reliability.

Understanding Kubota Part Numbers

Decoding the identification system used for machinery components is essential for ensuring proper maintenance and repair. Each component is assigned a unique identifier that provides valuable information regarding its specifications, compatibility, and origin. Grasping the structure of these identifiers can significantly streamline the procurement process and enhance overall operational efficiency.

Components of the Identifier often include a combination of letters and numbers, each signifying specific attributes. The initial letters may represent the category or type of item, while subsequent numbers can indicate size, model variations, or production series. Familiarity with these elements allows users to identify the exact requirements for their equipment without confusion.

Importance of Accuracy in selecting components cannot be overstated. Using incorrect identifiers can lead to misfits or functionality issues, which can disrupt workflow and incur additional costs. Thus, understanding the significance of these identifiers is crucial for anyone involved in maintenance or repair tasks.

Lastly, consulting official resources or authorized dealers when in doubt is advisable. These channels can provide up-to-date information and ensure that the selected identifiers meet the necessary standards for quality and compatibility.

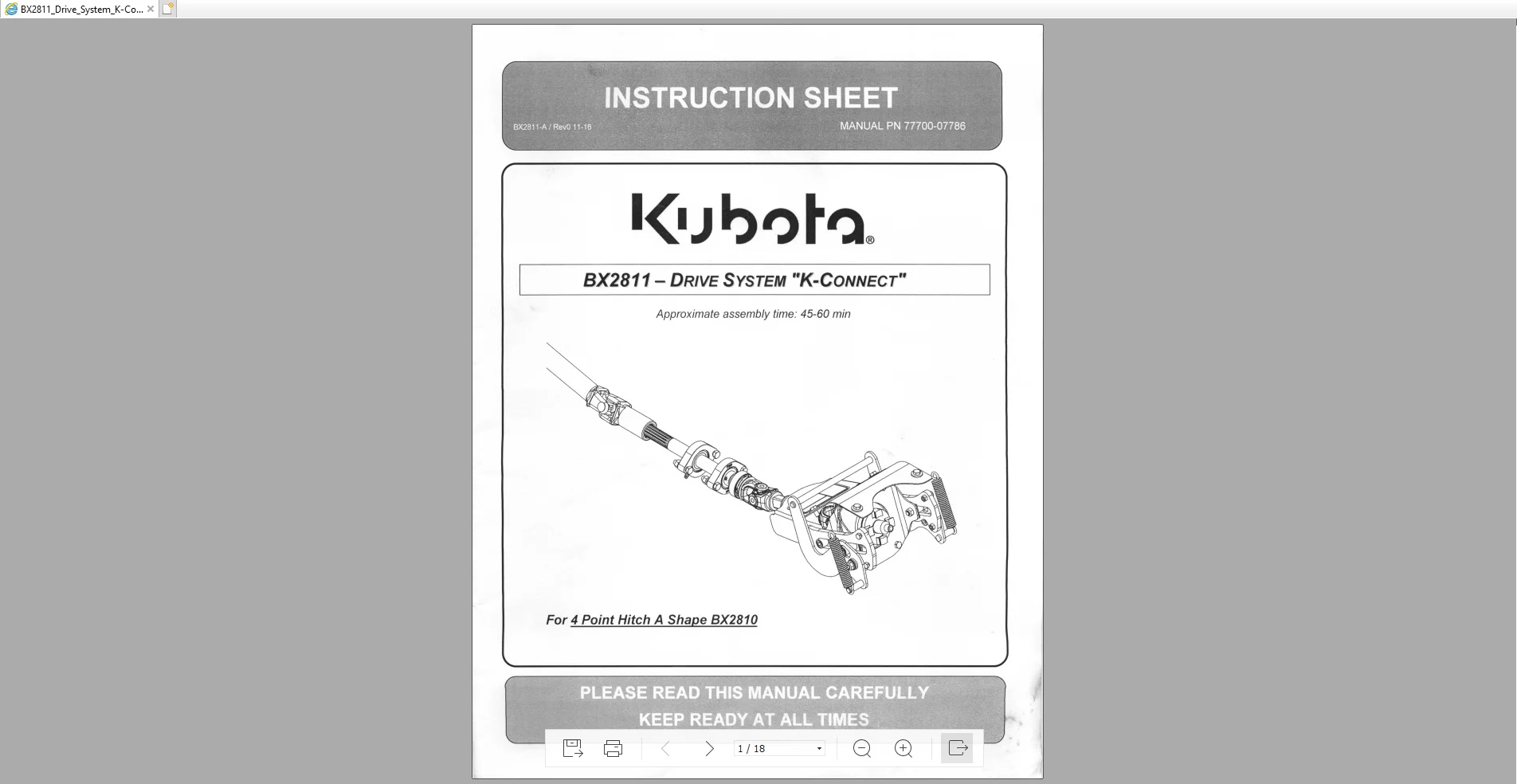

DIY Repairs and Upgrades

Taking on repairs and enhancements yourself can be a rewarding way to maintain your machinery and improve its performance. By understanding the essential components and their functions, you can address issues and implement upgrades without relying solely on professional services. This not only saves money but also enhances your skills and knowledge about the equipment you use.

Begin by gathering the necessary tools and resources. Familiarize yourself with the system layout and identify potential areas for improvement or common problems. This preparation will empower you to tackle tasks confidently and efficiently. Consider starting with simple maintenance tasks, such as replacing worn-out elements or lubricating moving parts, before progressing to more complex modifications.

Documentation is crucial in this process. Whether you’re following a guide or referring to schematics, having clear instructions will facilitate your work and minimize mistakes. Take your time to ensure each step is completed correctly, as attention to detail can prevent future complications.

Additionally, don’t hesitate to seek advice from online communities or local experts. Sharing experiences and learning from others can provide valuable insights that enhance your DIY projects. Over time, you’ll develop a deeper understanding of your equipment and gain the confidence to tackle increasingly challenging tasks.

Resources for Kubota Owners

For enthusiasts and operators of compact machinery, access to reliable information and tools is essential for maintaining performance and efficiency. A wealth of resources exists to support users in their endeavors, from manuals and guides to community forums and specialized retailers. This section explores various options available to ensure optimal operation and care of your equipment.

Online Forums and Communities

Engaging with fellow users through online platforms can provide valuable insights and practical advice. Many dedicated forums allow operators to share experiences, troubleshoot issues, and exchange tips on maintenance and upgrades. Participating in these communities can enhance your knowledge and foster connections with like-minded individuals.

Official Manuals and Guides

Access to comprehensive manuals is crucial for understanding the intricacies of your machine. Official documentation often includes troubleshooting tips, maintenance schedules, and detailed specifications. These resources can help you navigate repairs and ensure your equipment runs smoothly, extending its lifespan and reliability.